Safe electric heating health care thin mattress made of far infrared material

A technology of far-infrared materials and electric heating pads, which is applied in the direction of beds, other seating furniture, household appliances, etc., can solve the problems that the surface of the electric heating pad 3 is not smooth enough, the step-up temperature of the pillow is easy to catch fire, and electric shock accidents are easy to occur. Fewer points and thick metal wires, better comfort, and higher production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

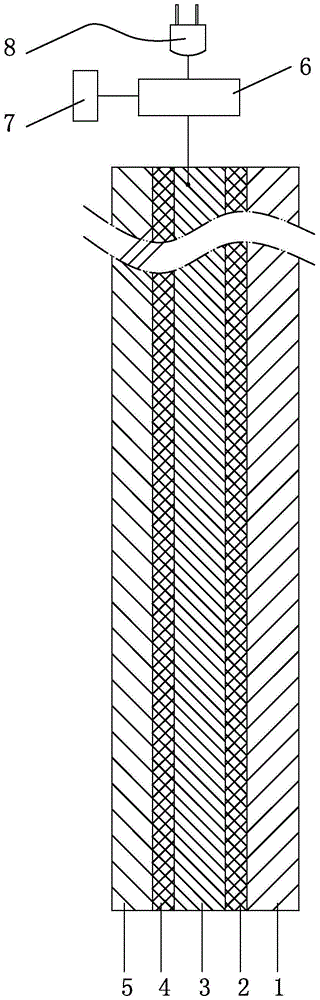

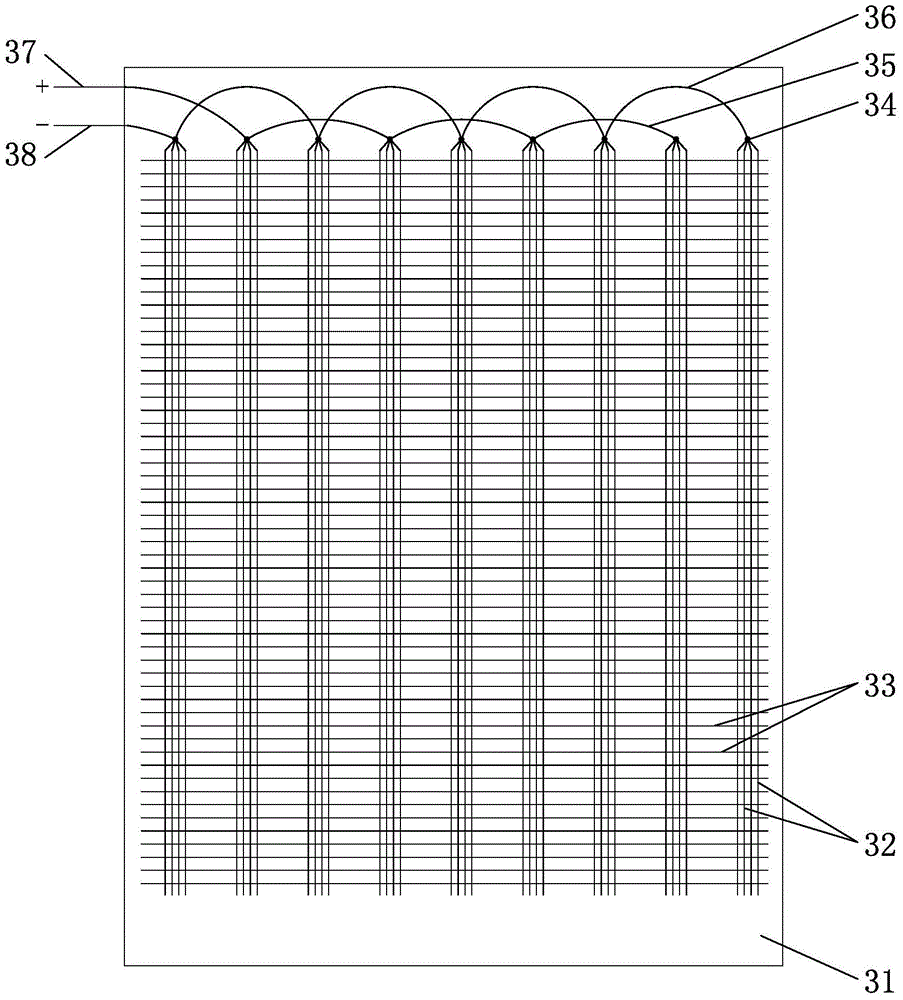

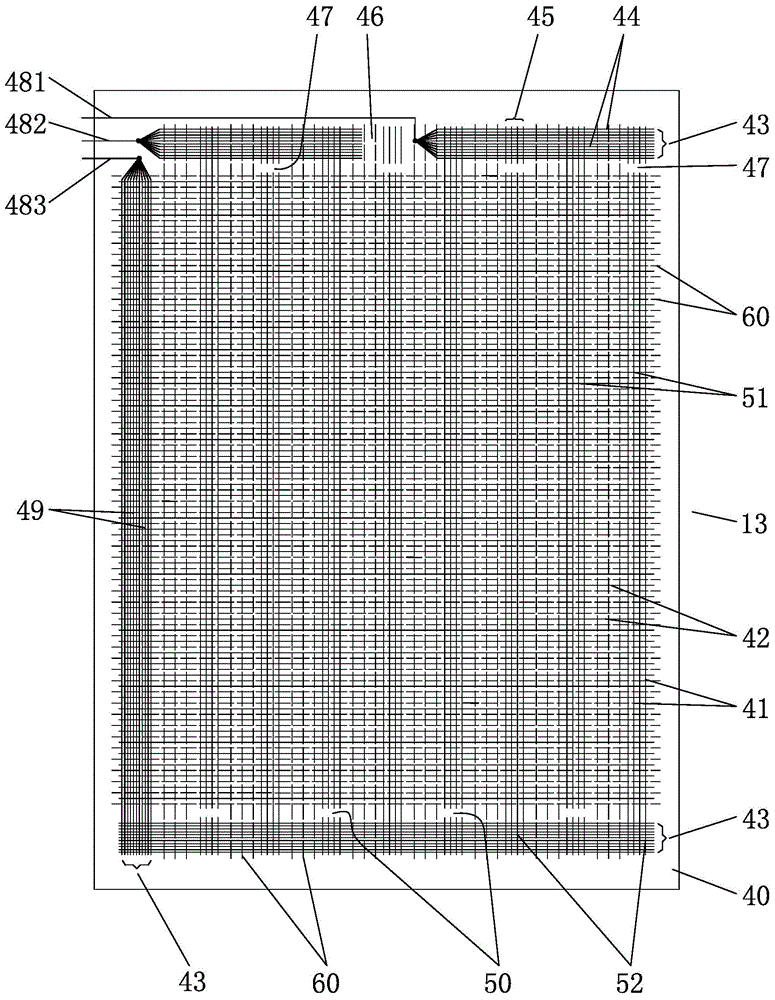

[0046] Example 1, see image 3 :

[0047] The safe electric heating health-care thin mattress made of far-infrared material uses glass fiber silk or chemical fiber or cotton thread 60 as warp and weft threads to weave the orthogonally woven fabric. The weft thread interval is woven with carbon crystal silk 42. More than one glass fiber filament or chemical fiber or the weft thread of cotton thread 60 replaces the weft thread of glass fiber filament or chemical fiber or cotton thread 60 with a carbon crystal silk 42, and the warp thread is woven with thin metal wire electrode groups 45 at intervals, and the warp thread interval weaving is The warps of more than one glass fiber filaments or chemical fibers or cotton threads 60 are replaced with a carbon crystal filament 42, the warps of the upper and lower ends of the orthogonally woven cloth and the weft threads of at least one side The fine metal wire conductive group 43 is woven, the fine metal wire conductive group 43 at th...

Embodiment 2

[0051] Example 2, see image 3 — Figure 5 :

