Patents

Literature

42results about "Linked sausage separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

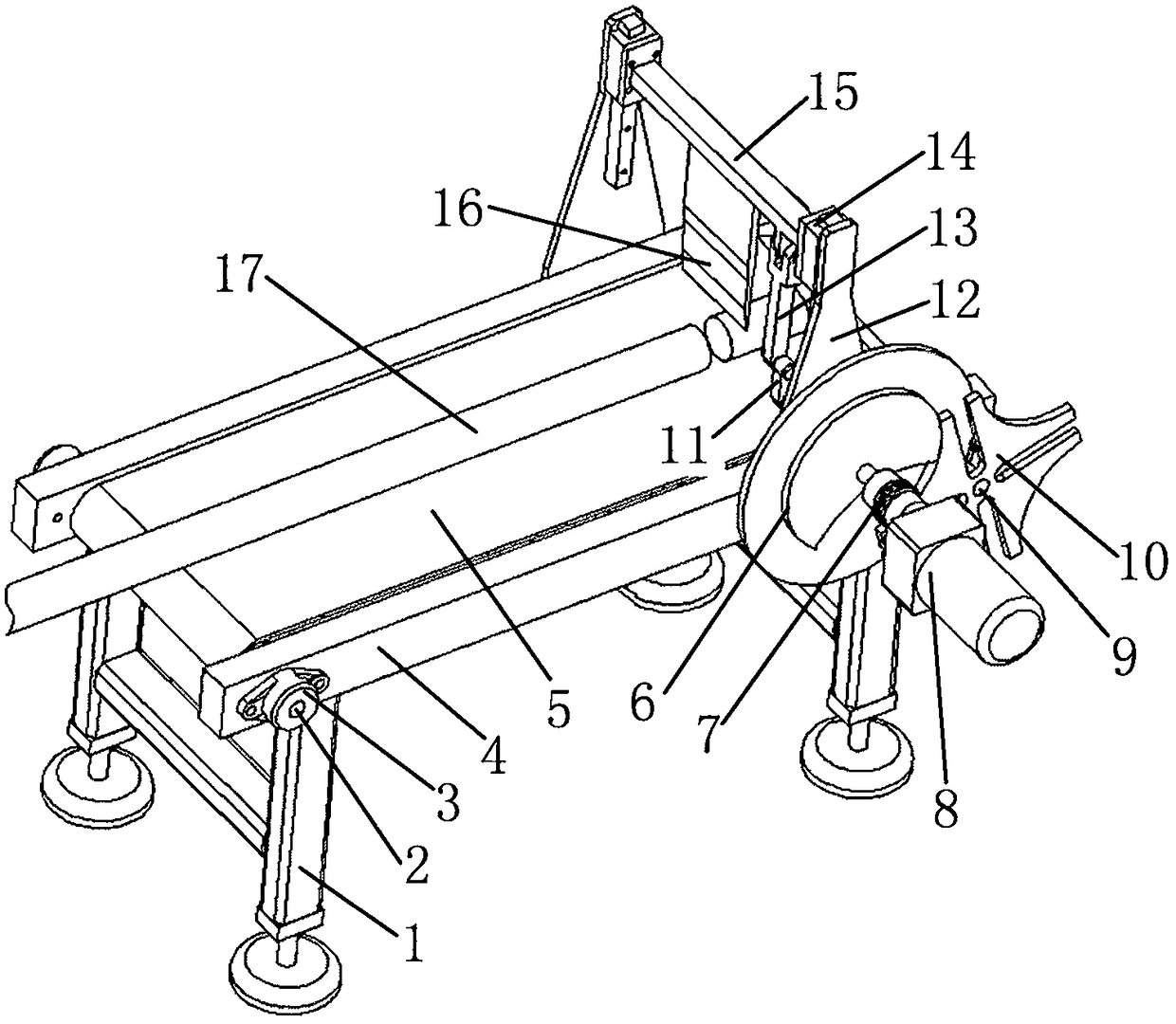

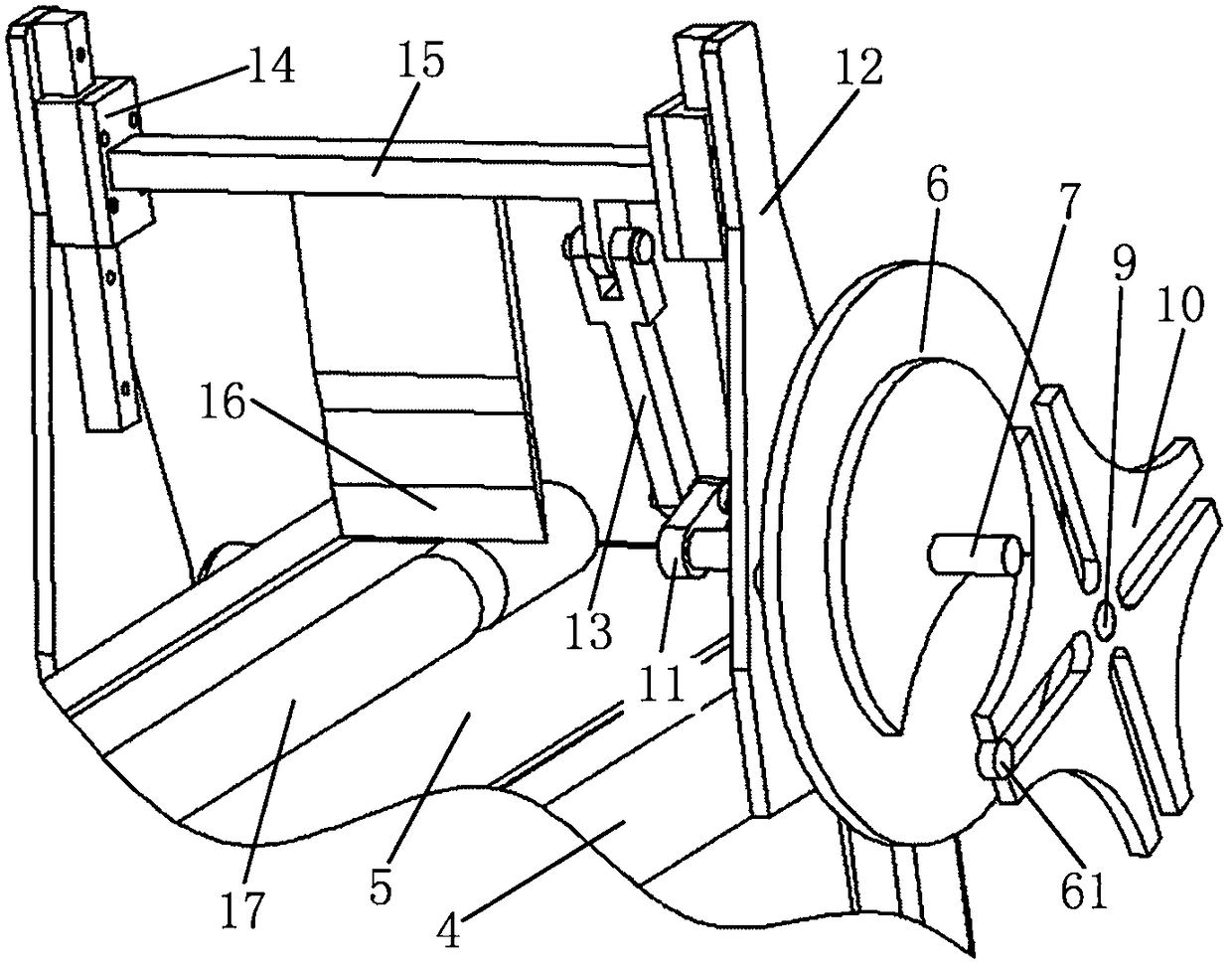

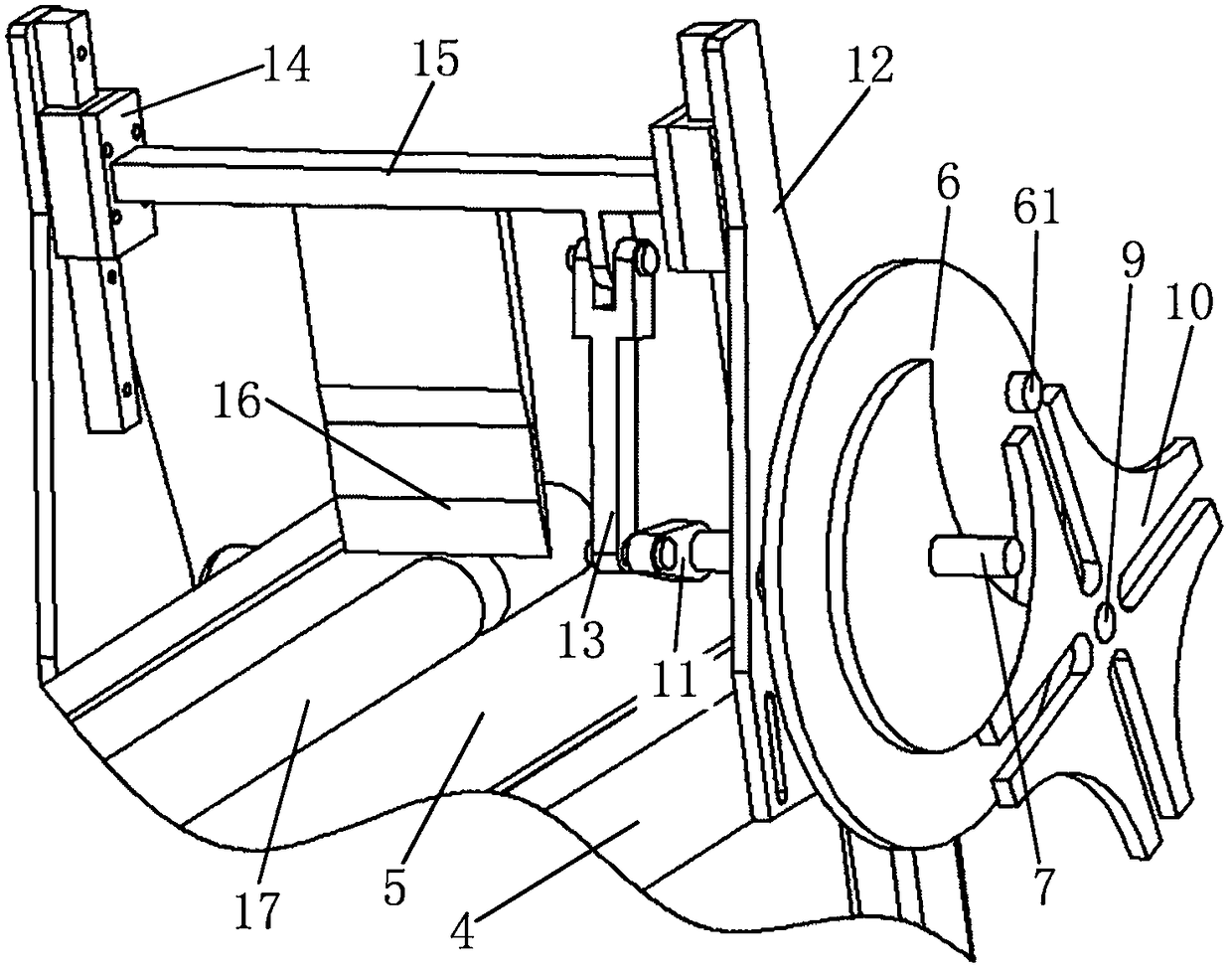

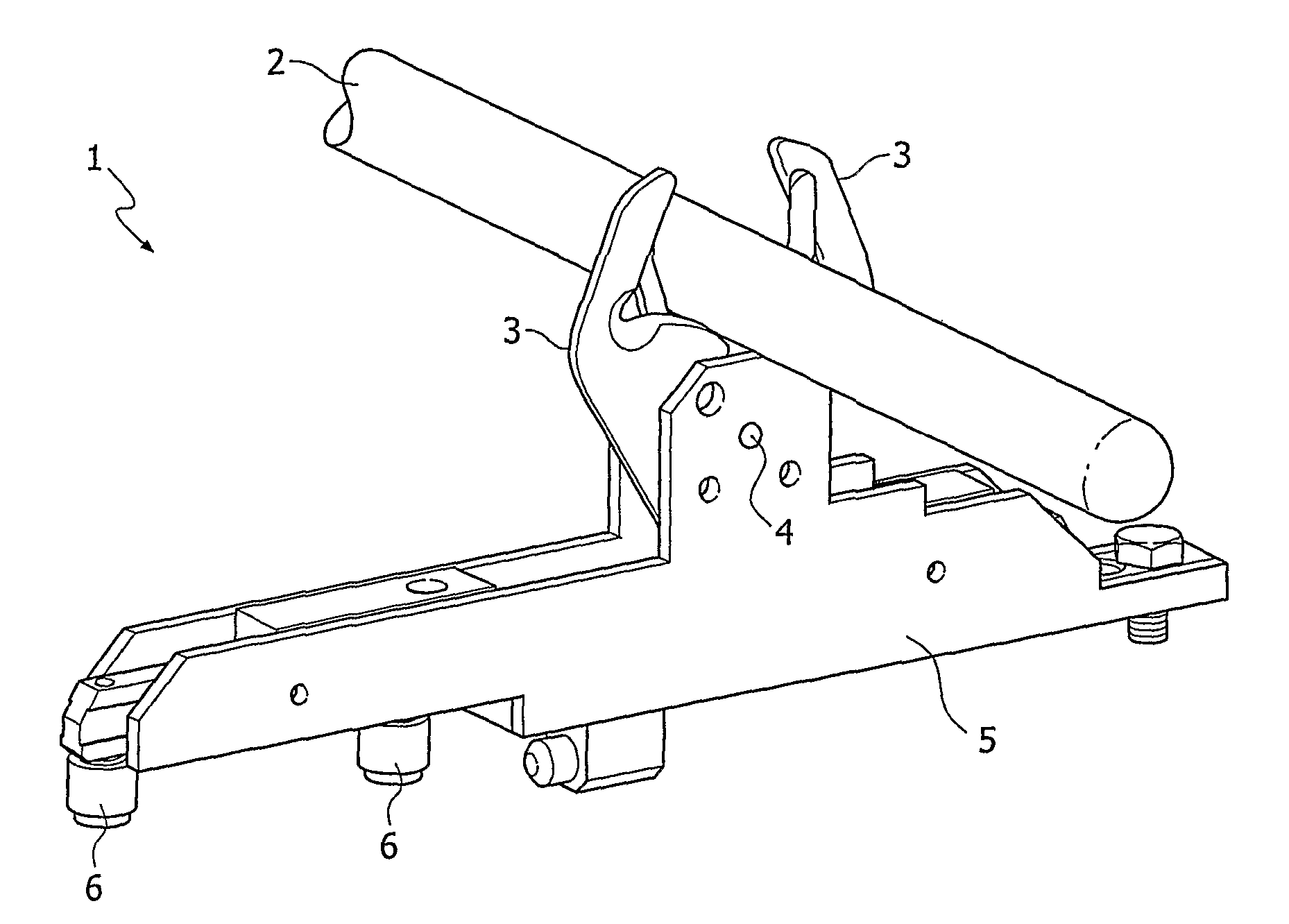

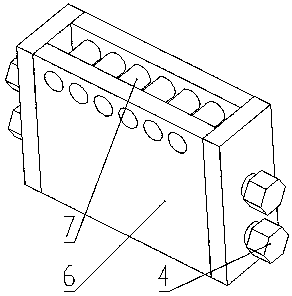

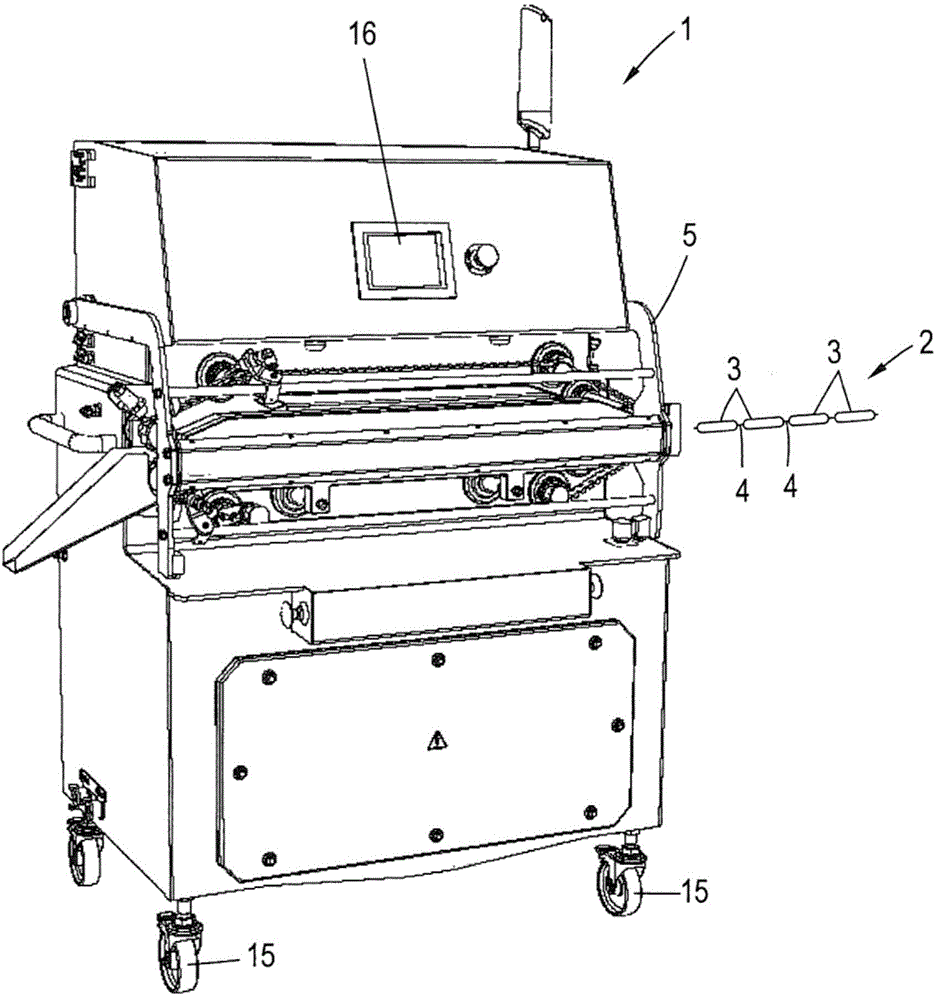

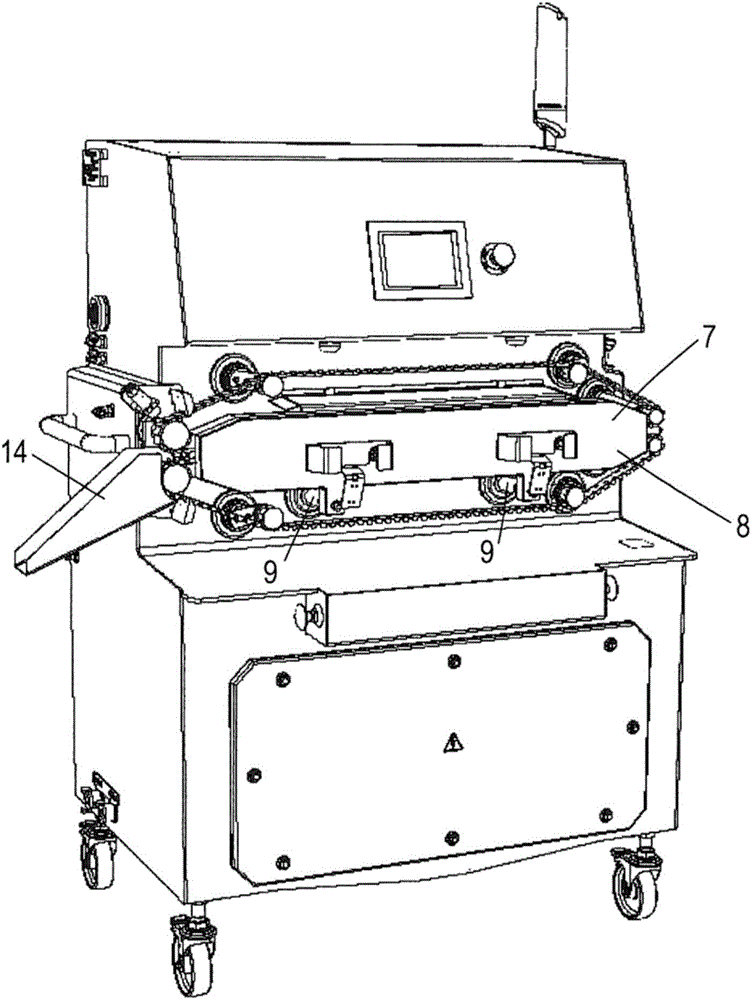

