Patents

Literature

70results about How to "Strong production operability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

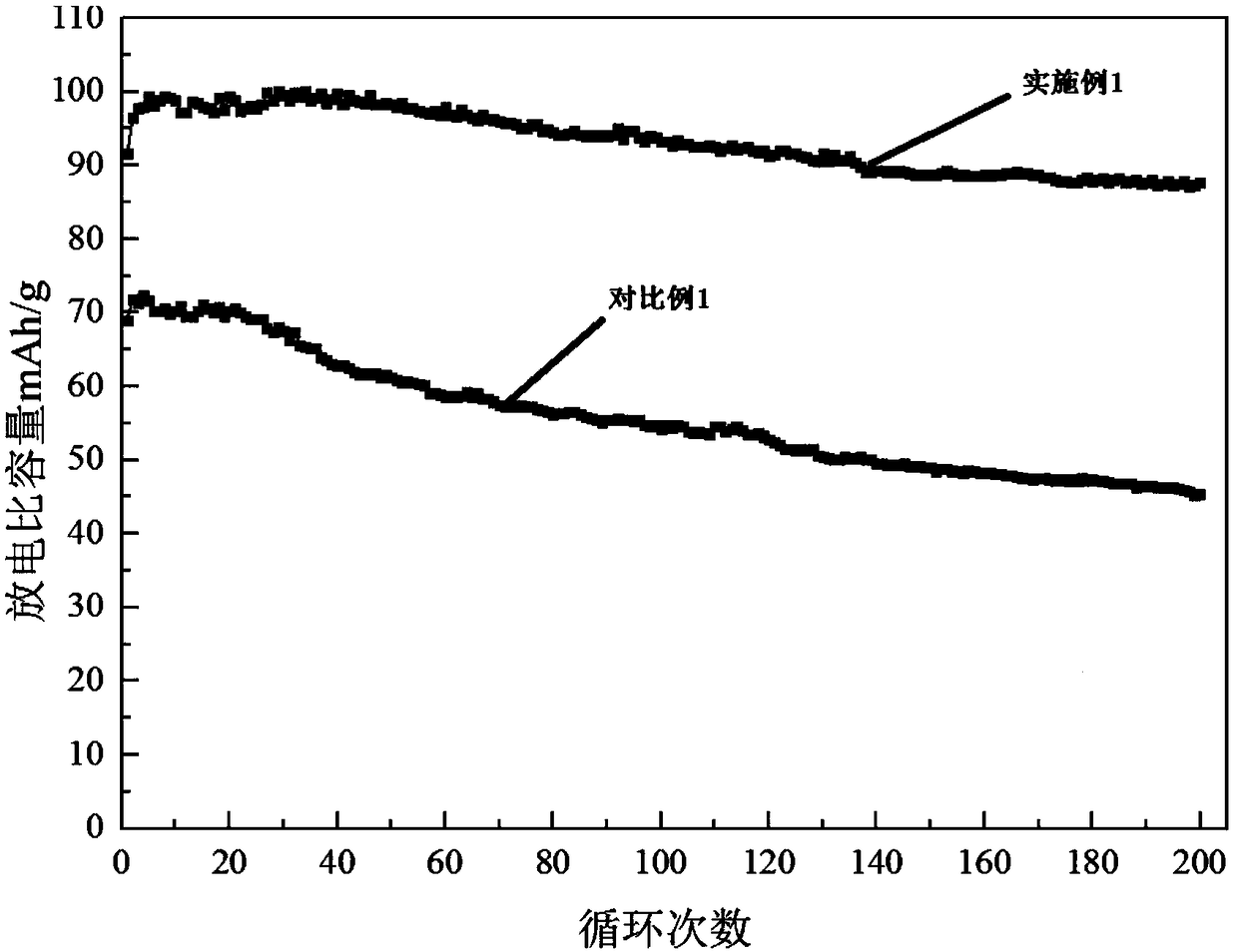

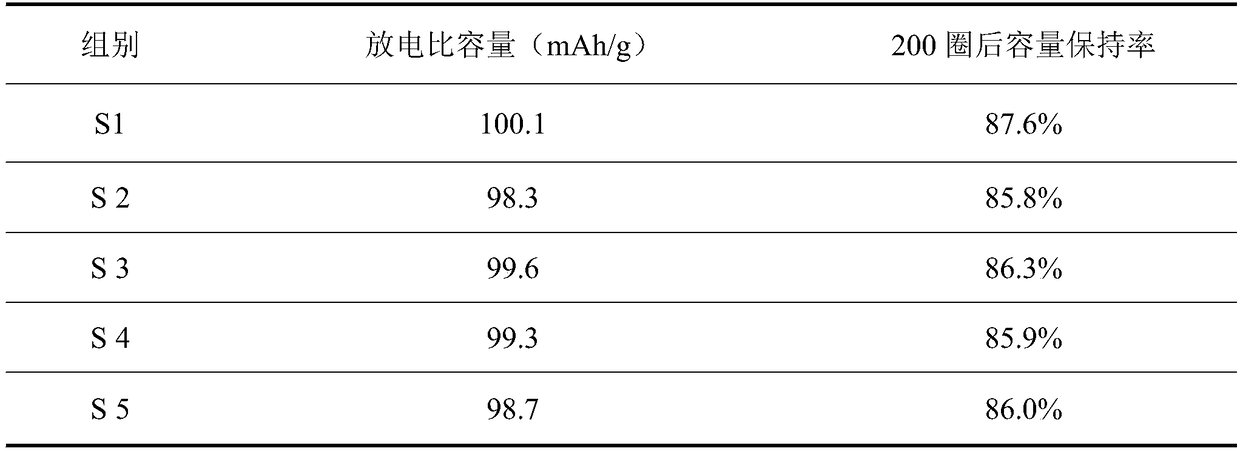

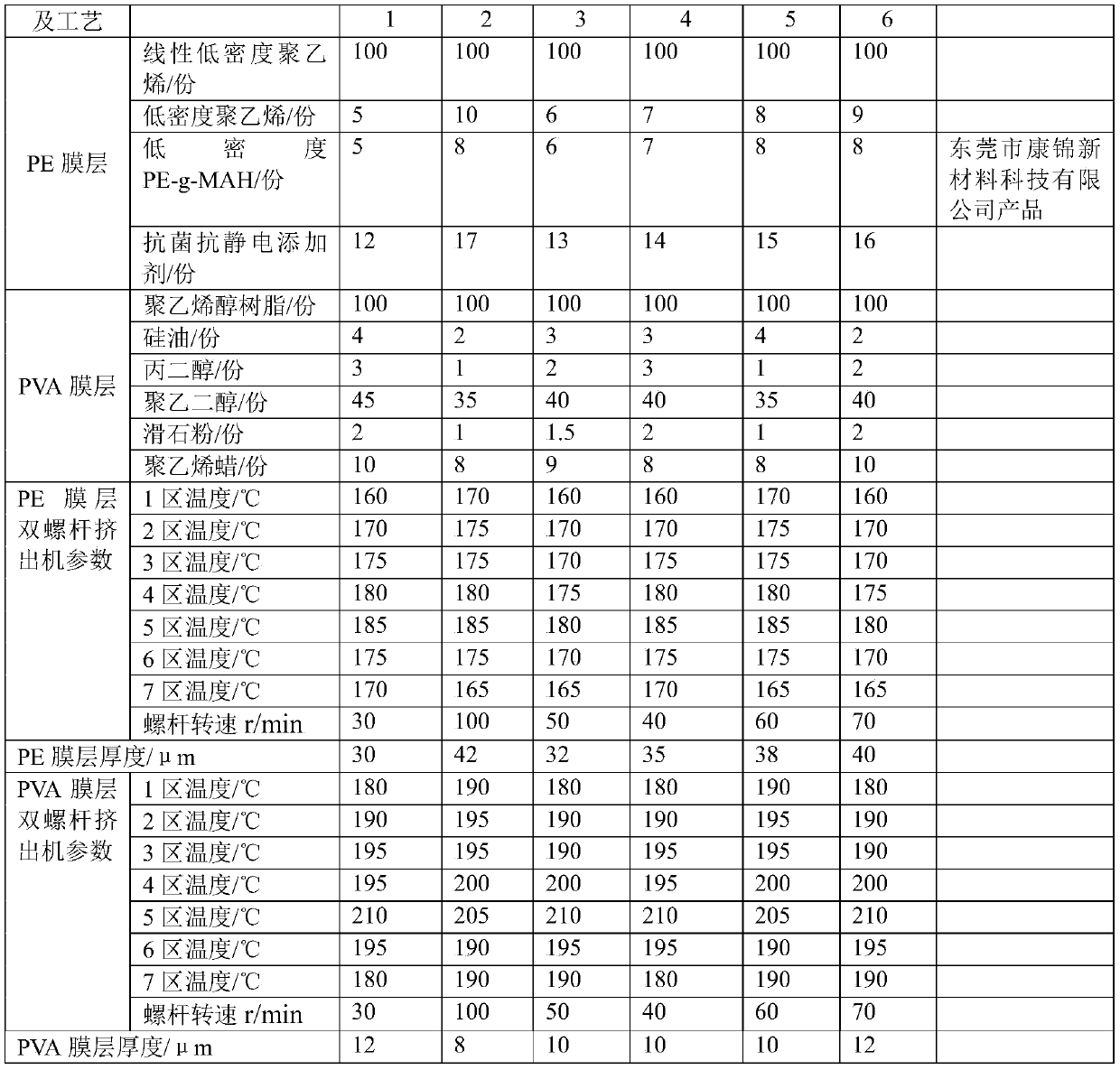

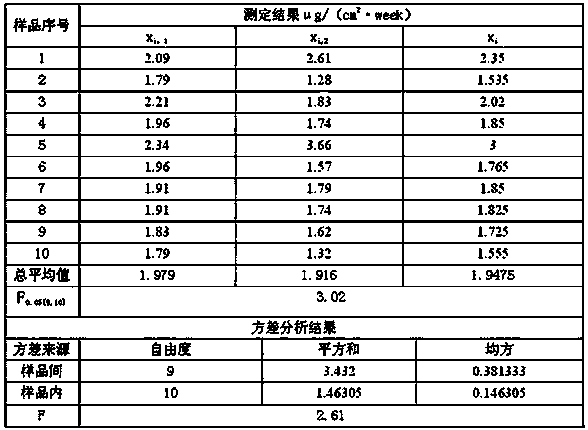

Method for evaluating self-discharge consistency of lithium iron phosphate battery

ActiveCN102508165AGood voltage consistencyImprove self-discharge rateElectrical testingLithium iron phosphateElectrical battery

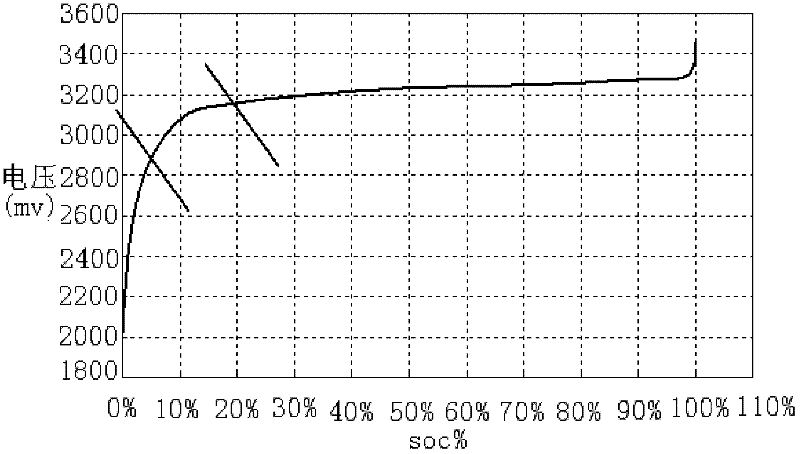

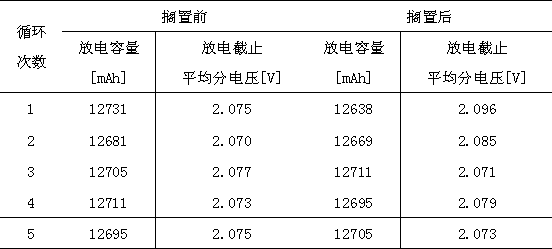

The invention discloses a method for evaluating self-discharge consistency of a lithium iron phosphate battery. The method mainly comprises the following steps of: measuring open circuit voltage after the battery is charged and open circuit voltage after the battery is laid at high temperature under the conditions of constant voltage and constant current; calculating the voltage drop of the battery, a mean value and a standard difference; and determining the upper control limit of the voltage drop to determine that the battery has high self-discharge consistency under the condition that the voltage drop does not surpass an upper specification limit. By the method for evaluating the self-discharge consistency of the lithium iron phosphate battery, evaluation accuracy, high production operability and obvious practical meaning are achieved, and the grouping consistency of the lithium iron phosphate battery is effectively improved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Lithium secondary battery consistency screening method

ActiveCN102861726AEnsure initial state of chargeEnsure consistencyFinal product manufactureSortingDelta-vInternal resistance

