PE antibacterial film and preparation method thereof

A technology of antibacterial film and antibacterial powder, which is applied in the field of PE antibacterial film and its preparation, can solve the problems of poor tear resistance, poor film stiffness, light and heat sensitivity, etc., and achieve high tensile strength and broad spectrum strength Effective antibacterial performance, good compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

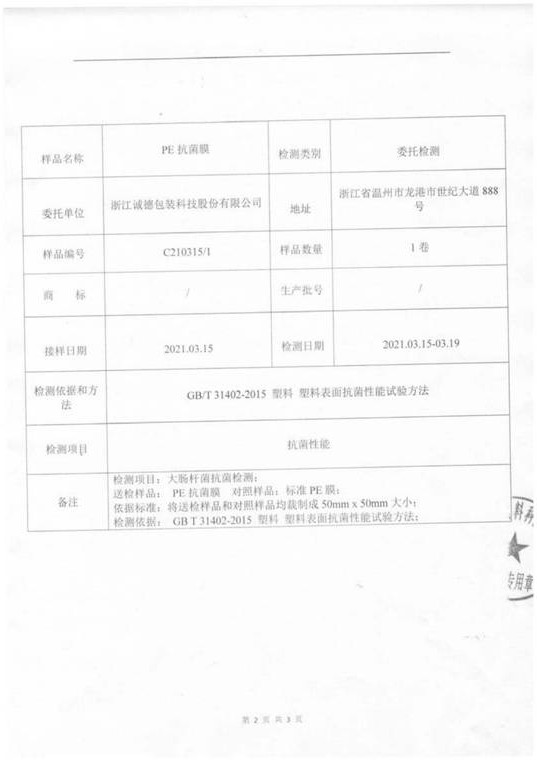

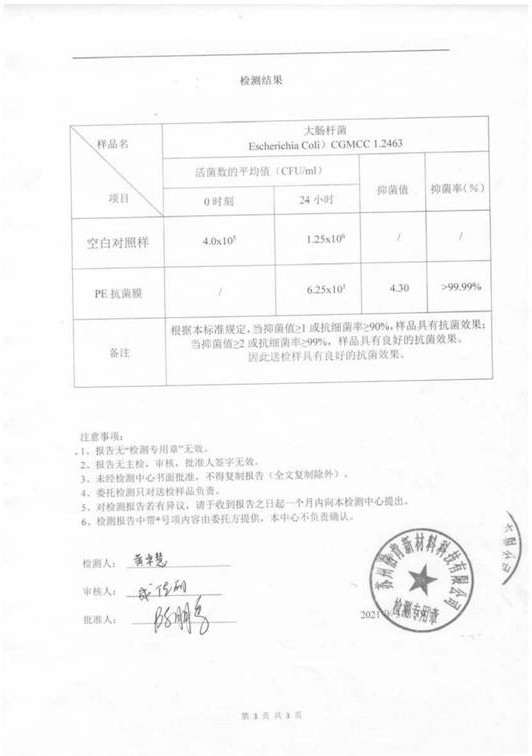

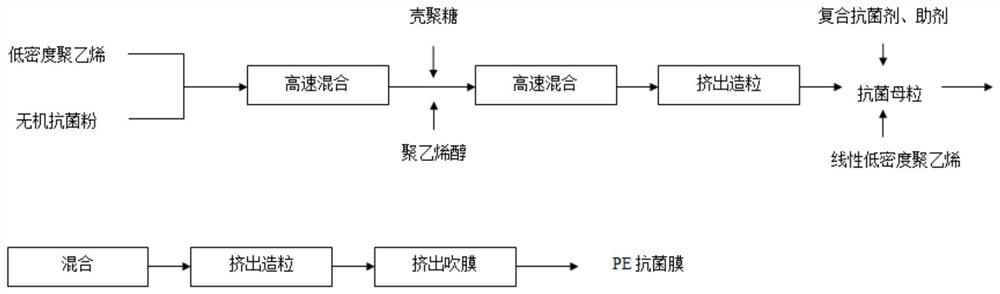

[0037] A kind of PE antibacterial film and preparation method thereof

[0038] PE antibacterial film, said PE antibacterial film includes the following raw materials in parts by weight: linear low density polyethylene 100kg, antibacterial masterbatch 25kg, composite antibacterial agent 18kg, hexylene glycol butyl ether acetate 15kg, glycerin 8kg, antioxidant 0.5kg , 0.5 kg of preservative; the antibacterial masterbatch includes the following components in parts by weight: 50 kg of low-density polyethylene, 20 kg of polyvinyl alcohol, 10 kg of chitosan, and 3 kg of inorganic antibacterial powder.

[0039] The above inorganic antibacterial powder is ZnO / TiO 2 Nanocomposite powder; the ZnO / TiO 2The molar ratio of Zn:Ti in the nanocomposite powder is 1.5:1; the above-mentioned ZnO / TiO 2 Nanocomposite powders were prepared by hydrothermal method.

[0040] The preparation of above-mentioned compound antibacterial agent comprises the following steps:

Embodiment 2

[0050] A kind of PE antibacterial film and preparation method thereof

[0051] PE antibacterial film, said PE antibacterial film includes the following raw materials in parts by weight: linear low density polyethylene 115kg, antibacterial masterbatch 28kg, composite antibacterial agent 20kg, hexylene glycol butyl ether acetate 16kg, glycerin 10kg, antioxidant 0.7kg , preservative 0.6kg; the antibacterial masterbatch includes the following components in parts by weight: 55kg of low-density polyethylene, 25kg of polyvinyl alcohol, 12kg of chitosan, and 4kg of inorganic antibacterial powder.

[0052] The above inorganic antibacterial powder is ZnO / TiO 2 Nanocomposite powder; the ZnO / TiO 2 The molar ratio of Zn:Ti in the nanocomposite powder is 1.5:1; the above-mentioned ZnO / TiO 2 Nanocomposite powders were prepared by hydrothermal method.

[0053] The preparation of above-mentioned compound antibacterial agent comprises the following steps:

Embodiment 3

[0063] A kind of PE antibacterial film and preparation method thereof

[0064] PE antibacterial film, said PE antibacterial film includes the following raw materials in parts by weight: linear low density polyethylene 120kg, antibacterial masterbatch 30kg, composite antibacterial agent 22kg, butyl glycol ether acetate 17kg, glycerin 13kg, antioxidant 1.2kg , preservative 0.6kg; the antibacterial masterbatch includes the following components in parts by weight: 65kg of low-density polyethylene, 25kg of polyvinyl alcohol, 13kg of chitosan, and 4kg of inorganic antibacterial powder.

[0065] The above inorganic antibacterial powder is ZnO / TiO 2 Nanocomposite powder; the ZnO / TiO 2 The molar ratio of Zn:Ti in the nanocomposite powder is 1.5:1; the above-mentioned ZnO / TiO 2 Nanocomposite powders were prepared by hydrothermal method.

[0066] The preparation of above-mentioned compound antibacterial agent comprises the following steps:

[0067] S1, mix zinc nitrate solution, silv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com