Diaphragm used for zinc ion battery and preparation method thereof

A zinc-ion battery and separator technology, applied in secondary batteries, battery pack parts, circuits, etc., can solve the problem that the safety of the separator is not high, and cannot significantly improve the physical index and electrochemical performance, puncture resistance, Problems such as poor liquid retention, to achieve the effect of improving electrochemical performance, improving liquid retention and puncture resistance, and improving liquid retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

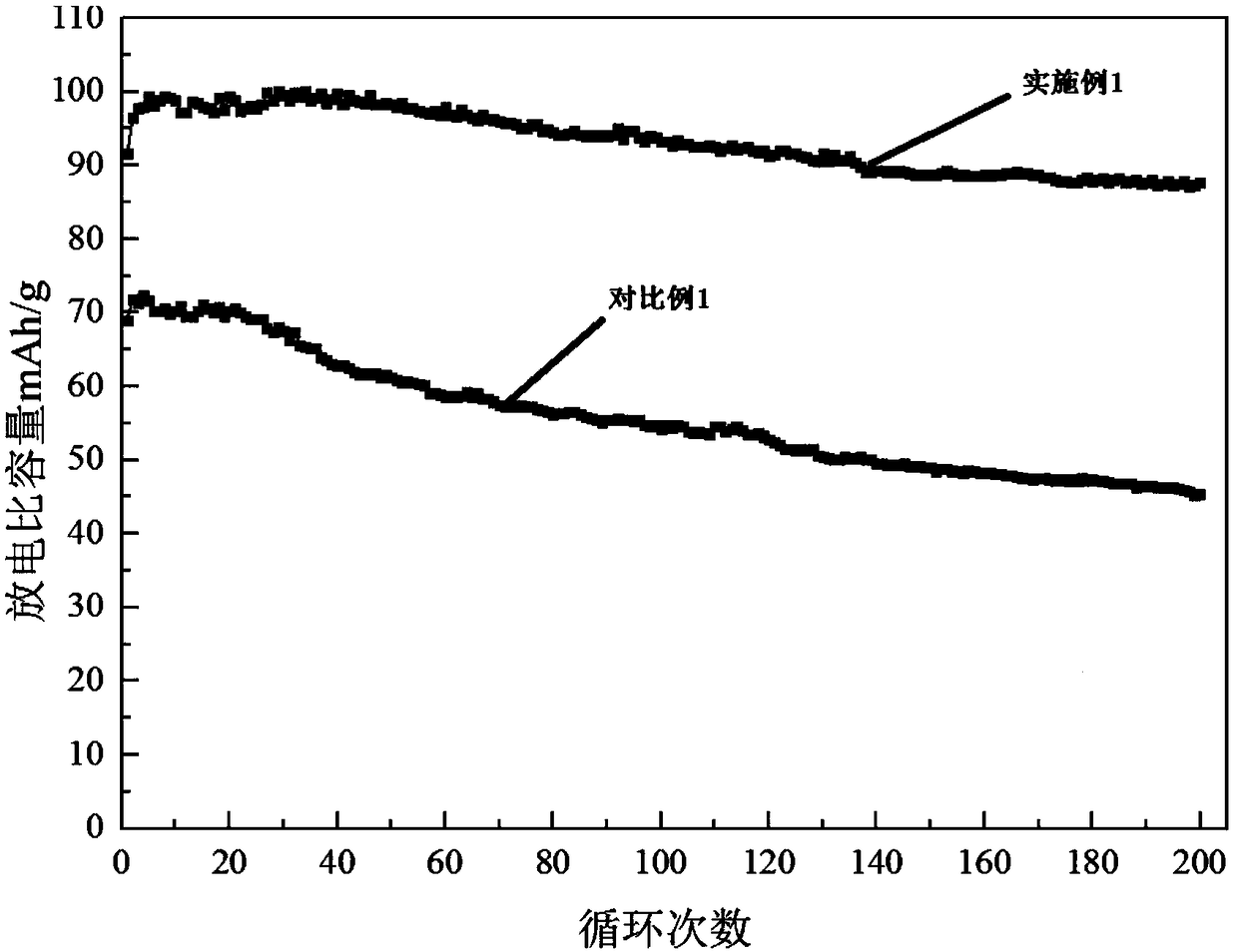

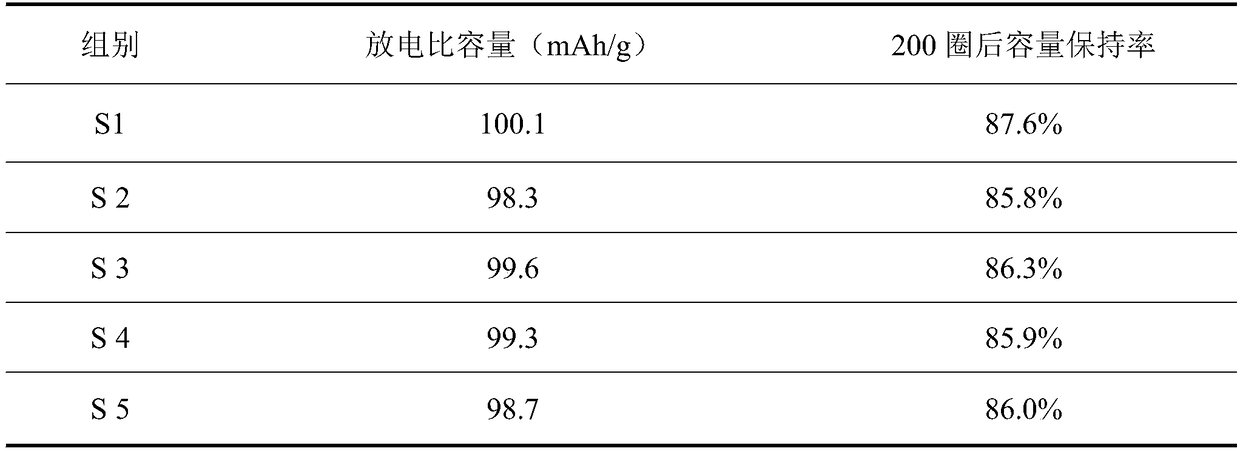

Embodiment 1

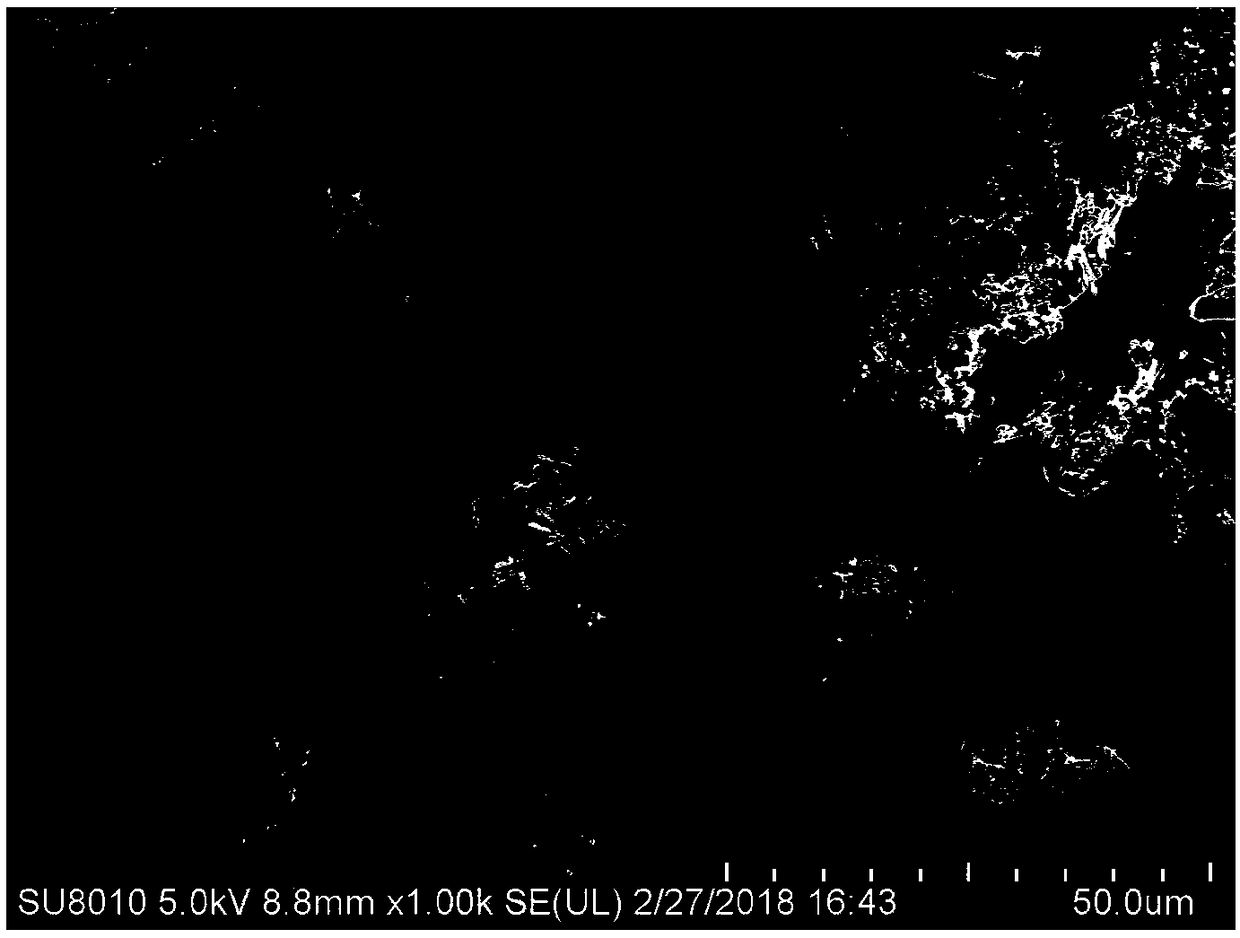

[0032] This embodiment provides a diaphragm for a zinc ion battery, comprising a diaphragm base and coating layers arranged on the two surfaces of the diaphragm base, the diaphragm base is an adsorption glass fiber mat type diaphragm (AGM diaphragm), and the coating layer is an oxide aluminum layer.

[0033] The single-sided coating thickness of the alumina slurry on the surface of the AGM diaphragm is controlled at 4 μm, the thickness of the AGM diaphragm is 0.5 mm, and the weight of the AGM diaphragm is increased by 20.5% after the alumina slurry is coated. The particle diameter of alumina is 300-400 nm.

