Method for evaluating self-discharge consistency of lithium iron phosphate battery

A lithium iron phosphate battery and evaluation method technology, applied in the direction of measuring electricity, measuring electrical variables, measuring devices, etc., can solve the problems of poor voltage consistency, different rebound degree and speed, etc., achieve good voltage consistency, improve self- Efficiency of discharge rate and ease of data analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: The present invention provides a method for evaluating the self-discharge consistency of a lithium iron phosphate battery by using the voltage difference at a lower state of charge. The technical solution is: a method for evaluating the self-discharge consistency of a lithium iron phosphate battery, comprising the following steps:

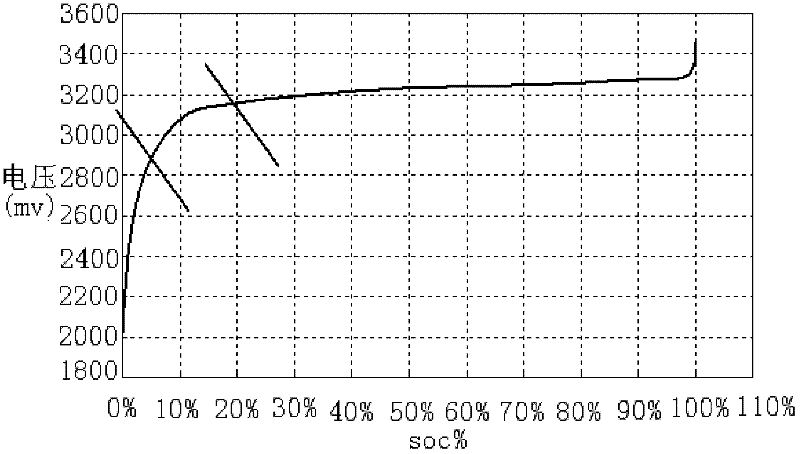

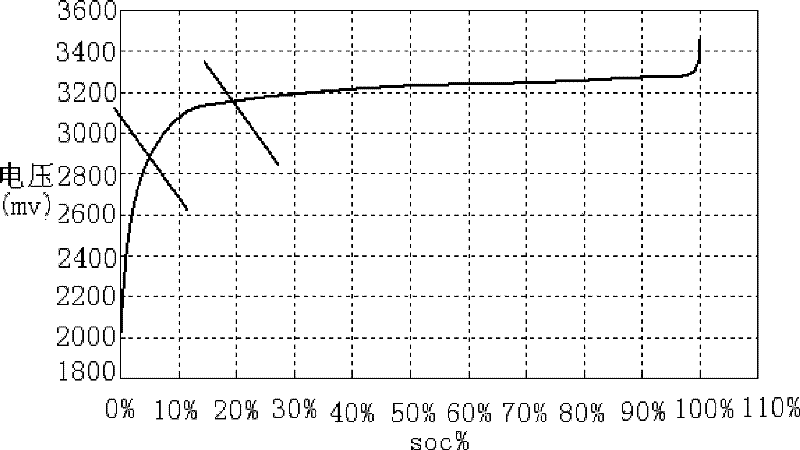

[0023] (1) After discharging multiple batteries, perform constant current charging to the specified voltage; the specified voltage is 2.8V-3.2V, preferably 2.9-3.1V, and the state of charge of the battery corresponding to this voltage is relatively low, about 3% -20% as in figure 1 , and then carry out constant voltage charging at the specified voltage until the cut-off current is 0.01C-0.03C;

[0024] (2) Measure the open circuit voltage OCV1 after the battery is charged;

[0025] The measurement time of OCV1 in this step is 2-24 hours, preferably 8-16 hours after the battery is charged.

[0026] (3) Put the battery in a hi...

Embodiment 2

[0033] Charge 1000 lithium iron phosphate batteries with a rated capacity of 10Ah at a constant current and constant voltage at a current of 3500mA after discharge. The cut-off current is 200mA; measure 0CV1 8 hours after the battery is charged; then place the battery in a high-temperature environment of 35°C for 10 days; measure the open-circuit voltage OCV2 of the battery after being placed in a high-temperature environment; calculate the voltage drop of the battery ΔV=OCV1- OCV2 or the voltage drop K=(OCV1-OCV2) / t per unit time; calculate the average value X and standard deviation s of ΔV or K values of 1000 batteries, and delete all those exceeding the control limit of [X-3s, X+3s] point, re-analyze until all points are within the control limit range; according to the control upper limit finally determined by the above steps, set the upper limit of the specification of the ΔV or K value, and judge that the self-discharge of the battery with the value of ΔV or K within the...

Embodiment 2-3

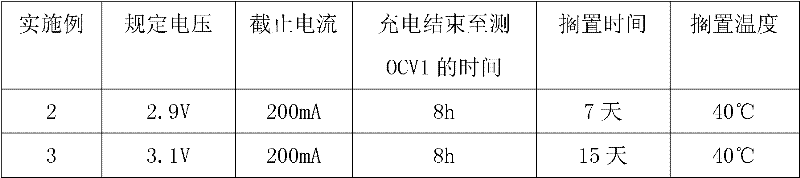

[0035] Embodiment 2-3 adopts the same processing steps as Embodiment 1, and its specific processing parameters are shown in Table 1.

[0036] Table 1

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com