Method of increasing oxygen content in vertical pulling silicon single crystal rod and automatic aerator

An oxygen booster and single crystal rod technology, which is applied in the field of doping technology and devices, can solve the problems of increased opportunities for silicon single crystals, increased silicon monoxide deposits, and unfavorable growth of silicon crystals stably, and achieves a wide range of types and structures. Simple, oxygen-increasing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

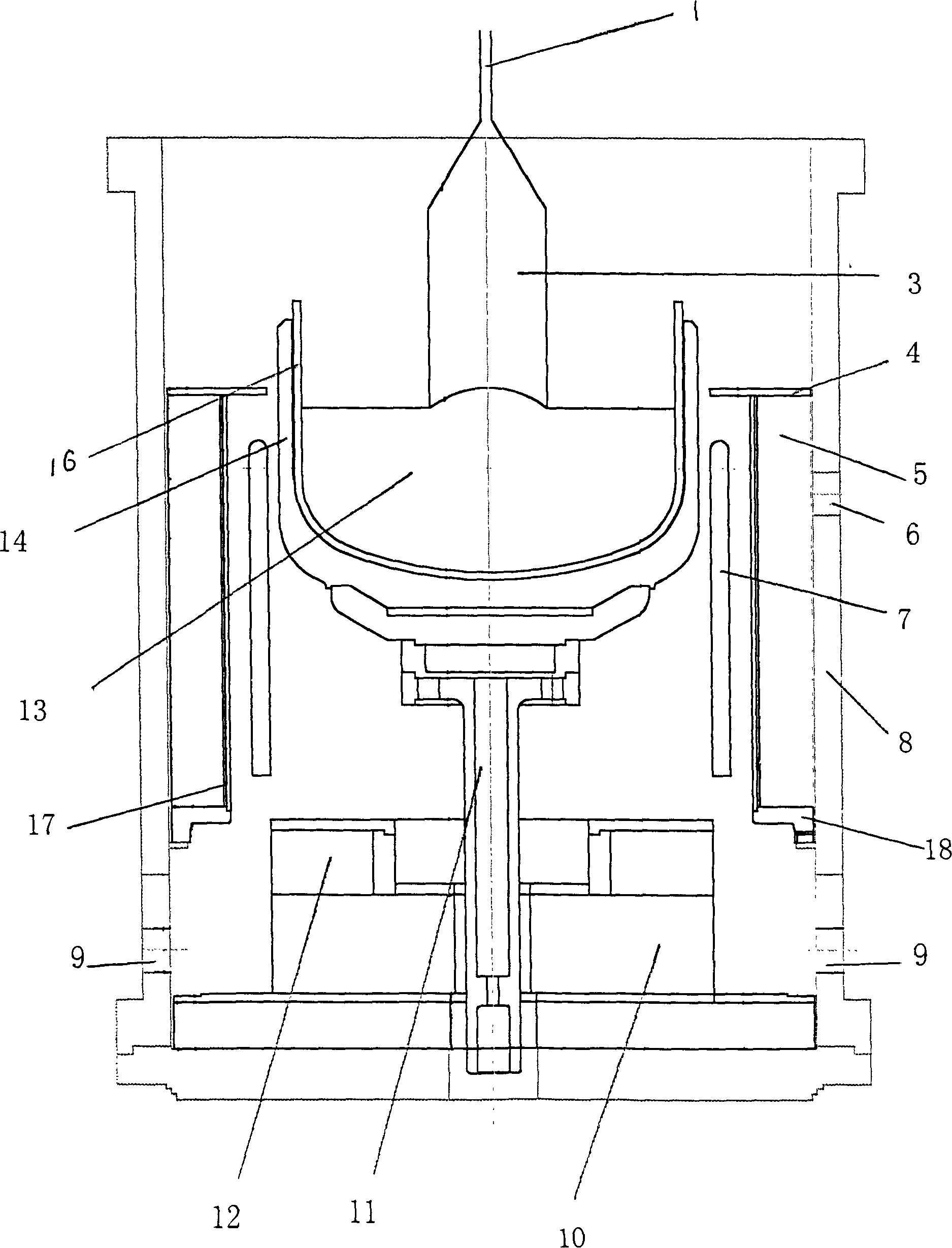

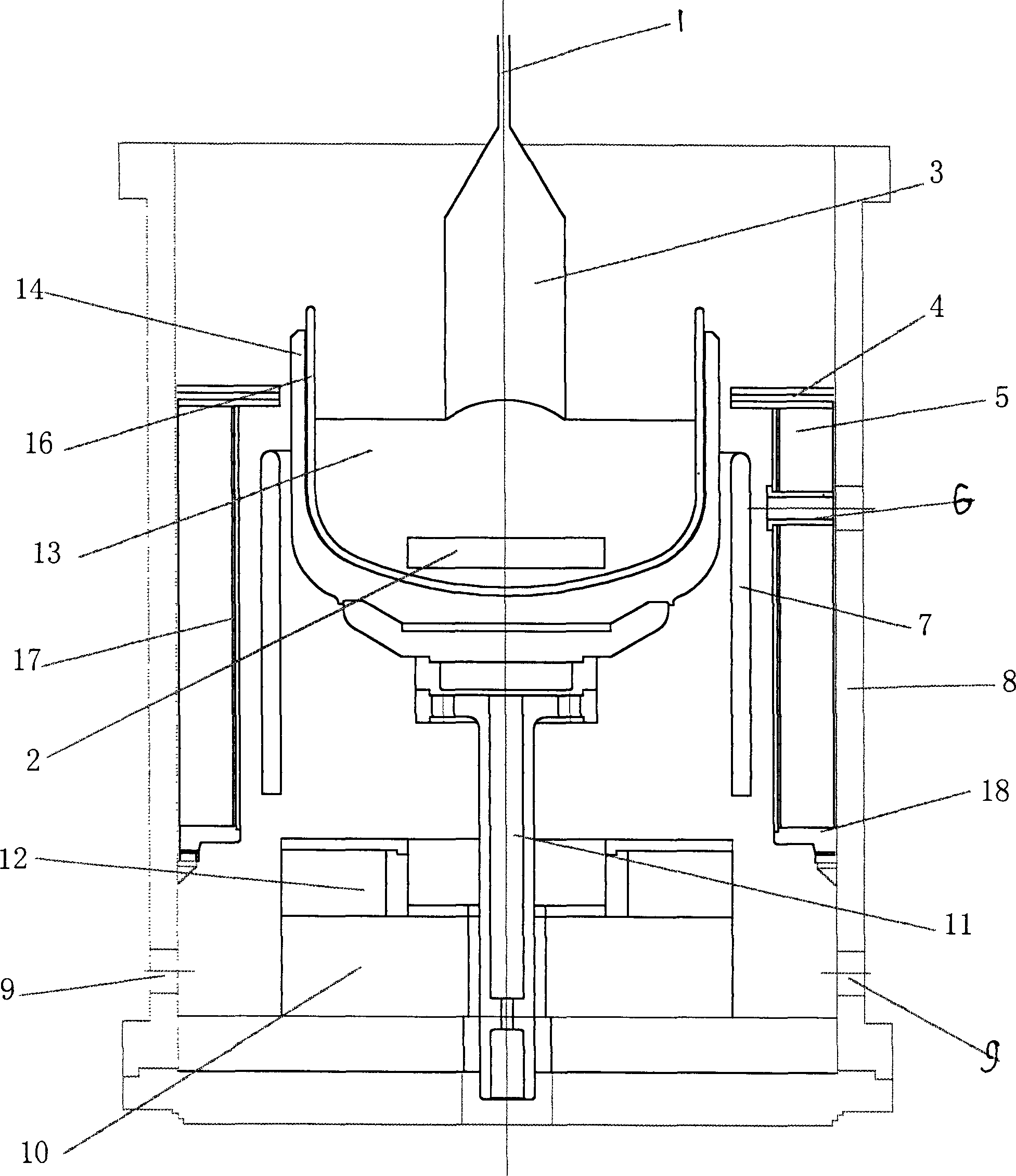

Embodiment 1

[0051] In the present embodiment, at first the aerator of the frustum-shaped body made of semiconductor grade quartz is placed at the bottom center of the quartz crucible 16, and 60 kilograms of polysilicon as a raw material are added on the aerator, during the melting process of the heated polysilicon , the aerator and the inner wall of the quartz crucible are welded together, the seed crystal with a specific crystal orientation is installed, the furnace chamber is closed, and the vacuum is evacuated to 5.0×10 3 pa, and then heated to melt the polysilicon. After the polysilicon is melted, the oxygenator remains in the stone-made silicon melt. During the whole process of pulling silicon single crystal, the oxygenator also remains in the melt, and gradually drops to near the melting point of the molten silicon. (1420° C.), make the quartz crucible and the seed crystal reversely rotate, the quartz crucible rotates at 10 rpm, and the seed crystal rotates at 20 rpm. Slowly lower t...

