Rolling machine

A technology for rolling mills and rolling materials, applied in the field of rolling mills, can solve problems such as shortening sticking molds, lowering productivity, and not being rolled

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

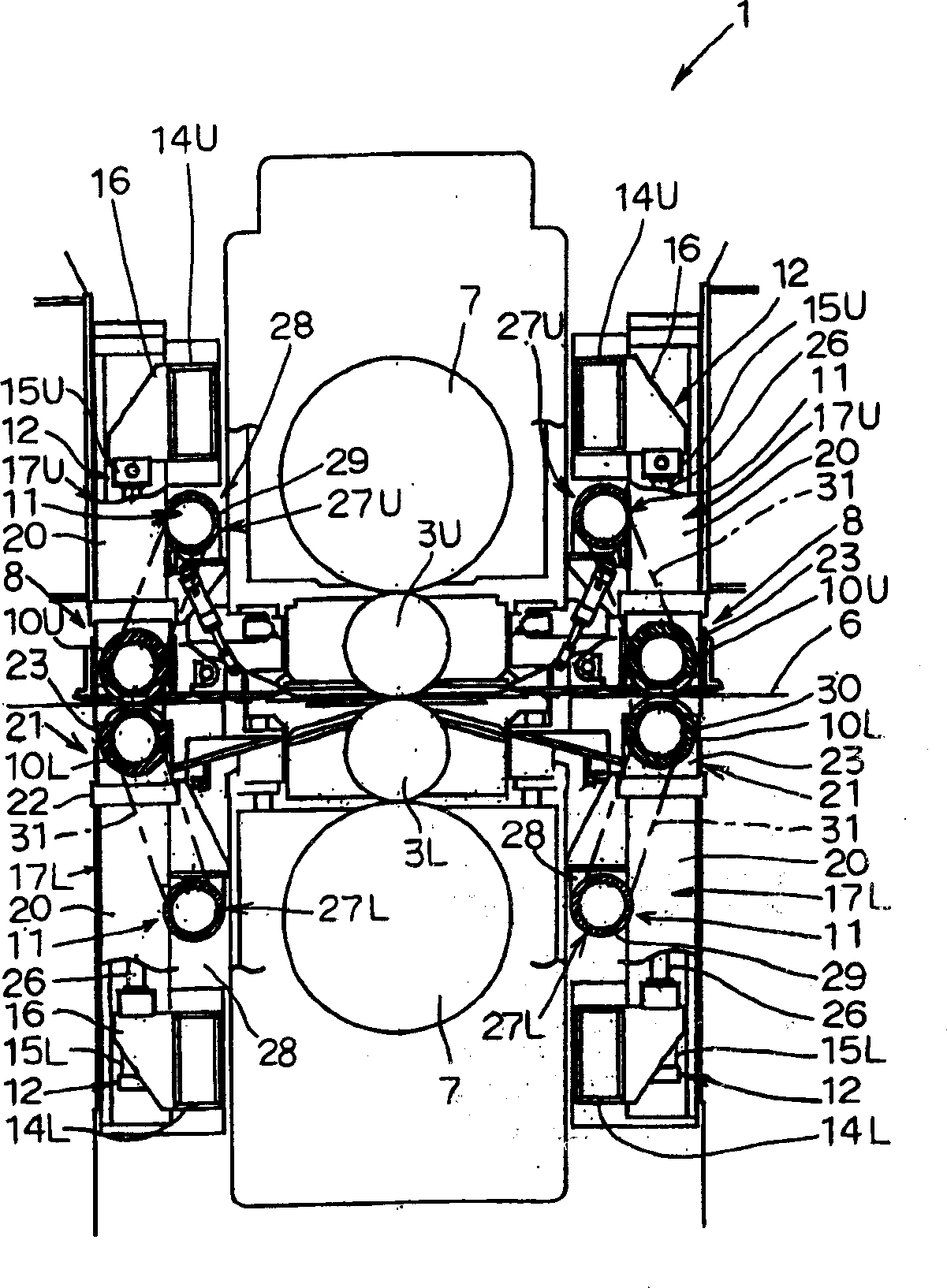

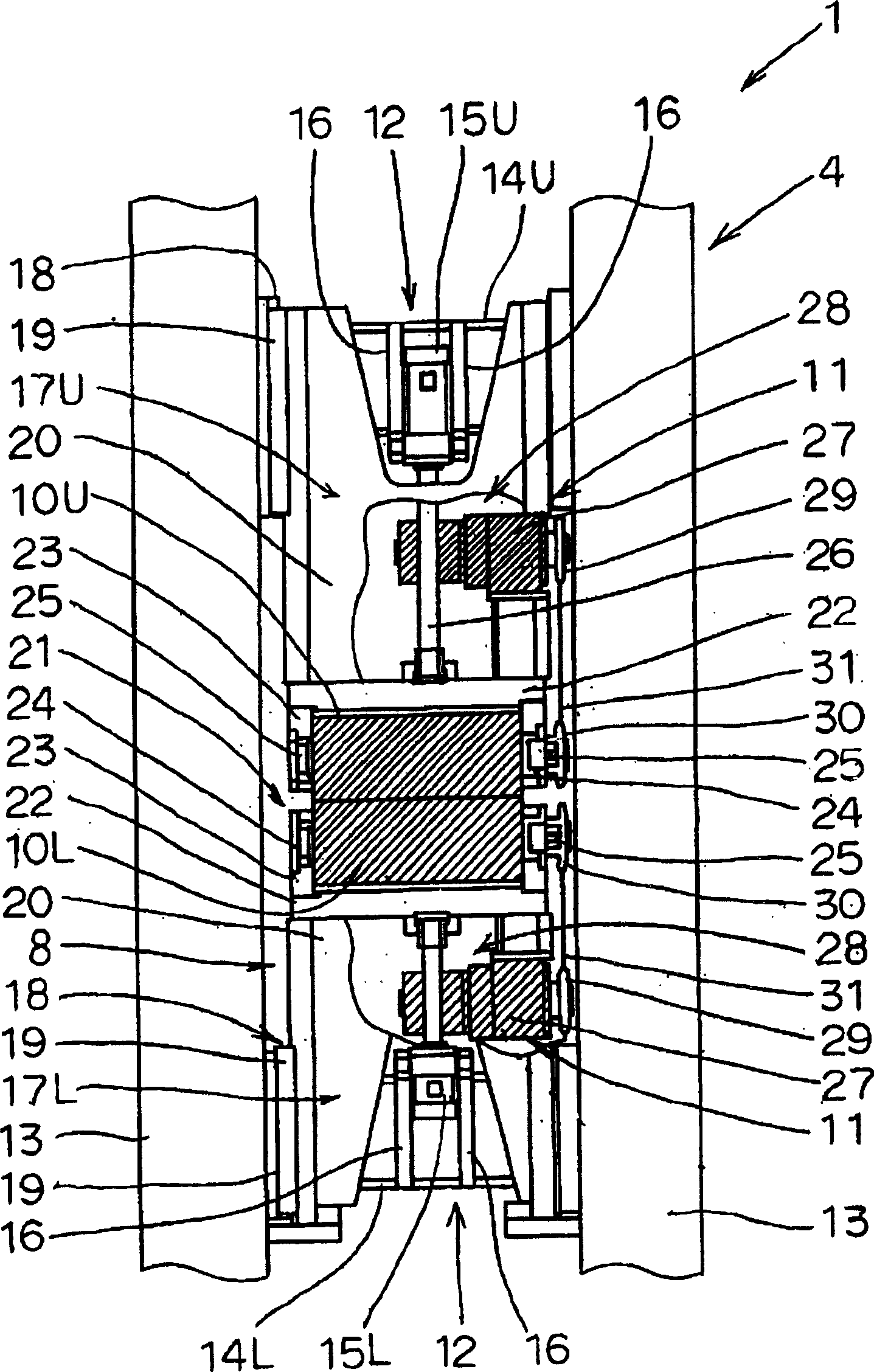

[0028] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings.