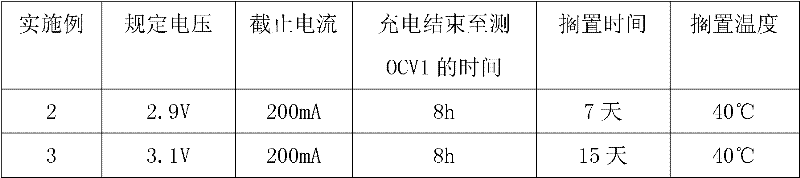

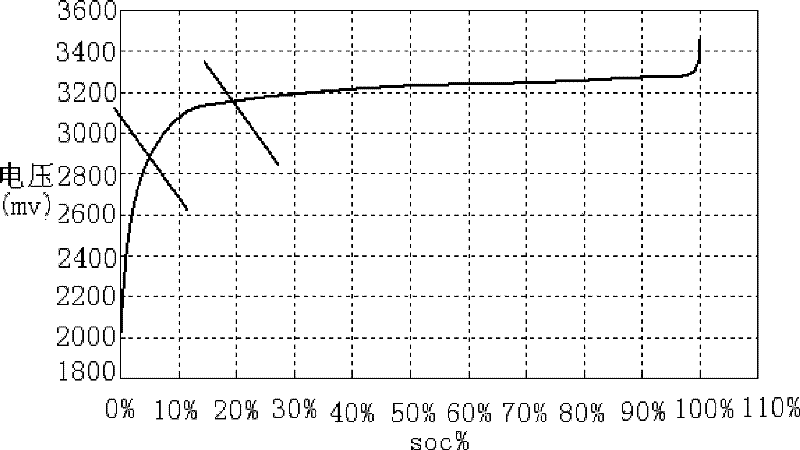

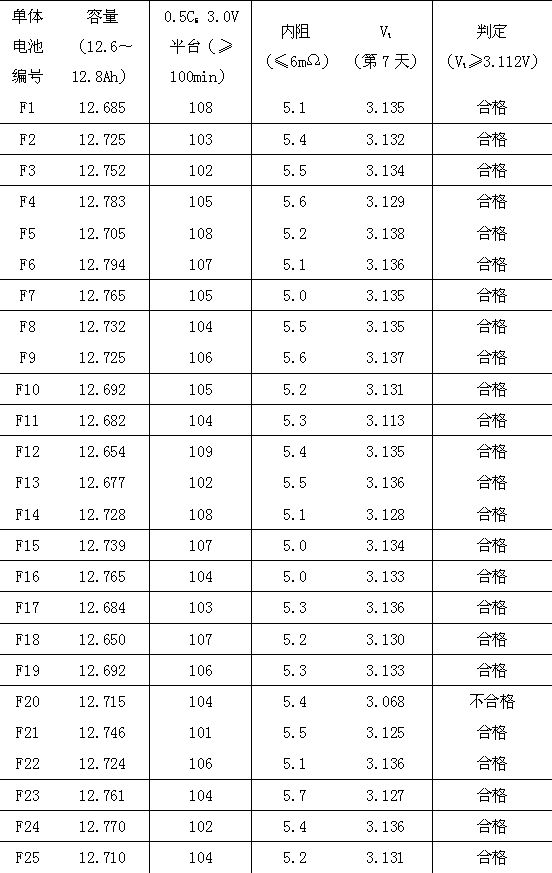

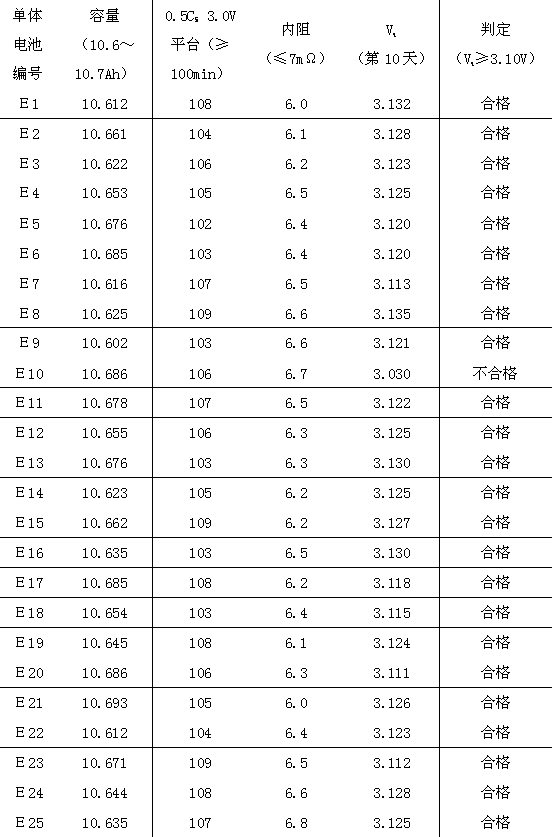

The invention discloses a lithium secondary battery consistency screening method, belonging to the field of secondary batteries, characterized in that: a unit battery grades the capacity, platform, and internal resistance when conducting capacity grading and detection, and then the unit battery is charged by multi-step constant current and constant voltage, wherein a constant current of 0.3-5C5 is used for charging to a voltage V0, when the charging current is 0.1-0.3 C5, the charge is stopped and the battery is shelved; after the battery is shelved for 5-30 min, the charging is continued with a constant current of 0.1-0.3 C5 to the voltage V0, when the charging current is 0.05-0.1 C5, the charge is stopped and the battery is shelved; after the battery is shelved for 5-30 min, the charging is continued with a constant current of 0.05-0.1 C5 to the voltage V0, when the charging current is 0.03-0.05 C5, the charge is stopped and the battery is shelved; after the battery is shelved for 5-30 min, the charging is continued with a constant current of 0.03-0.05 C5 to the voltage V0, when the charging current is 0.01-0.03 C5, the charge is stopped; after the charging is complete, the unit battery is shelved at a normal temperature, the shelving time is no less than 24h, when the shelving ends, measurement is carried out on the open-circuit voltage Vt of the unit battery, if the open-circuit voltage Vt is no less than the result of V0 minus delta V0 and minus n*delta V, the unit battery is qualified. According to the invention, the qualified unit battery screened by the invention has low self-consuming hazards, the combined battery pack has good self-discharge consistency, high reliability, and rapidness, simpleness and easy operation in practical application, and has a good market application prospect.

Owner:GUANGZHOU FULLRIVER BATTERY NEW TECH

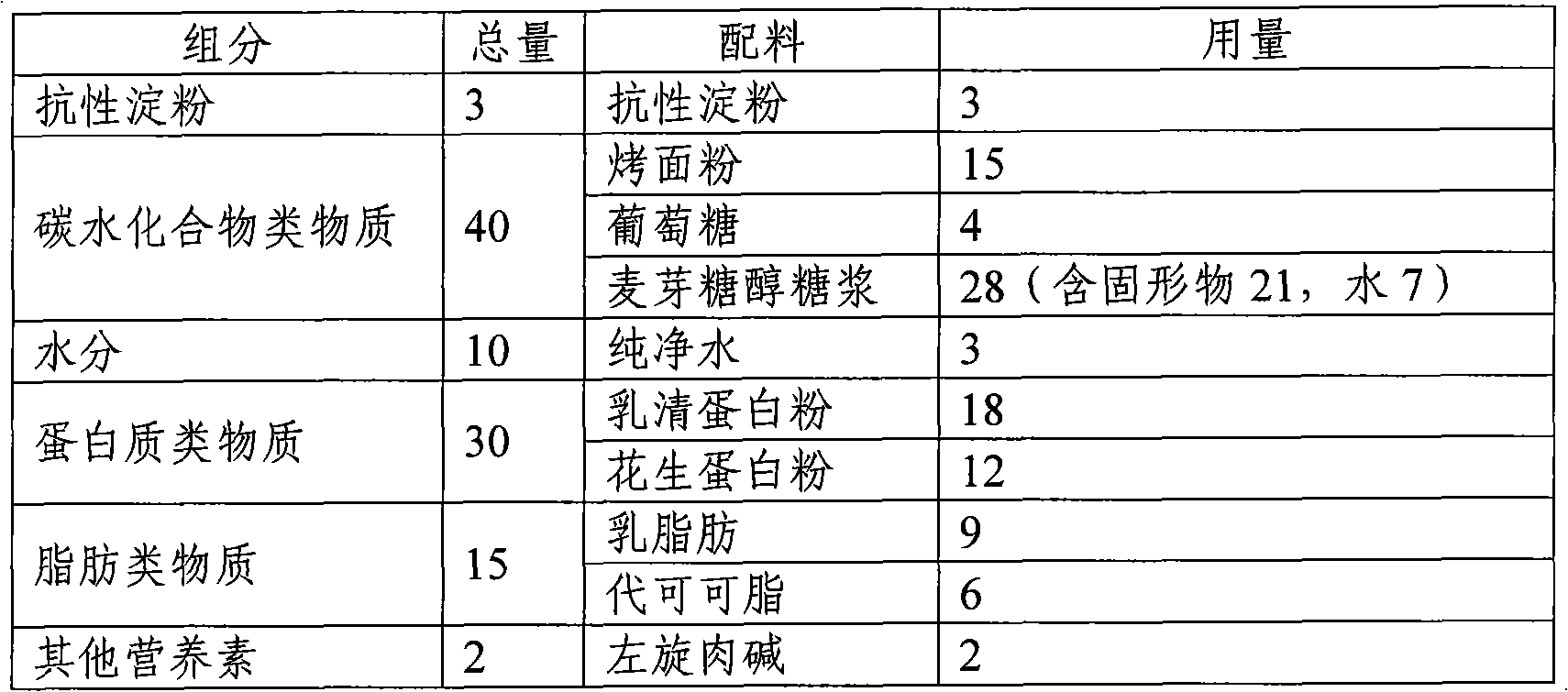

Dietary fiber bar

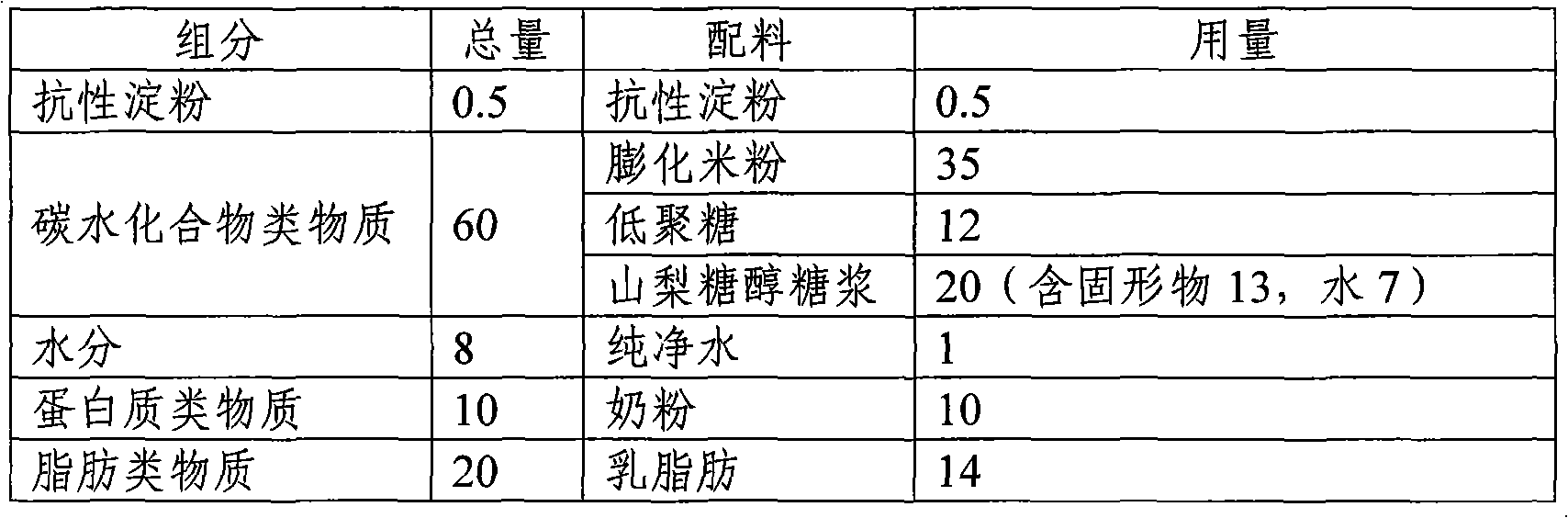

The invention provides a dietary fiber bar, comprising resistant starch, weight of which is 0.5-20% of gross weight. The dietary fiber bar adds with a water-insoluble dietary fiber-resistant starch, thereby meeting reinforcement quantity and functionality, solving the problem of the drying and the hardening of products, guaranting the stable quality in the process of storage, and prolonging storage life.

Owner:BEIJING COMPETITOR SPORTS SCI & TECH

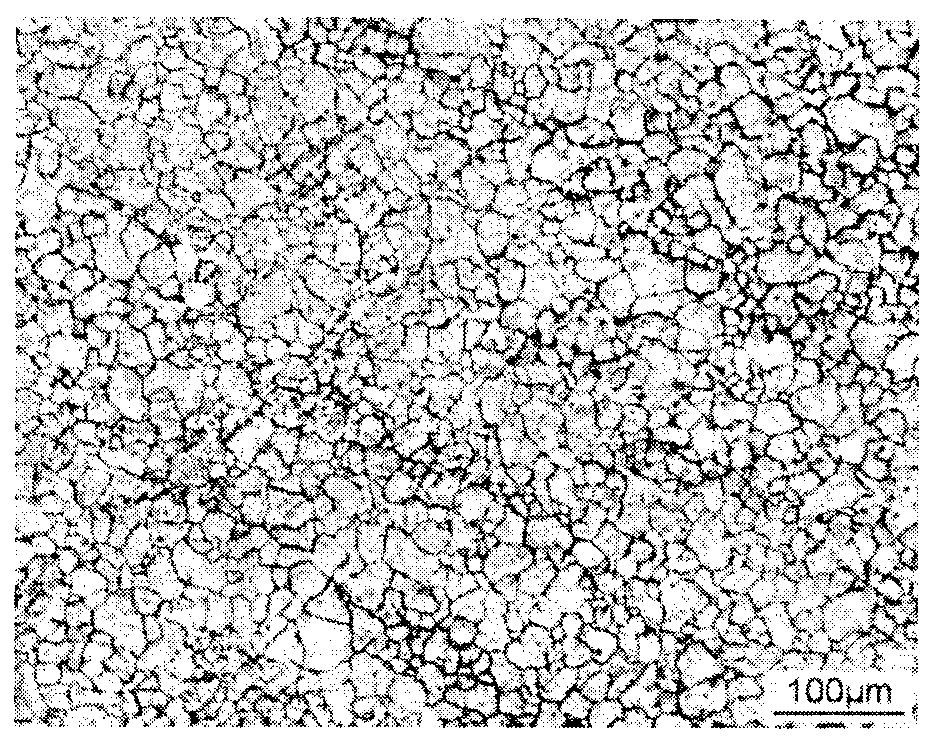

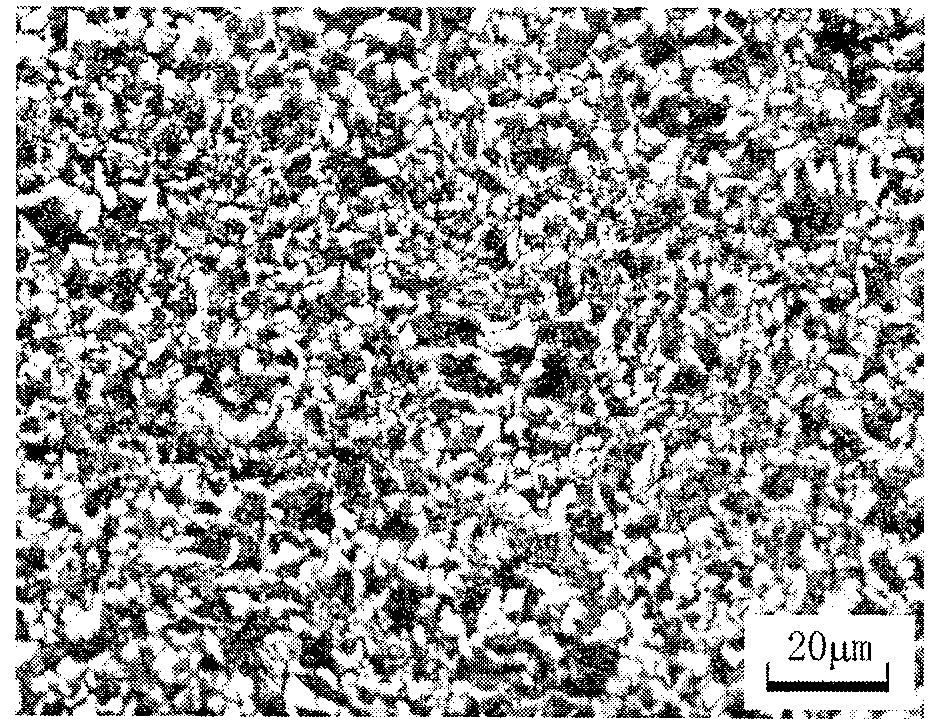

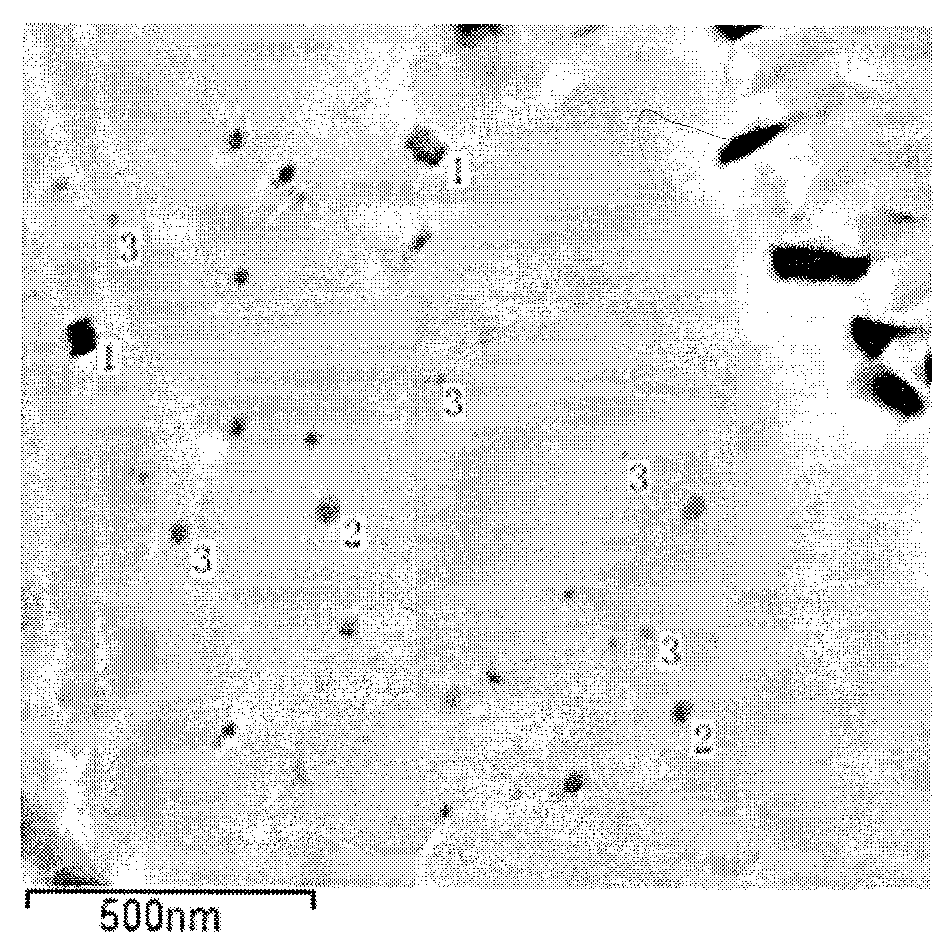

Fine-grain ferrite + pearlite type N80-1 non-quenched and tempered seamless oil bushing, and production method thereof

InactiveCN103290324AAvoid it happening againEasy to controlDrilling rodsDrilling casingsFurnace temperatureAustenite

The invention relates to a fine-grain ferrite + pearlite type N80-1 non-quenched and tempered seamless oil bushing. The components of the oil bushing comprise 0.35-0.40mass% of C, 0.20-0.35mass% of Si, 1.55-1.75mass% of Mn, 0.020mass% or less of P, 0.010mass% or less of S, 0.20mass% or less of Cu, 0.10mass% or less of Ni, 0.30mass% or less of Cr, 0.05mass% or less of Mo, 0.105-0.145mass% of V, 0.02mass% or less of Nb, 0.005-0.025mass% of Ti, 0.0085-0.0140mass% of N, and the balance Fe and inevitable impurities, wherein the sum of the mass percentages of As, Sn, Pb, Sb and Bi is not greater than 0.050%. A production method of the oil bushing comprises a step of blank material heating, a step of perforating, a step of tube rolling, a step of phase transition recrystallization and temperature-controlled crude tube cooling to 500DEG C or less, a step of reheating for controlling the furnace temperature in a range of 900-950DEG C, a step of sizing or reducing, and a step of air cooling. The method avoids the large maneuverability difficulty of the control of the steel tube deformation parameters and the cooling speed, effectively controls the phase transition recrystallization and the reheating furnace temperature through the reasonable matching and addition of alloy elements, and refines and improves the structure through fully utilizing the carbonitride precipitating effect of V in austenite in order to improve the toughness without reducing or substantially reducing the strength.

