Low-leakage high-reliability low-voltage transient suppression diode chip and production method

A technology of transient suppression and production method, applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve problems such as unstable breakdown voltage, poor product reliability, large reverse breakdown leakage, etc., to avoid local current Excessive, prolong life, reduce the effect of reverse leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

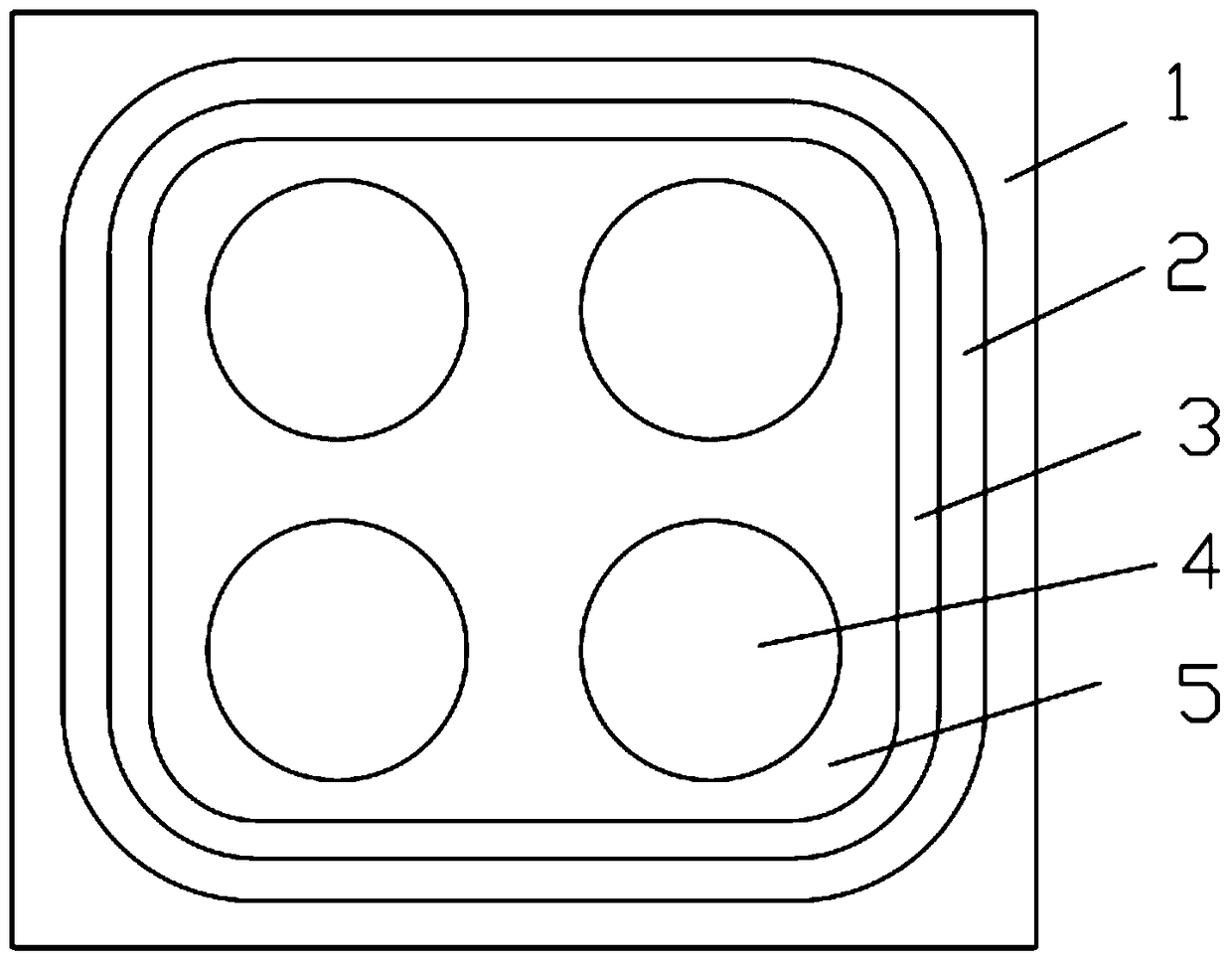

[0063] In this embodiment, the unidirectional low-leakage high-reliability low-voltage transient suppression diode chip production method provided by the present invention, such as figure 1 As shown, the front structure of the unidirectional / bidirectional low-leakage high-reliability low-voltage transient suppression diode chip is as follows: chip 1; corrosion mesa 2; glass edge 3; P + diffusion junction 4; metal layer 5.

[0064] Such as Figure 4 As shown, the cross-sectional structure of the unidirectional low-leakage high-reliability low-voltage transient suppression diode chip is as follows: chip 1; glass edge 2; P+ diffusion junction 4; metal layer 5; N+ diffusion junction 6; P ++ Diffusion junction7.

