DD750 cold-rolled low-carbon steel strip for electricians, and manufacturing method thereof

A technology of DD750, cold-rolled steel strip, applied in the field of cold-rolled steel strip manufacturing, can solve the problems of short service life, high content, poor electromagnetic performance of magnetic circuit iron core, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

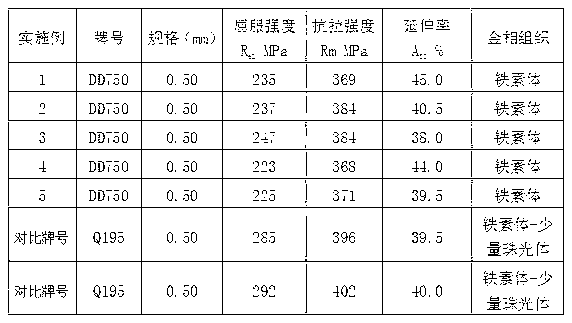

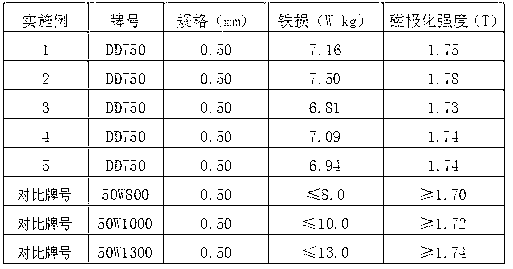

Examples

Embodiment 1

[0026] A kind of DD750 low-carbon steel cold-rolled strip for electricians of the present embodiment, the manufacturing method is as follows:

[0027] (1) Steelmaking and continuous casting process: smelting in a top-bottom re-blown oxygen converter, the molten steel is then refined in a RH vacuum furnace, and the alloy is added to adjust the composition. The cycle time is 6 minutes, and the composition is homogenized. After refining, the molten steel is sent to Continuous casting is carried out in the continuous casting workshop, the temperature of the tundish is 1538°C, the continuous casting is protected throughout the casting process, and the thickness of the continuous casting slab is 230mm. Sampling test results show that the composition of the slab is: C 0.003%, Mn 0.40%, Si 0.15%, P 0.095%, S 0.005%, and the rest are iron Fe and unavoidable impurity elements;

[0028] (2) Hot continuous rolling slab heating process: heating the slab to 1145°C, and the total hea...

Embodiment 2

[0033] A kind of DD750 low-carbon steel cold-rolled strip for electricians of the present embodiment, the manufacturing method is as follows:

[0034] (1) Steelmaking and continuous casting process: smelting in a top-bottom double-blown oxygen converter, the molten steel is then refined in a RH vacuum furnace, and the alloy is added to adjust the composition. The cycle time is 7 minutes, and the composition is homogenized. After refining, the molten steel is sent to Continuous casting is carried out in the continuous casting workshop, the temperature of the tundish is 1560°C, the continuous casting is protected throughout the casting process, and the thickness of the continuous casting slab is 230mm. Sampling test results show that the composition of the slab is: C 0.004%, Mn 0.20%, Si 0.60%, P 0.040%, S 0.007%, and the rest are iron Fe and unavoidable impurity elements;

[0035] (2) Hot continuous rolling slab heating process: heating the slab to 1200°C, and the total h...

Embodiment 3

[0040] A kind of DD750 low-carbon steel cold-rolled strip for electricians of the present embodiment, the manufacturing method is as follows:

[0041] (1) Steelmaking and continuous casting process: smelting in a top-bottom re-blown oxygen converter, the molten steel is then refined in a RH vacuum furnace, and the alloy is added to adjust the composition. The cycle time is 6 minutes, and the composition is homogenized. After refining, the molten steel is sent to Continuous casting is carried out in the continuous casting workshop, the temperature of the tundish is 1563°C, the continuous casting is protected throughout the casting process, and the thickness of the continuous casting slab is 230mm. Sampling test results show that the composition of the slab is: C 0.015%, Mn 0.28%, Si 0.40%, P 0.068%, S 0.004%, and the rest are iron Fe and unavoidable impurity elements;

[0042] (2) Hot continuous rolling slab heating process: heating the slab to 1100°C, and the total hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com