[0052] Using the electric heating pad 13 made in Example 1, the upper surface or the lower surface of the electric heating pad 13 is provided with a fur cushion layer 10, and the lower surface or the upper surface is provided with a cortical layer 14 or a mat layer, so that a kind of fur integrated The electric heating mattress; the upper or lower surface of the electric heating pad 13 is provided with more than one temperature sensor 15 or temperature protector, so that after one temperature sensor 15 fails, it can be switched to another by the controller. , to ensure accurate and reliable temperature control, and the temperature protector can automatically power off and shut down when the temperature reaches the set temperature. A cast adhesive layer or a film adhesive layer or a glue composite adhesive layer 11 is arranged between the layers, and the three wires and the temperature sensor of the electric heating pad 13 are el...

Embodiment 3

[0053] Example 3, see image 3 , Image 6 , Figure 7 :

[0054] The structure of this embodiment is basically similar to that of Embodiment 3, and the difference is that more than one auxiliary layer is arranged between the above-mentioned wool cushion layer 10 and the electric heating pad, between the electric heating pad and the cortical layer 14 or the mat layer, Between the wool cushion layer 10 and the auxiliary layer, between the auxiliary layer and the electric heating pad, between the cortex layer 14 or the mat layer and the auxiliary layer are all bonded by a cast adhesive layer or a film adhesive layer or a glue composite adhesive layer connection; the auxiliary layer is more than one elastic layer or / and more than one support layer; the elastic layer is made of 3D material, and the support layer is flame-retardant cotton or chemical fiber material Made; the cast adhesive layer or film adhesive layer uses TPU or EVA or PE or glue material; the material of the cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com