Embodiment 2

[0054] The operation method and equipment are basically the same as in Example 1, except that the oxygen generator is not placed at the bottom center of the quartz crucible, and the oxygen concentration at the head of the silicon single crystal rod is 37ppma.

Embodiment 3

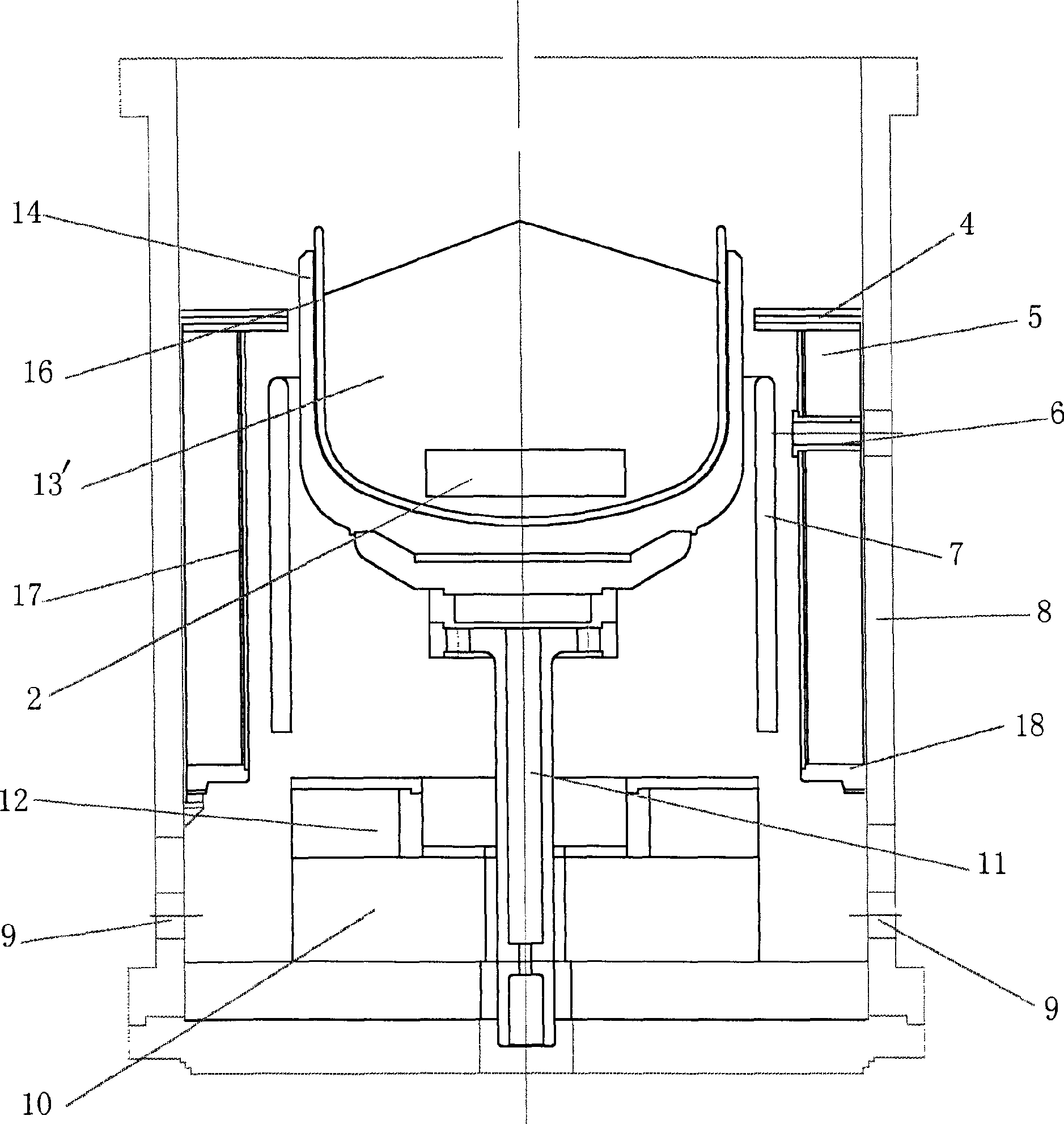

[0056] Its method of operation and equipment are basically the same as embodiment 1, and only difference is that the aerator made of semiconductor grade quartz used is a conical body, and the height of the conical body is 32mm, and the diameter of the upper top surface of the conical body is 10mm, Its base diameter is 20 mm, and their diameter ratio is 1:2. The head oxygen concentration in the silicon single crystal rod was 39.0 ppma.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com