Demoulding device for barb injection molded part

A demolding device and injection molding technology, which is applied in the field of plastic molds, can solve the problems of easy seizing and jamming, oblique pin pulling, complex structure of core pulling mechanism, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

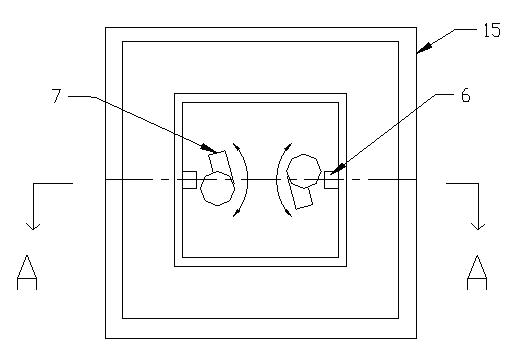

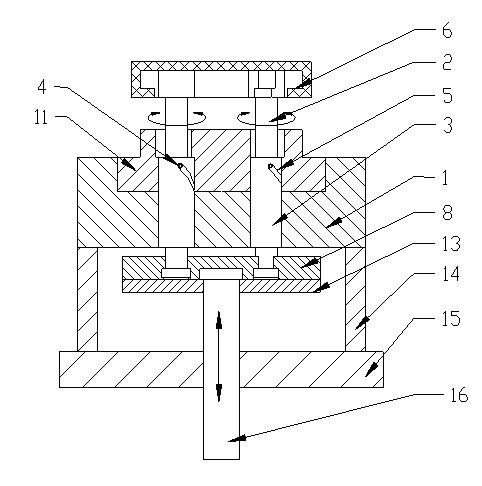

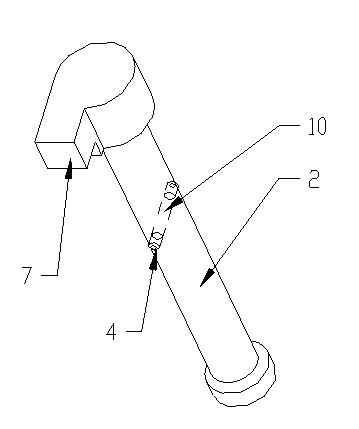

[0015] With reference to the accompanying drawings, a demoulding device for barb injection molded parts includes a movable template 1 and a mold core 11 arranged on the movable template for forming workpieces, and is characterized in that: the movable template 1 and the mold core are pierced with a stripper A mold ejector pin 2, a sleeve 3 is arranged between the demoulding ejector pin 2, the movable template 1 and the mold core 11, the sleeve 3 is fixedly connected with the movable template 1, and the sleeve 3 is also provided with a The convex twists 4 on both sides of the ejector pin correspond to the matching spiral chute 5, so that when demoulding, the movable template 1 forces the upper part of the demoulding ejector pin 2 to be embedded in the outer surface of the hook-shaped body 6 of the product through the spiral chute 5 and the convex twist 4. The inflection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com