Owner:HENGYANG VALIN STEEL TUBE

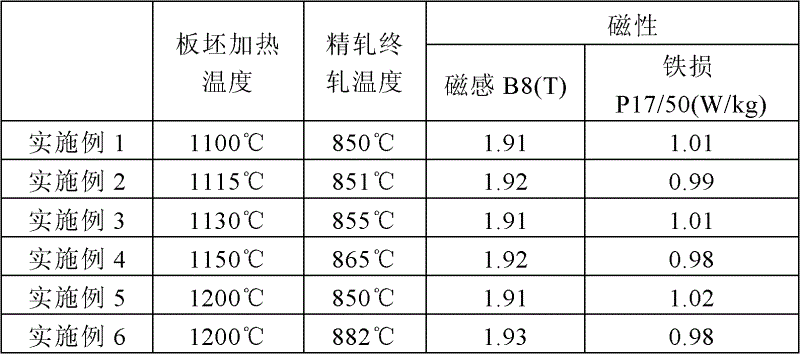

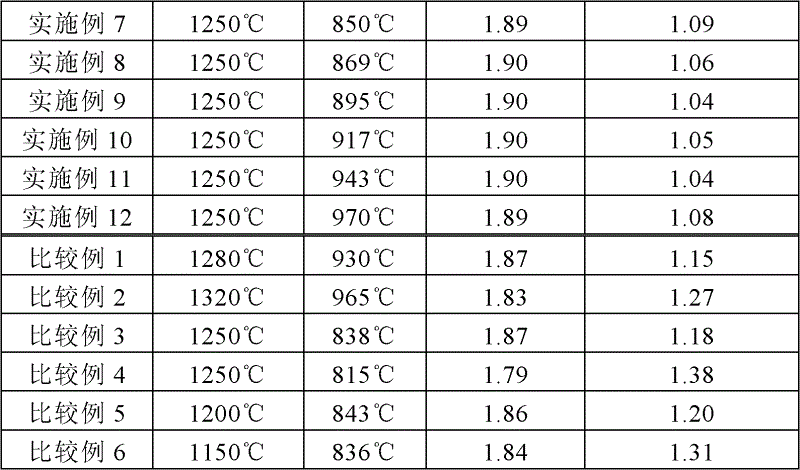

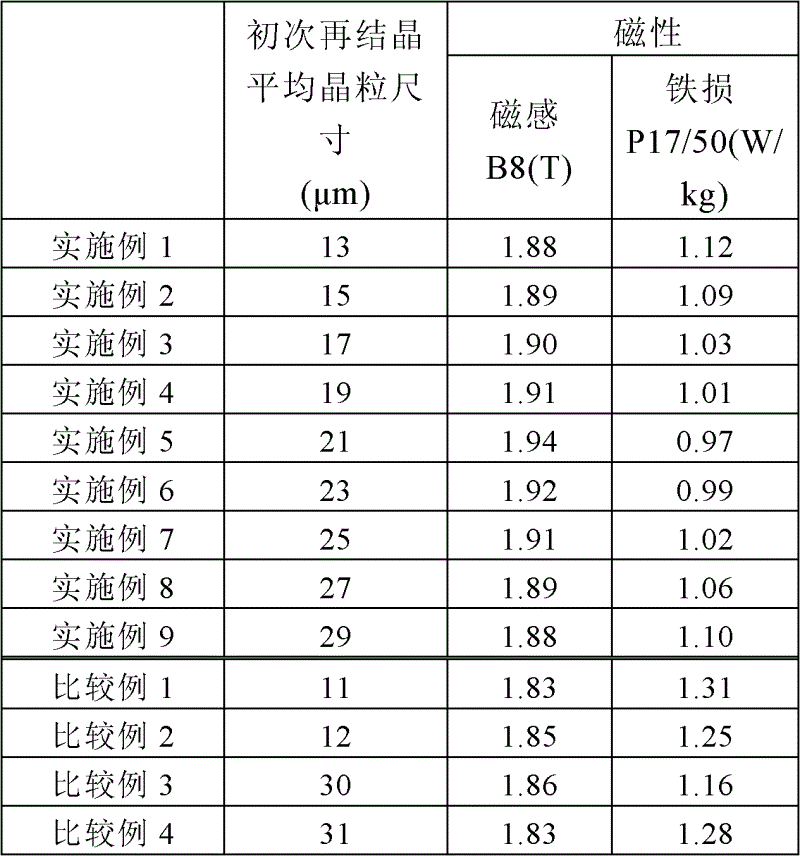

Production method of high magnetic induction oriented silicon steel

The invention discloses a production method of high magnetic induction oriented silicon steel, comprising the following steps: a) carrying out steel-making and continuous casting to produce slabs, wherein the slabs comprise 0.05-0.10 wt% of C, 2.5-4.0 wt% of Si, 0.008-0.028 wt% of S, 0.008-0.040 wt% of Als, 0.004-0.012 wt% of N, 0.08-0.20 wt% of Mn, 0.08-0.30 wt% of Cu, and the balance of Fe; b) preserving heat at no higher than 1250 DEG C and then carrying out hot rolling, wherein the finishing temperature is higher than 850 DEG C; c) carrying out annealing, pickling, once cold rolling or twice cold rolling containing intermediate annealing to get finished product thickness; d) decarburizing annealing, and preserving heat in wet nitrogen-hydrogen protective atmosphere; e) coating an annealing isolation agent and then carrying out high temperature annealing; f) carrying out nitriding treatment; and g) coating an insulating coating, and carrying out stretching, flattening and annealing. According to the invention, the types and distribution of the inhibitor is adjusted, the stable and high inhibition capability is guaranteed, by cooperating with hot rolling and twice recrystallization, the high magnetic induction oriented silicon steel with stable properties is obtained.

Owner:BAOSHAN IRON & STEEL CO LTD

Preparation method of high-gloss PET film transfer mirror-surface polyurethane synthetic leather

The invention provides a preparation method of high-gloss PET film transfer mirror-surface polyurethane synthetic leather. The preparation method comprises the following steps: firstly ironing wet polyurethane synthetic leather by a post-treatment calender at a temperature of 120-140 DEG C, and cooling to obtain a wet polyurethane synthetic leather semi-finished product; using a high-gloss PET mirror-surface film as a release film, and uniformly coating the front surface of the high-gloss PET mirror-surface film with a layer of polyurethane slurry to form a surface layer, and drying to obtain a high-gloss PET film; and finally heat-conglutinating a bonding layer of the high-gloss PET film and the front surface of the wet polyurethane synthetic leather semi-finished product, drying, cooling, and stripping the high-gloss PET mirror-surface film so as to obtain the high-gloss PET mirror-surface polyurethane synthetic leather. The mirror-surface effect of the leather is similar to the mirror-surface effect of patent leather. In addition, the leather provided by the invention has high gloss, high transparency, high flex resistance, resistance to yellowing and fogging resistance.

Owner:ANHUI ANLI MATERIAL TECH

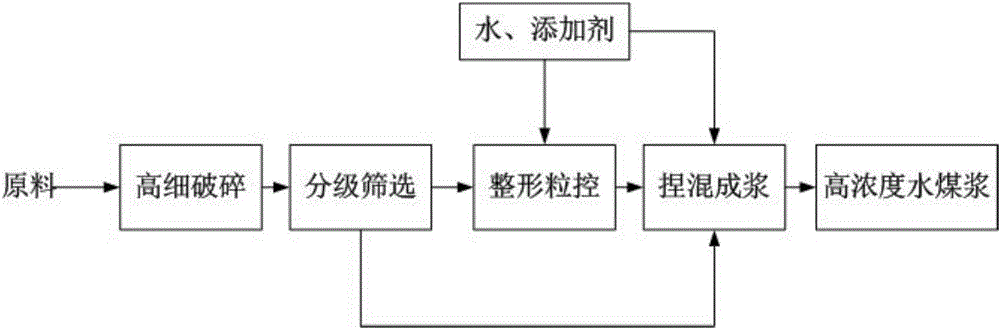

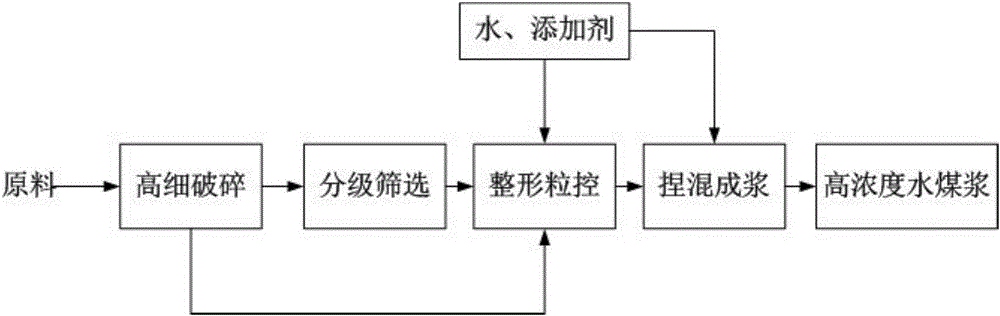

High-concentration coal water slurry and method for efficient classified grain control preparation of high-concentration coal water slurry

ActiveCN106244268AIncrease concentrationReasonable particle size distributionLiquid carbonaceous fuelsHigh concentrationCoal water

The invention provides high-concentration coal water slurry and a method for efficient classified grain control preparation of the high-concentration coal water slurry. Components of the high-concentration coal water slurry comprise coarse-grained coal powder, fine-grained coal slurry or fine-grained coal powder, an additive or water, and the concentration of the coal water slurry is 50 to 75 weight percent, wherein the mass ratio of the dry basis content of the coarse-grained coal powder, the dry basis content of the fine-grained coal slurry or the fine-grained coal powder and the additive is (0-90):(10-100):(0.1-1.0). The high-concentration coal water slurry is reasonable in grain size distribution and high in coal slurry concentration, flowability, stability and atomization performance. By the preparation method, the accumulation efficiency of the coal slurry can be improved, grain size distribution of the coal slurry can be optimized, and compared with a conventional single-rod / ball mill water coal slurry preparation process, the method has the advantage that the concentration can be increased by 4-6 percent or above; the flow is simple, extremely high in operability and extremely low in energy consumption, and long-term safe and continuous production requirements can be met; the prepared coal slurry can meet requirements on gasifying water coal slurry and combustion coal water slurry.

Owner:CCTEG CLEAN ENERGY CO LTD

Sulbenicillin sodium and sulbenicillin sodium used for injection

InactiveCN102161667AReduce contentReduce pollutionAntibacterial agentsPowder deliveryDichloromethanePhenylacetic acid

The invention provides a synthesis method of sulbenicillin sodium and sulbenicillin sodium used for injection, which comprises the concrete steps of: using 6-APA and BSA to synthesize an organic salt, and dissolving the organic salt into dichloromethane; using a sulphur phenylacetic acid triethylamine salt and pivaloyl chloride to make mixed anhydride; carrying out anhydrous condensation on the sulphur phenylacetic acid triethylamine salt and the pivaloyl chloride in the dichloromethane; and then forming a sodium salt, free-drying and obtaining a finished product. The new technical process is stable and feasible, better and stable in product quality and strong in operability of production, and reduces the environmental pollution.