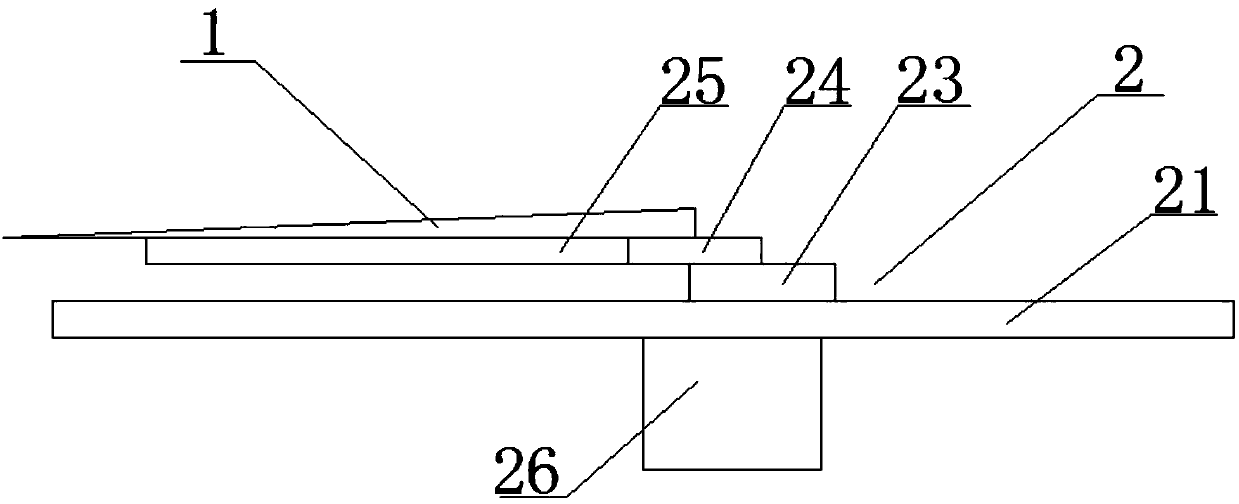

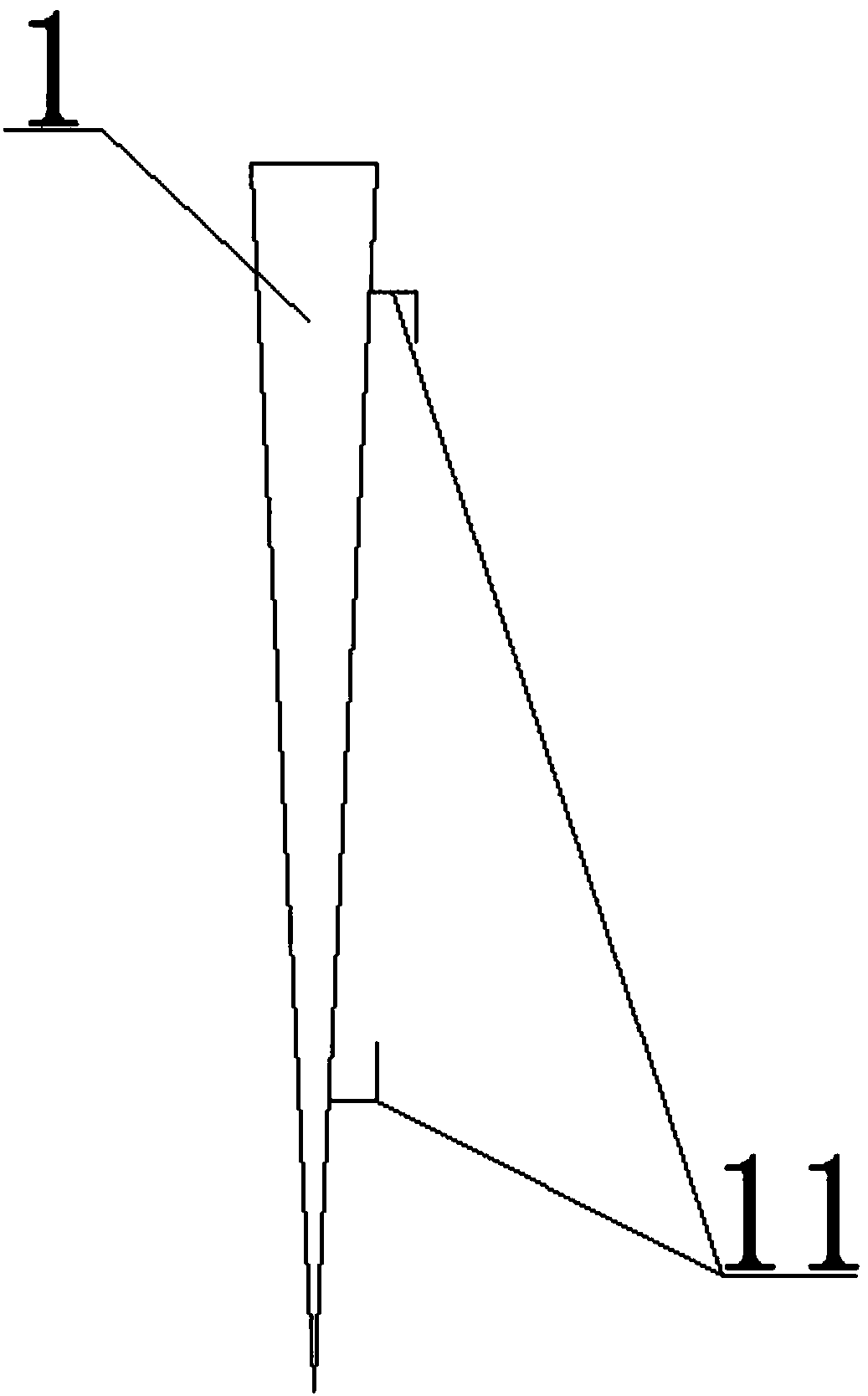

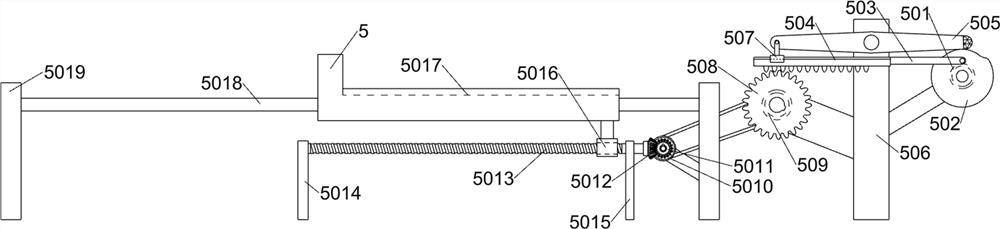

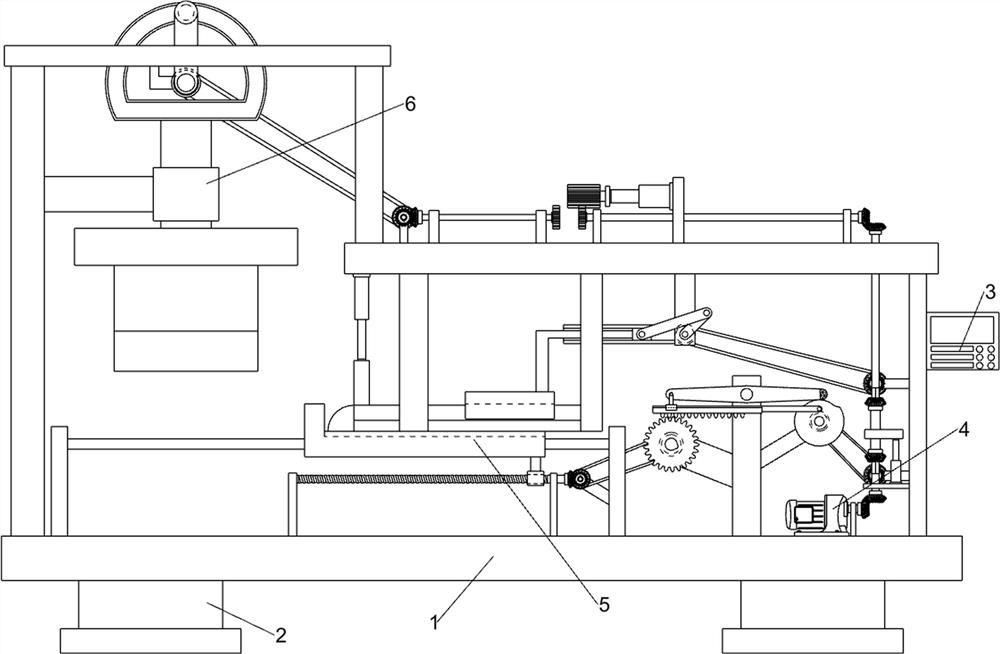

Sausage splitting equipment

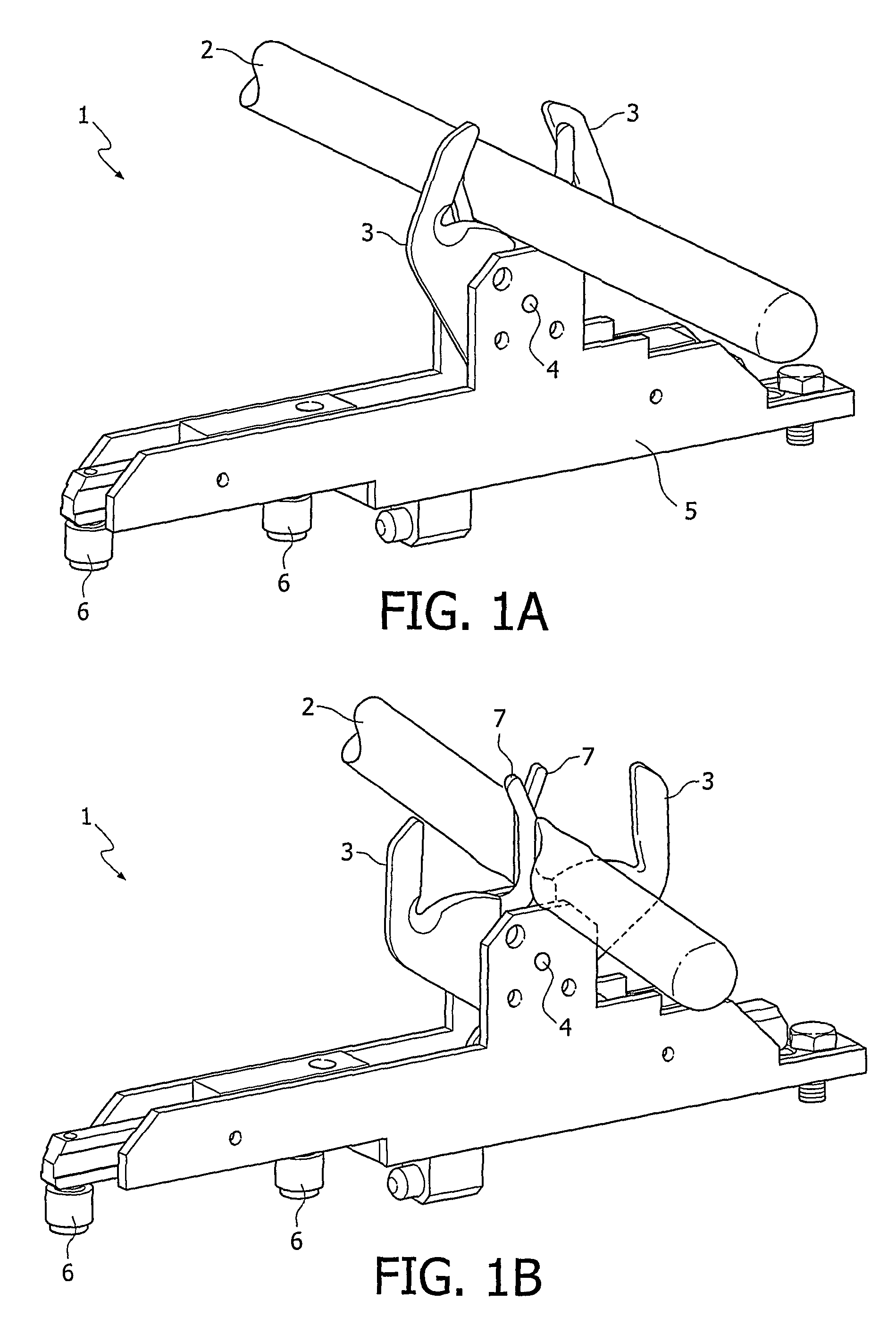

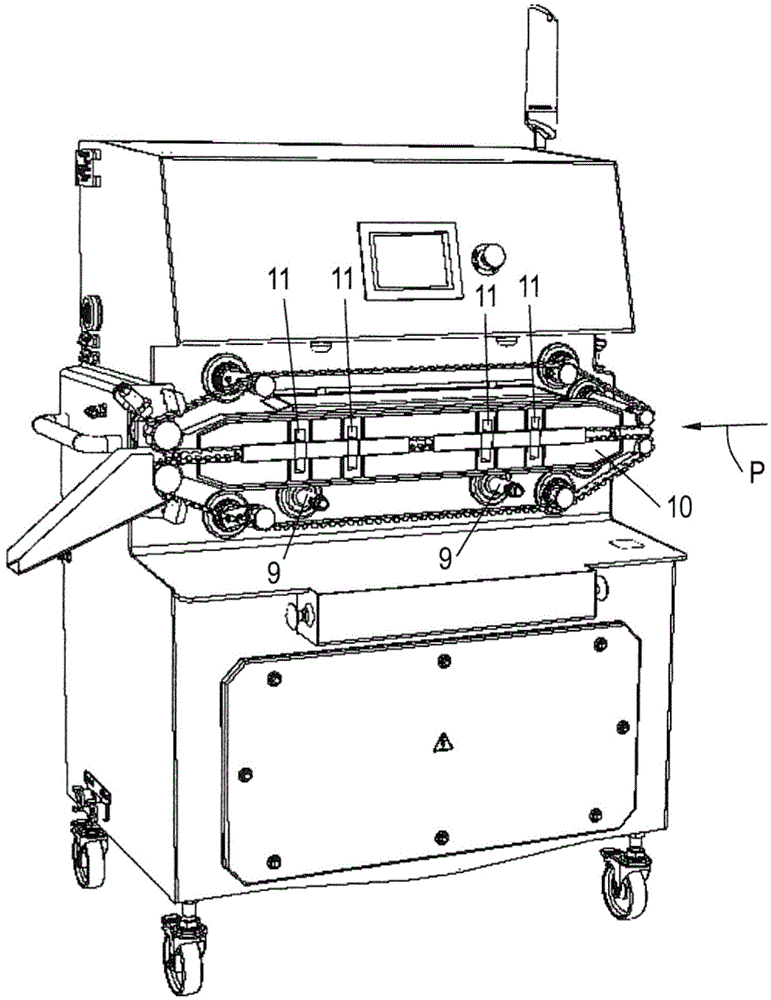

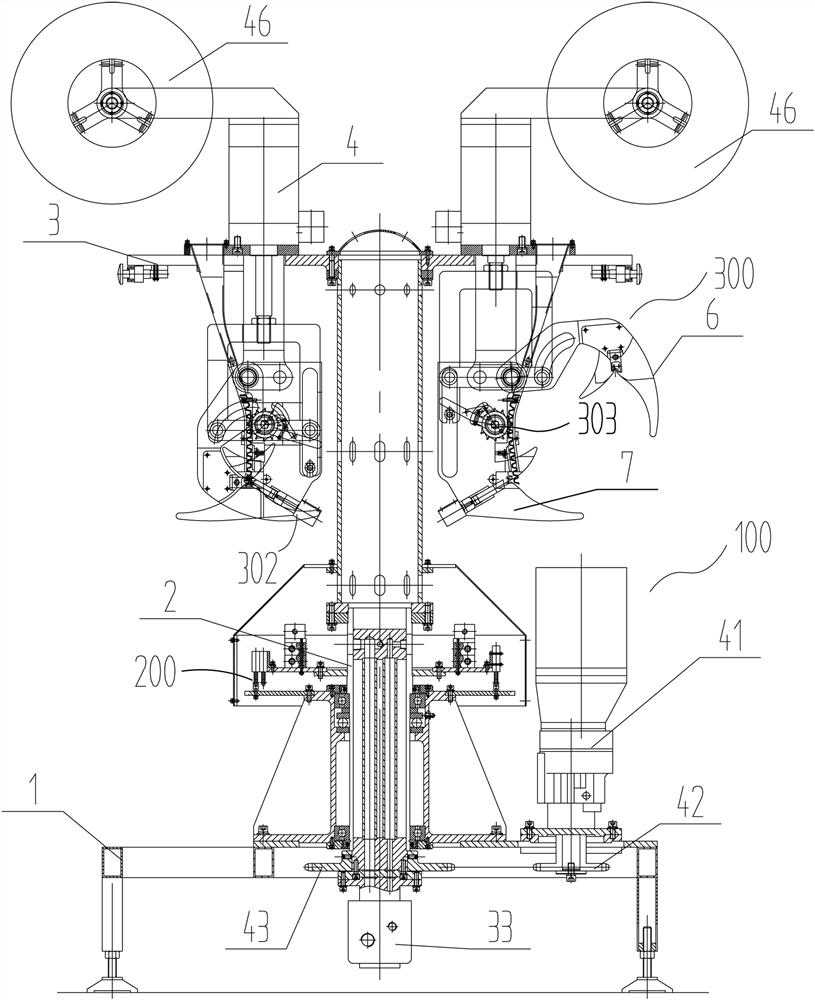

PendingCN108453802ASimple structureEasy maintenanceLinked sausage separationMetal working apparatusDrive shaftEngineering

