Mold for preparing EPP steering wheel

A steering wheel and mold technology is applied in the field of molds for preparing EPP steering wheels to achieve the effects of high quality, high density and increased density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

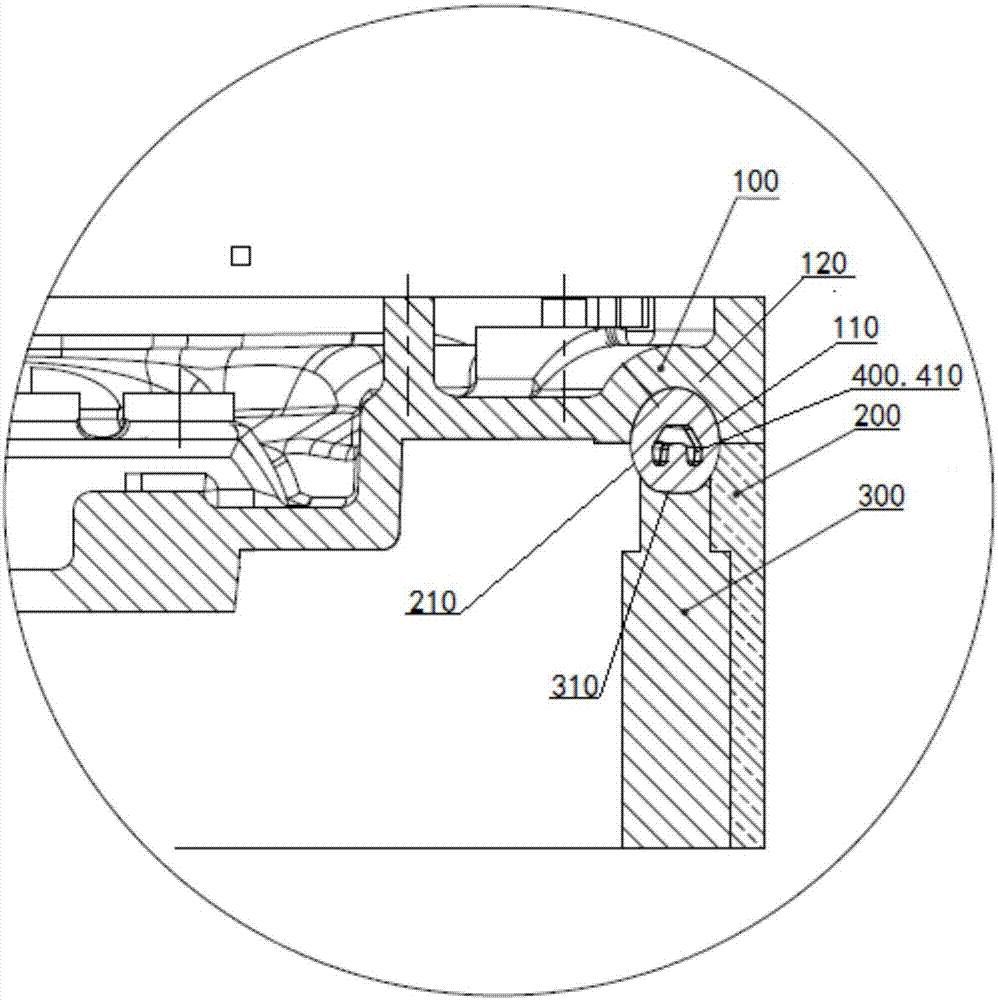

[0017] see figure 1 , the figure is a mold for preparing an EPP steering wheel, including an upper mold 100 and a lower mold 200, an upper mold cavity 110 is provided in the upper mold 100, a lower mold cavity 210 is provided in the lower mold 200, and a lower mold cavity 210 is arranged in the lower mold 200. The movable insert 300 is driven to move up and down in the lower mold 200 by a driving mechanism (not shown in the figure), and a movable cavity 310 is arranged on the top of the movable insert 300, and the upper cavity in the upper mold 100 110 , the lower cavity 210 in the lower mold 200 and the movable cavity 310 in the movable insert 300 cooperate to form a molding cavity for molding the EPP buffer layer 420 on the ring 410 of the steering wheel frame 400 .

[0018] The position of the movable cavity 310 at the top of the movable insert 300 is lower than the parting plane A between the upper mold 100 and the lower mold 200 . The upper cavity 110 in the upper mold 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com