Owner:辽宁科泰生物基因制药股份有限公司

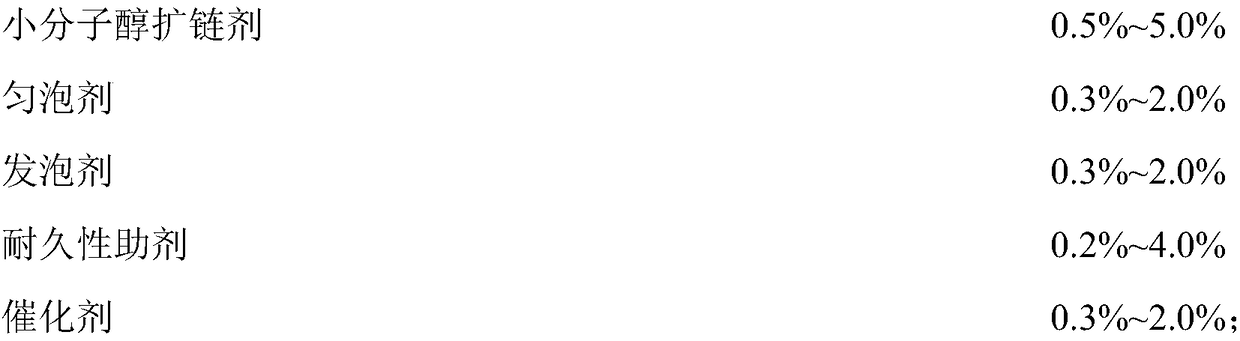

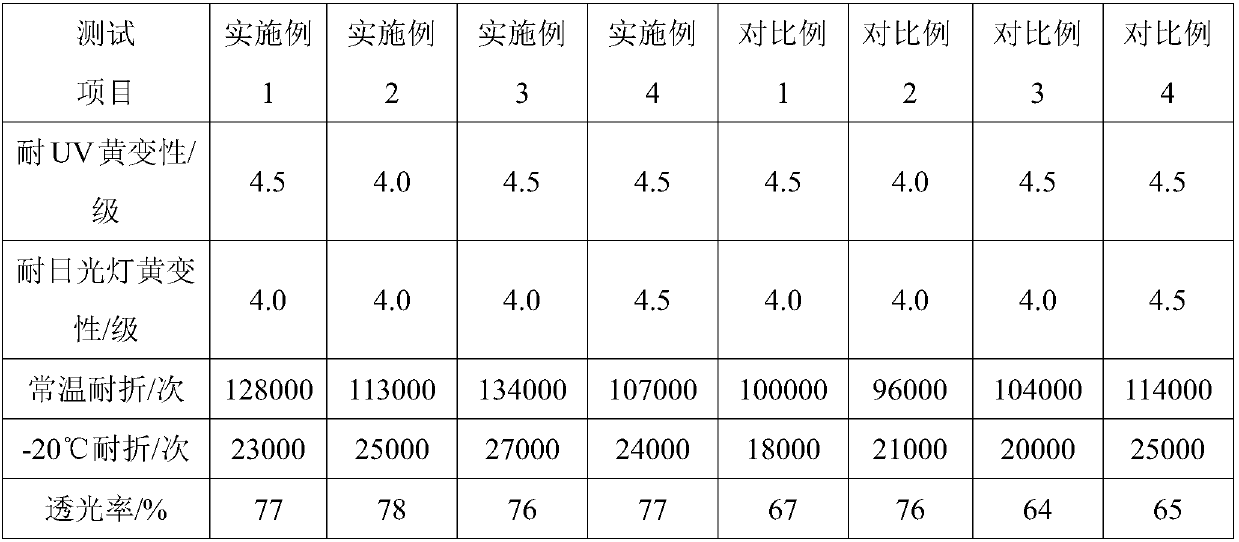

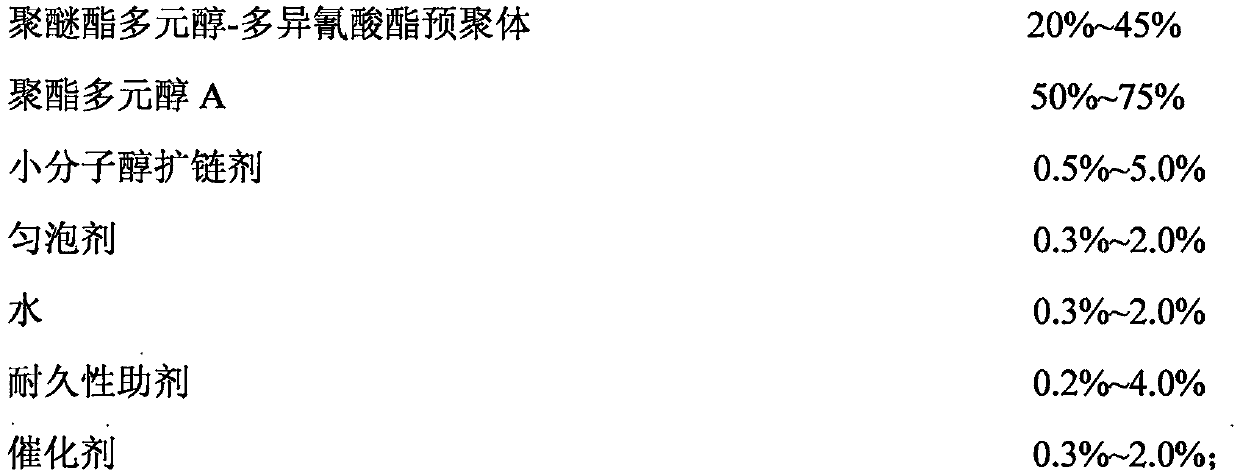

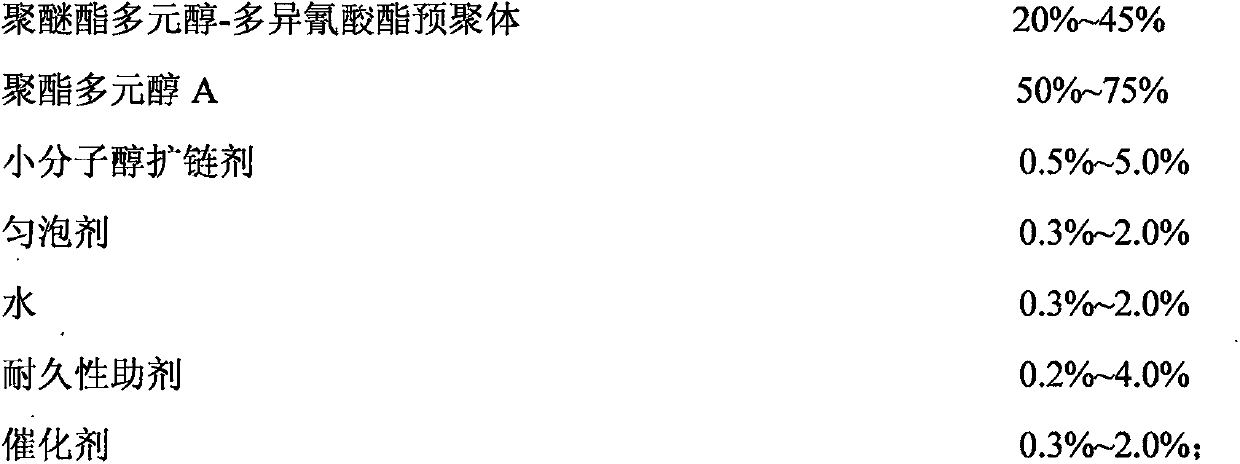

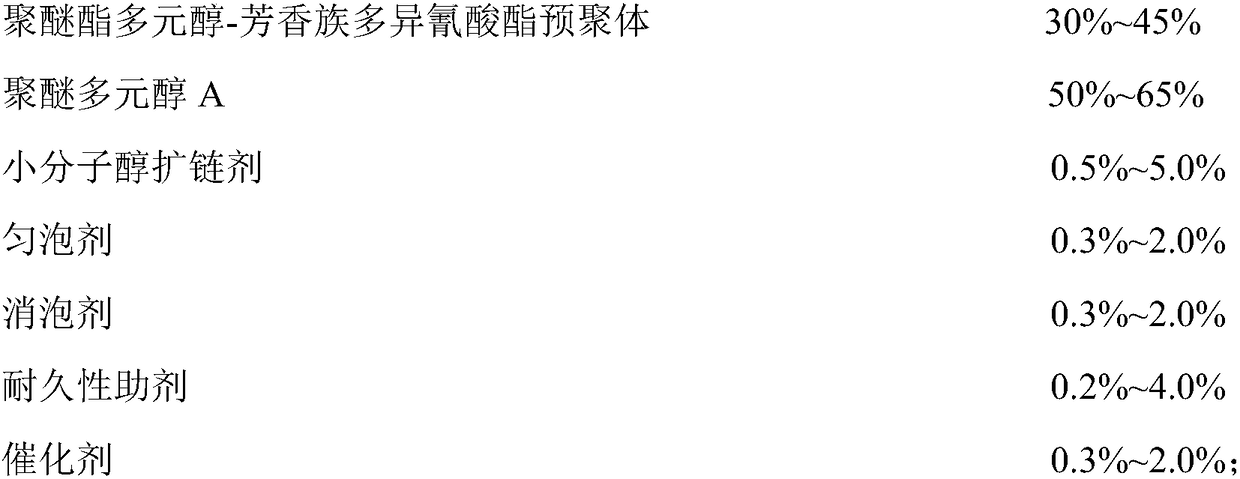

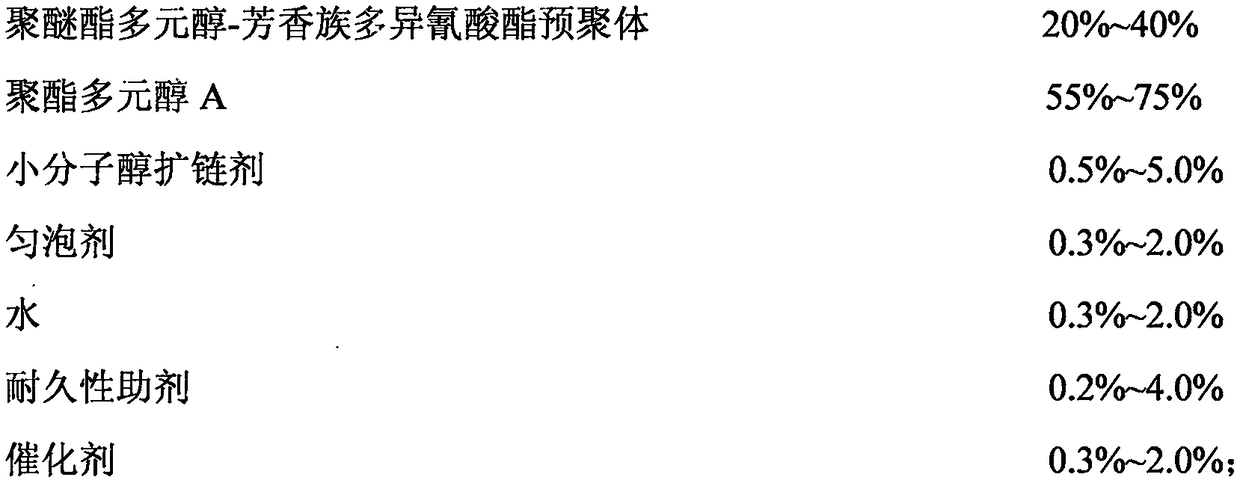

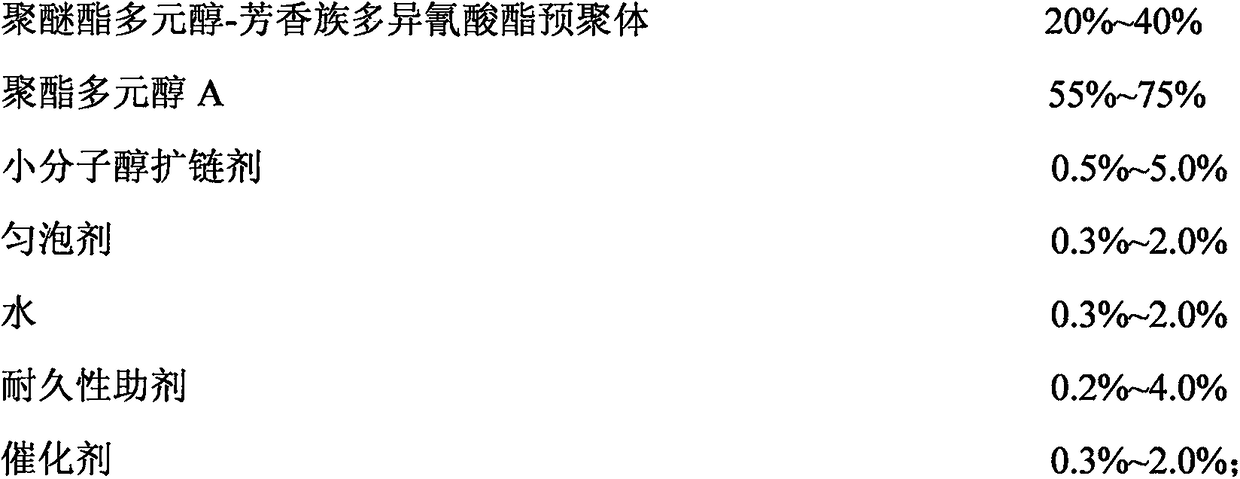

Blocked high-temperature resistant integrated solvent-free polyurethane resin for leather, and preparation method and application thereof

InactiveCN108570137AStrong production operabilityLow costPolyurea/polyurethane coatingsTextiles and paperPolyesterFoaming agent

Blocked high-temperature resistant integrated solvent-free polyurethane resin for leather, and a preparation method and application thereof are disclosed. The polyurethane resin comprises a resin component A and a resin component B. The resin component A comprises a polyether ester polyol-polyisocyanate prepolymer, polyester polyol, a small molecule alcohol chain extender, a foaming agent and a catalyst. The resin component B comprises diisocyanate, polyester polyol and a NCO blocking agent. The blocking agent is one or more selected from phenol, nitrophenol, 2-pyridinol, 3-hydroxyquinoline, triphenylmethanethiol, hexanethiol, dodecanethiol, 3,5-dimethylpyrazole, 1,2,4-triazole, 2-methyl imidazoline, 2-ethyl-4-methylimidazole, caprolactam, N-methylacetamide, phenylacetamide, bisulfate or amine. The polyurethane resin can be used for preparing high-temperature resistance solvent-free polyurethane synthetic leather. The production efficiency is high. Equipment specially used for solvent-free leather synthesis is not needed, operable time is long after product mixing and stability is high.

Owner:ZHEJIANG HUAFON SYNTHETIC RESIN

Method for manufacturing organic supercapacitor electrode plate

The invention provides a method for manufacturing an organic supercapacitor electrode plate. The method comprises the following steps of: manufacturing an aluminum foil pretreatment coating, adding an adhesive into deionized water, and uniformly stirring at normal temperature; adding a conductive agent, absolute ethanol, a carbon nano tube and sodium carboxymethyl cellulose, stirring at a high speed and dispersing to obtain the coating; uniformly coating the manufactured pretreatment coating on an aluminum foil by employing a coating process, coating active substance slurry on the pretreated aluminum foil, and drying to manufacture the electrode plate. A corrosive aluminum foil is replaced by a common aluminum foil, the cost of raw materials is effectively reduced, and the production operability and stability are improved; meanwhile, after the aluminum foil is pretreated, internal resistance of the supercapacitor is greatly reduced, and high-power output performance of the product is improved.

Owner:JIANGSU FRONT NEW ENERGY

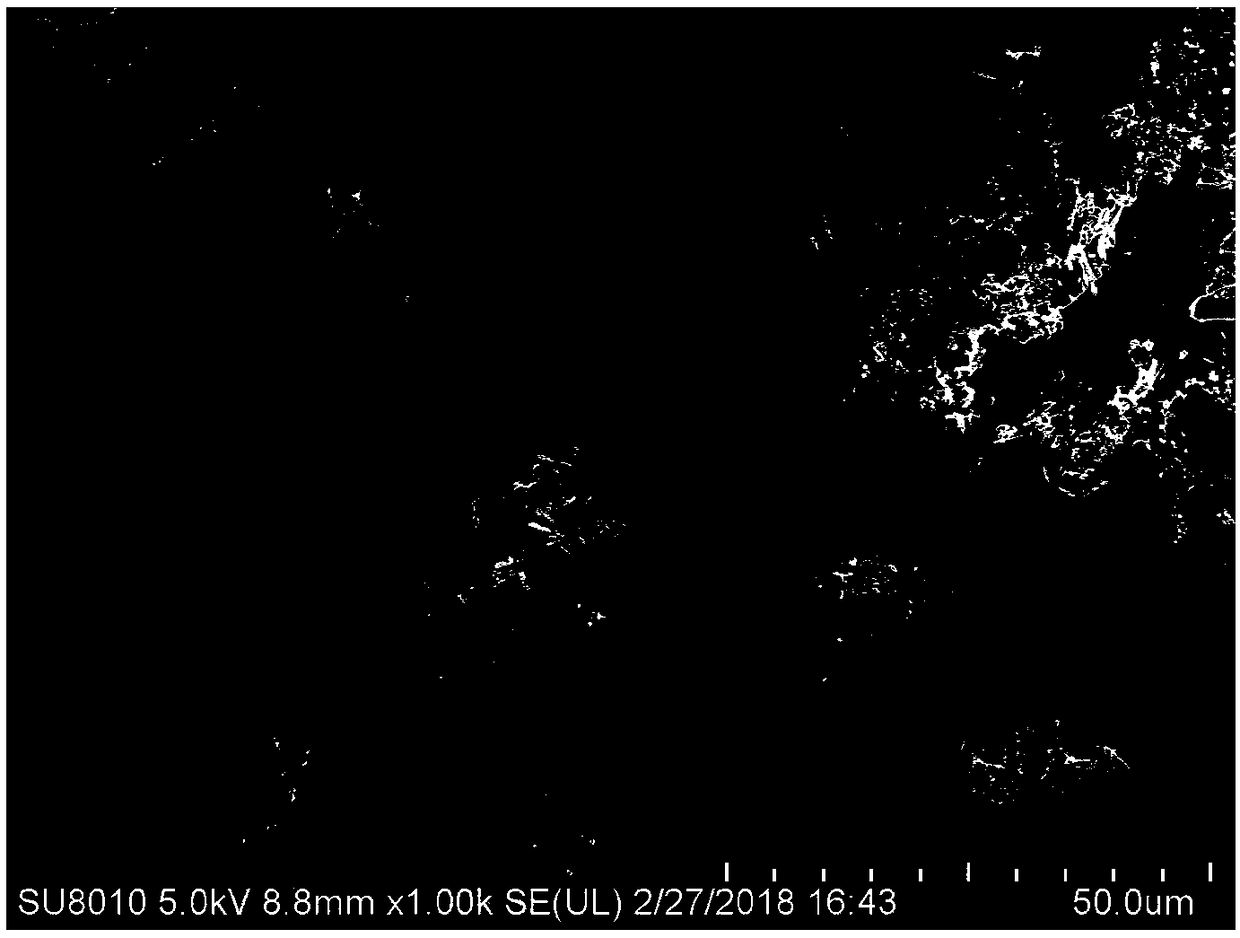

Lithium ion battery alumina hydrate coating membrane and preparation method thereof

InactiveCN105932210AImprove securityImprove heat resistanceCell component detailsAlumina hydrateAdhesive

The invention belongs to the field of lithium ion battery materials, and discloses a lithium ion battery alumina hydrate coating membrane and preparation method thereof. The alumina hydrate slurry is coated on the surface of the lithium ion battery membrane. The preparation method comprises the following steps: mixing nano-level alumina hydrate, surfactant, thickening agent, adhesive, dispersing agent, defoaming agent and solvent, stirring, using a coating device to uniformly coat the slurry on the frontage and the back surface of the lithium ion battery membrane so as to form the coating layer, drying the coating layer to obtain the lithium ion battery alumina hydrate coating membrane, winding and sealing to store. Besides the high security of the coating membrane, the heat resistance, puncture strength, and the electrolyte retention of the lithium ion battery membrane are improved, the electrochemical property of the lithium ion battery can be obviously improved, and the production operability is strong.

Owner:湖南锂顺能源科技有限公司

Preparation method of licorice extract of bulk drug for livestock

InactiveCN101607980AReasonable workmanshipStrong production operabilitySteroidsSocial benefitsFood safety

The invention relates to a preparation method of glycyrrhetinic acid of a bulk drug for livestock, in particular to a method for extracting effective components from a plant medicine to prepare the bulk drug of a medicine for livestock, particularly a preparation method for extracting purified glycyrrhetinic acid from licorice, which is used for preventing and treating the disease of the livestock. The invention starts off from the feasibility of actual production, develops the preparation and the method thereof of the glycyrrhetinic acid of the bulk drug for the livestock, is widely applied to the nuisance-free breeding industry, promotes the production of nuisance-free foods and guarantees the safety of the foods, and the purity of the glycyrrhetinic acid is high. The invention has reasonable technology, strong production operability and large value of practical application, is economical and practical and can hopefully bring favorable economic benefit and social benefit, and the purity of a product can reach more than 90%.