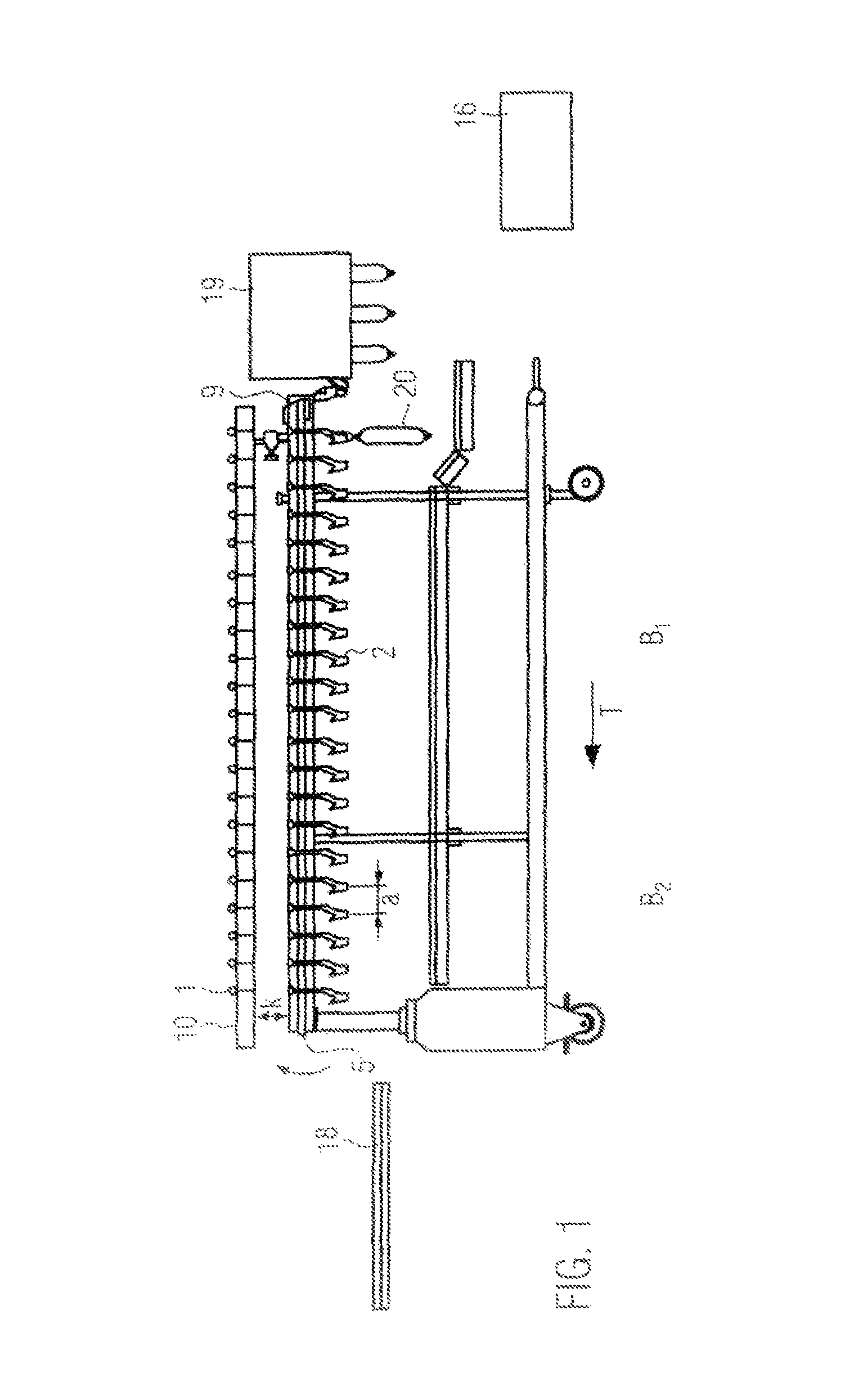

The invention discloses sausage splitting equipment. Two side plates of the sausage splitting equipment are fixed with supporting legs. A drive shaft penetrates through the front ends of the side plates, and a driven shaft penetrates through the rear ends of the side plates. A conveying belt is arranged between the drive shaft and the driven shaft. One end of the drive shaft protrudes out of the corresponding side plate in the axial direction, and the protruding portion is connected with a sheave. Two supporting plates are fixed to the outer sides of the two side plates correspondingly. A drive short shaft is arranged on the middle lower portion of the supporting plate on the side with the sheave, one side of the drive short shaft protrudes out of the corresponding side plate and is provided with a notched rotary plate and a motor, and the other side of the drive short shaft penetrates through the corresponding supporting plate to be fixedly connected with one end of a crankshaft. Sliding rail assemblies are installed on the inner sides of the two supporting plates. A cutter rest is located above the conveying belt, and the two ends of the cutter rest are connected with the slidingrail assemblies. A lug shaft is arranged below the cutter rest and is close to the side with the sheave. One end of a connecting rod is connected with the lug shaft on the cutter rest, and the otherend of the connecting rod is connected with the crankshaft. A cutter with a cutting edge facing downward is arranged under the cutter rest. The sausage splitting equipment has the characteristics thatsausages are divided consistently, incisions are standard, the structure is simple, and maintenance is easy.

Owner:侯凯希 +1

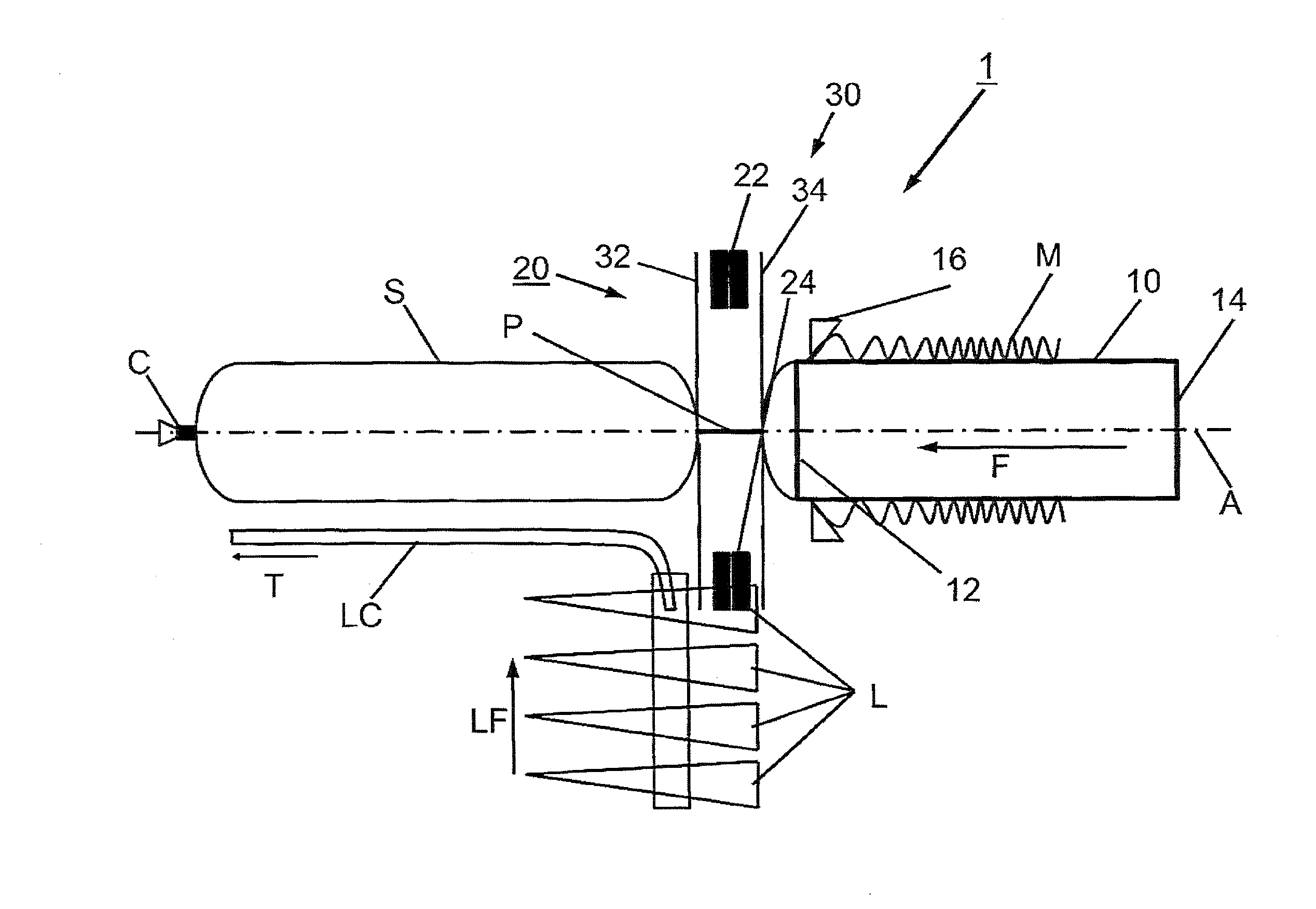

Suspension apparatus and method for suspending sausages, in particular sausage chains

ActiveUS20140073231A1Accurate operationEasily identifiableMeat/sausage hanging-upLinked sausage separationEngineering

Owner:ALBERT HANDTMANN MASCHFABRICK

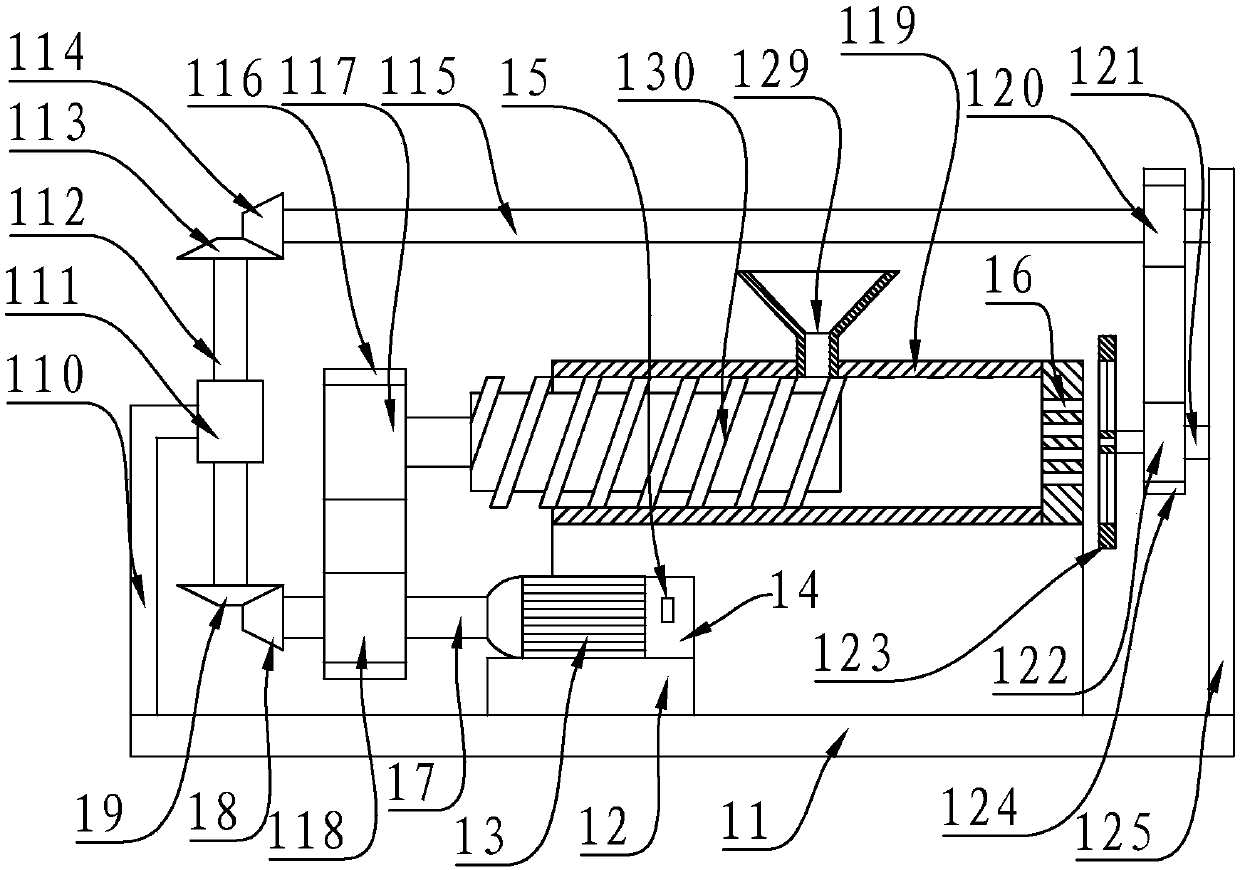

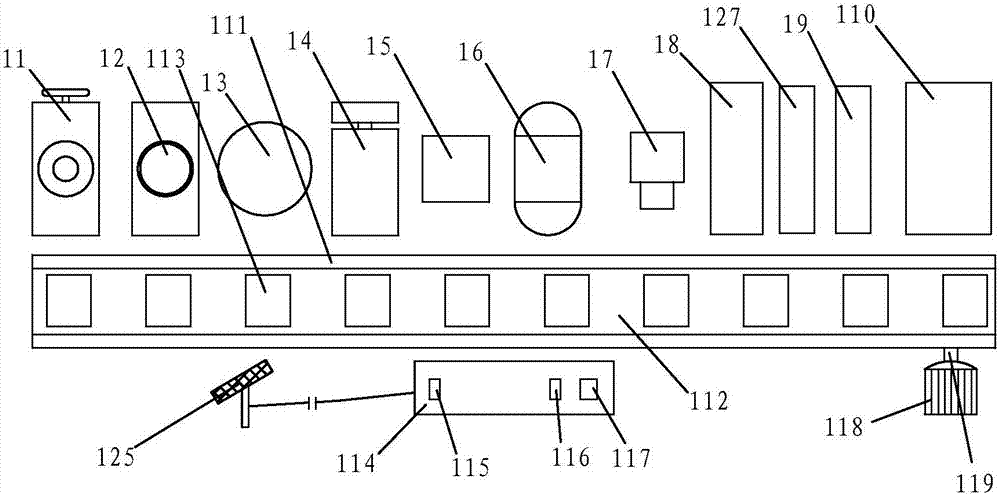

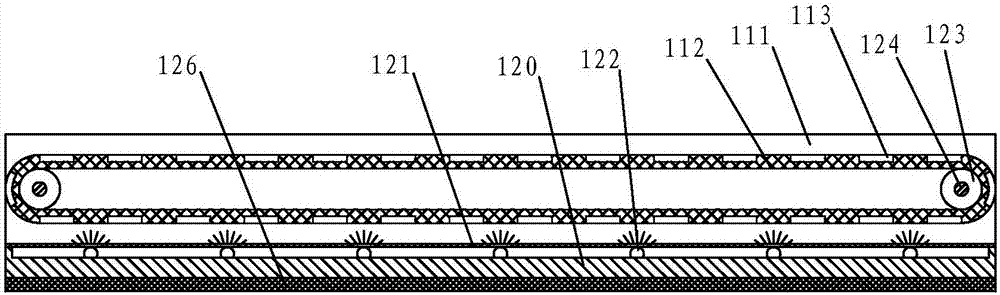

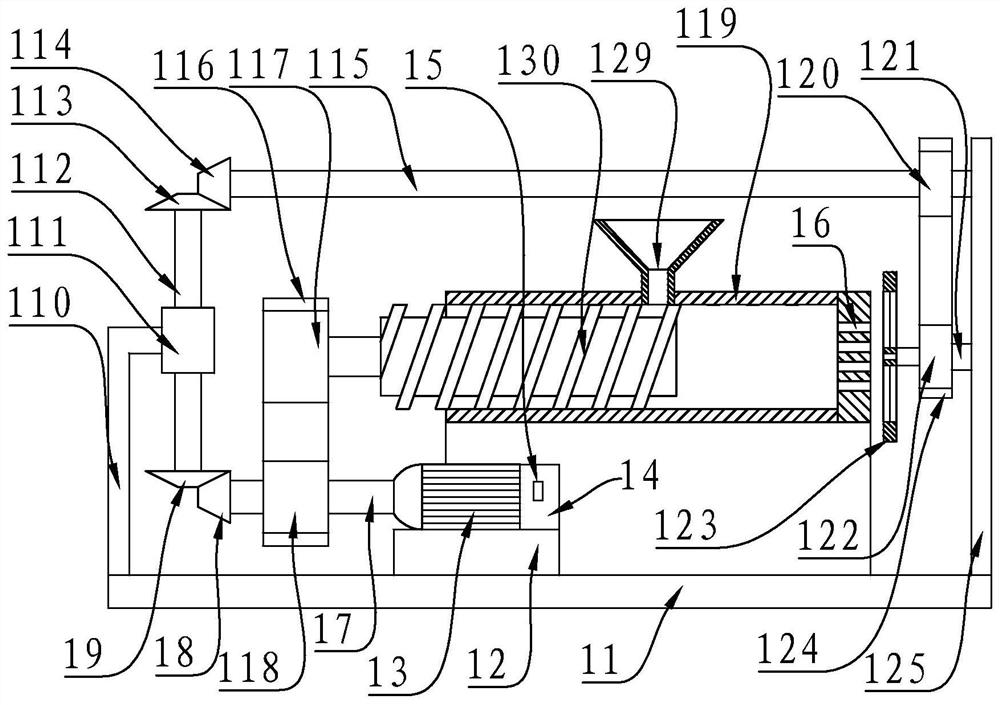

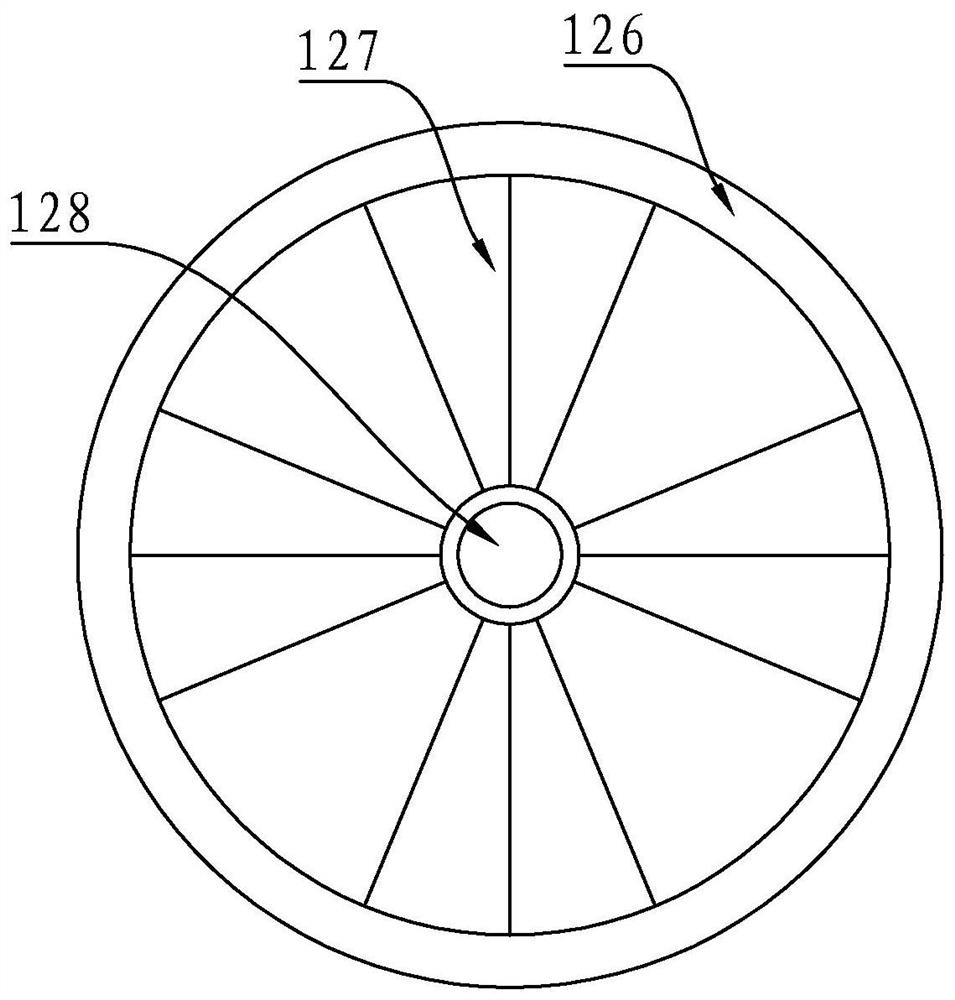

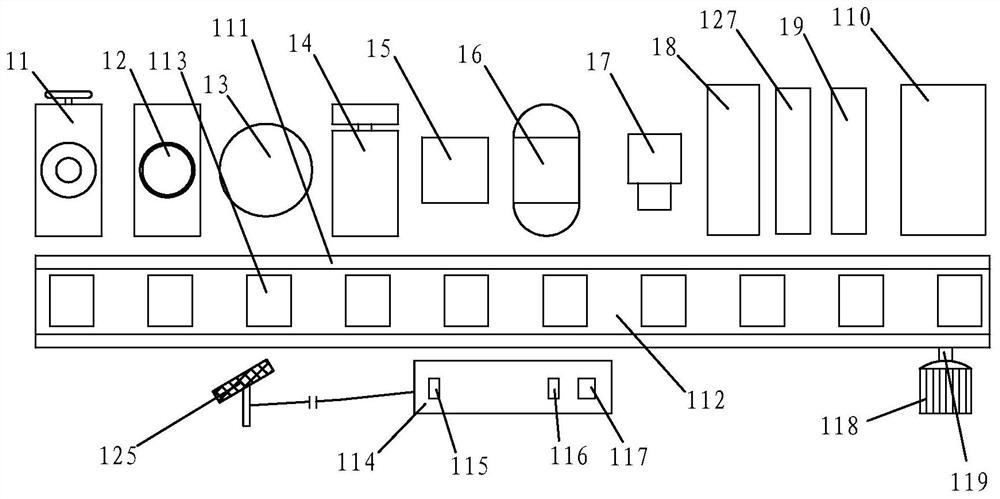

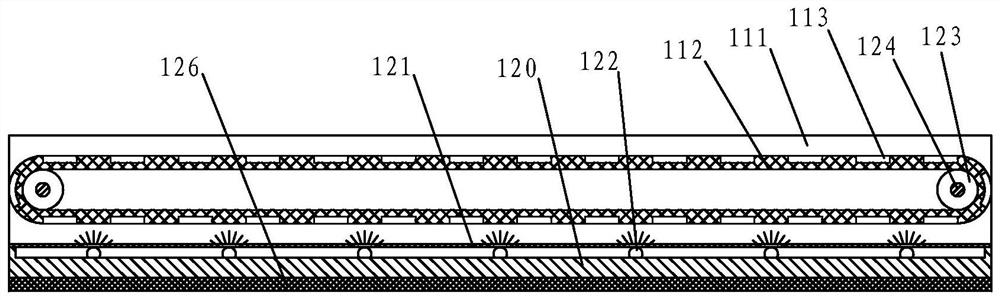

Energy-saving environment-friendly production process of sausages and production device of sausages

ActiveCN107897743AThe production process is simple and applicableSteady improvement in qualityLinked sausage separationSausage filling/stuffing machinesElectric machineryAutomation

The invention provides an energy-saving environment-friendly production process of sausages and a production device of the sausages. The device comprises a weighing and stirring system, a sausage filling system, a smoking system, an air exhaust cooling and shaping system and a cutting system; a meat mincing system comprises a screw cylinder and a first screw rod which are matched with each other;the outer end of the first screw rod is provided with a first belt pulley; a rinsing system comprises a rinsing barrel made of a transparent material, a second motor, a first stirring sleeve and a second controller; a pickling system comprises a top cover and a pickling barrel; and a third rotating shaft is transversely arranged inside the pickling barrel. According to the invention, all importantdevices in sausage production process are improved, the automation degree of the production process is further improved, more mechanized operations are adopted, labor cost is reduced, production efficiency is improved at the same time, the error rate is lower, and the quality of the sausage is improved stably.

