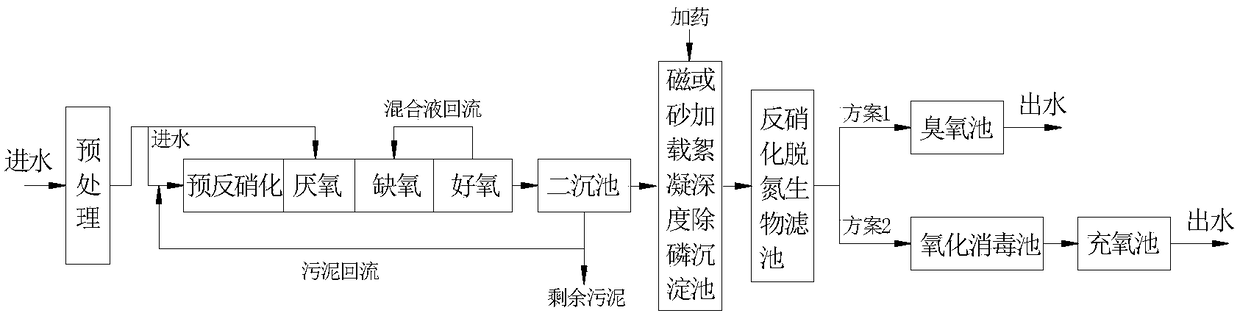

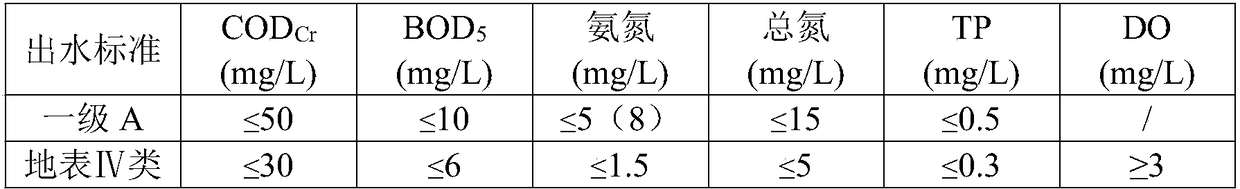

Standard reaching to ground surface water grade IV water urban sewage treatment process

A technology for urban sewage and treatment process, applied in water/sewage treatment, biological water/sewage treatment, oxidized water/sewage treatment, etc. problems, to facilitate industrialization and large-scale promotion, save iron-based or aluminum-based salts, and improve the effect of denitrification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] A kind of magnetically loaded sludge collection and separation equipment and treatment method of the present invention will be further described below in conjunction with accompanying drawing:

[0032] (1) Urban sewage is pretreated to remove sand, stone and large particulate matter in sewage; to ensure the stability of biochemical reactions in the later stage; the pretreatment step is to pretreat sewage through grilles, grit chambers or primary sedimentation tanks .

[0033](2) After pretreatment, the sewage is divided into two parts of sewage; part of the sewage (10% to 40%) is fully mixed with the muddy water returned from the secondary settling tank and then enters the pre-denitrification tank, and the organic matter (suspended solids SS and Dissolved organic matter) and nitrate (nitrate nitrogen, nitrite nitrogen) in the return sludge water to carry out pre-denitrification reaction to remove nitrate nitrogen and organic matter in the return sludge, and reduce the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com