High-strength austenitic stainless steel and preparation method thereof

An austenitic stainless steel, high-strength technology, applied in the field of iron and steel metallurgy, can solve problems such as general strengthening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

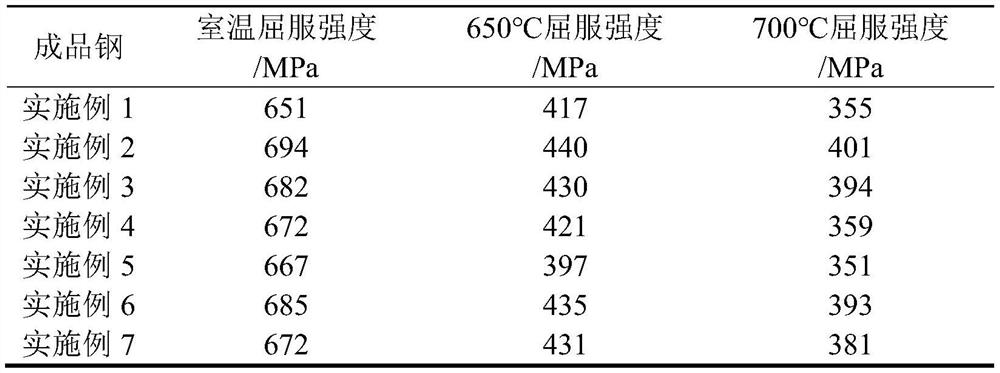

Examples

preparation example Construction

[0044] The preparation method of the high-strength austenitic stainless steel of the present invention comprises the following steps:

[0045] (1) Preparation of nanoparticles: the size of the nanometer Y of 10-15nm 2 o 3 and nano-Al powder with a size of 10-30nm are placed in a ball mill for high-speed ball-milling alloying; wherein nano-Y 2 o 3 The mass ratio to nano-Al powder is 3:1-1.5, the ball-to-material ratio is 10:1-1.5, the high-speed ball milling speed is 550-600 rpm, the ball milling time is 5-7 hours, and the ball milling atmosphere is atmospheric atmosphere.

[0046] (2) Nanoparticle ball mill mixing: the nanoparticles and austenitic steel powder prepared in step (1) are placed in a ball mill for high-speed ball mill mixing; wherein the size of the austenitic stainless steel is 40 to 50 μm, and the nanoparticles and The mass ratio of austenitic steel is 0.1-0.2:100, high-speed ball milling, the ball-to-material ratio is 10:1-1.5, the speed is 500-550 rpm, the ...

Embodiment 1

[0052] The high-strength austenitic stainless steel in this embodiment includes an austenitic stainless steel matrix and micron nitrides, submicron oxides and nano-oxides dispersed in the austenitic stainless steel matrix; wherein, the micron nitrides are TiN, and the submicron Oxide is Al 2 o 3 , the nano oxide is Y-Al-O. In high-strength austenitic stainless steel, the mass content of micron particles is 0.005%, the particle size is 0.5-1.0 μm, and the number is 1.2×10 14 piece / m 3 ; The mass content of submicron particles is 0.002%, the particle size is 0.1-0.5 μm, and the number is 9.1×10 17 piece / m 3 ; The mass content of nanoparticles is 0.1%, the particle size is 5-10nm, and the number is 1.3×10 2 piece / m 3 . Austenitic stainless steel matrix is 304 austenitic stainless steel matrix

[0053] The preparation method of the high-strength austenitic stainless steel of the present embodiment comprises the following steps:

[0054] (1) Preparation of nanoparticles:...

Embodiment 2

[0062] The high-strength austenitic stainless steel in this embodiment includes an austenitic stainless steel matrix and micron nitrides, submicron oxides and nano-oxides dispersed in the austenitic stainless steel matrix; wherein, the micron nitrides are TiN, and the submicron Oxide is Al 2 o 3 , the nano oxide is Y-Al-O. In high-strength austenitic stainless steel, the mass content of micron particles is 0.01%, the particle size is 0.5-1.0 μm, and the number is 8.6×10 14 piece / m 3 ; The mass content of submicron particles is 0.001%, the particle size is 0.1-0.5 μm, and the number is 1.3×10 17 piece / m 3 ; The mass content of nanoparticles is 0.2%, the particle size is 5-10nm, and the number is 9.1×10 25 piece / m 3 . Austenitic stainless steel matrix is 304 austenitic stainless steel matrix

[0063] The preparation method of the high-strength austenitic stainless steel of the present embodiment comprises the following steps:

[0064] (1) Preparation of nanoparticles:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com