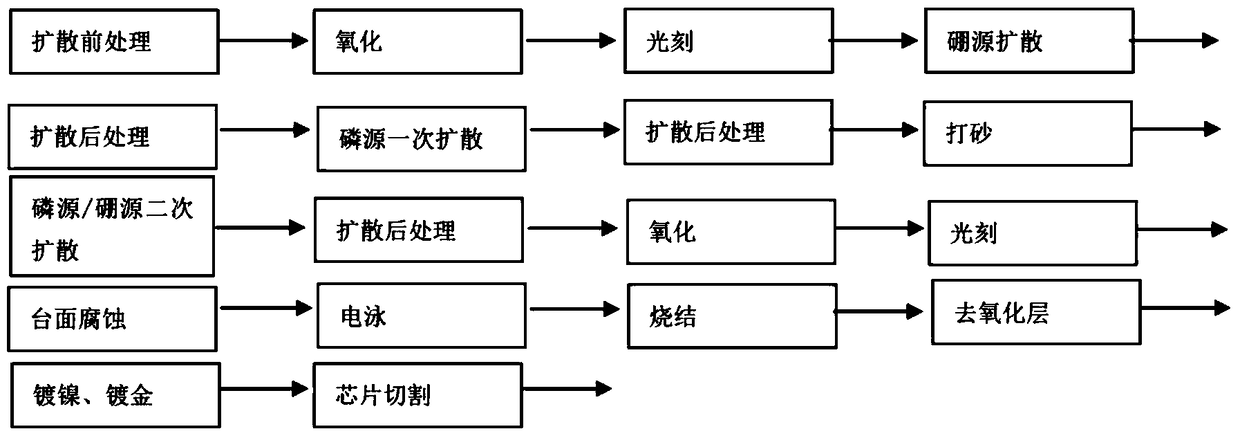

[0065] Such as figure 2 As shown, the production method of the unidirectional low-leakage high-reliability low-voltage transient suppression diode chip provided by the present invention, the flow process is as follows:

[0066] Step 1: Pre-diffusion treatment: chemic...

Embodiment 2

[0087] Such as Figure 5 As shown, in this embodiment, the bidirectional low-leakage high-reliability low-voltage transient suppression diode chip cross-sectional structure provided by the present invention is as follows: chip 1; glass edge 3; P + Diffusion junction 4; metal layer 5; N + Diffusion junction6.

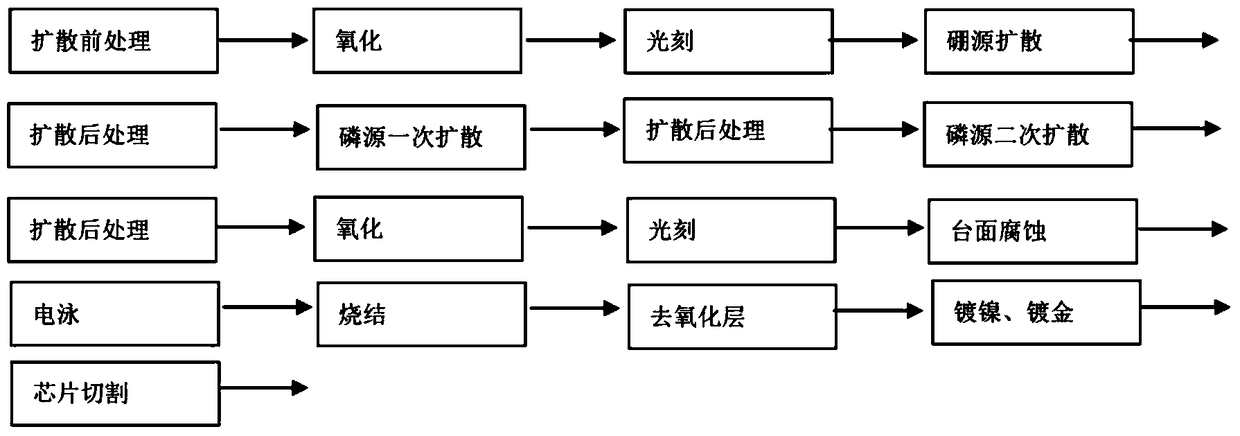

[0088] The bidirectional low-leakage high-reliability low-voltage transient suppression diode chip production method provided by the present invention comprises the following steps:

[0089] Step 1: Diffusion pre-treatment, through acid, alkali, deionized water ultrasonic cleaning and other processes, chemically treat the surface of the silicon wafer to make the surface of the silicon wafer unstained;

[0090] Step 2: For the first oxidation, put the silicon wafer that has been pre-diffused in an oxidation furnace at 1100-1200°C to grow a first oxide layer; the thickness of the first oxide layer is

[0091] Step 3: For the first photolithography, the oxidized silico...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com