Owner:福建舜洋食品有限公司

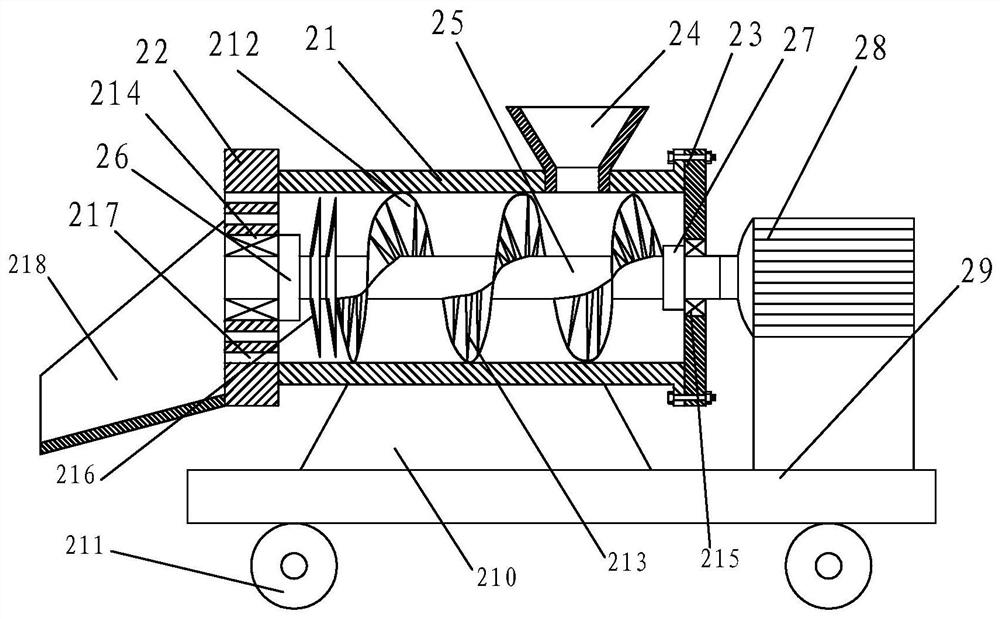

Energy-saving, environmentally-protective and high-quality production technology and production device of qinqin sausage (short and juicy sausage)

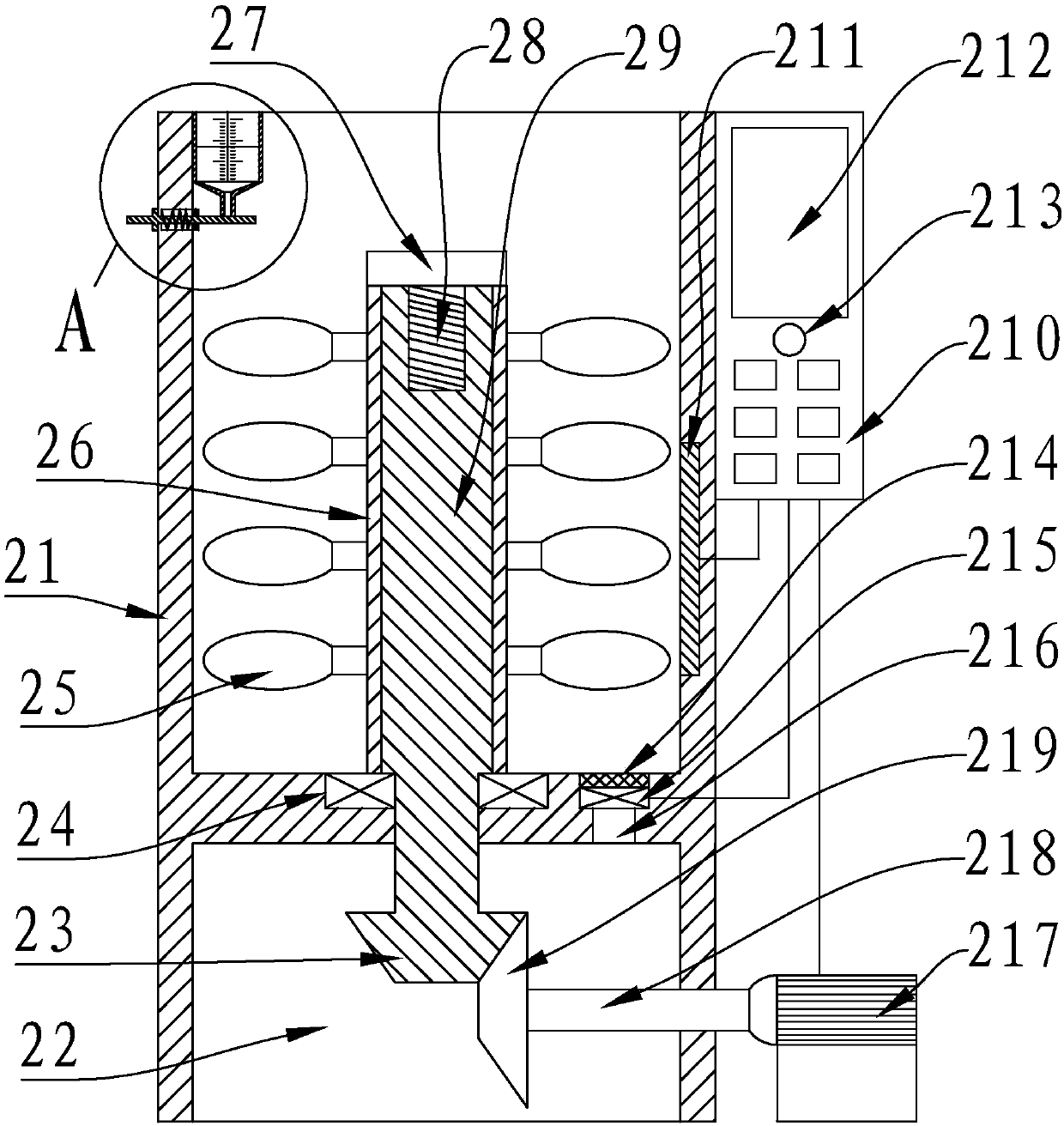

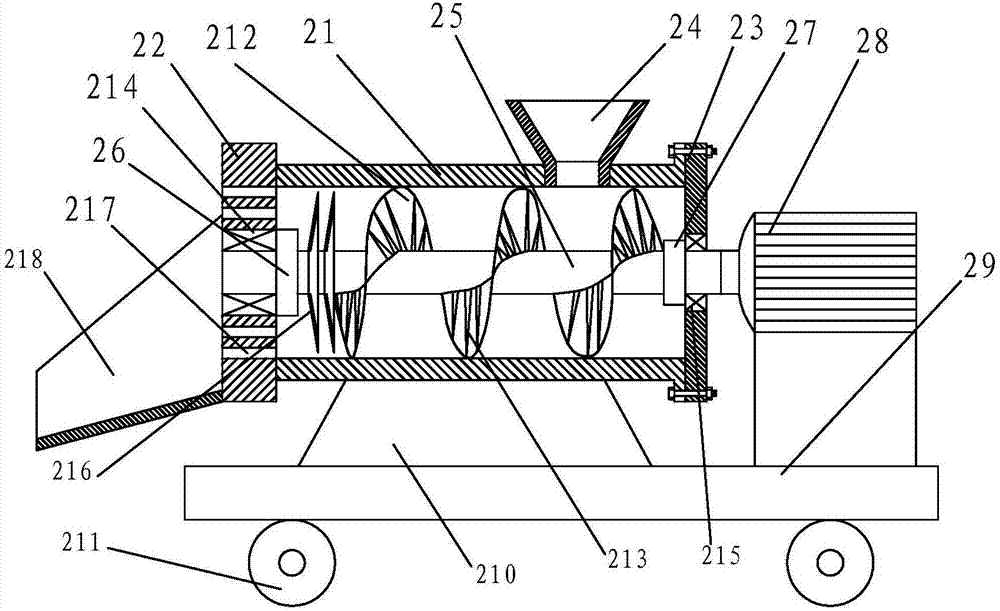

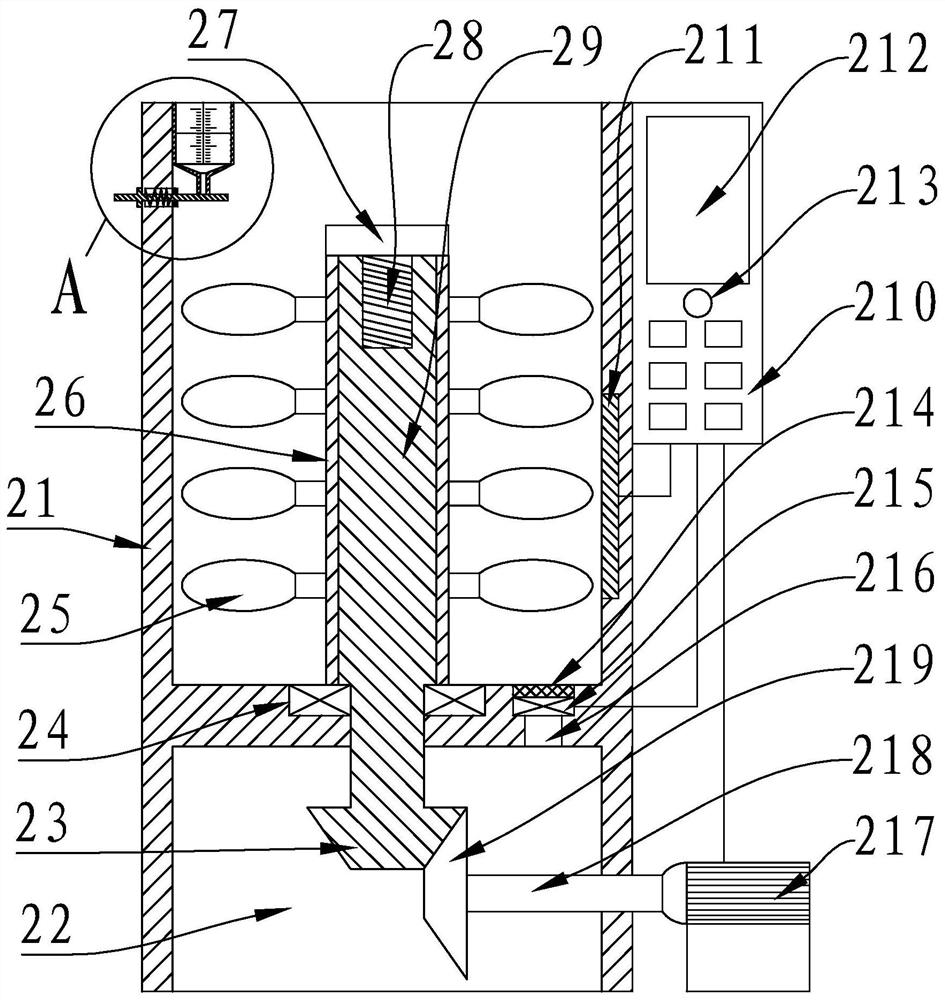

ActiveCN107996668AThe production process is simple and applicableSteady improvement in qualityLinked sausage separationSausage filling/stuffing machinesEngineeringControl table

The present invention provides an energy-saving, environmentally-protective and high-quality production technology and production device of a qinqin sausage (a short and juicy sausage). The processingdevice comprises a base seat. A control table is arranged at one side of the base seat, a meat grinder system is arranged at a left end of the other side of the base seat, a right side of the meat grinder system is successively provided with a stuffing blending system, a pickling tank, a rolling system, a weighing system, a sausage filling system, a steaming and smoking system, a cooling room, acutting system, a secondary sterilization system and a cold storage. Each system transfers the sausage via a conveyor belt, transportation labor is reduced, important devices are improved, automationdegrees of production processes are further improved, more mechanized operations are used, labor costs are reduced, and at the same time, the production device can improve production efficiency, is lower in error rate and steadily improves quality of the qinqin sausage.