Owner:北京九草堂药物研究院有限公司

Boracic low-carbon hot rolling pickling plate and production method thereof

InactiveCN108517459AImprove performanceLower transition temperatureTemperature control deviceBoronAustenite

The invention relates to the field of hot rolling pickling plates, in particular to a boracic low-carbon hot rolling pickling plate and a preparation method thereof. Boron with the content of 0.0010-0.0030% is added into a low-carbon hot rolling pickling plate, wherein the thickness is larger than or equal to 2.0 mm and less than or equal to 6.0 mm, and thus based on the ideal structural performance, multiple kinds of measures for controlling the surface quality can be taken, so that steel plate mixed crystals are effectively avoided, and the problem of rolled edge mixed crystals is especiallysolved. The boron is added into the low-carbon hot rolling pickling plate to reduce the transformation temperature from austenite to ferrite, so that structural transformation does not happen at thefinishing rolling temperature of 840-860 DEG C at a hot rolling stage, that is to say, no mixed crystal defects exist, finally, the even structural performance is obtained, and meanwhile, an advantageis created for inputting a large amount of descaling water to overcome scale defects at the hot rolling stage.

Owner:BENGANG STEEL PLATES

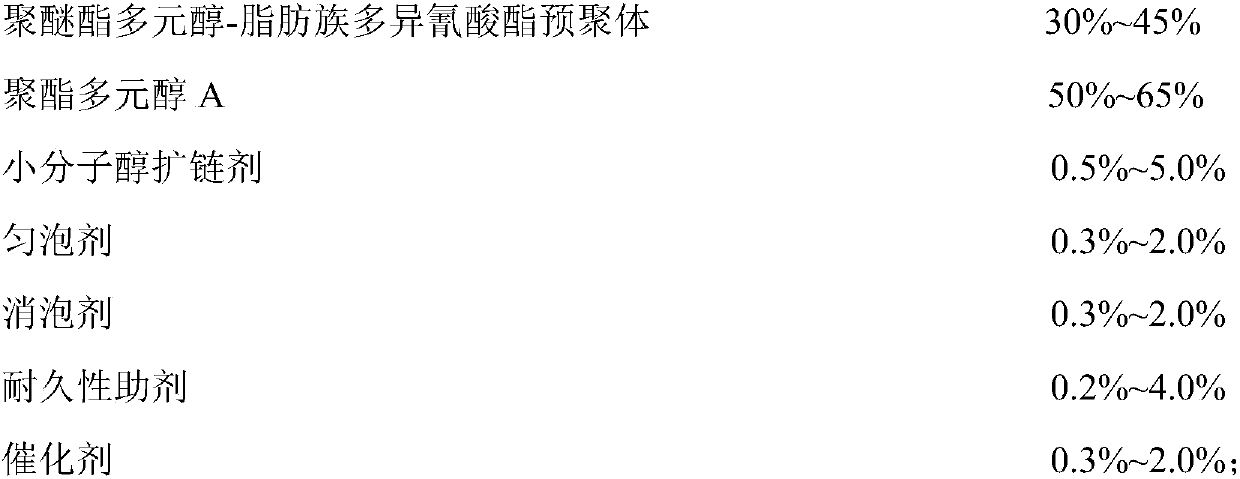

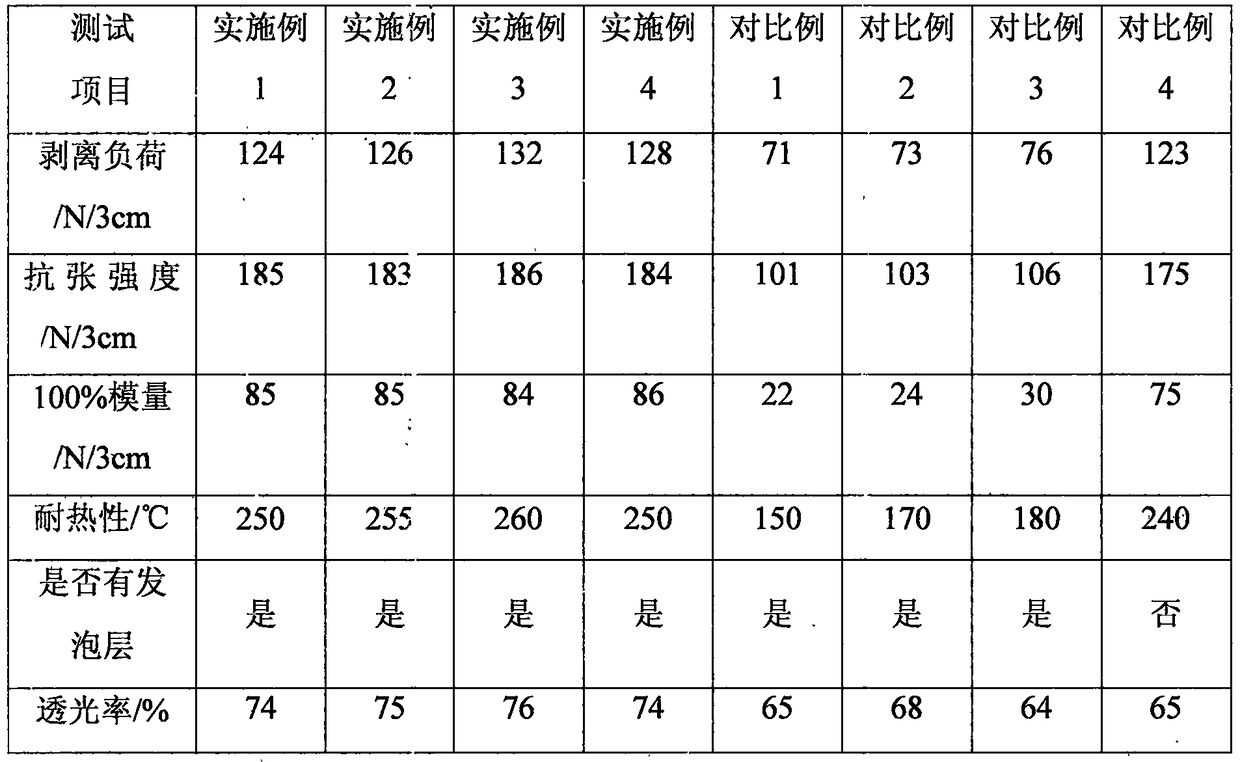

Solvent-free, non-yellowing, high-transparency and high-brightness polyurethane resin for leather as well as preparation method and application

InactiveCN108017770AImprove yieldTranslucent surfacePolyurea/polyurethane coatingsSurface layerRoom temperature

The invention discloses solvent-free, non-yellowing, high-transparency and high-brightness polyurethane resin for leather as well as a preparation method and application. The solvent-free, non-yellowing, high-transparency and high-brightness polyurethane resin is prepared from a resin component A and a resin component B, wherein the mass ratio of the resin component A to the resin component B ranges from (7 to 3) to (1 to 3). The resin component A contains a polyether ester polyol-aliphatic polyisocyanate pre-polymer with the mass percent of 30 percent to 45 percent and the resin component B contains aliphatic diisocyanate with the mass percent of 20 percent to 60 percent. A surface layer of synthetic leather is coated with the solvent-free, non-yellowing, high-transparency and high-brightness polyurethane resin for the leather, disclosed by the invention, and the synthetic leather has a non-yellowing, high-transparency and high-brightness aesthetic extent; in a production process, a curing speed is rapid and the rate of finished products is high; the anti-yellowing grade is greater than or equal to grade 4; the room-temperature folding resistance and the low-temperature folding resistance are high and the surface is transparent and bright.

Owner:ZHEJIANG HUAFON SYNTHETIC RESIN

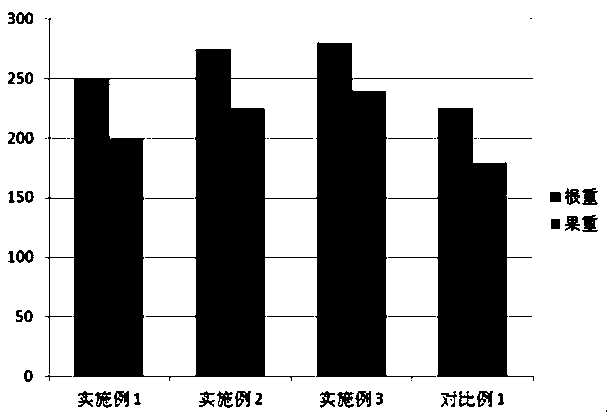

Foliar fertilizer for puer tea trees and preparation method thereof

InactiveCN107382495AImprove securityGrowth inhibitionBio-organic fraction processingBioloigcal waste fertilisersInsect pestPlant disease

The invention discloses foliar fertilizer for puer tea trees. The foliar fertilizer is prepared from the following components in parts by weight: 4 to 10 parts of fresh puer tea leaves, 8 to 21 parts of jatamans valeriana rhizome medicine residues, 8 to 21 parts of radix puerariae medicine residues, 5 to 13 parts of rhizoma dioscoreae medicine residues, 6 to 15 parts of poria cocos medicine residues, 8 to 18 parts of fructus jujubae medicine residues, 5 to 16 parts of fructus lycii medicine residues, 10 to 25 parts of Xiaoqu fen-flavor liquor vinasse and 1 to 8 parts of brown sugar. The foliar fertilizer disclosed by the invention is obtained by fermentation; the foliar fertilizer contains a large quantity of nutrient elements including amino acids, polypeptides, vitamins and the like and can be used for supplementing nutrient element deficiency caused by various factor influences; the foliar fertilizer can also be used for rapidly balancing the ecology of probiotics in the tea leaves, increasing the plant disease and insect pest resisting capability of the tea trees and improving the quality of the tea leaves; the foliar fertilizer provided by the invention is produced by adopting industrial waste materials; a preparation technology is simple and the production operability is very strong; the planting production cost of puer tea is greatly saved.

Owner:YUNNAN LONGRUN TEA TECH

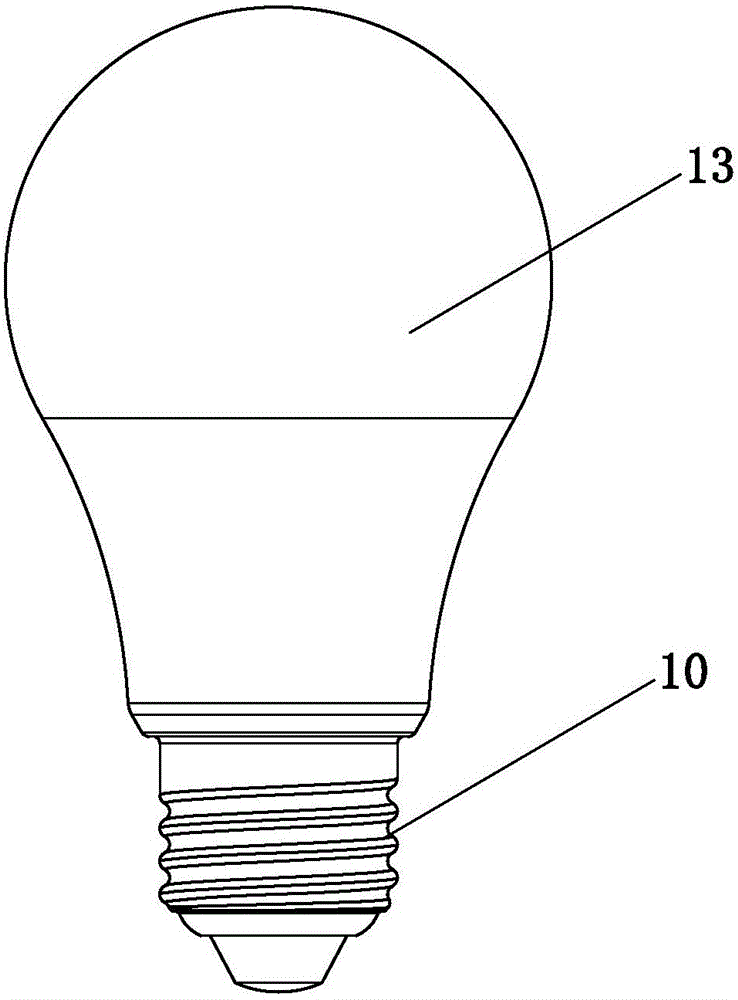

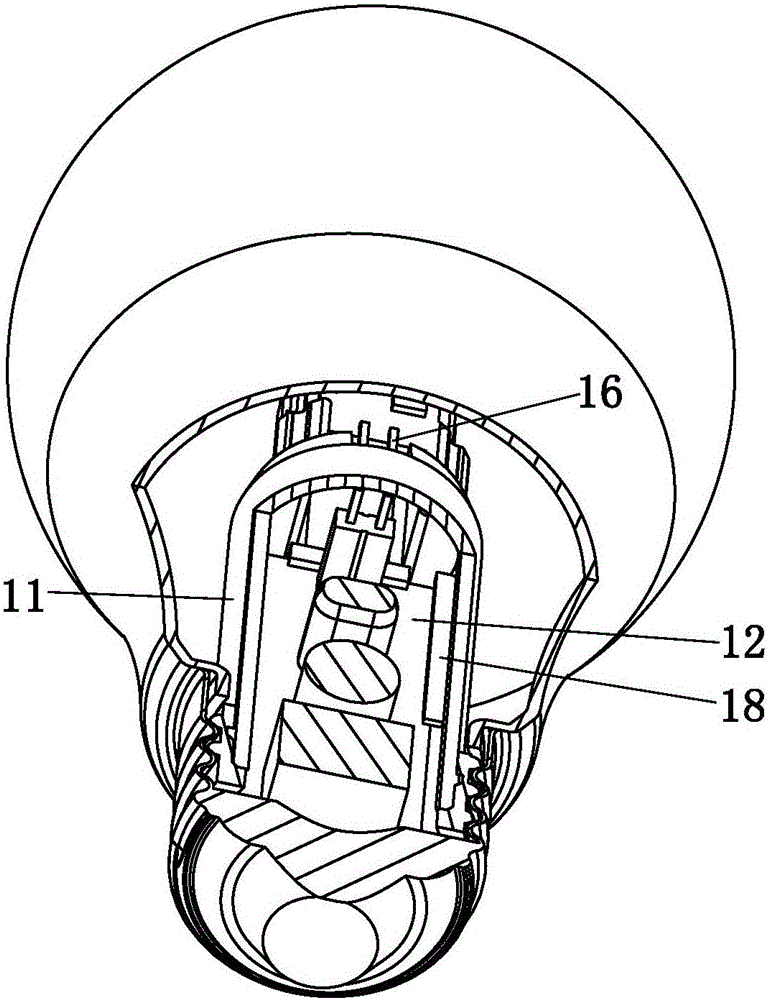

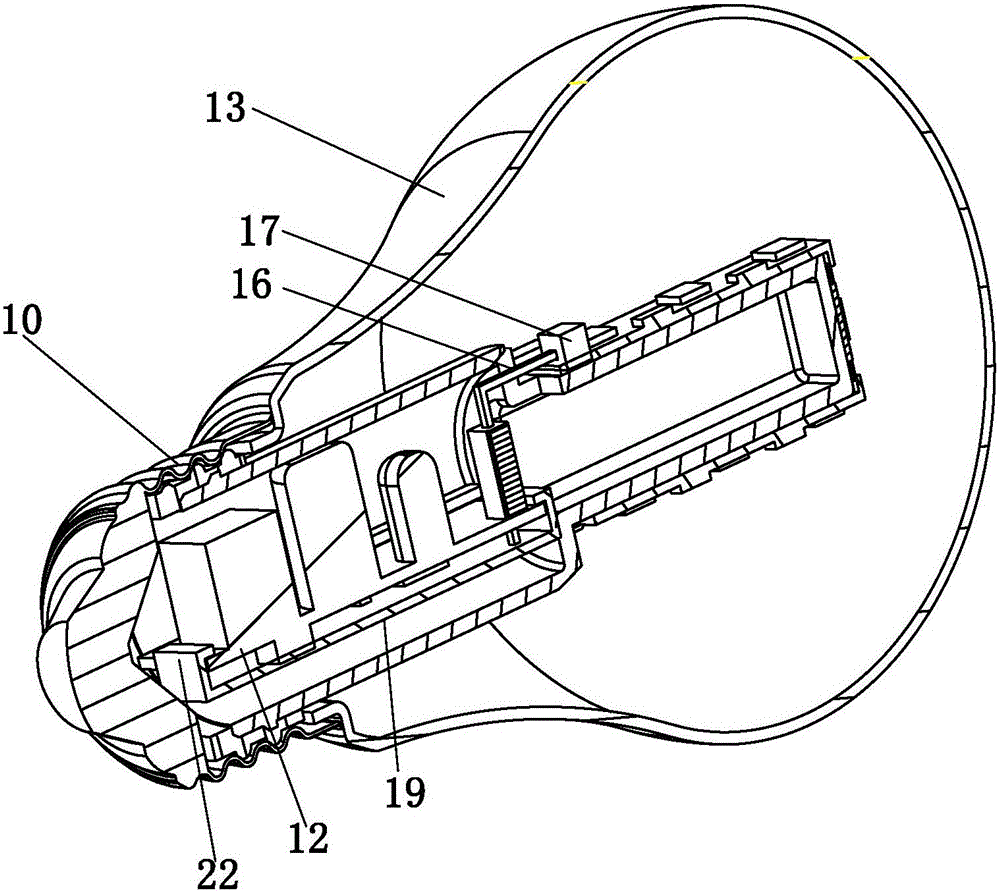

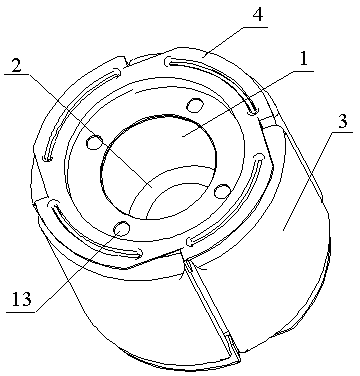

LED light source module and LED lamp

InactiveCN105972461AStrong production operabilitySimple production processElectric circuit arrangementsLighting heating/cooling arrangementsEngineeringLED lamp

