Method for preparing large-size three-dimensional photonic crystal through constant-temperature liquid baking method

A photonic crystal, large-scale technology, applied in the directions of crystal growth, chemical instruments and methods, solutions from liquid solvents at room temperature, etc., can solve the problem that the structure of three-dimensional photonic crystals is not well arranged, prone to large-area defects, and three-dimensional photonic crystal defects. and other problems, to achieve the effect of novel idea, good structure and short time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

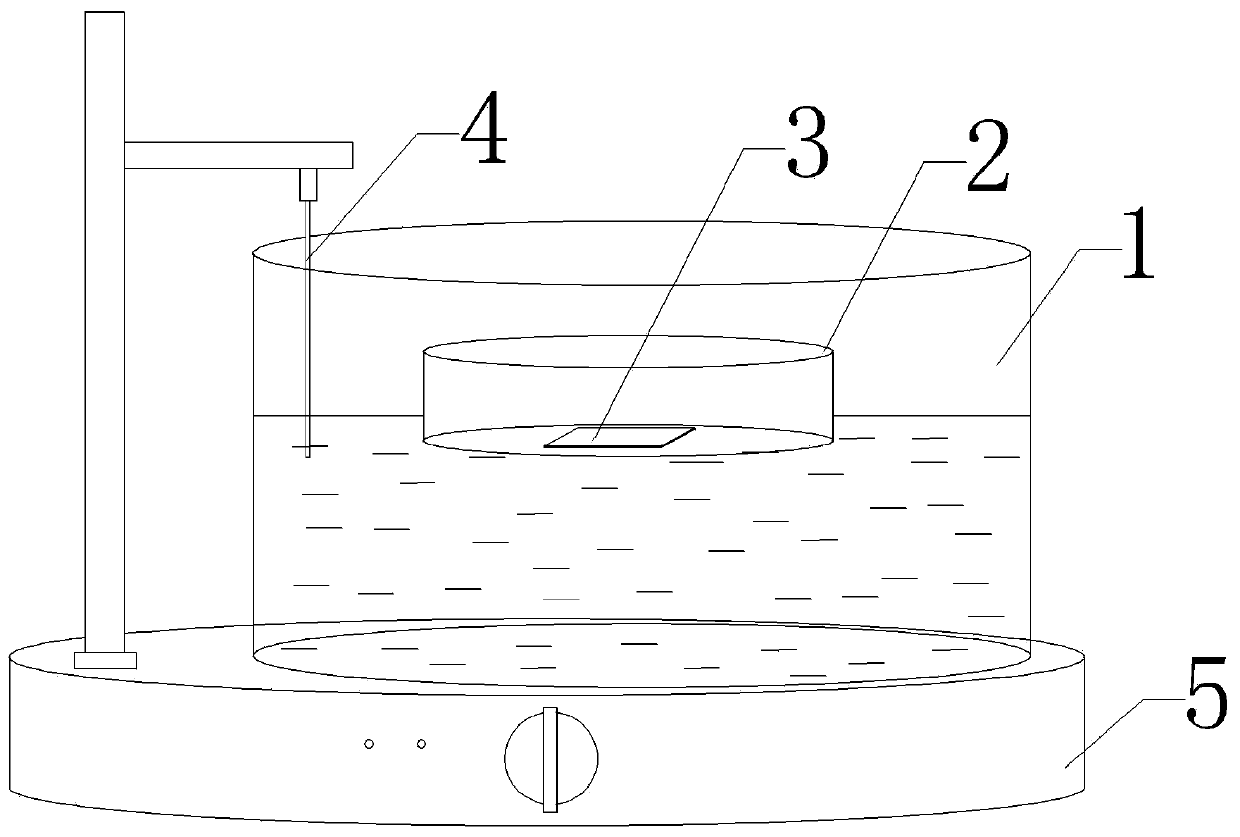

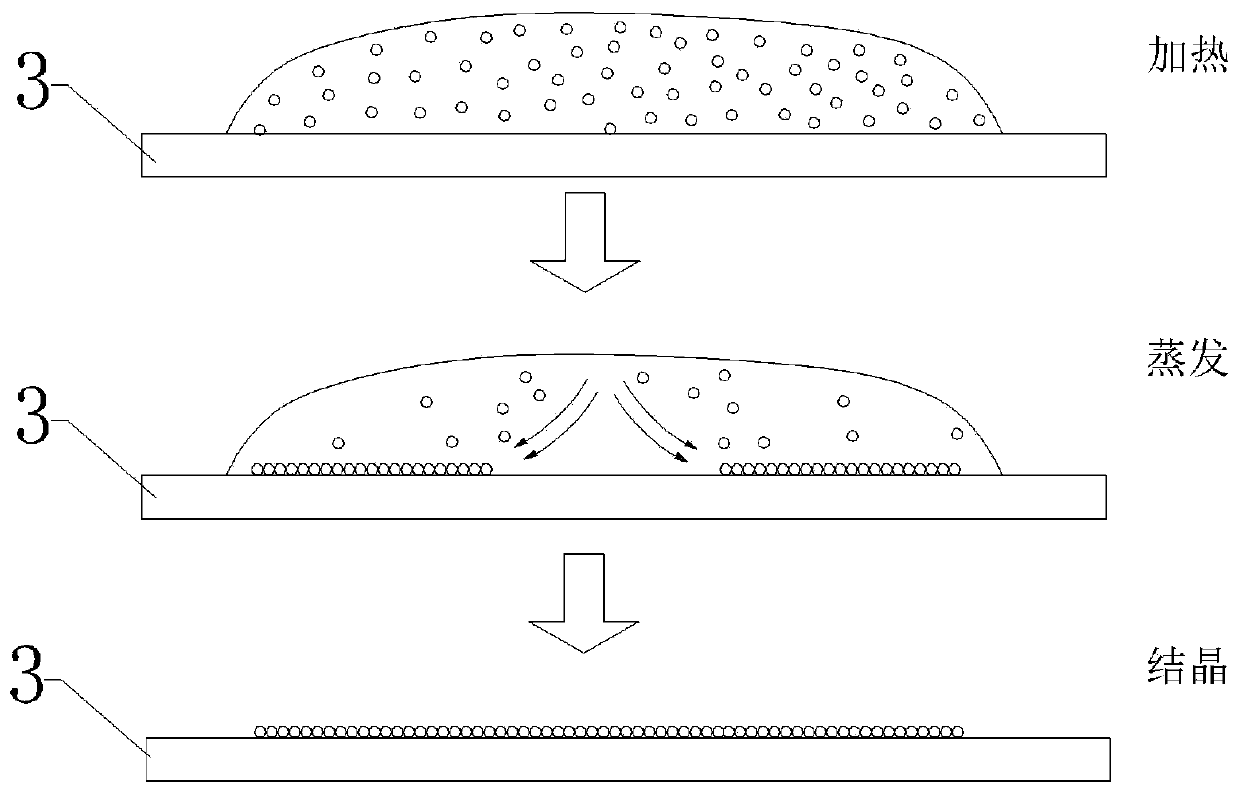

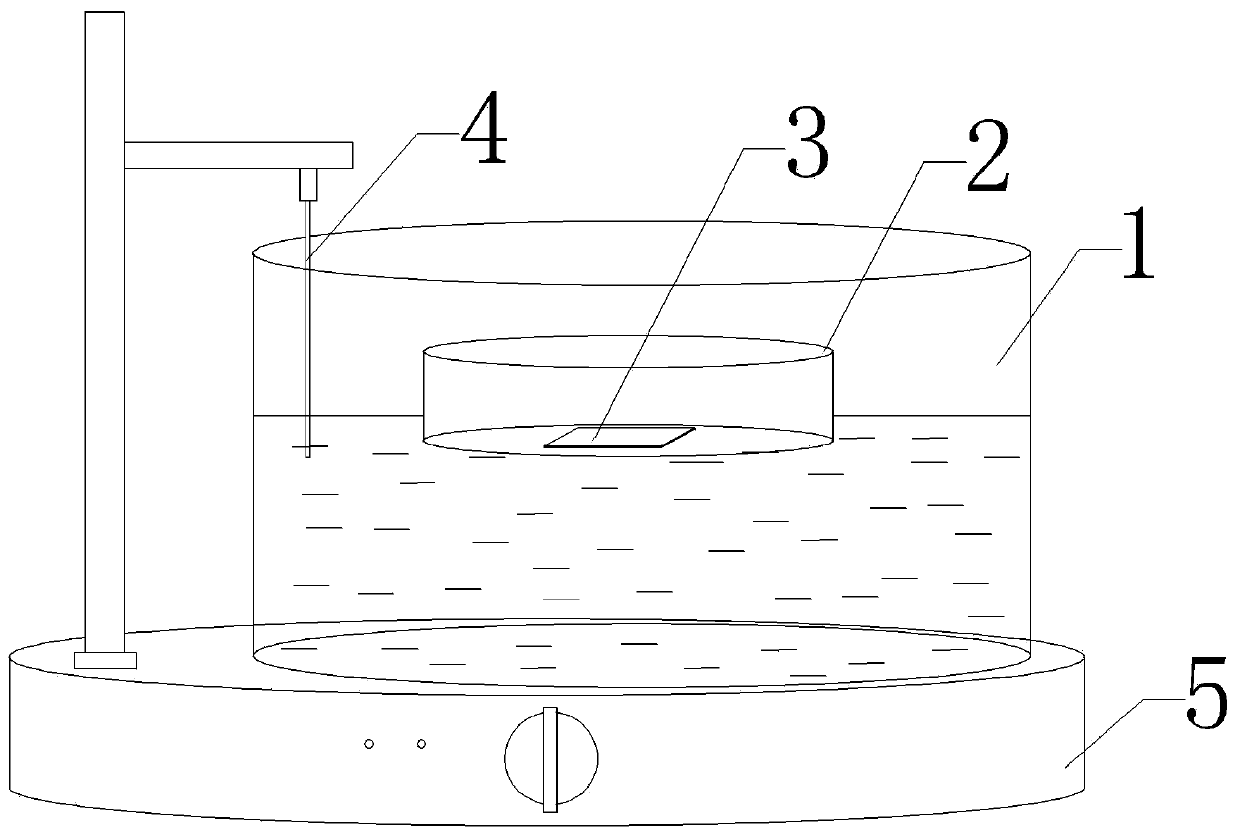

[0025] Such as Figure 1 to Figure 2 A method for preparing a large-size three-dimensional photonic crystal by a constant temperature liquid baking method includes the following steps:

[0026] 1) Prepare polystyrene microspheres with micron size and uniform particle size, the outer diameter of the polystyrene microspheres is 1 μm-10 μm, the substrate 3 after hydrophilic treatment, the dispersion medium, and the temperature is Constant temperature water at 57°C, the first container 1 and the second container 2 which