A kind of powder coating composition prepared by utilizing ultra-fine drill pipe and oil pipe inner coating epoxy powder waste

A powder coating and epoxy powder technology, applied in powder coatings, epoxy resin coatings, coatings, etc., can solve the problems of powder coating suspension, inability to electrostatic spraying, hazardous waste, etc., and achieve the effect of reducing hazardous waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

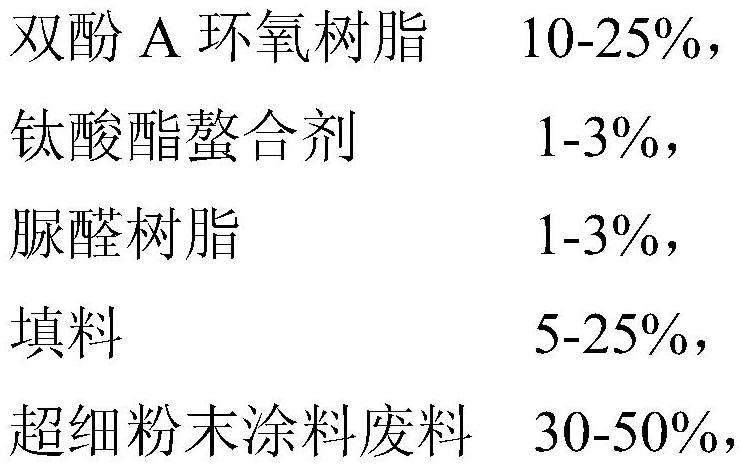

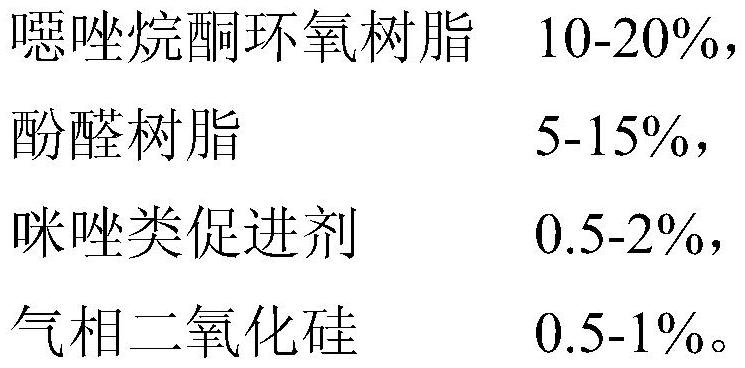

[0027] Table 1. Embodiment 1 powder coating formula

[0028]

[0029] Preparation method: Melt and extrude A, B, C, D, and E through a screw extruder at 130-150°C and press and break to obtain an intermediate, then add F, G, and H to the intermediate and mix and melt at 120-130°C Melt reaction extrusion, tablet crushing, and then adding I during the milling process, passing through a 100-mesh sieve, can obtain a powder coating with a qualified particle size between 20-150 microns.

[0030] The prepared powder coating TG2 is 120°C, gel time is 90S; the particle size range is 15-140 microns, the particle size range is D99140 microns, D50 is 80 microns, and D95 is 120 microns. The steel pipe is heated to 230°C, sprayed with powder coating, and then cured for 90 minutes. The obtained coating can pass the SY / T 6717 (2016) and SY / T0544 (2016) standards.

Embodiment 2

[0032] Table 2. Embodiment 2 powder coating formula

[0033]

[0034] Preparation method: Melt and extrude A, B, C, D, and E through a screw extruder at 130-150°C and press and break to obtain an intermediate, then add F, G, and H to the intermediate and mix and melt at 120-130°C Melt reaction extrusion, tablet crushing, and then adding I during the milling process, passing through a 100-mesh sieve, can obtain a powder coating with a qualified particle size between 20-150 microns.

[0035] The prepared powder coating is TG2 106°C, gel time 110S; particle size range D99140 microns, D5080 microns, D95120 microns. The steel pipe is heated to 230°C, sprayed with powder coating, and then cured for 90 minutes. The obtained coating can pass the SY / T6717 (2016) and SY / T 0544 (2016) standards.

Embodiment 3

[0037] Table 3. Embodiment 3 powder coating formula

[0038]

[0039] Preparation method: Melt and extrude A, B, C, D, and E through a screw extruder at 130-150°C and press and break to obtain an intermediate, then add F, G, and H to the intermediate and mix and melt at 120-130°C Melt reaction extrusion, tablet crushing, and then adding I during the milling process, passing through a 100-mesh sieve, can obtain a powder coating with a qualified particle size between 20-150 microns.

[0040] The prepared powder coating is TG2 105°C, gel time 80S, particle size range 15-140 microns, particle size range D99140 microns, D50 80 microns, D95 120 microns. The steel pipe is heated to 230°C, sprayed with powder coating, and then cured for 90 minutes. The obtained coating can pass the SY / T 6717 (2016) and SY / T0544 (2016) standards.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com