The invention relates to an LED light source module and an LED lamp. The module comprises a first LED lamp band and a second LED lamp band. The first LED lamp band comprises a first middle part and bent first ribs symmetrically arranged on the two sides of the first middle part and provided with LED chips. The second LED lamp band comprises a second middle part and bent second ribs symmetrically arranged on the two sides of the second middle part and provided with LED chips. The first LED lamp band and the second LED lamp band are arranged in a crossed manner, and the first middle part and the second middle part are stacked together. The invention further provides the LED lamp based on the above light source module. According to the module, the first LED lamp band and the second LED lamp band are arranged in the crossed manner, the crossed positions are stacked together, electric conduction connection between metal is achieved through contact in crossed stacking, and additional circuit connection through a lead is not needed any more. Meanwhile, the first ribs and the second ribs are bent, a certain angle is kept between the first ribs and the first LED lamp band, a certain angle is kept between the second ribs and the second LED lamp band, and a large angle light emitting body is formed.

Owner:ZHEJIANG SHENGHUI LIGHTING

Polyurethane resin for solvent-free leather and preparing method and application thereof

The invention discloses polyurethane resin of solvent-free synthetic leather and a preparing method and application thereof. The polyurethane resin of the solvent-free synthetic leather comprises a resin component A and a resin component B, wherein the resin component A is prepared from, by weight, 20-45% of polyether ester polyol-polyisocyanates prepolymer and 0.3-2.0% of water, the resin component B is prepared from, by weight, 20-60% of diisocyanate, and the mass ratio of the resin component A to the resin component B is 3:1-1:3. When the polyurethane resin of the solvent-free synthetic leather is used for producing the synergic leather, what is only needed is to scrape solvent-free resin so that a surface layer structure, an adhesive layer structure and a foaming layer structure can beprovided, the technology process is simple, and the physical and mechanical performance is excellent.

Owner:ZHEJIANG HUAFON SYNTHETIC RESIN

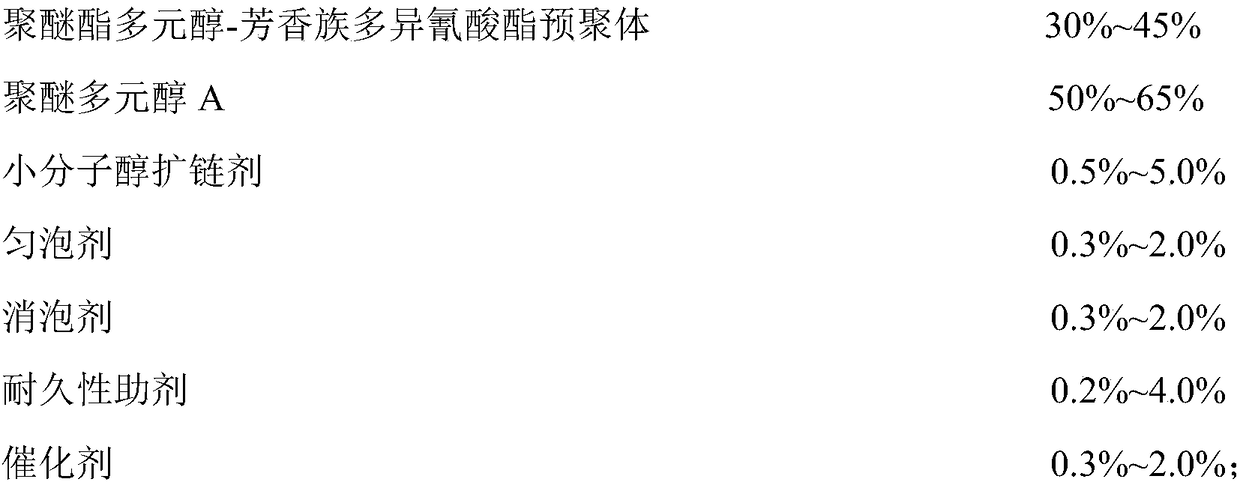

Polyurethane resin used for non-solvent leather with high brightness and bending resistance, preparation method and application

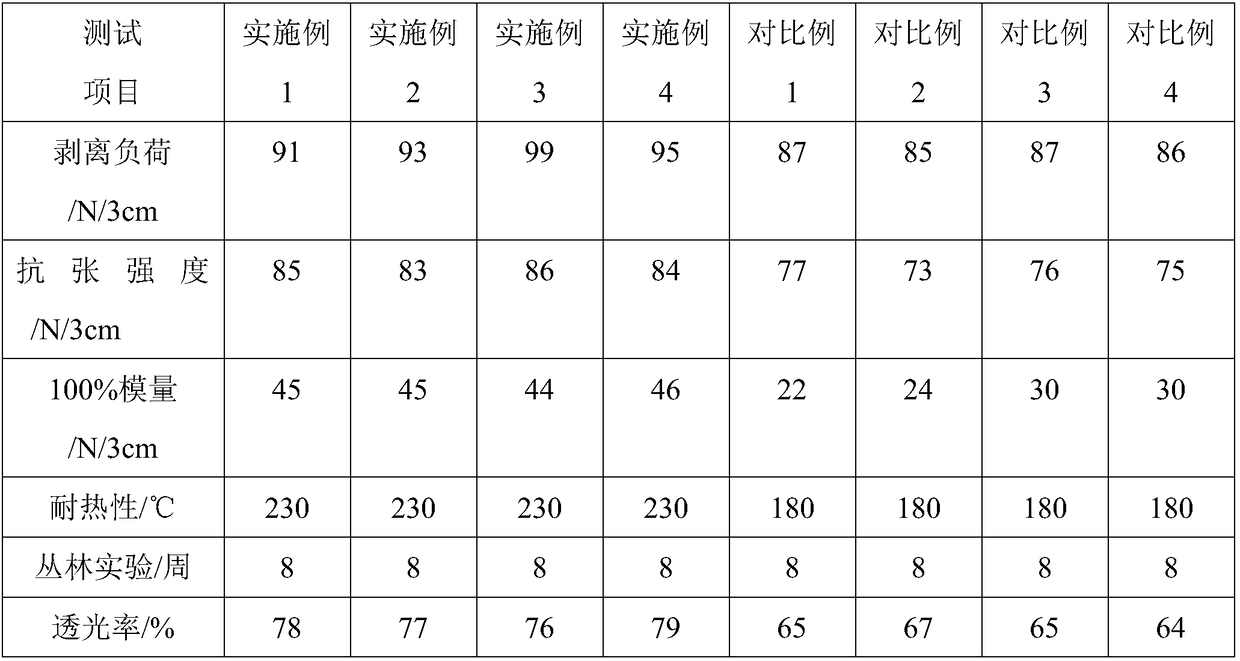

ActiveCN108252115AHigh transparency and high brightness aestheticsHigh peel strengthPolyurea/polyurethane coatingsTextiles and paperPrepolymerIsocyanate

The invention discloses a polyurethane resin used for non-solvent leather with high brightness and bending resistance, a preparation method and application. The polyurethane resin used for non-solventleather with high brightness and bending resistance comprises a resin component A and a resin component B; the resin component A comprises 30% to 45% of ether-ester polyhydric alcohol-aromatic polyisocyanates prepolymer; the resin component B comprises 15% to 60% of aromatic diisocyanate. The resin can be used for preparing polyurethane synthetic leather, the synthetic leather is high in brightness and attractive in appearance, the physical and mechanical properties, such as bending resistance, of the synthetic leather are improved preferably, the production operability of the non-solvent synthetic leather in the mass production process is improved, and the matching stability of the resin component A and the resin component B during machining is guaranteed.

Owner:ZHEJIANG HUAFON SYNTHETIC RESIN

Lithium ion power battery

ActiveCN102810693AImprove securityPrevent short circuit and other problemsFinal product manufactureCell component detailsPower batteryLithium

The invention provides a lithium ion power battery, which can improve the tab location accuracy while winding an electrode plate, improve the production efficiency and the yield and further improve the cell security. The lithium ion power battery comprises a case with a cylindrical surface, a cell in the inner cavity of the case, an upper cover plate and a lower cover plate on both ends of the cell, and an upper electrode part and a lower electrode part on both ends of the cell. The cell includes an electrode plate assembly formed by arranging and connecting a plurality of positive electrode plates, negative electrode plates and an isolating membrane between adjacent positive electrode plate and negative electrode plate in a winding manner; the cell also includes one or more aluminum rings with a cylindrical structure, wherein the aluminum rings are arranged in the inner cavity of the case to divide the electrode plate assembly into a plurality of sections; and a portion of the electrode plate assembly is located inside the aluminum ring, and the other portion of the electrode plate assembly is sheathed outside the aluminum ring. An aluminum plate for dissipating heat is arranged on both ends of the cell, and is connected with the end part of the aluminum ring.

Owner:YINLONG ENERGY CO LTD

Diaphragm used for zinc ion battery and preparation method thereof

ActiveCN108832062AImprove liquid retention capacityImprove securitySecondary cellsCell component detailsPorosityGlass fiber

The invention belongs to the technical field of zinc ion batteries, and particularly relates to a diaphragm used for a zinc ion battery. The diaphragm comprises a diaphragm base and a coating layer arranged on at least one surface of the diaphragm base; the diaphragm base is an adsorptive glass fiber mat type diaphragm; and the coating layer is an oxide layer. Compared with the prior art, the diaphragm has the advantages of high safety, puncture resistance, high liquid retention and high porosity. Moreover, the invention also discloses a preparation method of the diaphragm.

Owner:SHENZHEN CITY THROUGH SCI & TECH OF NEW ENERGY CO LTD

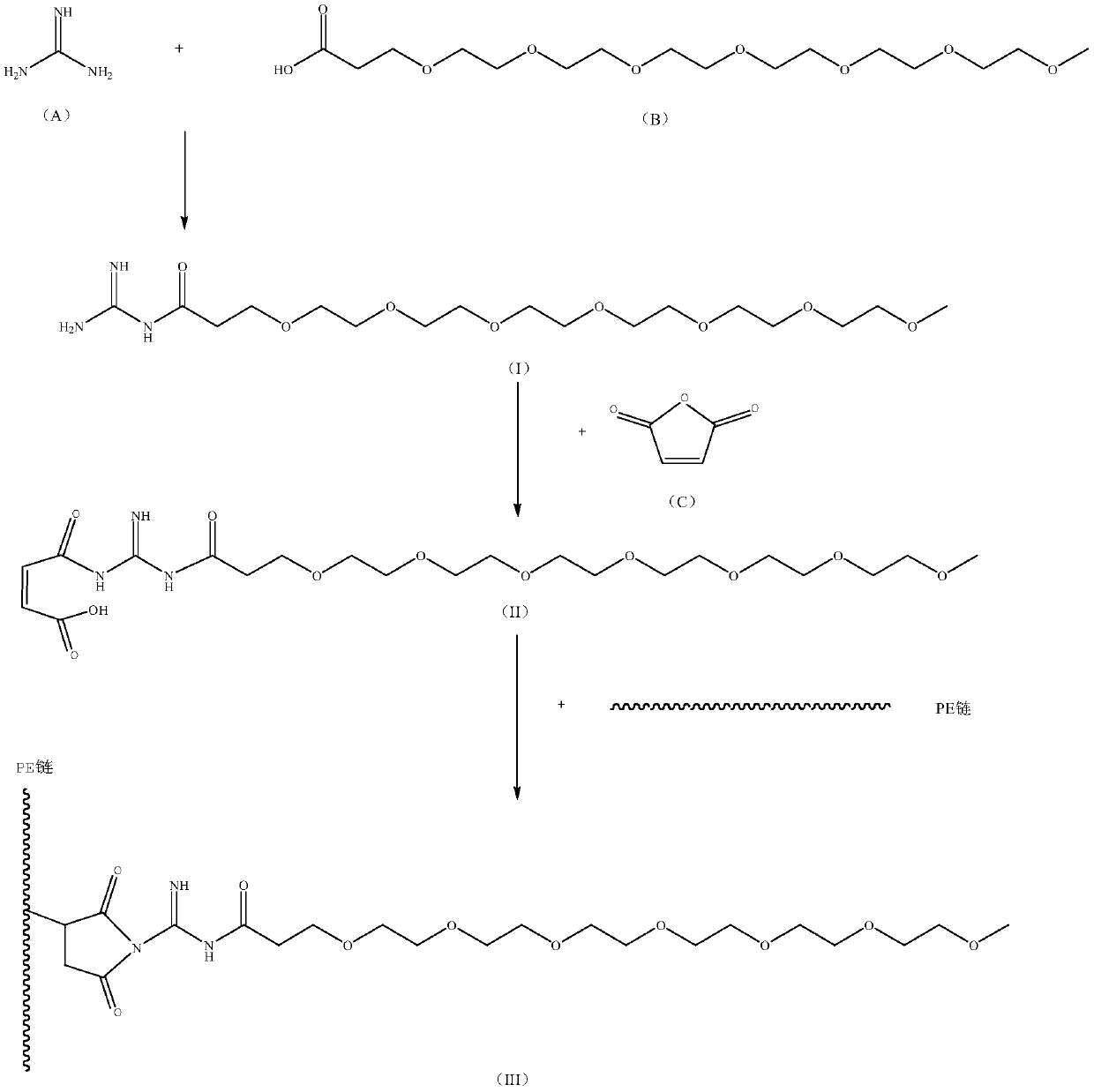

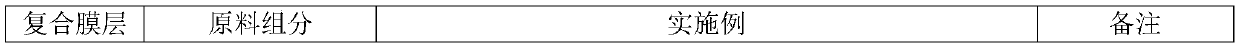

Antibacterial high-oxygen barrier PE composite film and preparation method thereof

The invention belongs to the field of packaging materials, and particularly relates to an antibacterial high-oxygen barrier PE composite film and a preparation method thereof. The antibacterial high-oxygen barrier PE composite film sequentially comprises a PE film layer, a PVA film layer and a PE film layer from outside to inside and is prepared through three-layer co-extrusion compounding. The antibacterial high-oxygen barrier PE composite film has excellent antibacterial and antistatic properties while effectively improving the poor moisture resistance, oxygen barrier property and film interlayer binding force of an existing PE composite film, has the advantage of good comprehensive performance, has wide application space, and is especially suitable for food packaging and medical treatment.

Owner:山东亚新塑料包装有限公司

Nickel release detection standard substance preparation method

InactiveCN103471880ALow costSimple materialPreparing sample for investigationIntermediate frequencyOperability

The present invention relates to a nickel release detection standard substance preparation method, which comprises: uniformly mixing brass powder and nickel powder according to a certain ratio to prepare a pre-smelting raw material; placing the raw material in a graphite crucible, adding a layer of active carbon powder on the surface, and placing into an intermediate frequency induction device; setting an initial induction current to 70+ / -5 A, carrying out heat smelting, and maintaining for 3-5 min; reducing the current value to 50+ / -5 A, and maintaining for 1-2 min; repeatedly performing the previous steps three times, and carrying out argon gas protection during the processes; increasing the current value to 80 A, heating for 0.5-1 min, and then pouring into a graphite mold to prepare a round bar-like specimen; cutting the specimen into a sheet with phi20*1.3 mm, grinding to achieve a thickness of 1.2 mm and a weight of about 3.0 g; and cleaning the grinded specimen with alcohol, and carrying out hot air drying. The preparation method has characteristics of simple process, strong production operability, easy operation, low cost, easily available raw materials, and easy marketization, wherein the obtained standard substance has good uniformity and good stability.