Owner:福建舜洋食品有限公司

Food processing device

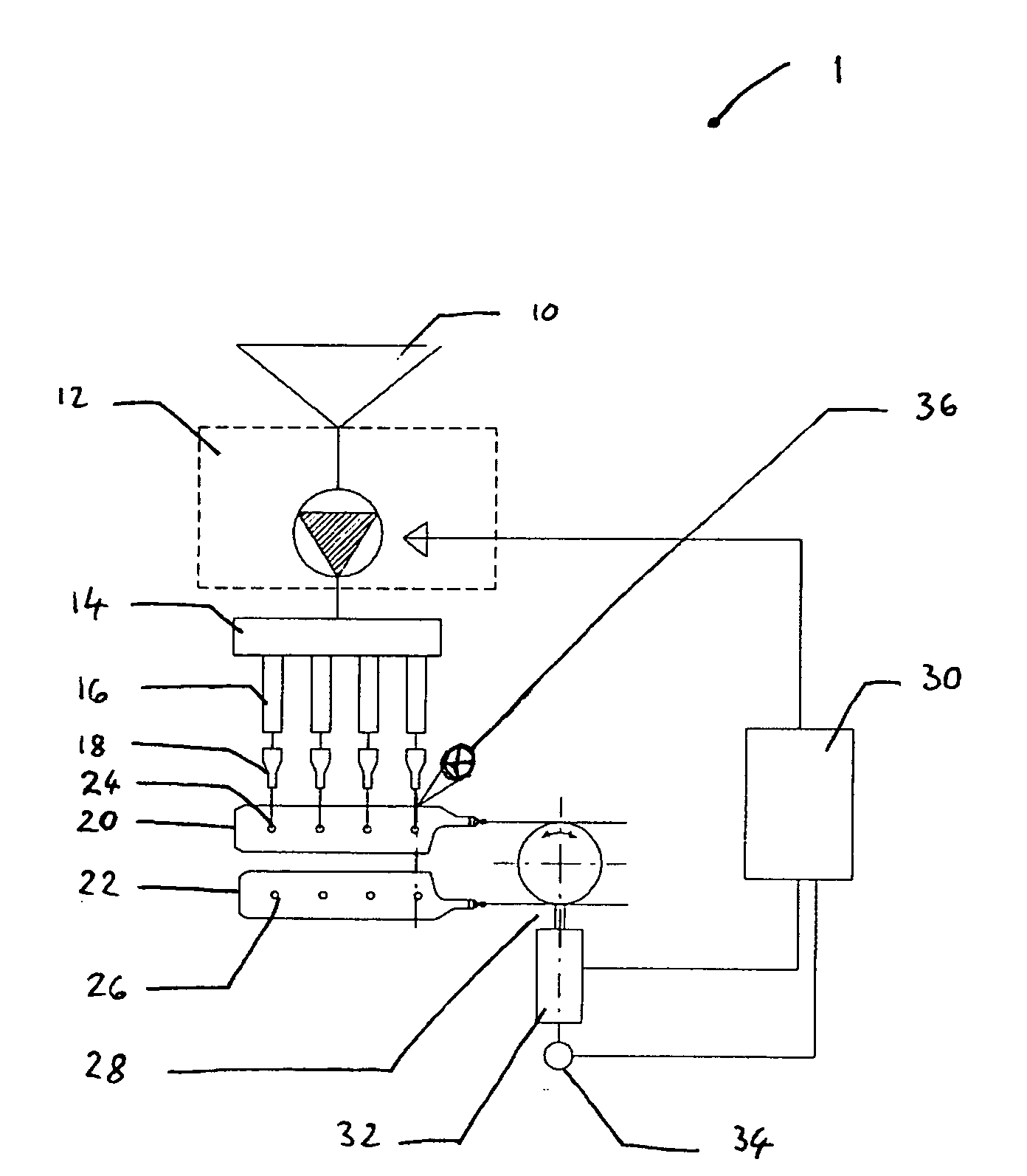

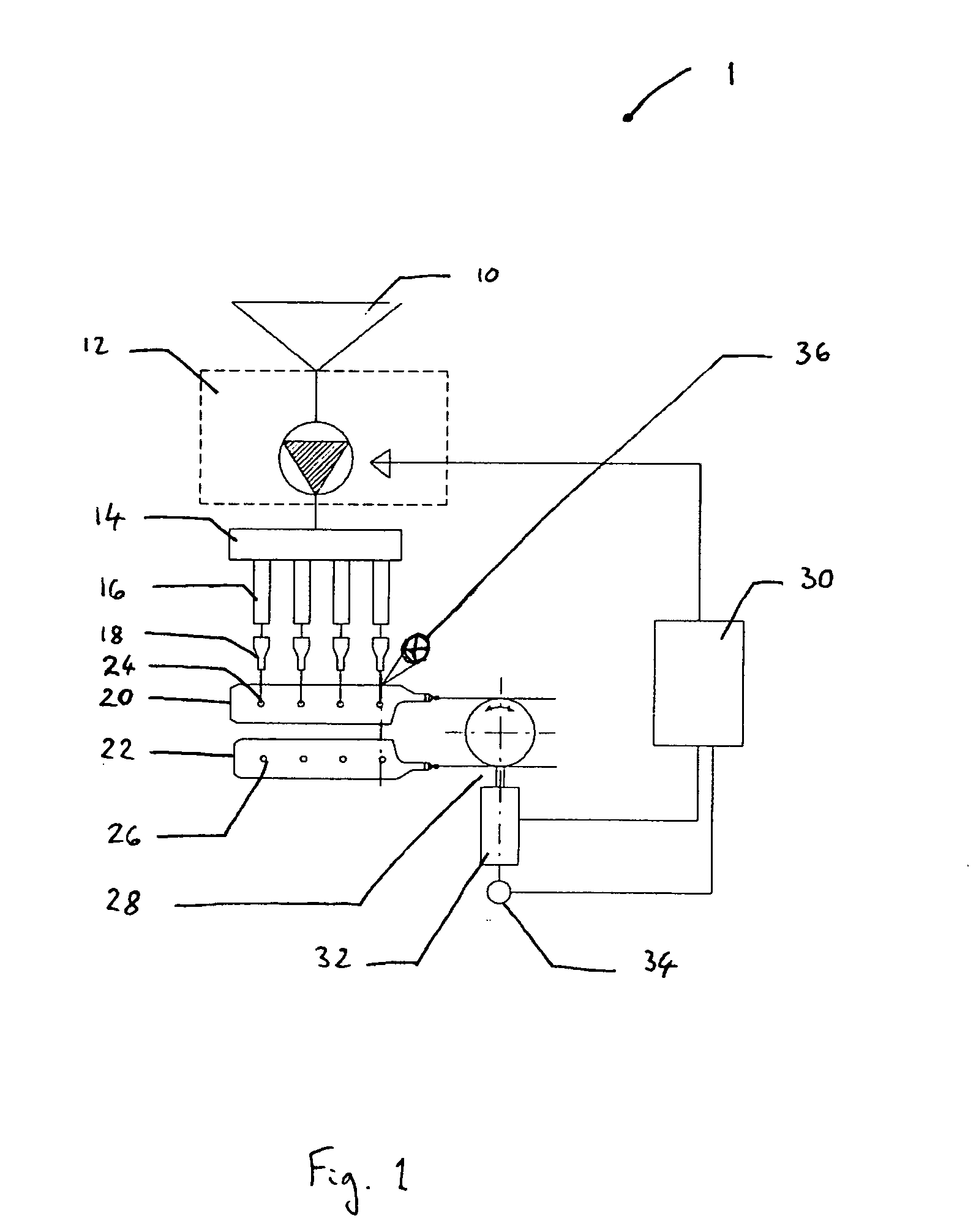

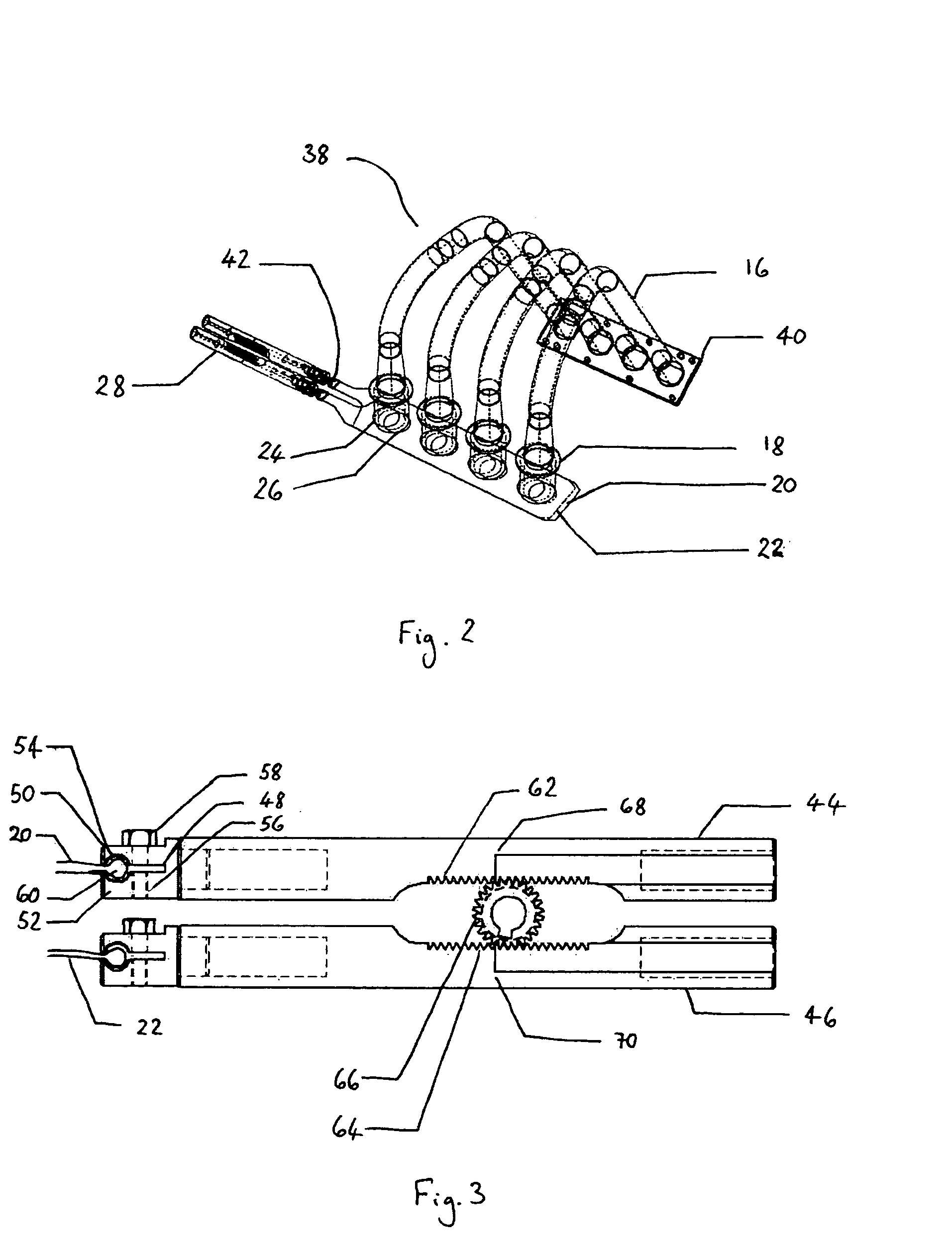

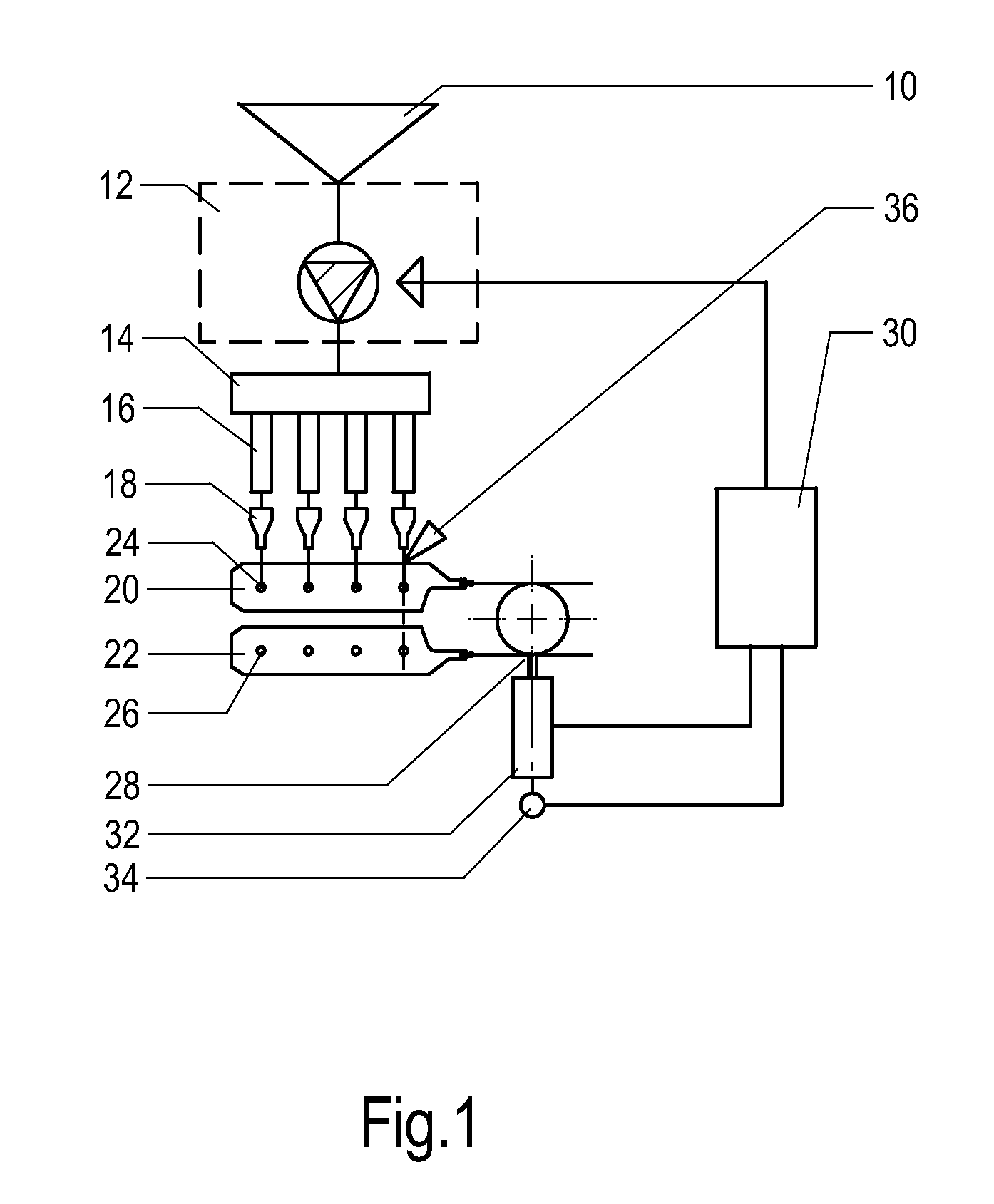

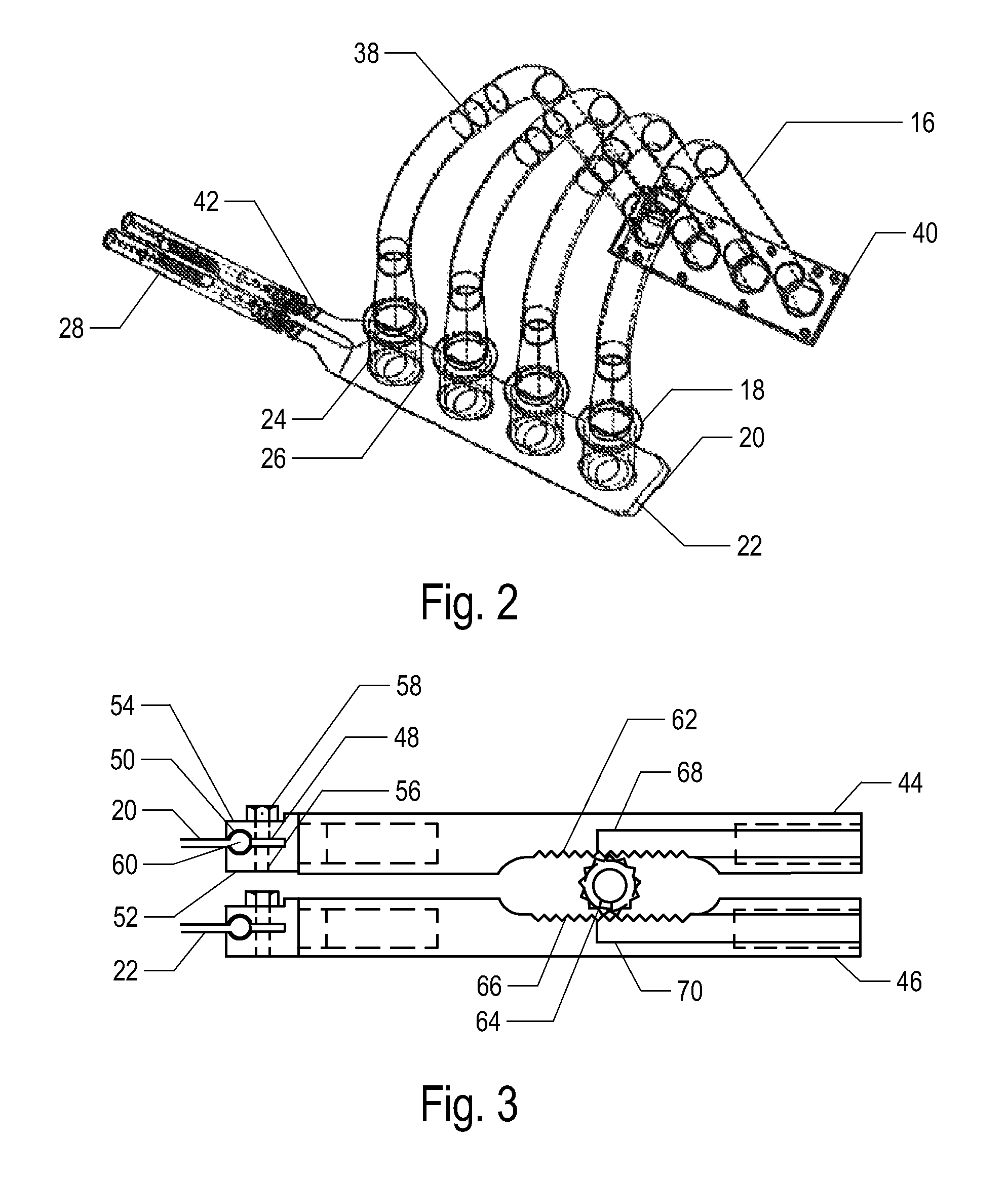

ActiveUS20070295222A1Improve cutting performanceReduce actionLinked sausage separationFood shapingElectricityLine tubing

A food processing device comprises a paste reservoir, a feed pump and a flow divider. The flow divider is provided with outlets to four supply lines all of which receive a substantially equal supply of paste as a result of the operation of the flow divider. Each of the outlets is connected to a nozzle. A pair of knives is located ahead of the nozzles, each being provided with four apertures. The knives are provided with an actuating mechanism and a controller. Controller registers and controls operation of the meatball forming device and is electrically connected to the feed pump, to a servomotor and to a shaft encoder.

