Marine microorganism adhesion-resistant olefin composite material and preparation method thereof

A technology of marine microorganisms and composite materials, which is applied in the field of olefin composite materials resistant to the adhesion of marine microorganisms and its preparation, can solve problems such as affecting marine safety operations, adhesive corrosion, corrosion, etc., and achieve excellent marine anti-corrosion performance, avoid agglomeration, The effect of avoiding agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

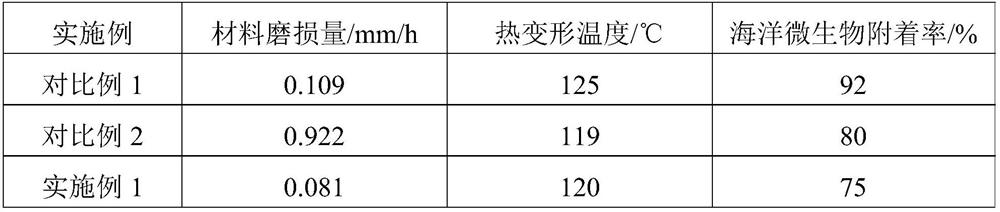

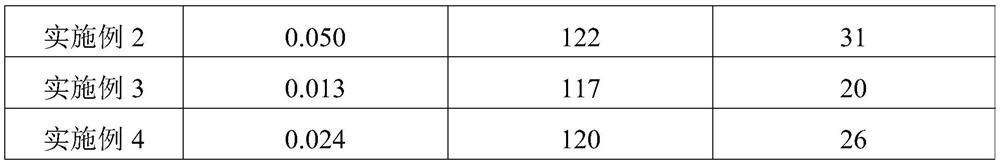

Examples

Embodiment 1

[0039]The marine anti-corrosion polyolefin composite material in the embodiment is prepared by reaction injection molding process using dicyclopentadiene monomer, Grubbs ruthenium catalyst, and copolymerized olefin as raw materials. The dicyclopentadiene monomer is polymerization grade; the catalyst is Grubbs catalyst ethyl acetate solution; the mass ratio of dicyclopentadiene monomer to Grubbs ruthenium catalyst is 3000:1; the reaction temperature of injection molding is 70°C. The copolymerized olefin is trimethylolpropane triacrylate, the amount of the copolymerized olefin is 15% of the mass of the dicyclopentadiene monomer, and the injection molding temperature is 70°C.

[0040] The preparation method of the olefin composite material resistant to marine organism adhesion of the present embodiment comprises the following steps:

[0041] Using toluene as a solvent, the Grubbs ruthenium catalyst is ultrasonically dissolved and dispersed to form an ethyl acetate solution of the...

Embodiment 2

[0043] The marine anti-corrosion polyolefin composite material in the embodiment is prepared by reaction injection molding process using dicyclopentadiene monomer, Grubbs ruthenium catalyst, copolymerized olefin, and inorganic nano-components as raw materials. The dicyclopentadiene monomer is polymerization grade; the catalyst is Grubbs catalyst ethyl acetate solution; the mass ratio of dicyclopentadiene monomer to Grubbs ruthenium catalyst is 3000:1; the reaction temperature of injection molding is 70°C. The copolymerized olefin is trimethylolpropane triacrylate, the amount of the copolymerized olefin is 15% of the mass of the dicyclopentadiene monomer, the inorganic nano component is nano-cuprous oxide, and the added amount of the inorganic nano component is dicyclopentadiene 0.1% of the mass of vinyl monomer, and the injection molding temperature is 70°C.

[0044] The preparation method of the olefin composite material resistant to marine organism adhesion of the present em...

Embodiment 3

[0047] The marine anti-corrosion polyolefin composite material in the embodiment is prepared by reaction injection molding process using dicyclopentadiene monomer, Grubbs ruthenium catalyst, copolymerized olefin, and inorganic nano-components as raw materials. The dicyclopentadiene monomer is polymerization grade; the catalyst is Grubbs catalyst toluene solution; the mass ratio of dicyclopentadiene monomer to Grubbs ruthenium catalyst is 3000:1; the reaction temperature of injection molding is 70°C. The copolymerized olefin is an ethylene-styrene copolymer, the addition of the copolymerized olefin is 10% of the mass of the dicyclopentadiene monomer, the inorganic nano-component is silver nitrate, and the addition of the inorganic nano-component is the mass of the dicyclopentadiene monomer 0.1% of the injection molding temperature is 70 ℃.

[0048] The preparation method of the olefin composite material resistant to marine organism adhesion of the present embodiment comprises t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com