[0034] The preparation method of the separator for the zinc ion battery at least comprises the following steps:

[0035] The first step: the preparation of oxide slurry, add 5% alumina, 3% binder, 0.8% surfactant, 0.6% thickener, 0.3% dispersant, 2% defoamer and 88.1% solvent In the high-speed dispersing equipment tank, start the mixer while adding and stir to obtain uni...

Embodiment 2

[0042] This embodiment provides a diaphragm for a zinc ion battery, comprising a diaphragm base and coating layers arranged on the two surfaces of the diaphragm base, the diaphragm base is an adsorption glass fiber mat type diaphragm (AGM diaphragm), and the coating layer is an oxide aluminum layer.

[0043] The single-sided coating thickness of the alumina slurry on the surface of the AGM diaphragm is controlled at 3 μm, the thickness of the AGM diaphragm is 0.6 mm, and the weight of the AGM diaphragm is increased by 22.5% after the alumina slurry is coated. The particle diameter of alumina is 500-700 nm.

[0044] The preparation method of the separator for the zinc ion battery at least comprises the following steps:

[0045] The first step: the preparation of oxide slurry, add 10% alumina, 5% binder, 1.0% surfactant, 0.8% thickener, 0.6% dispersant, 3% defoamer and 79.6% solvent In the high-speed dispersing equipment tank, start the mixer while adding and stir to obtain a ...

Embodiment 3

[0049] This embodiment provides a diaphragm for a zinc ion battery, comprising a diaphragm base and coating layers arranged on the two surfaces of the diaphragm base, the diaphragm base is an adsorption glass fiber mat type diaphragm (AGM diaphragm), and the coating layer is an oxide zirconium layer.

[0050] The single-side coating thickness of the zirconia slurry on the surface of the AGM diaphragm is controlled at 2 μm, and the thickness of the AGM diaphragm is 0.4 mm. After the zirconia slurry is coated on the AGM diaphragm, the weight increases by 18.3%. The particle diameter of zirconia is 200-400 nm.

[0051] The preparation method of the separator for the zinc ion battery at least comprises the following steps:

[0052] The first step: the preparation of oxide slurry, add 19% zirconia, 3% binder, 0.7% surfactant, 0.7% thickener, 0.3% dispersant, 1.5% defoamer and 74.8% solvent In the high-speed dispersing equipment tank, start the mixer to stir while adding, and obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com