Vacuum hot rolling method of multi-layer ti6al4v-tibw/ti6al4v composite

A technology of ti6al4v-tibw and composite materials, which is applied in the field of hot rolling for the production of multilayer titanium-based composite materials, can solve the problems of restricting the development of titanium-based composite materials, uneven layer thickness and size, and poor interlayer interface bonding, etc., to achieve The effect of layered direction enhancement is obvious, the mechanical anisotropy is enhanced, and the strengthening effect is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

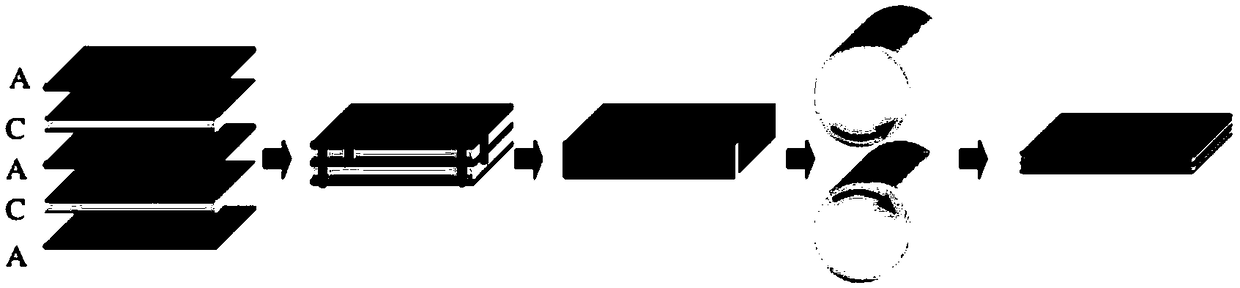

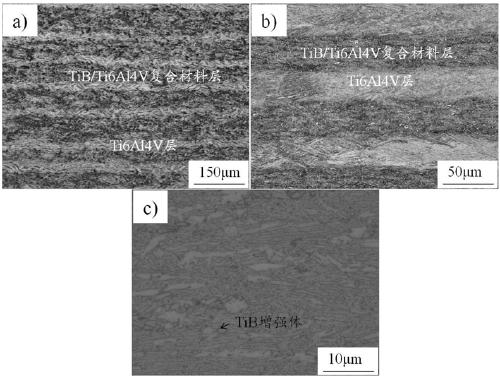

[0027] 1: Take the Ti6Al4V and TiBw / Ti6Al4V composite material foil with a side length of 100 mm and a thickness of 500 μm, and soak it in a hydrofluoric acid solution with a volume fraction of 5% to 10% for about 2 minutes to corrode the surface. The surface of the composite foil is cleaned and dried with a hair dryer;

[0028] 2: Take stainless steel with a side length of 120mm and a thickness of 40mm, mill out a square groove with a side length of 101mm and a depth of 32mm on a milling machine, and open a small hole with a diameter of 3-6mm on one side to lead into the groove. 30 layers of Ti6Al4V and TiBw / Ti6Al4V foils are stacked in the groove in ACAC order;

[0029] 3: Take a stainless steel block with a side length of 101mm and a thickness of 6mm and put it into the upper end of the tank, and hit it with a hammer until the foil is not dragged (that is, the foil is compacted and fixed without misalignment), and the stainless steel block and the edge of the tank are conne...

Embodiment 2

[0038] 1: Take the Ti6Al4V and TiBw / Ti6Al4V composite foils with a side length of 100 mm and a thickness of 400 μm, and use hydrofluoric acid with a volume fraction of 5% to 10% to dissolve and corrode the surface, and surface the titanium alloy and titanium-based composite foils. Rinse well and dry with a hair dryer;

[0039] 2: Take stainless steel with a side length of 120mm and a thickness of 40mm, mill out a square groove with a side length of 101mm and a depth of 32mm on a milling machine, and open a small hole with a diameter of 3-6mm on one side, and mix Ti6Al4V and TiBw / Ti6Al4V foils are stacked in the slot in ACAC order;

[0040] 3: Take a stainless steel block with a side length of 101mm and a thickness of 6mm and put it into the upper end of the tank, hit it with a hammer until the foil is no longer dragged, and seal the stainless steel block and the edge of the tank tightly with arc welding;

[0041] 4: Weld a stainless steel tube with an outer diameter of 8-12m...

Embodiment 3

[0044] 1: Take the Ti6Al4V and TiBw / Ti6Al4V composite foils with a side length of 100 mm and a thickness of 300 μm, and use hydrofluoric acid with a volume fraction of 5% to 10% to dissolve and corrode the surface, and the surface of the titanium alloy and titanium-based composite foils Rinse well and dry with a hair dryer;

[0045] 2: Take stainless steel with a side length of 120mm and a thickness of 40mm, mill out a square groove with a side length of 101mm and a depth of 32mm on a milling machine, and open a small hole with a diameter of 3-6mm on one side, and mix Ti6Al4V and TiBw / Ti6Al4V foils are stacked in the slot in ACAC order;

[0046] 3: Take a stainless steel block with a side length of 101mm and a thickness of 6mm and put it into the upper end of the tank, hit it with a hammer until the foil is no longer dragged, and seal the stainless steel block and the edge of the tank tightly with arc welding;

[0047] 4: Weld a stainless steel tube with an outer diameter of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com