Owner:许菲菲

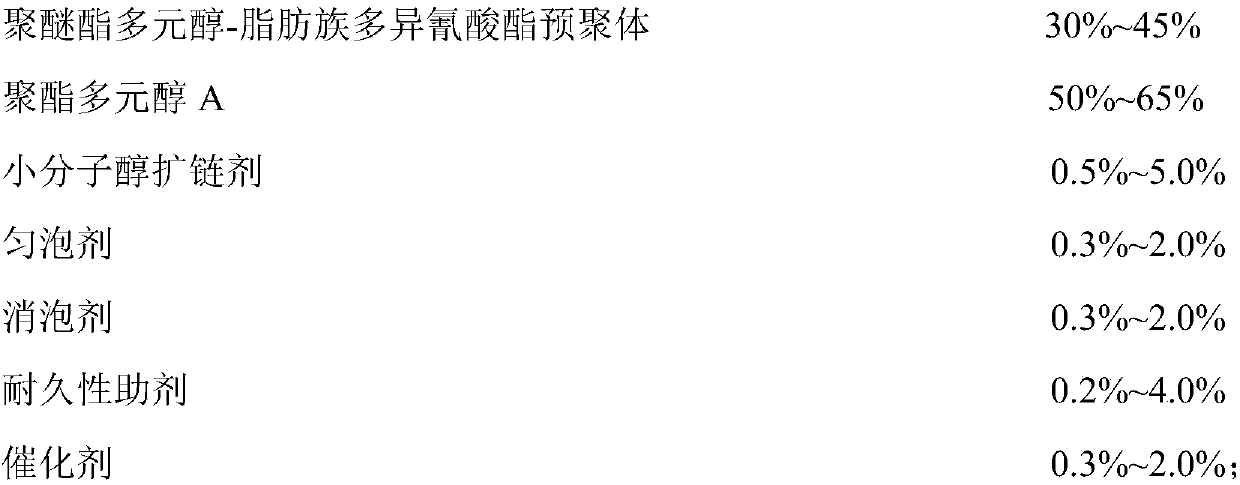

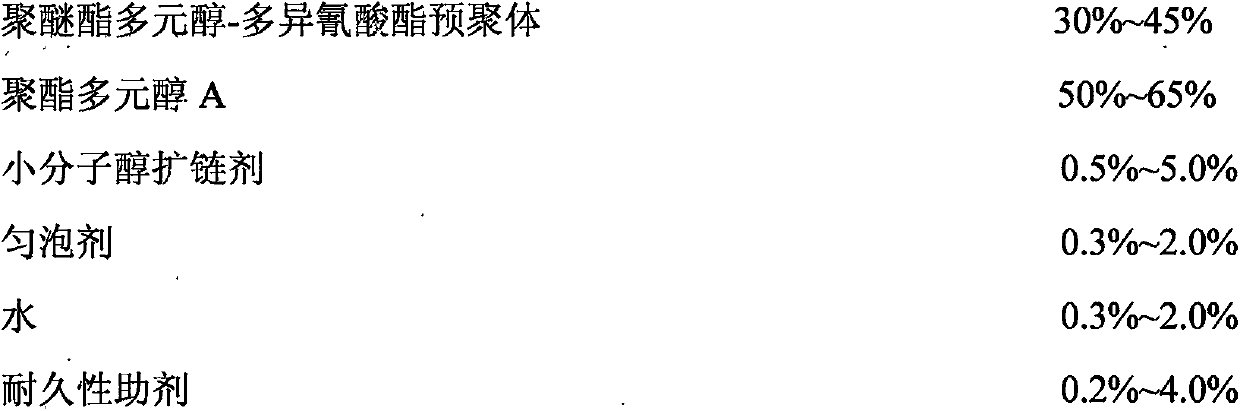

Polyurethane resin for high temperature resistant integrated solvent-free leather as well as preparation method and application of the polyurethane resin

InactiveCN108164675AGood workmanshipIncrease productivityCoatingsTextiles and paperPolyolSurface layer

The invention discloses a polyurethane resin for high temperature resistant integrated solvent-free leather as well as a preparation method and application of the polyurethane resin. The polyurethaneresin for high temperature resistant integrated solvent-free leather comprises a resin A component and a resin B component, wherein the resin A component comprises 20%-40% by weight percentage of a polyether ester polyol-aromatic polyisocyanate prepolymer and 0.3%-2.0% by weight percentage of water; and the resin B component comprises 15%-85% by weight percentage of aromatic diisocyanate. Only knife coating of one knife of the solvent-free resin is needed when the polyurethane resin for high temperature resistant integrated solvent-free leather is used for producing synthetic leather, and thenthe produced synthetic leather can have a surface layer, bonding layer and foaming layer structure, the process is simple, and the high temperature resistance is excellent.

Owner:ZHEJIANG HUAFON SYNTHETIC RESIN

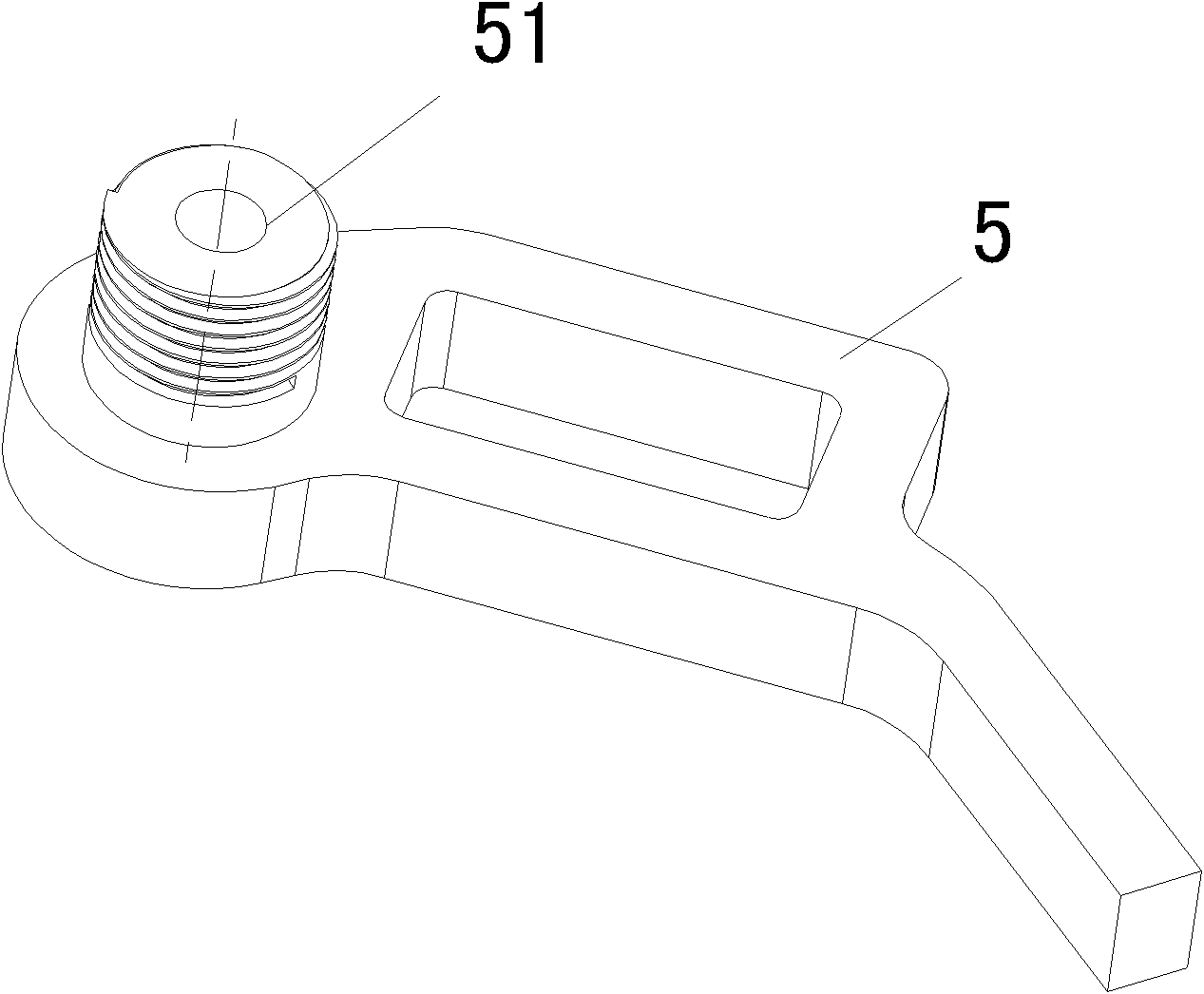

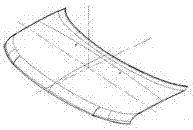

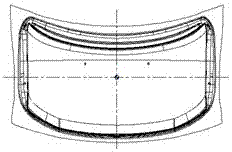

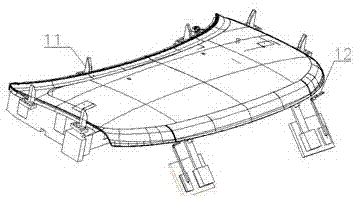

Process holes for back-end procedures in flat-shape covering part stamping production and locating method

InactiveCN106944537APrecise positioningHigh positioning accuracyMetal-working feeding devicesPositioning devicesIsoetes triquetraManufacturing engineering

The invention discloses process holes for back-end procedures in flat-shape covering part stamping production. Each process hole is in a periphery rounded equilateral triangle shape, and the size of each process hole is internally tangent to a circle of phi 3-phi 6. The process holes are used for part precise locating in procedures after trimming and punching and are formed in a supplement part of a drawing process. The number of the process holes is larger than or equal to 2. The invention discloses a locating method of a flat-shape covering part after trimming at the same time. According to the process holes for the back-end procedures in flat-shape covering part stamping production, it is guaranteed that the flat-shape covering part, an automobile engine hood outer plate, is fast and accurately located; locating precision is high; stamping production operation is convenient; product consistency is good; production efficiency is high; product quality is stable; and the product percent of pass is high.

Owner:LIUZHOU VOCATIONAL & TECHN COLLEGE

Method for reducing ignition residues in ginkgo leaf extract

InactiveCN102145028AReduced residue on ignitionSimple processGinkgophyta medical ingredientsAlcoholGinkgo biloba

The invention discloses a method for reducing ignition residues in a ginkgo leaf extract, which comprises the following steps of: performing water extraction or alcohol extraction on ginkgo leaf serving as a raw material to obtain an extract, concentrating under vacuum, filtering by using kieselguhr, and allowing filter liquor to pass through a macroporous resin column for separating; after sample liquor passes through the column, washing impurities by using deionized water until salt substances are washed completely; eluting by using ethanol, and collecting eluent; and concentrating the eluent until the eluent is dried, and crushing to obtain the ginkgo leaf extract with low content of ignition residues. In the method, the ignition residues are reduced to be lower than 0.2 percent under the condition that other active ingredients in the ginkgo leaf extract is not lost. The method has the advantages of simpleness, stable quality of products, high operability of production, and no influence on the active ingredients and yield of the products and the like, and can be used for the industrial production of the ginkgo leaf extract.

Owner:GUIZHOU UNIV

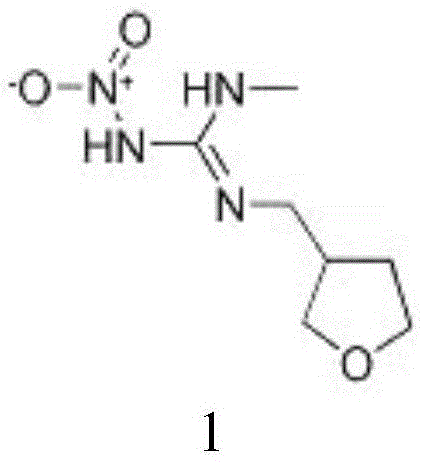

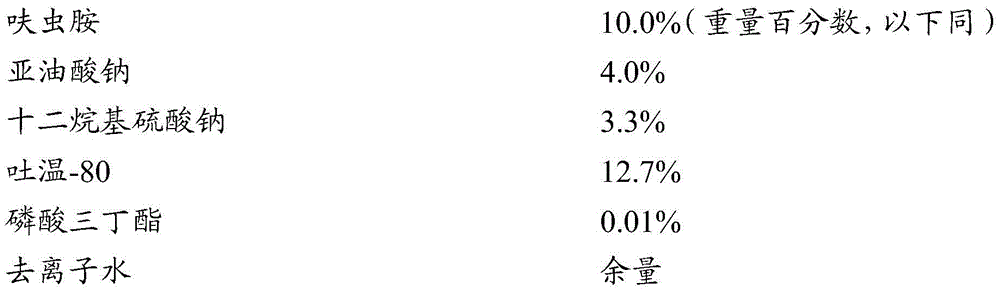

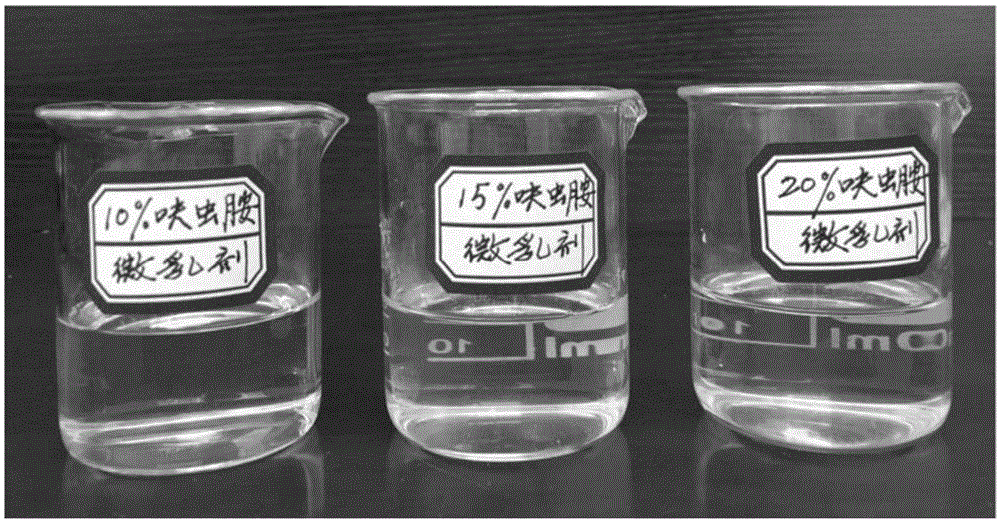

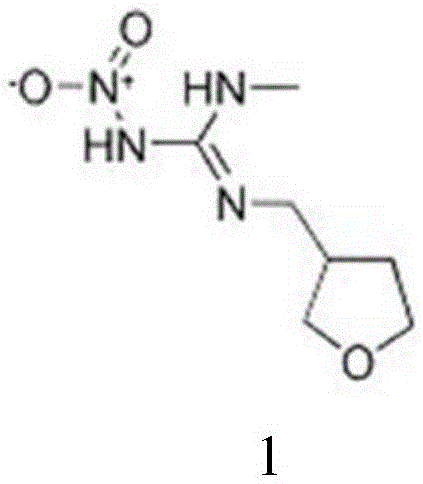

Environment-friendly dinotefuran microemulsion free of organic solvent and preparation method thereof

ActiveCN105638650AStrong production operabilityEnvironmentally friendly and excellent performanceBiocideAnimal repellantsDefoaming AgentsNonionic surfactant

The invention provides environment-friendly dinotefuran microemulsion free of an organic solvent and a preparation method thereof. The environment-friendly dinotefuran microemulsion is prepared from, by weight, 1-10% of dinotefuran, 4-10% of an anionic surfactant, 4-12% of a nonionic surfactant, 0.01-0.04% of a defoaming agent and the balance water. The anionic surfactant is selected from one or more of anionic surfactants with hydrophobic groups coming from vegetable oil hydrolytic or schizolytic linear chain alkyl groups or alkenyl groups and hydrophilic groups coming from carboxyl groups, sulfate groups or sulfonic groups. The nonionic surfactant is selected from one or more of polyoxyethylene ether nonionic surfactants with hydrophobic groups coming from vegetable oil or vegetable oil hydrolytic or schizolytic linear chain alkyl groups or alkenyl groups.