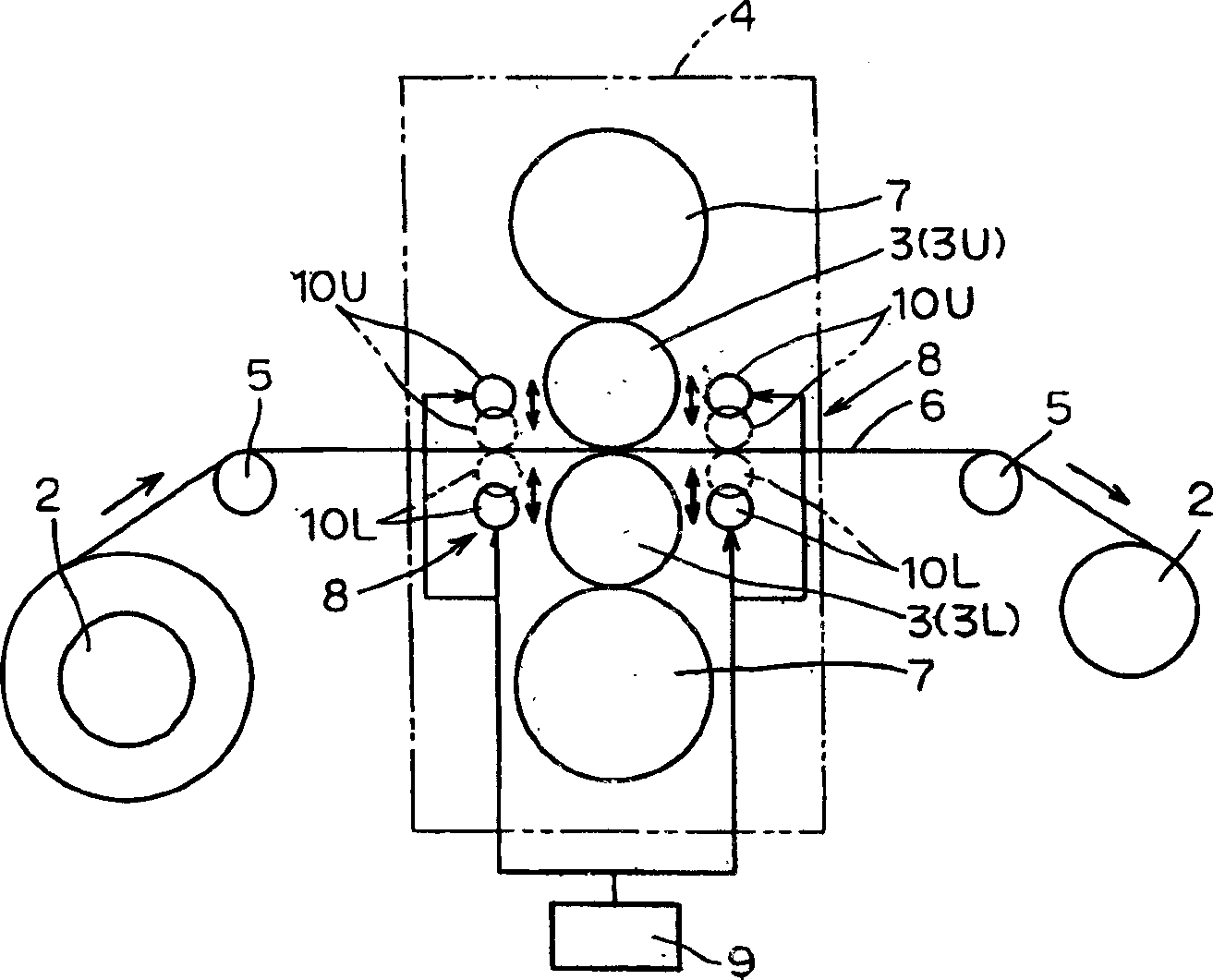

[0029] In this embodiment, a reversing cold rolling mill 1 is shown as an example of the rolling mill 1 . like figure 1 As shown, the configuration of the rolling mill 1 is that a rolling mill stand 4 is arranged between a pair of coilers 2 spaced apart from a predetermined interval, and the rolling mill stand 4 is equipped with a pair of upper and lower work rolls (rolls) 3 (3U, 3L). ).

[0030] One deflector roll 5 is disposed between each coiler 2 and the rolling stand 4 . The rolled material 6 (strip) is wound on a coiler 2, and when the rolling mill 6 reciprocates between each coiler 2, it is guided between each coiler 2 and the rolling stand 4 by the above-mentioned deflectors. Roller 5 is supported.

[0031] The upper and lower pair of work rolls 3 are freely rotated in forward and reverse directions by a drive motor. In addition, each work roll 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com