Owner:MACHINEFAB GEURTSEN DEVENTER

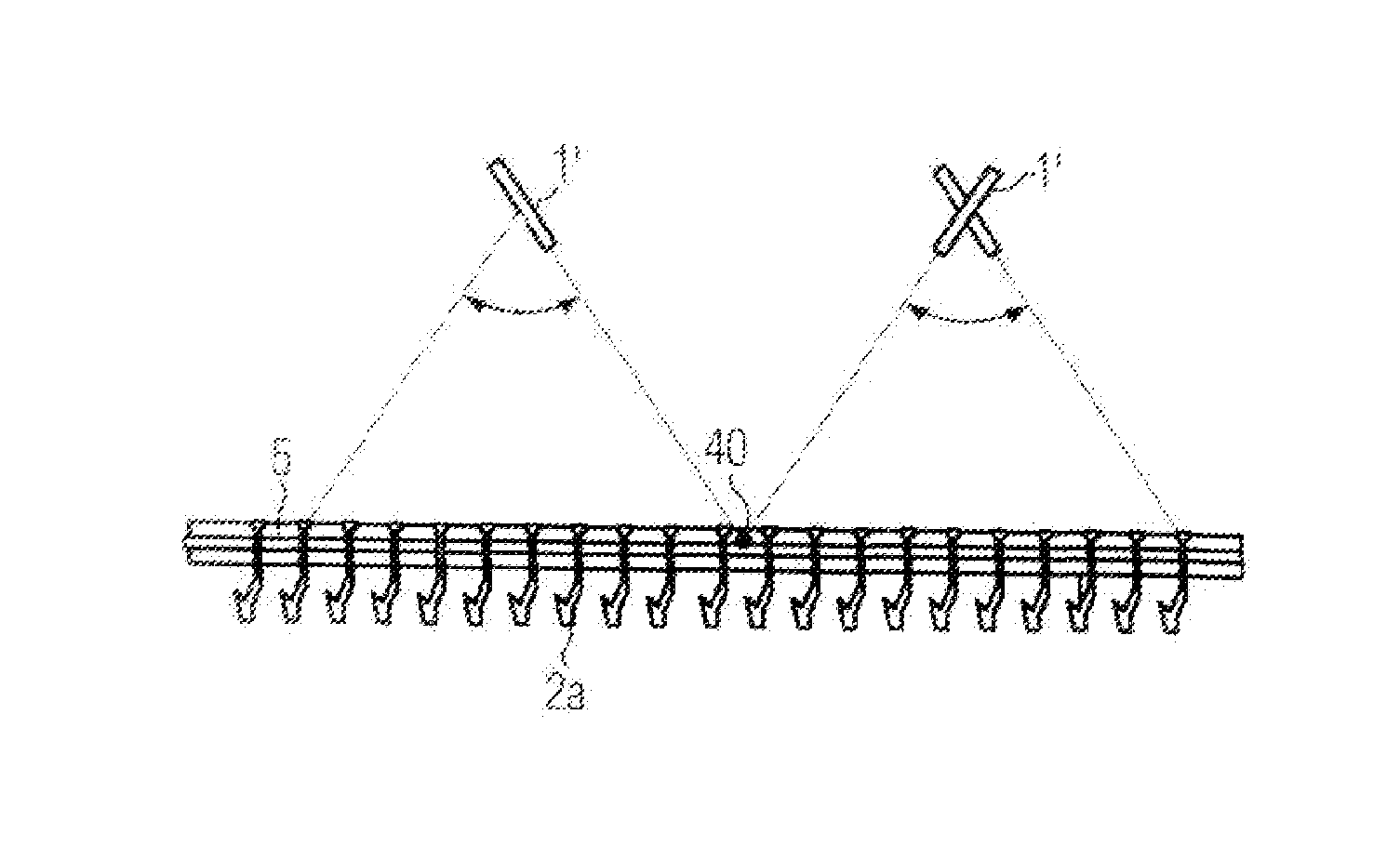

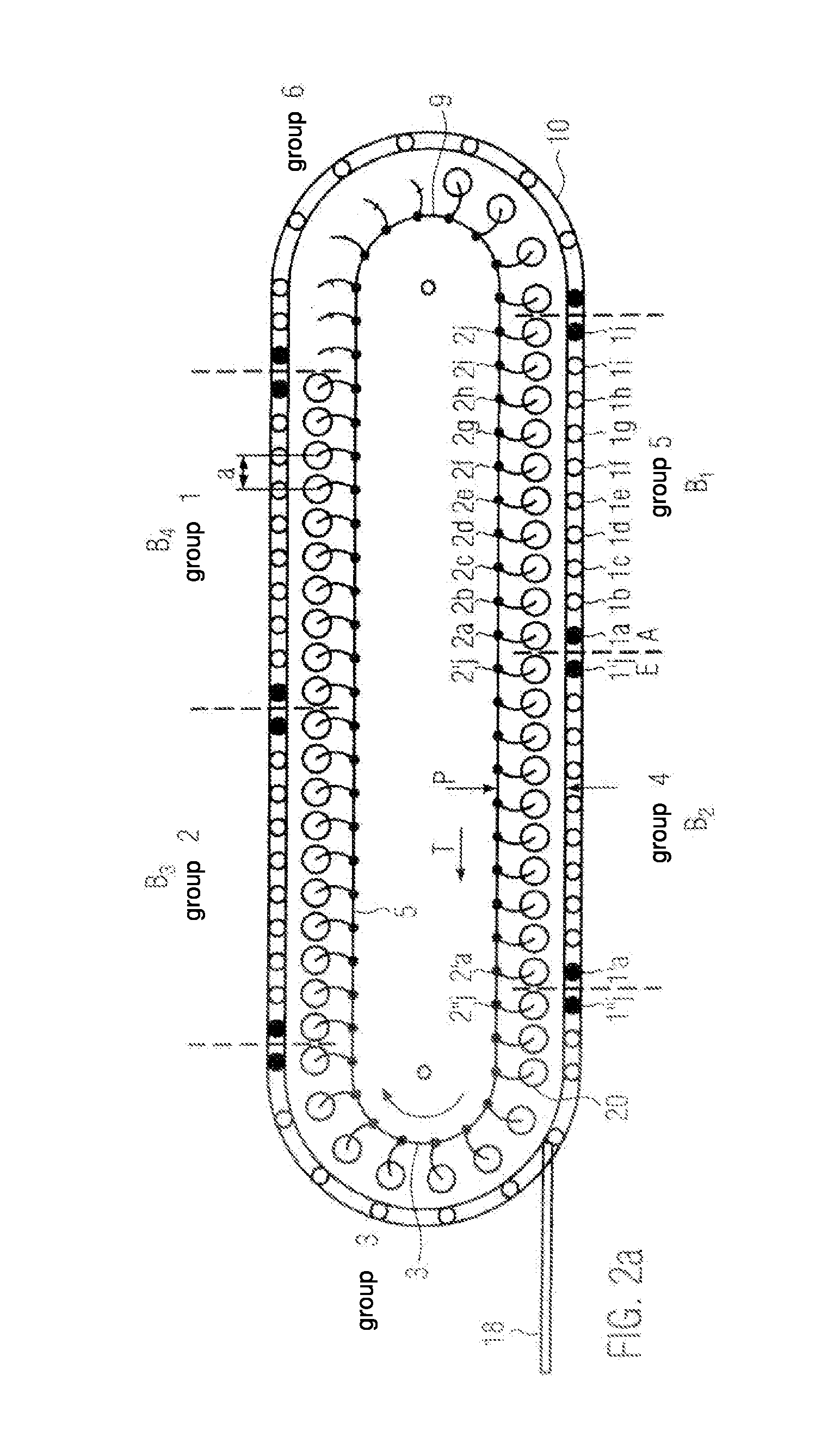

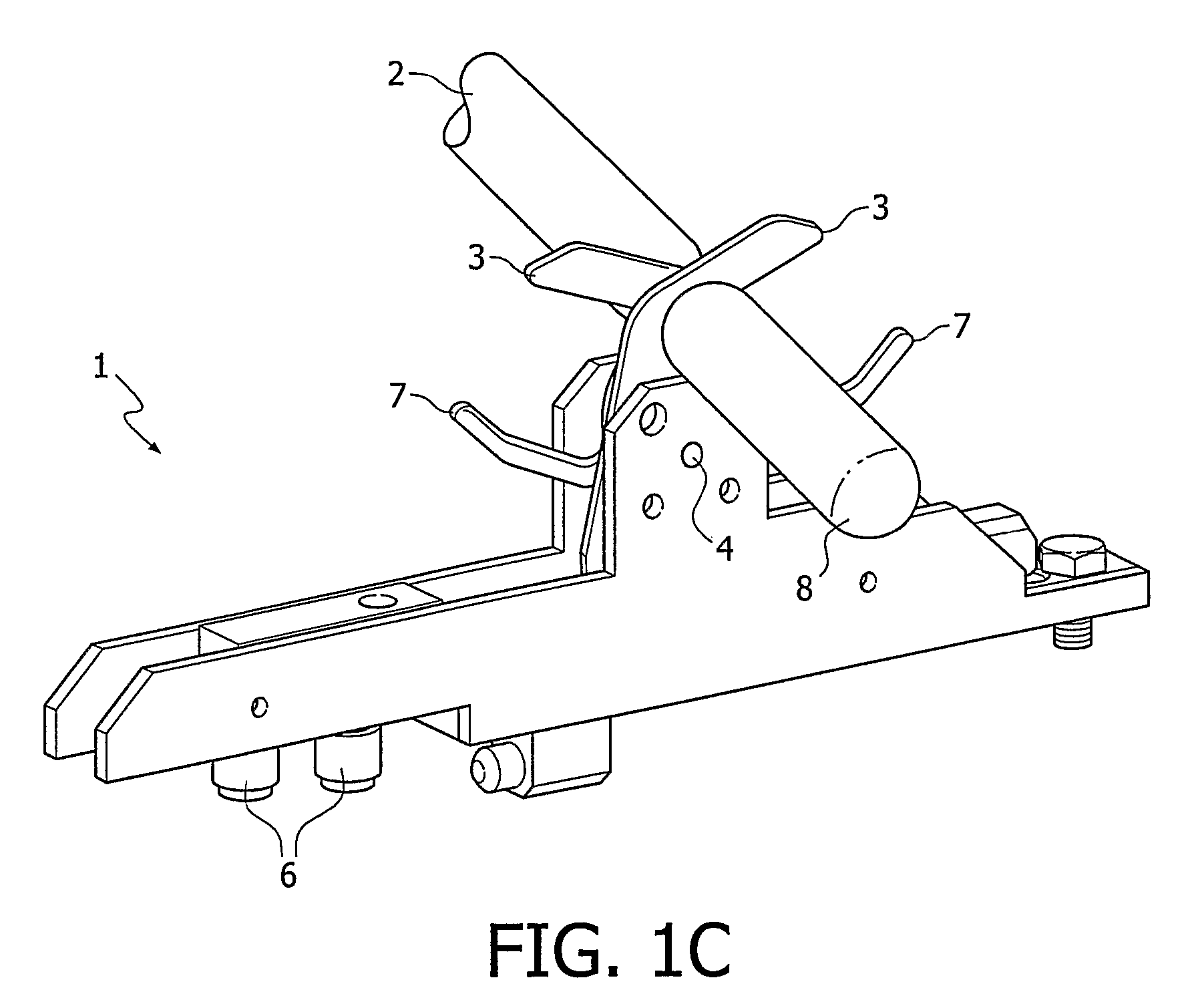

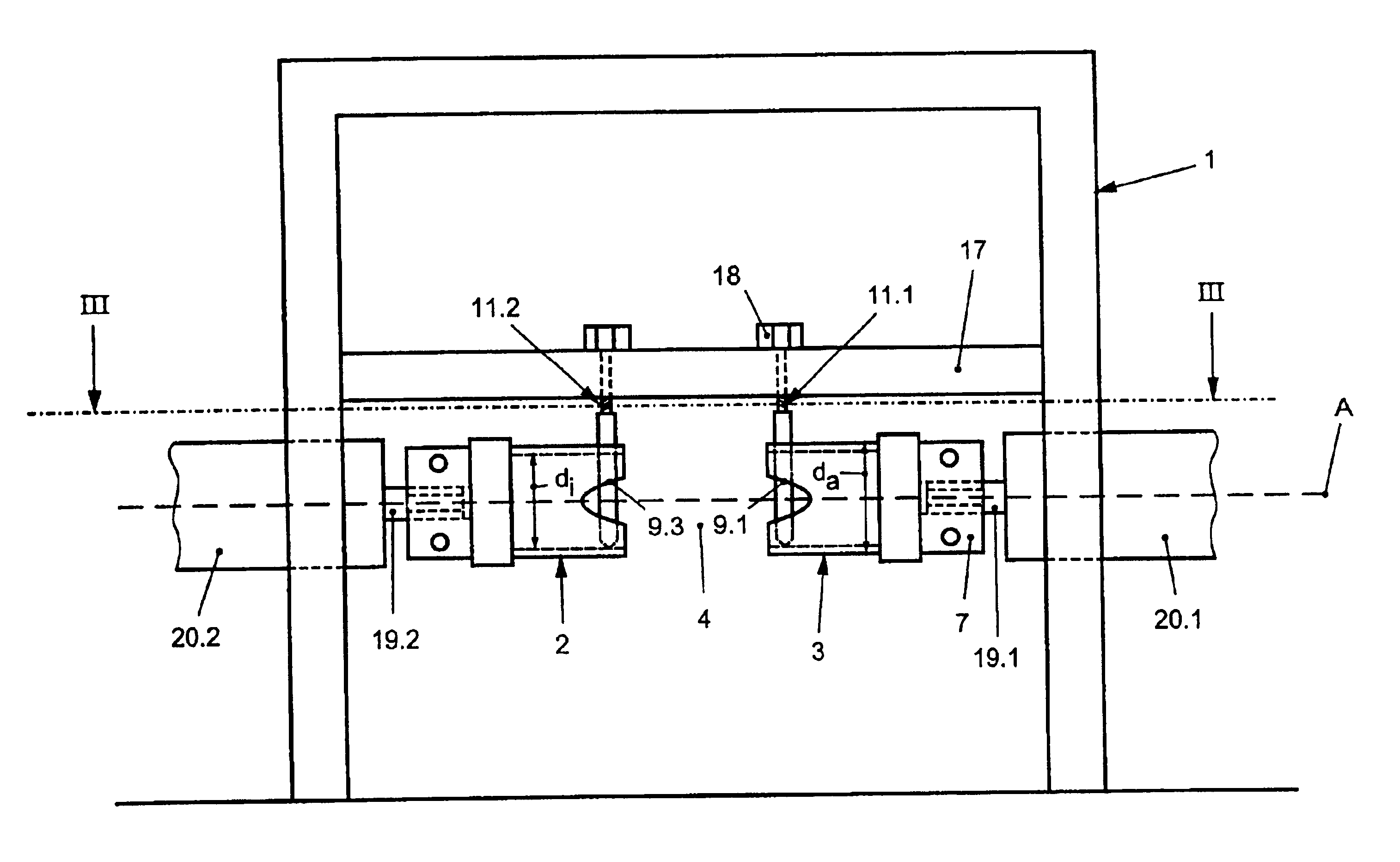

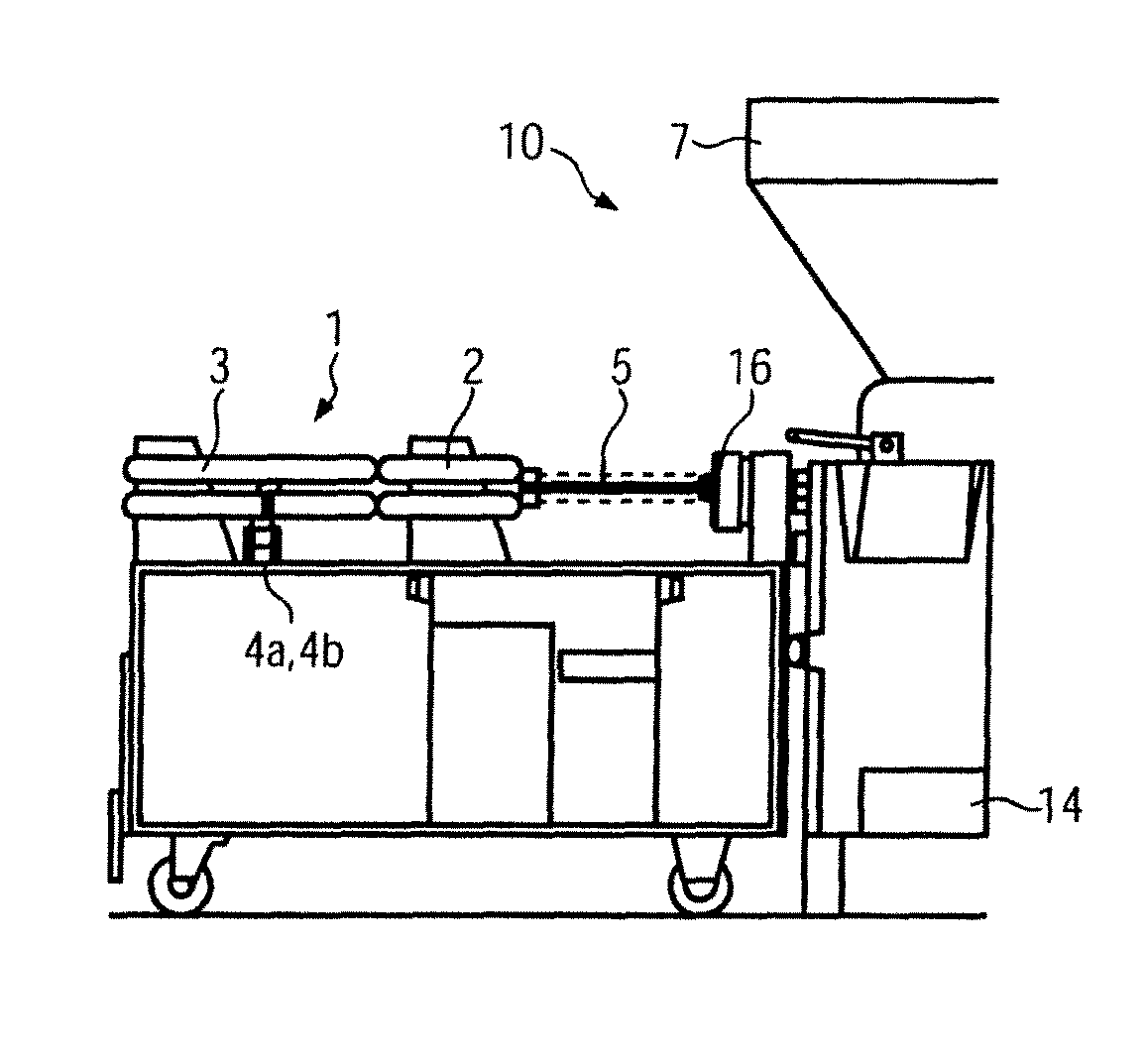

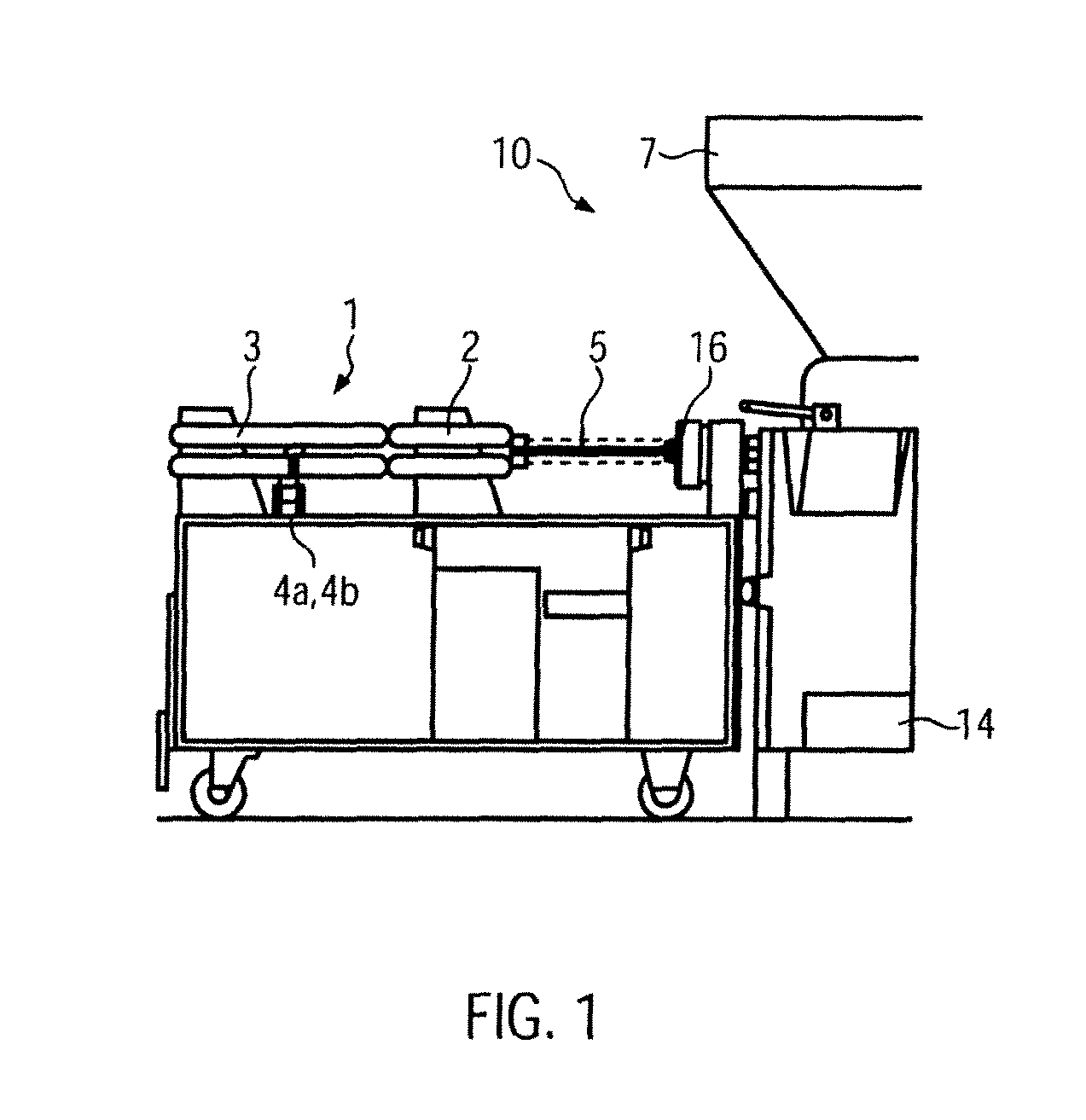

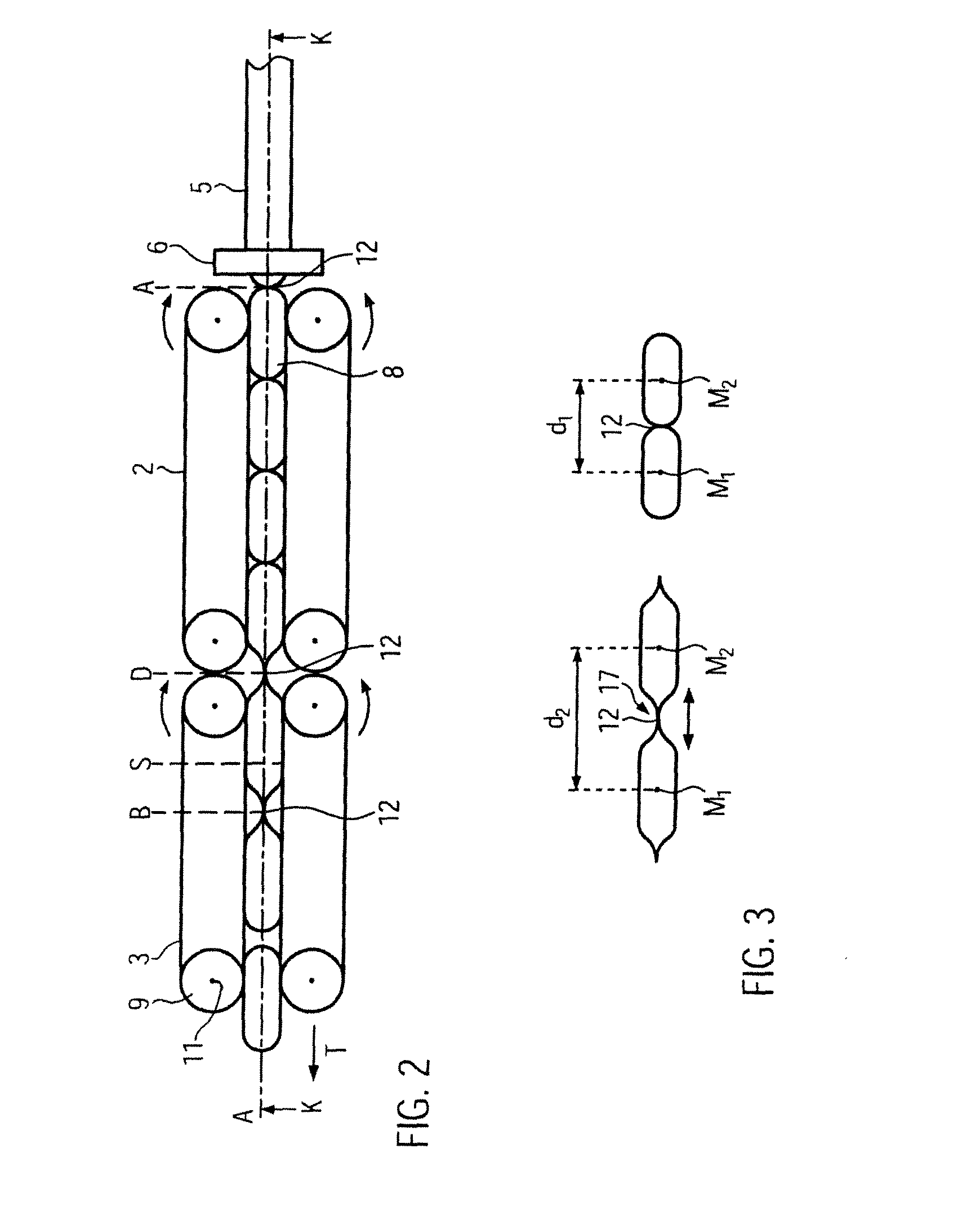

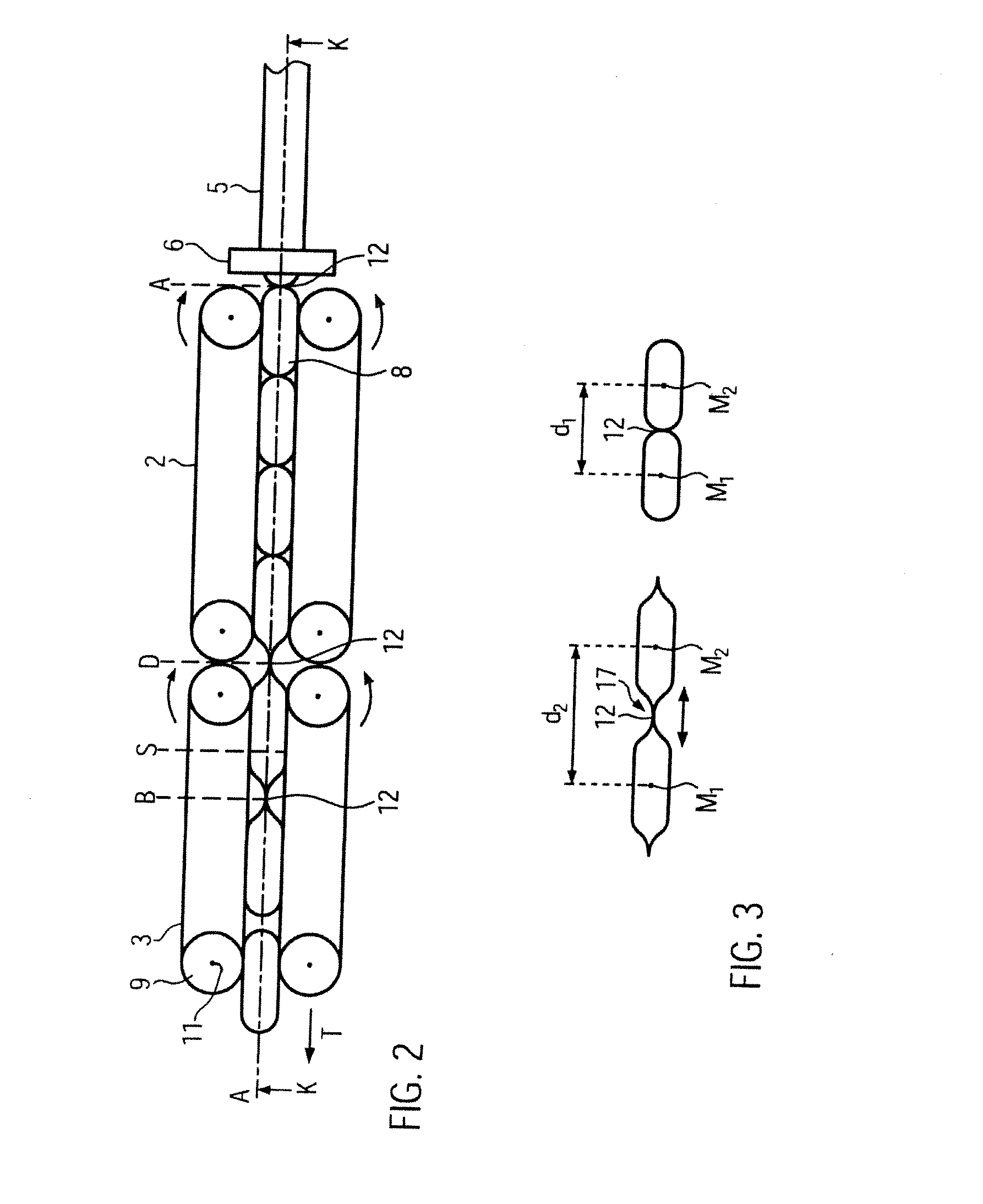

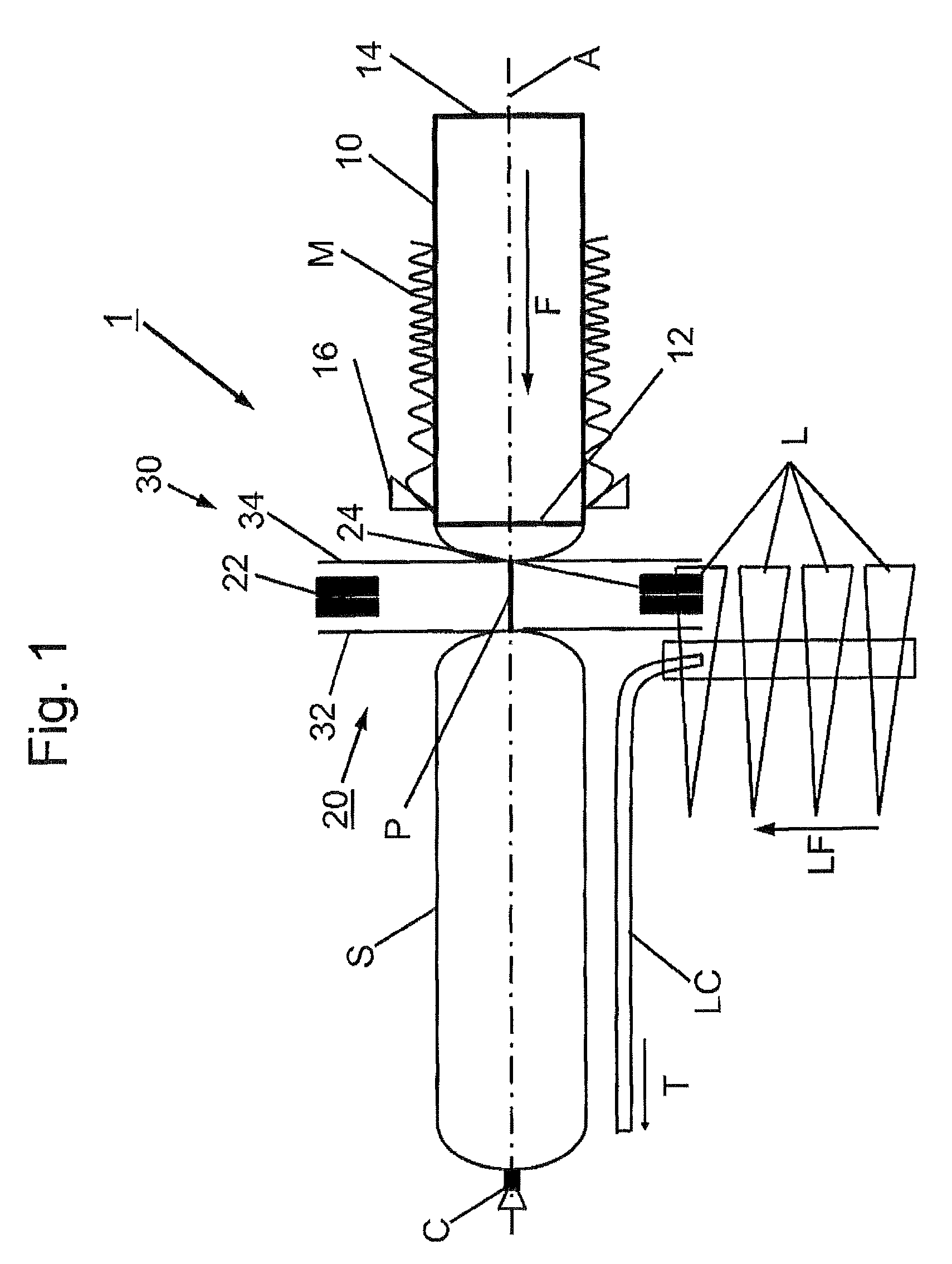

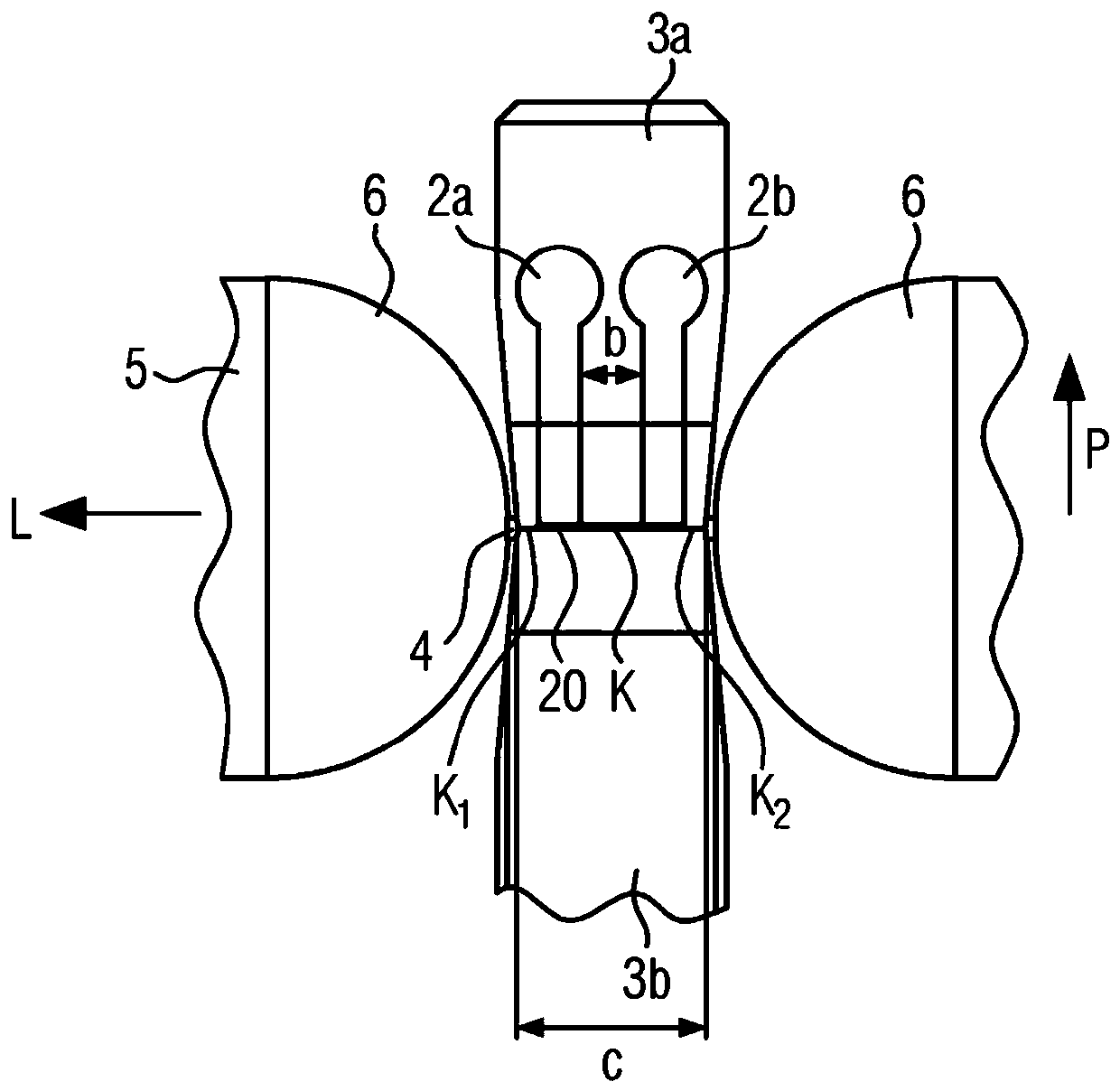

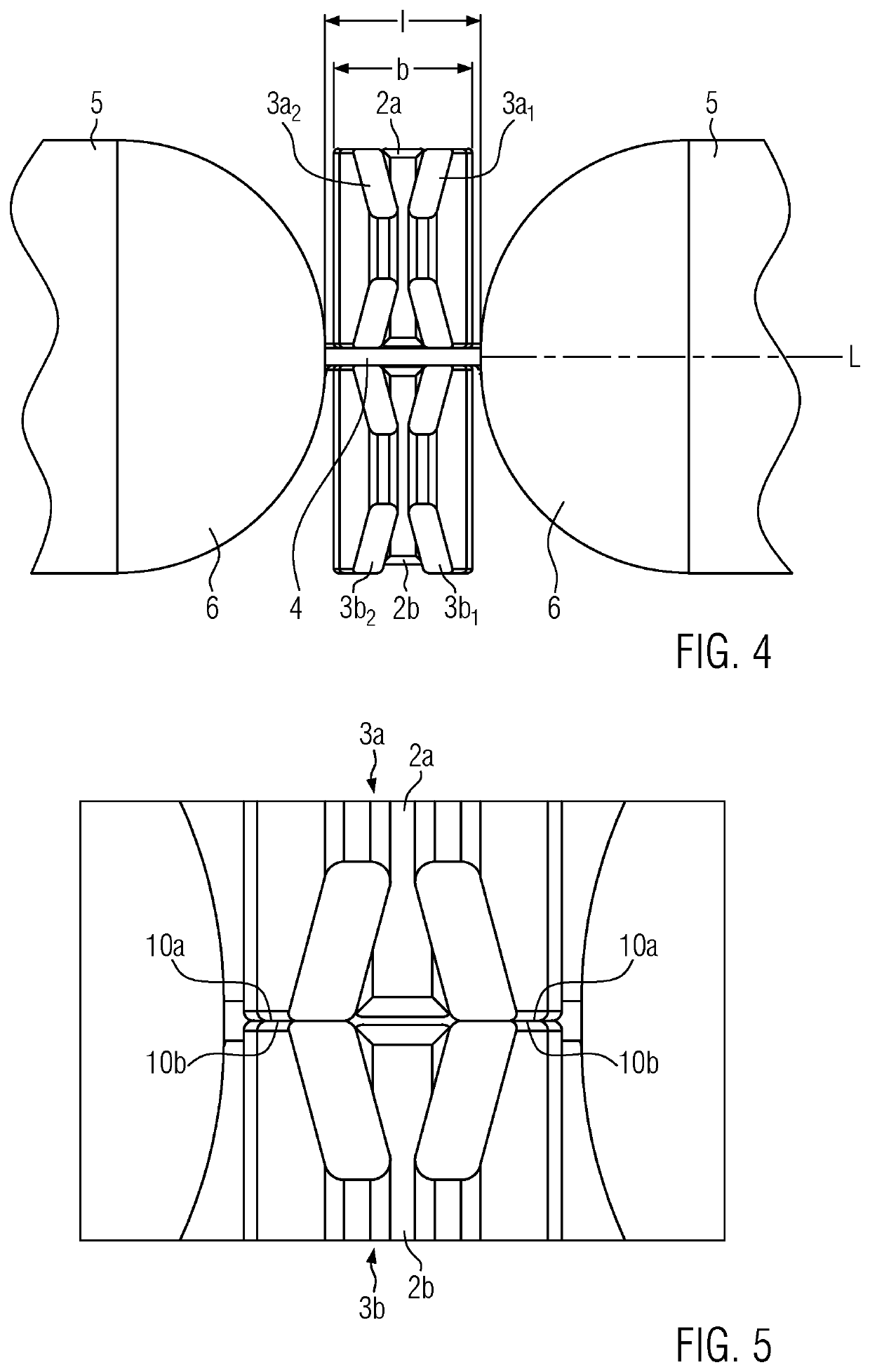