Owner:南京善思生态科技有限公司

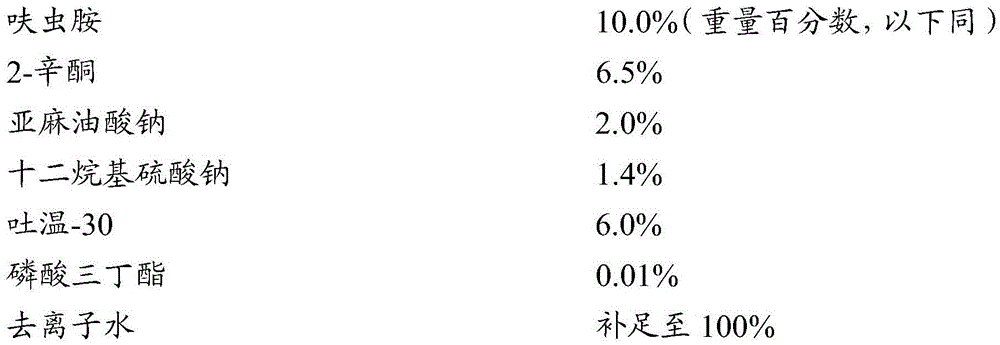

Environment-friendly dinotefuran microemulsion and preparation method thereof

ActiveCN105532656AStrong production operabilityEnvironmentally friendly and excellent performanceBiocideDead animal preservationDefoamerSurface-active agents

The invention provides an environment-friendly dinotefuran microemulsion which is prepared from the following components in percentage by weight: 1 to 20 percent of dinotefuran , 4 to 10 percent of anionic surface active agent, 2 to 12 percent of non-ionic surface active agent, 5 to 12 percent of ketone solvents with a boiling point above 150 DEG C, 0.01 to 0.04 percent of defoaming agent, and the balance of water, wherein the anionic surface active agent is selected from one or more of anionic surface active agents, wherein the hydrophobic group of the anionic surface active agents is vegetable oil hydrolyzed or pyrolysed linear chain alkyl or alkenyl, and the hydrophilic group of the anionic surface active agents is selected from carboxyl, acidophobe or sulfonic acid group; the non-ionic surface active agent is selected from one or more of polyethoxylated non-ionic surface active agents, wherein the hydrophobic group of the non-ionic surface active agent is vegetable oil or vegetable oil hydrolyzed or pyrolysed linear chain alkyl or alkenyl. The invention also provides a preparation method of the environment-friendly dinotefuran microemulsion.

Owner:南京善思生态科技有限公司

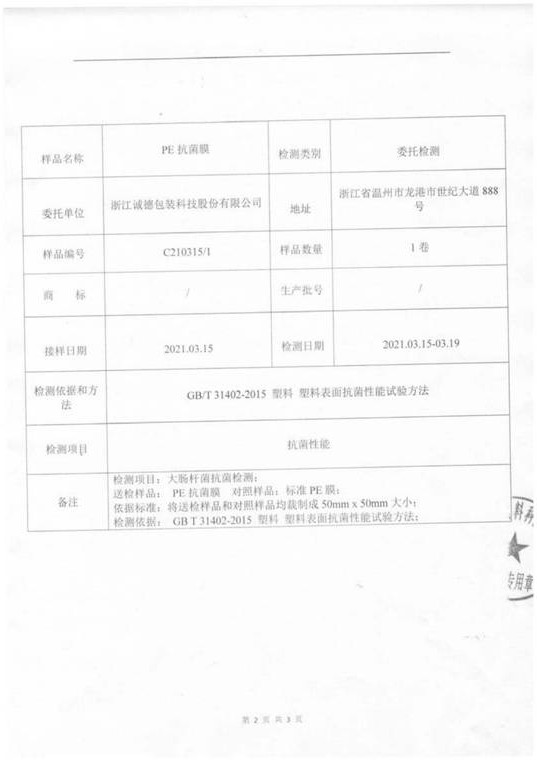

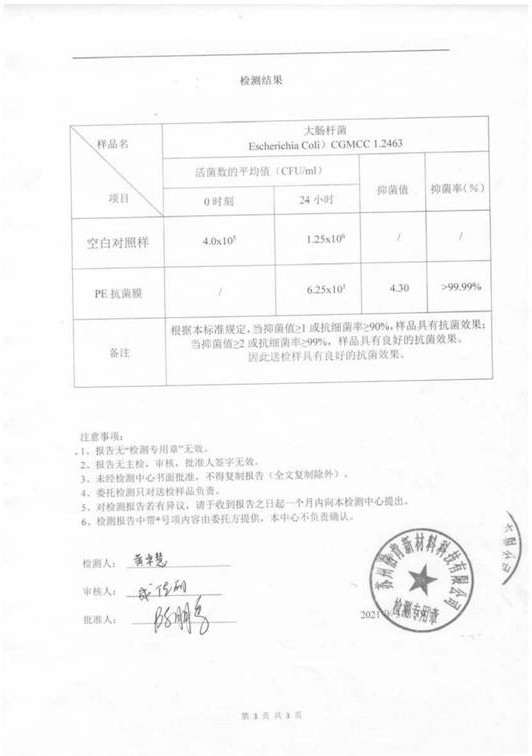

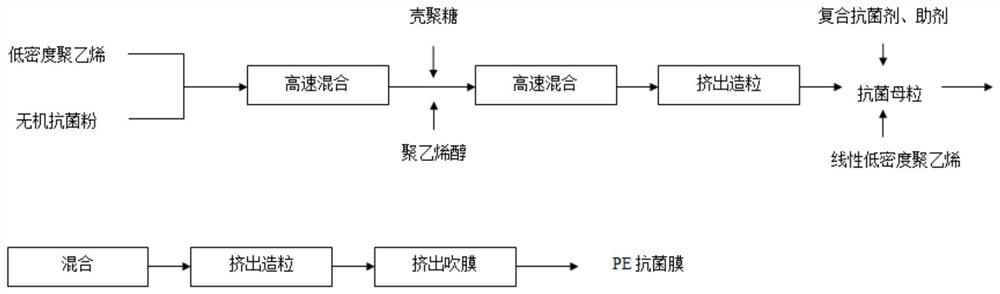

PE antibacterial film and preparation method thereof

InactiveCN113321865ABroad-spectrum potent antibacterial propertiesImprove mechanical propertiesLinear low-density polyethyleneLow-density polyethylene

The invention discloses a PE (polyethylene) antibacterial film and a preparation method thereof. The PE antibacterial film is prepared from the following raw materials in parts by weight: 100-150 parts of linear low-density polyethylene, 25-40 parts of antibacterial master batch, 18-25 parts of a composite antibacterial agent, 15-20 parts of hexanediol butyl ether acetate, 8-16 parts of glycerol, 0.5-1.5 parts of an antioxidant and 0.5-0.8 parts of a preservative. The antibacterial master batch is prepared from the following components in parts by weight: 50-70 parts of low-density polyethylene, 20-35 parts of polyvinyl alcohol, 10-20 parts of chitosan and 3-7 parts of inorganic antibacterial powder. The antibacterial master batch and the composite antibacterial agent are added into the linear low-density polyethylene, and the PE antibacterial film is prepared through the processes of extrusion granulation and extrusion film blowing. The antibacterial rate of the finally prepared PE antibacterial film on escherichia coli is larger than or equal to 99.99%, and meanwhile, the antibacterial rate on staphylococcus aureus and the antibacterial rate on candida albicans are larger than or equal to 99.14%. The PE antibacterial film has broad-spectrum and high-efficiency antibacterial performance, good mechanical performance and high tensile strength.

Owner:ZHEJIANG CHENGDE PACKAGING

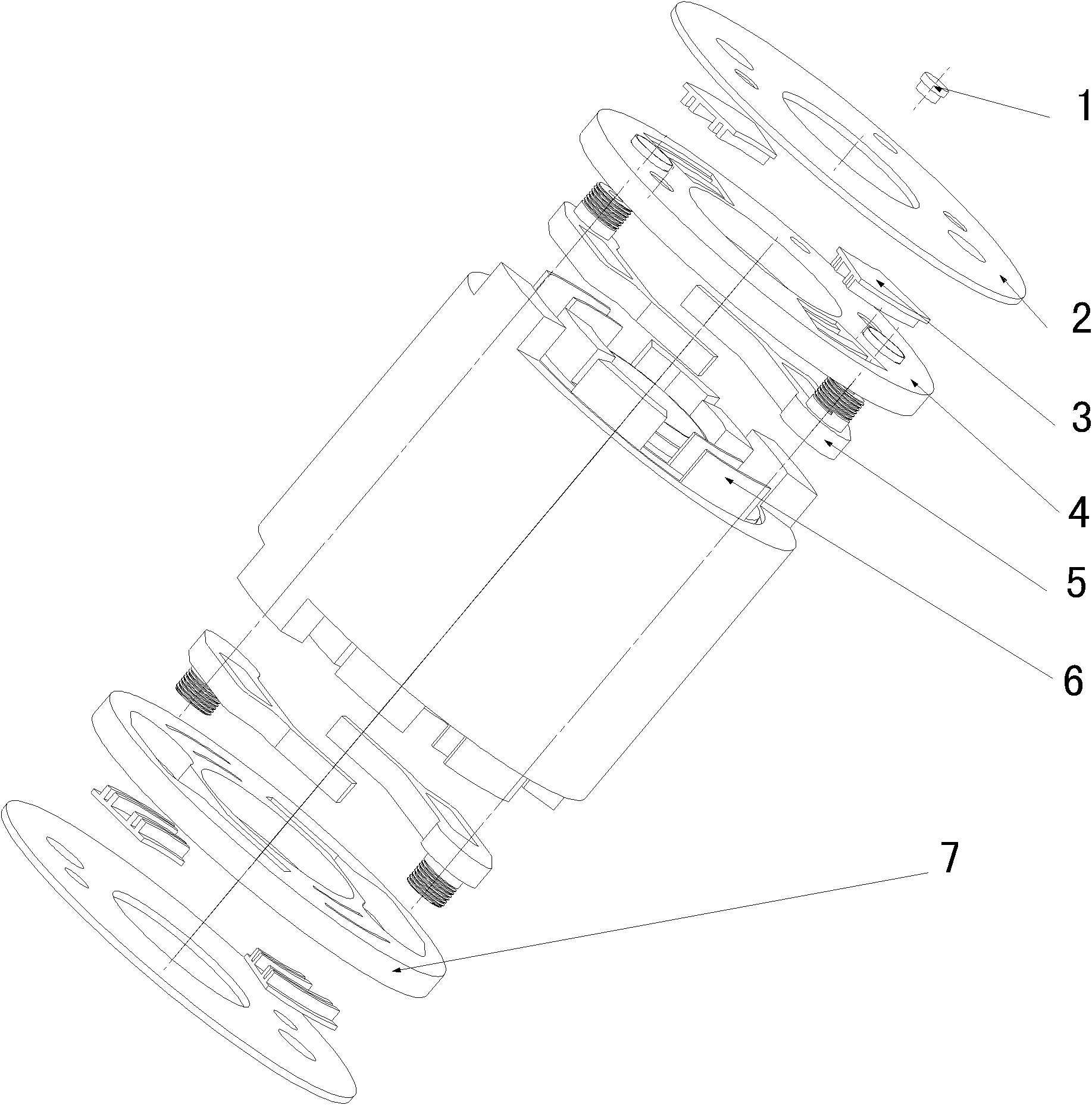

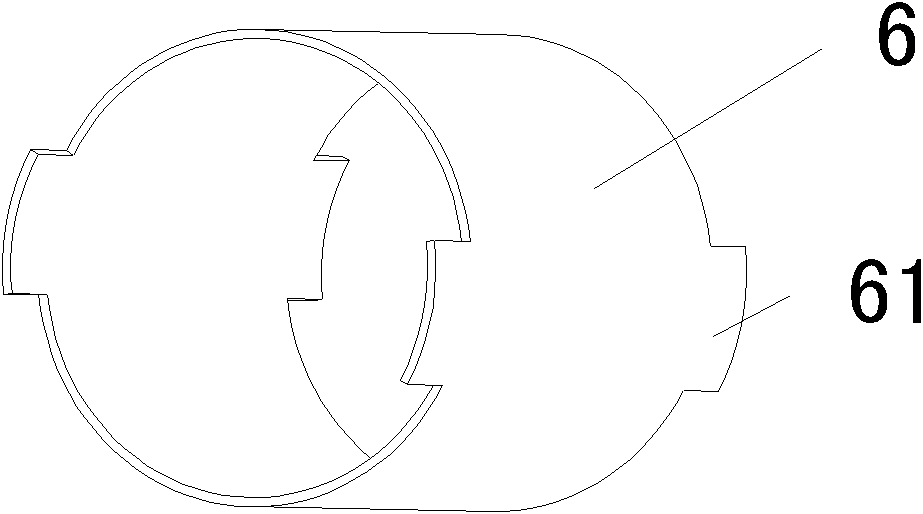

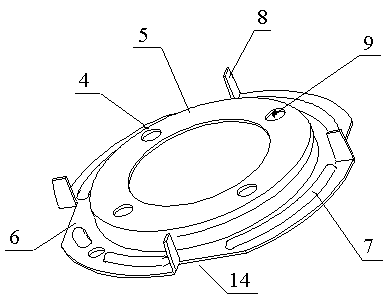

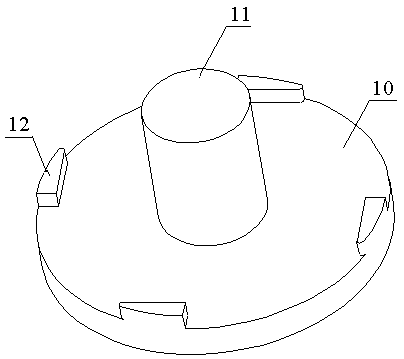

Permanent magnet motor rotor and manufacturing method thereof

ActiveCN103545960ARapid coolingAvoid starting and stopping timesMagnetic circuit rotating partsManufacturing stator/rotor bodiesRadial positionPermanent magnet motor

The invention relates to a permanent magnet motor rotor and a manufacturing method thereof. The permanent magnet motor rotor comprises a rotor core and magnetic steel fixed to the outer circumference of the rotor core. Rotor end covers are fixedly connected with the two ends of the rotor core. The rotor core is formed by first stamped steel and second stamped steel in a laminated mode, and the first stamped steel and the second stamped steel are manufactured in a punched mode. Each rotor end cover comprises an end plate and a magnetic steel positioning part fixedly connected with the end plate, each magnetic steel positioning part is arranged on the outer circumference of the corresponding end plate and fixedly provided with bosses used for identifying the axial position of magnetic steel and positioning ribs used for positioning the radial position of the magnetic steel, and the bosses and the positioning ribs are uniformly distributed on the circumferences of the magnetic steel positioning parts. The permanent magnet motor rotor is adopted for a freezer compressor, so that the rotor speed can be adjusted at will, refrigerating capacity of the compressor can be output, and the purposes of rapid refrigeration and low-speed refreshment of a freezer can be achieved. The permanent magnet motor rotor has the advantages of being high in efficiency, low in noise, suitable for volume production and the like.

Owner:WHIRLPOOL CHINA

Green environment-friendly curdlan slow release fertilizer and preparation method thereof

InactiveCN108440111APromote crop growthImprove qualityAgriculture gas emission reductionOrganic fertilisersFertilizerChemistry

The invention relates to the field of alkaline soil treatment, in particular to a green environment-friendly curdlan slow release fertilizer and a preparation method thereof. The green environment-friendly curdlan slow release fertilizer is prepared from curdlan, nutrient elements such as nitrogen, phosphorus and potassium, seaweed extracts, polyglutamic acid, urease inhibitors and nitrification inhibitors by scientific proportioning. The preparation method includes the steps: sequentially adding the seaweed extracts, the polyglutamic acid, the urease inhibitors (sodium phosphate and hydroxamic acid salt) and the nitrification inhibitors (CP, DCD and DMPP) into water in proportion; adding the curdlan and the nutrient elements such as nitrogen, phosphorus and potassium, continuously and uniformly stirring the materials and increasing temperature to reach 85 DEG C; cooling the materials and then chopping the materials into particles with the diameters of about 0.5cm, and drying the materials at the temperature of 90 DEG C to obtain finished products. The curdlan is introduced into slow release fertilizer production and application, the green environment-friendly curdlan slow releasefertilizer is developed by the aid of colorless and odorless properties and irreversible solid formation of the curdlan after heating and by integrating seaweed, the polyglutamic acid and various stabilizing additives, the process is simple, fertilizer effects are comprehensive and lasting, nutrient loss can be remarkably reduced by the prepared slow release fertilizer, and the use ratio of the slow release fertilizer is increased.

Owner:JINAN HANGCHEN BIOTECHNOLOGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com