is smaller in size than the first container 1 and has good thermal conductivity. In this embodiment, the substrate 3 is made of glass flakes, and the dispersion medium is absolute ethanol. The first container 1 is a beaker, the second container 2 is a glass Petri dish, and the outer diameter of the polystyrene microspheres is 1 μm;

[0027] 2) putting the polystyrene microspheres into the dispersion medium, and dispersing the polystyrene microspheres in the disper...

Embodiment 2

[0031] Such as Figure 1 to Figure 2 A method for preparing a large-size three-dimensional photonic crystal by a constant temperature liquid baking method includes the following steps:

[0032] 1) Prepare polystyrene microspheres with micron size and uniform particle size, the outer diameter of the polystyrene microspheres is 1 μm-10 μm, the substrate 3 after hydrophilic treatment, the dispersion medium, and the temperature is Constant temperature oil at 82°C, the first container 1 and the second container 2 which is smaller in size than the first container 1 and has good thermal conductivity. In this embodiment, the substrate 3 is made of silicon wafers, and the dispersion medium is deionized water. The first container 1 is a beaker, the second container 2 is a glass Petri dish, and the outer diameter of the polystyrene microspheres is 10 μm;

[0033] 2) putting the polystyrene microspheres into the dispersion medium, and dispersing the polystyrene microspheres in the disper...

Embodiment 3

[0037] Such as Figure 1 to Figure 2 A method for preparing a large-size three-dimensional photonic crystal by a constant temperature liquid baking method includes the following steps:

[0038] 1) Prepare polystyrene microspheres with micron size and uniform particle size, the outer diameter of the polystyrene microspheres is 1 μm-10 μm, the substrate 3 after hydrophilic treatment, the dispersion medium, and the temperature is Constant temperature oil at 70°C, the first container 1 and the second container 2 which is smaller in size than the first container 1 and has good thermal conductivity. In this embodiment, the substrate 3 is made of strontium titanate wafer, and the dispersion medium is glycerol Alcohol, the first container 1 is a beaker, the second container 2 is a glass Petri dish, and the outer diameter of polystyrene microspheres is 5 μm;

[0039] 2) putting the polystyrene microspheres into the dispersion medium, and dispersing the polystyrene microspheres in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com