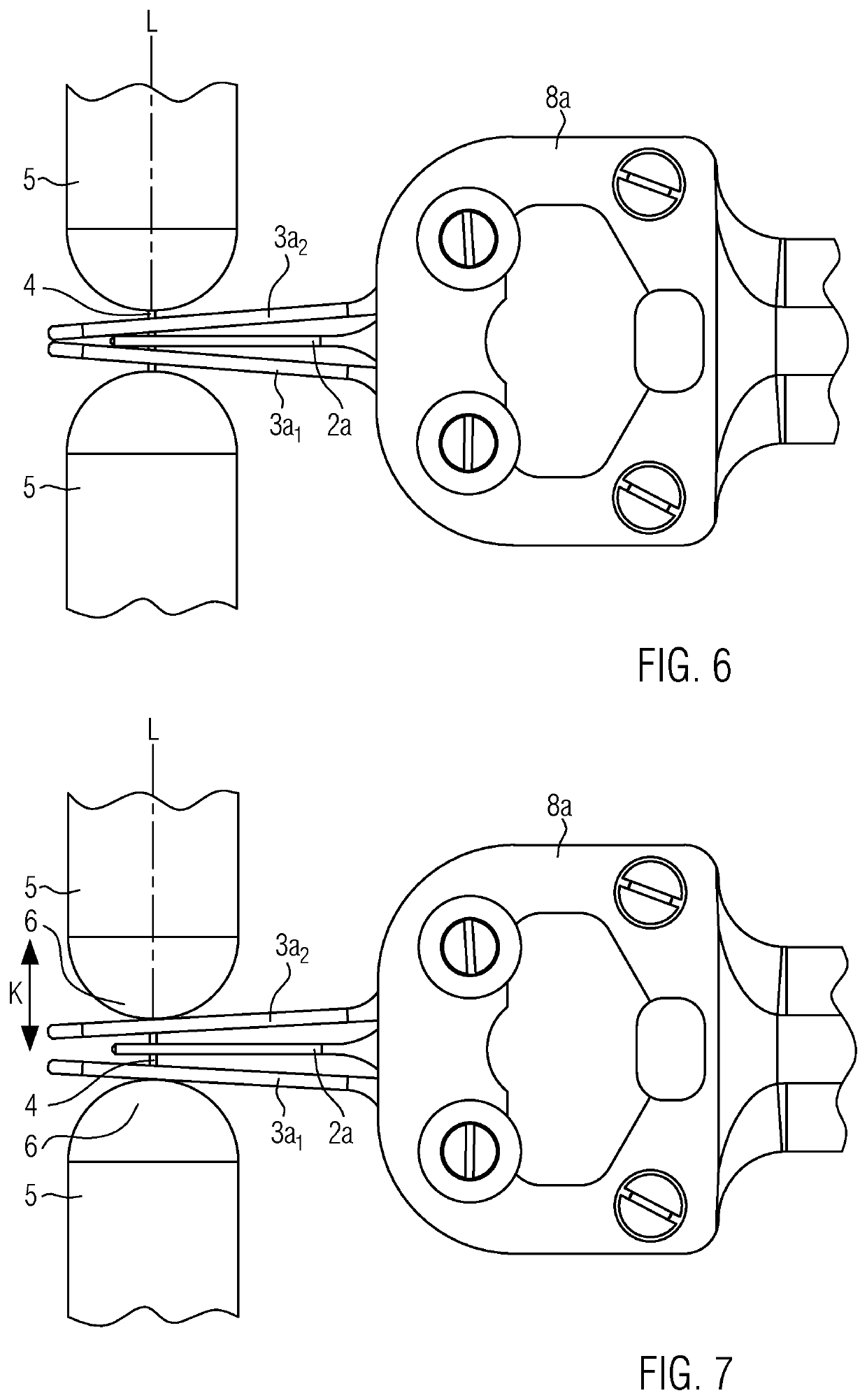

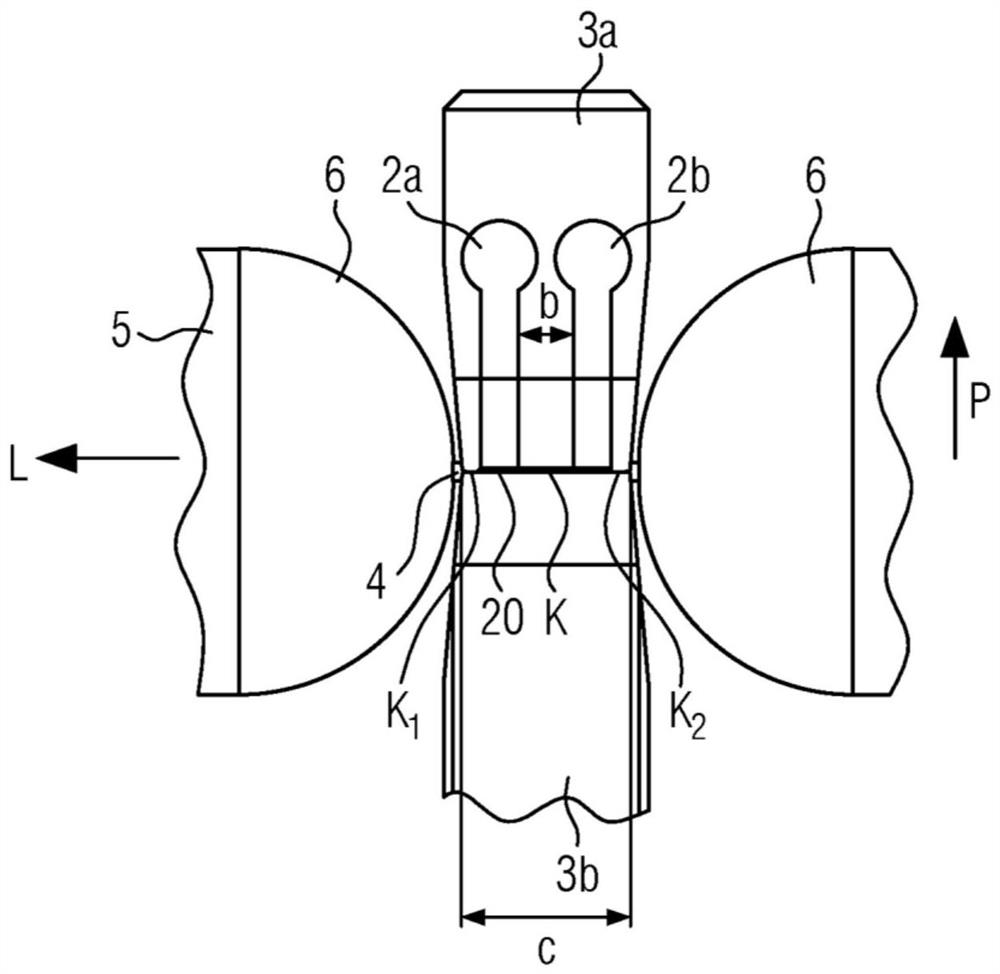

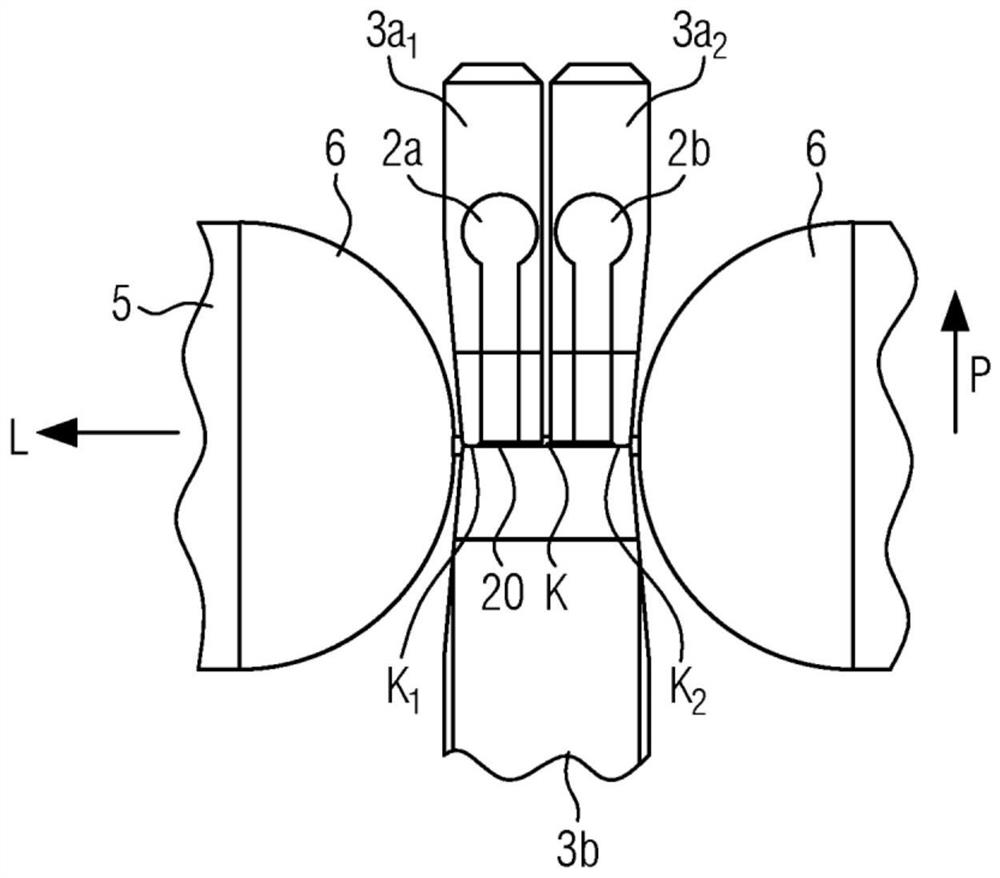

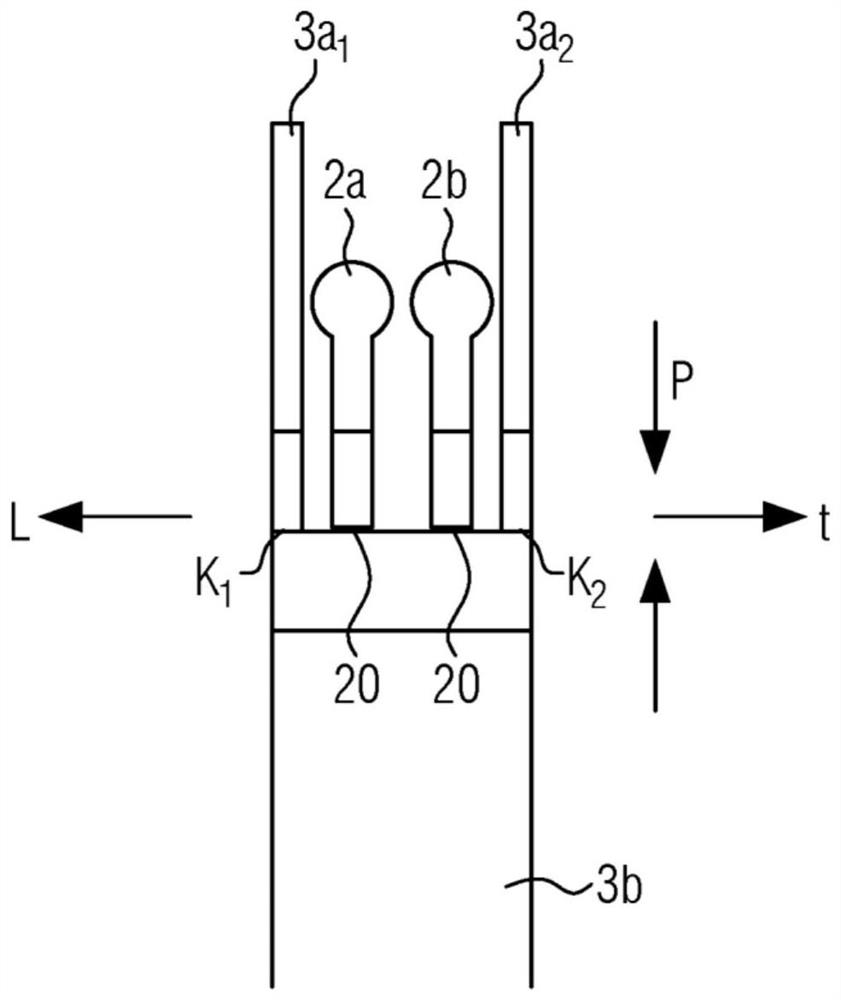

Method for phased separation of a sausage strand, separating element and assembly of separating elements

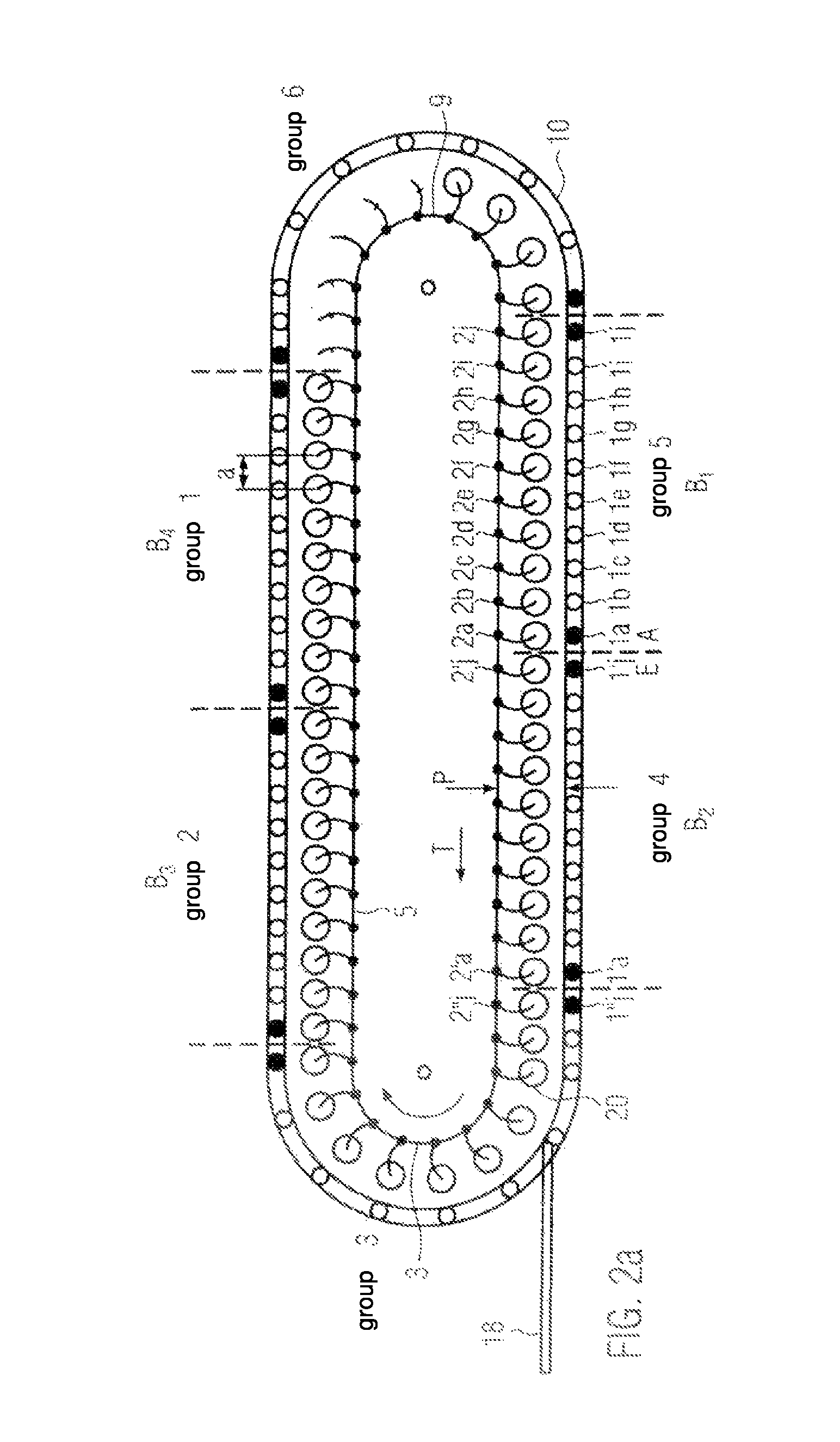

ActiveUS7625266B2Sufficient separating capacitySimple and inexpensive drivingLinked sausage separationSausage skin tying apparatusEngineeringControl manner

