Process holes for back-end procedures in flat-shape covering part stamping production and locating method

A technology of process holes and cover parts, which is applied in the field of process holes and positioning in the post-process stamping production of cover parts, which can solve the problem that the consistency and repeatability of stamping parts cannot be guaranteed, the quality requirements of mass production cannot be met, and the exact position of parts cannot be guaranteed and other issues, to achieve the effect of appearance quality assurance, product consistency, and product consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

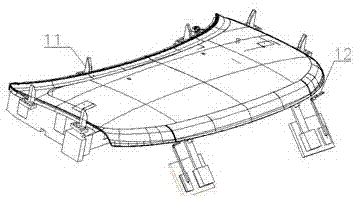

[0033] The technical scheme of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0034] Basic technical solutions of the present invention It should be understood that the following examples can only be used to explain and illustrate the technical solutions of the present invention, rather than be construed as limitations on the technical solutions of the present invention. Not only the outer panel of the hood of the automobile, but also the same applies to other flat-shaped covering parts.

[0035] Most of the car engine cover outer panels are divided into four stamping processes. The first process is drawing. On the first stamping equipment 1000 to 2000T press of the A line, the thin steel plate is used as the blank, and the car engine cover outer panel is used for drawing. Die, when the press works to the end, the drawn parts are formed, such as figure 2 shown.

[0036] Such as Figure 4 As shown, in the second orde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com