Fine-grain ferrite + pearlite type N80-1 non-quenched and tempered seamless oil bushing, and production method thereof

A production method and technology of ferrite, applied in casing, drill pipe, earthwork drilling, etc., can solve the problems of coarsening, reducing product toughness, failing to improve the structure and refining grains, etc., to improve the structure, The effect of reducing strength and saving heat treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

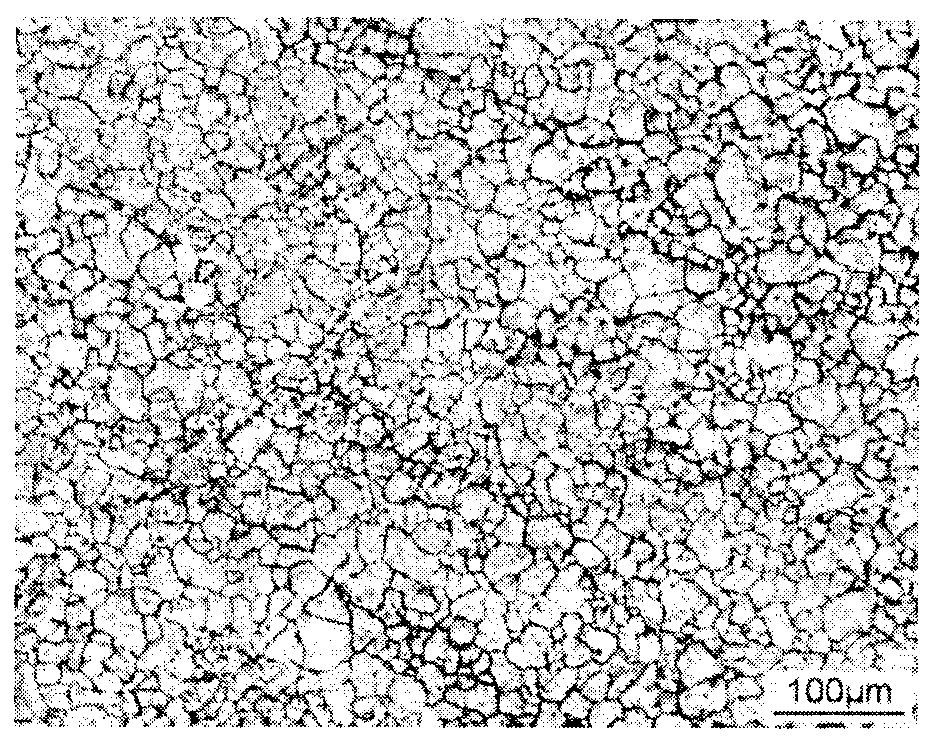

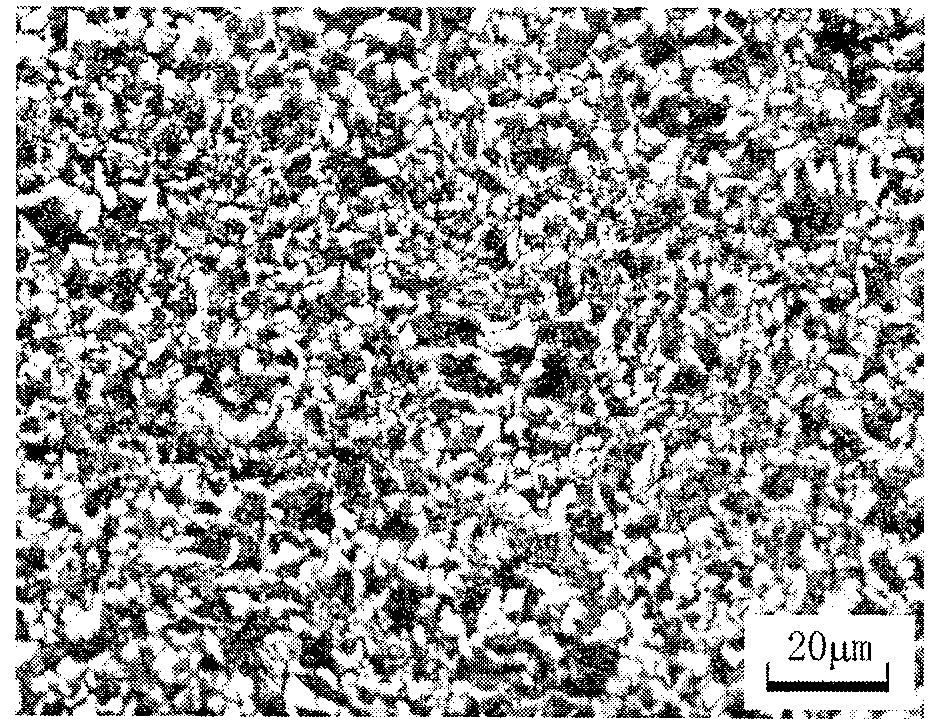

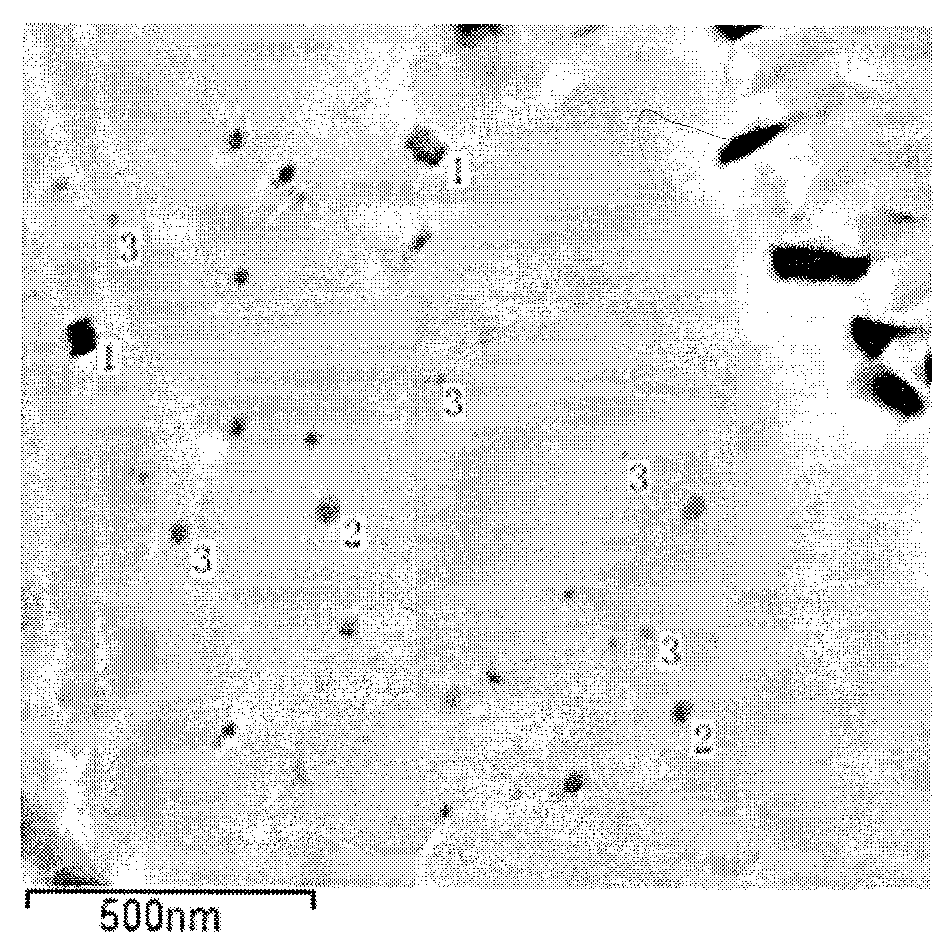

[0018] Embodiment 1. The fine-grained ferrite + pearlite type N80-1 non-quenched and tempered seamless oil casing produced in this embodiment has an outer diameter of 139.7mm and a wall thickness of 9.17mm, and the production unit is ∮340 unit.

[0019] The composition of the oil casing is measured by mass%, and the specific composition is: C: 0.38, Si: 0.23, Mn: 1.63, P: 0.011, S: 0.009, Cu: 0.05, Ni: 0.036, Cr: 0.11, Mo: 0.018, V: 0.121, Nb: 0.001, Ti: 0.014, N: 0.013, and the rest are Fe and unavoidable impurities, where ∑As+Sn+Pb+Sb+Bi: 0.041.

[0020] Its specific production method is as follows:

