Spinning device

A technology of spinning frame and negative pressure tube, applied in the field of spinning devices, can solve the problems of non-constant frictional resistance, unstable movement of the upper aprons, etc., to achieve the advance of the speed change point, the stable improvement of the yarn evenness quality, and the reasonable control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

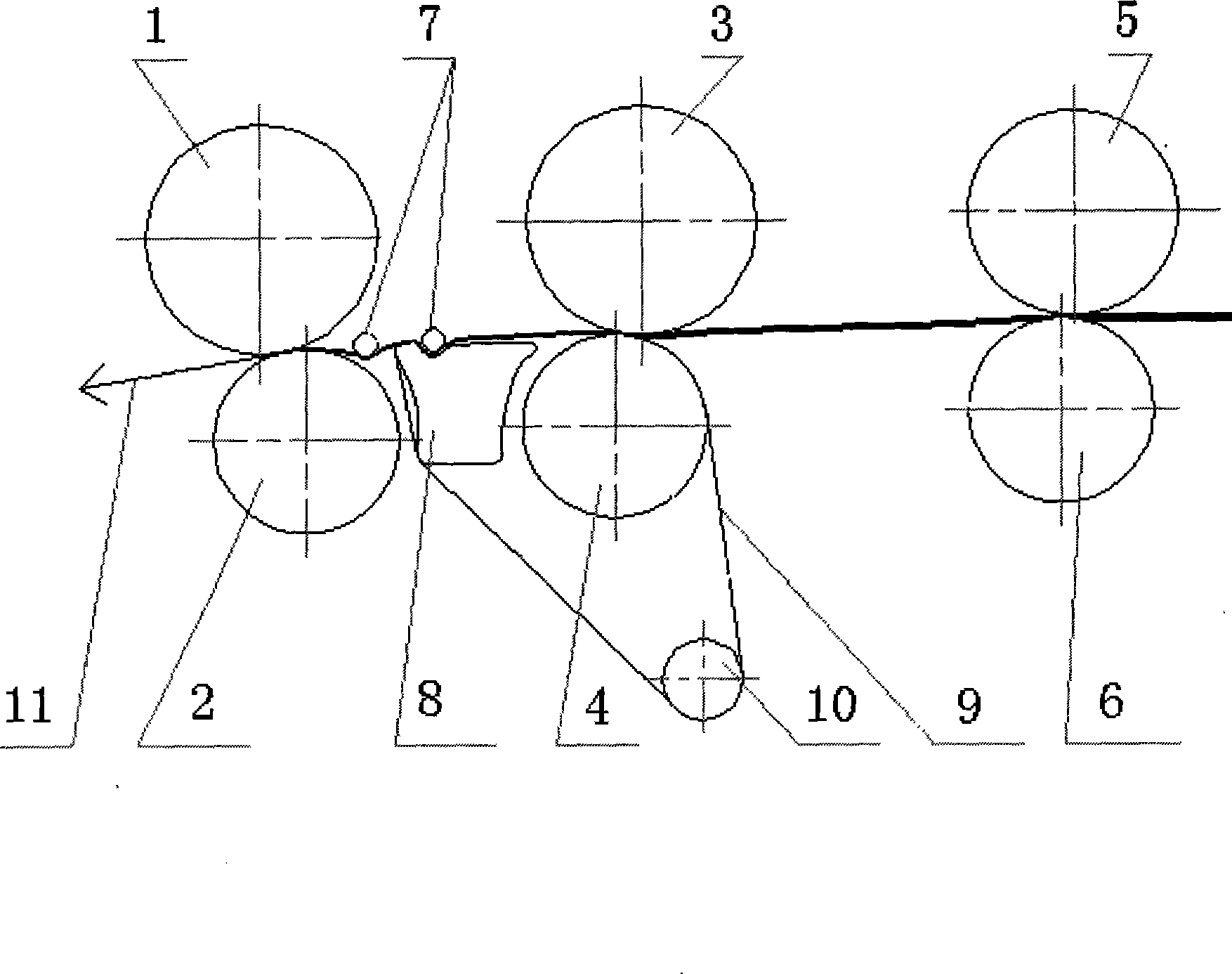

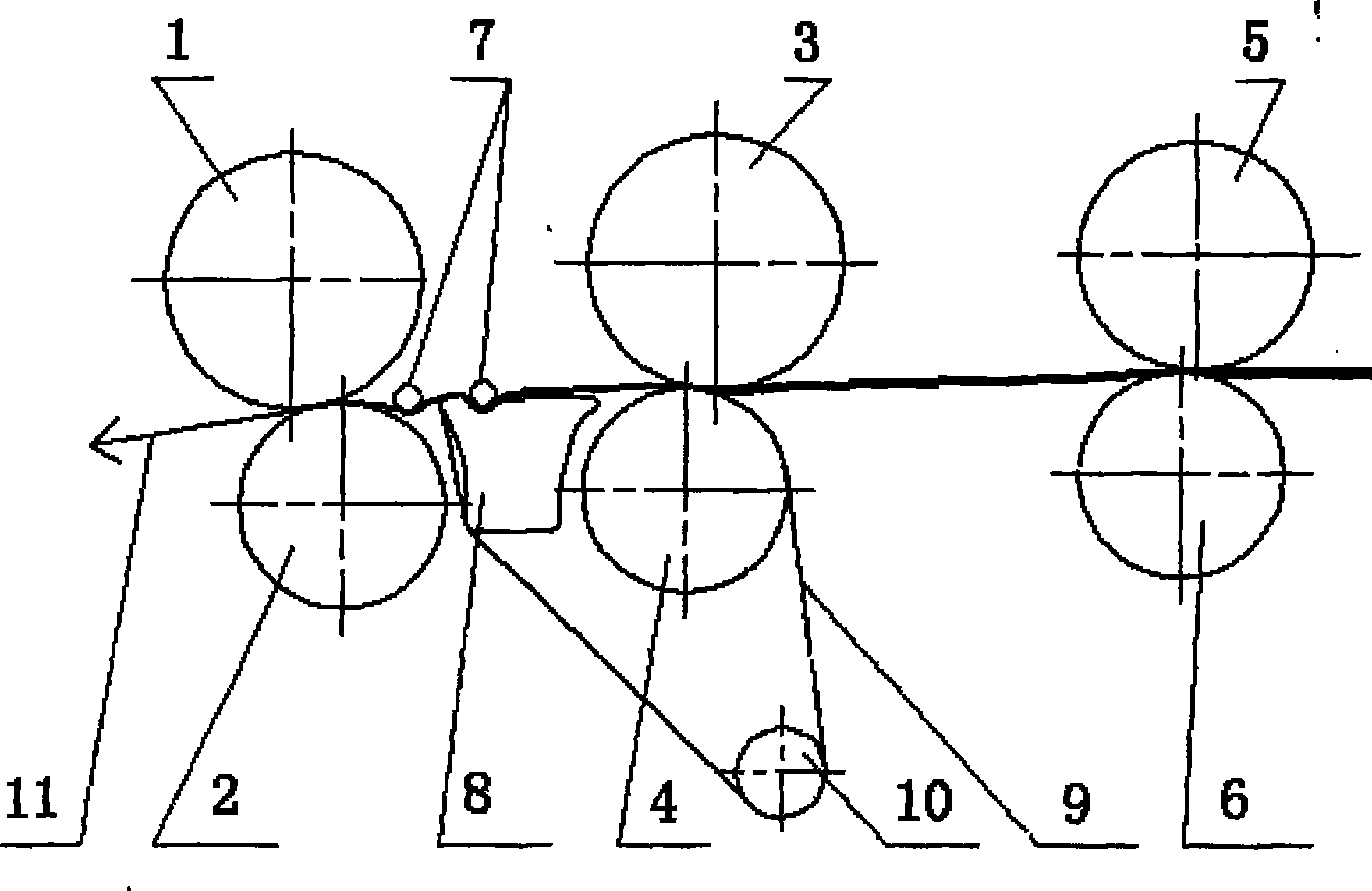

Embodiment Construction

[0012] The technical solution adopted by the present invention to solve the technical problem is: remove the negative pressure tube, the grid ring, the accumulation top roller, the gear, the transmission bridge gear, the pressure rod and the front drafting on the existing compact spinning frame. The upper pin, lower pin, compression spring, upper apron, lower apron and distance block in the area. Between the front jaw and the middle jaw, that is, a group of control rods, negative pressure tubes, and mesh rings are installed in the front drafting area. Among them, the negative pressure tube has a gradually narrowing suction groove at the spinning position, and the negative pressure tube is fixed and does not move; the mesh ring is a porous fabric ring with good air permeability but the fibers cannot pass through, and the mesh ring is wrapped in the negative pressure tube. In the spinning position, the grid ring moves by the transmission of the middle roller. There are grooves ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com