[0021] Billet heating (bill diameter ∮220mm, length 3.2M) → perforation (capillary outer diameter ∮246mm, wall thickness 19.1mm, length 8.8M) → tube rolling (barren tube outer diameter ∮201mm, wall thickness 8.1mm, length 24.5M) →Phase change recrystallization (blank tube temperature: 440~485℃)→reheating (furnace temperature 925~945℃)→sizing or reducing (outer diameter of stee...

Embodiment 2

[0024] Embodiment 2. The N80-1 non-quenched and tempered seamless oil casing produced in this embodiment has an outer diameter of 244.48mm, a wall thickness of 11.99mm, and a production unit of ∮340.

[0025] The composition of the oil casing is measured by mass%, and the specific composition is: C: 0.39, Si: 0.25, Mn: 1.61, P: 0.013, S: 0.007, Cu: 0.07, Ni: 0.026, Cr: 0.16, Mo: 0.02, V: 0.115, Nb: 0.001, Ti: 0.011, N: 0.012, and the rest are Fe and unavoidable impurities, among which ΣAs+Sn+Pb+Sb+Bi: 0.043.

[0026] Its specific production method is as follows:

[0027] Billet heating (billet diameter ∮280mm, length 4.53M) → perforation (capillary outer diameter ∮336mm, wall thickness 21.3mm, length 13M) → tube rolling (barren tube outer diameter ∮281mm, wall thickness 11.3mm, length 28.6M)→ Phase change recrystallization (blank tube temperature: 450-495°C) → reheating (furnace temperature 915-935°C) → sizing or reducing (steel pipe outer diameter ∮ 244.48mm, wall thickness ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com