A method for phased separation of a sausage strand, a separating element for phased separation of a sausage strand, and an assembly of a plurality of such separating elements. In the production of sausages it frequently occurs that a sausage strand must be divided into smaller segments, and the result of this division is achieved in controlled manner by the present invention.

Owner:STORK TOWNSEND BV

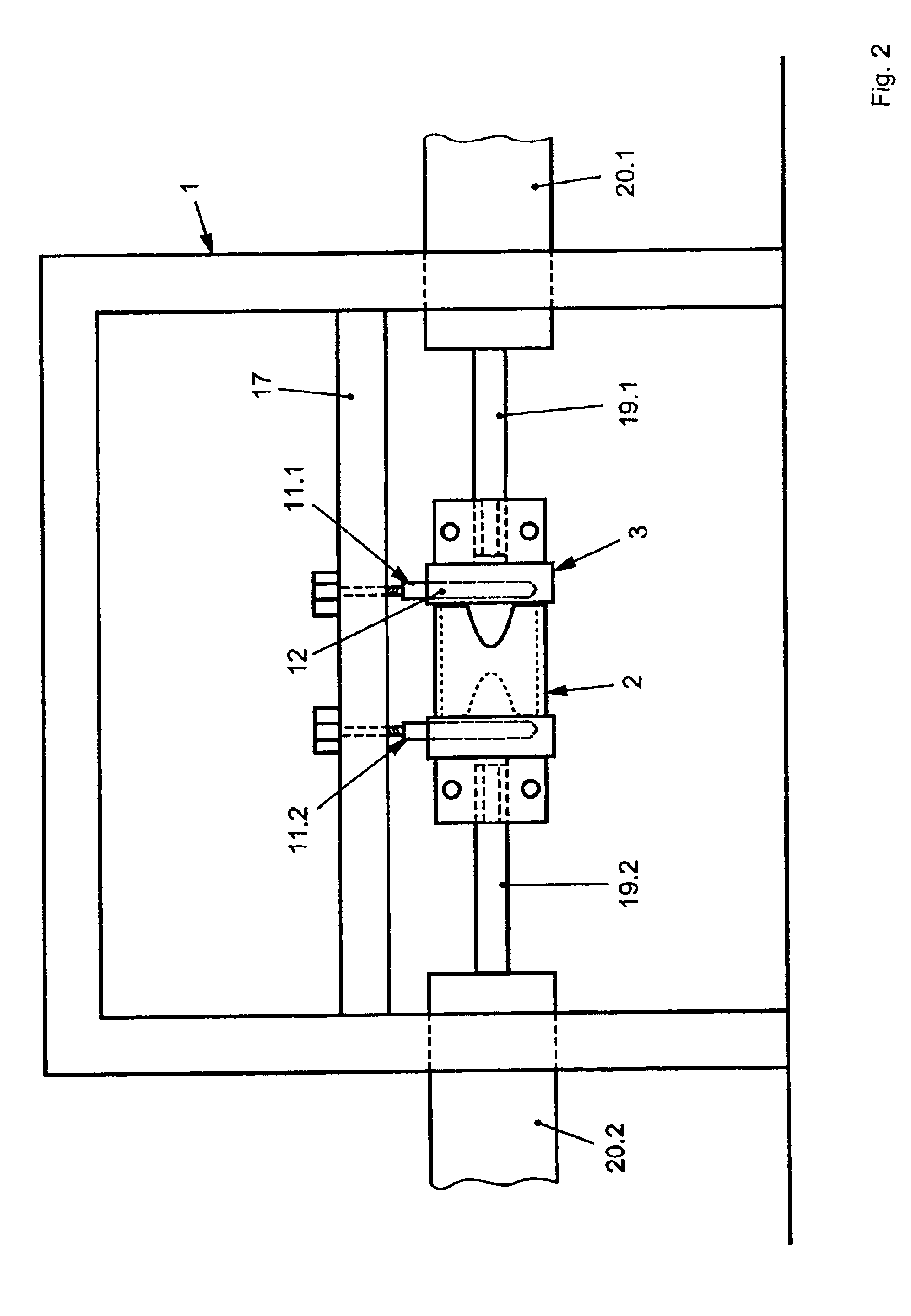

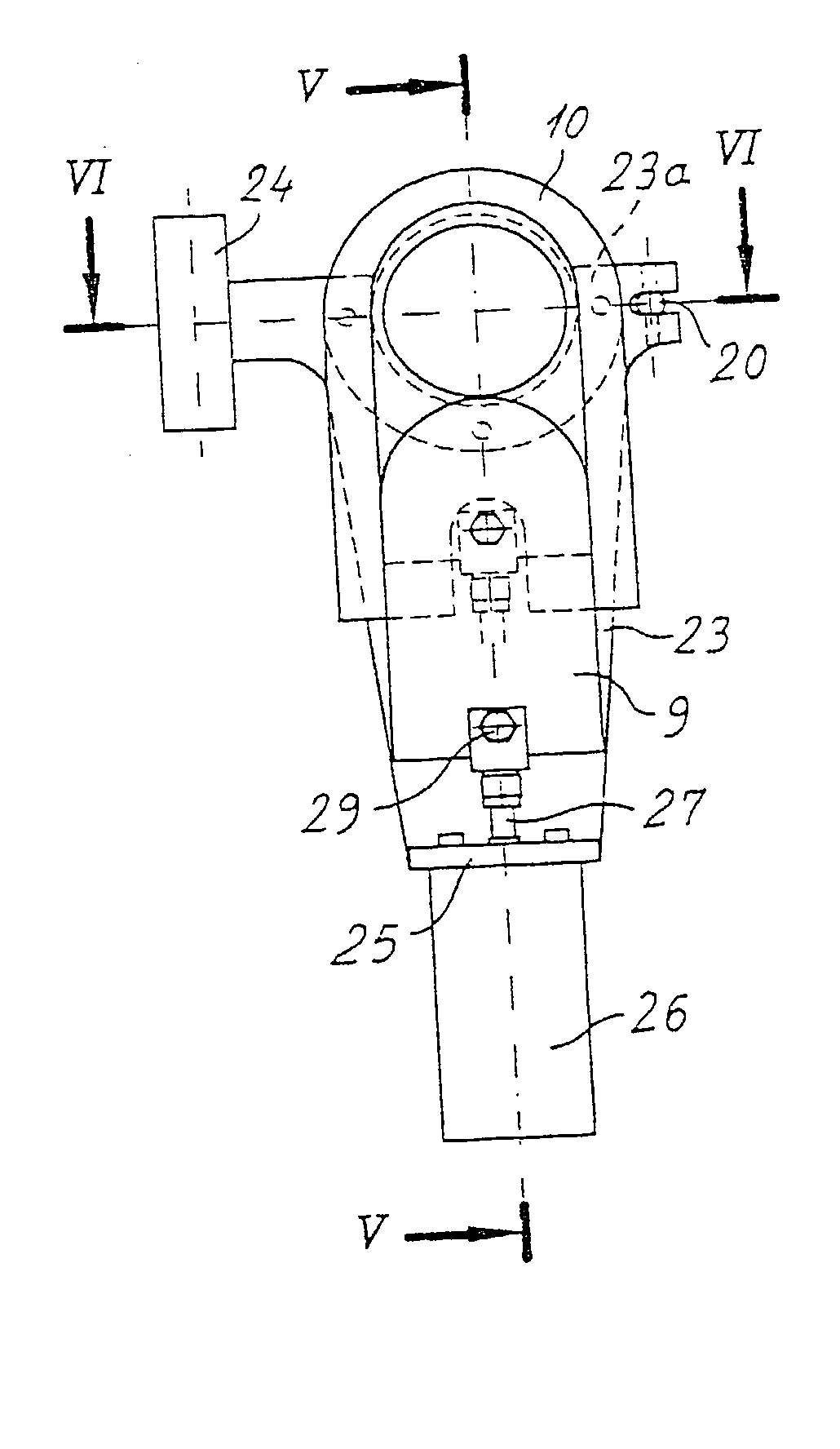

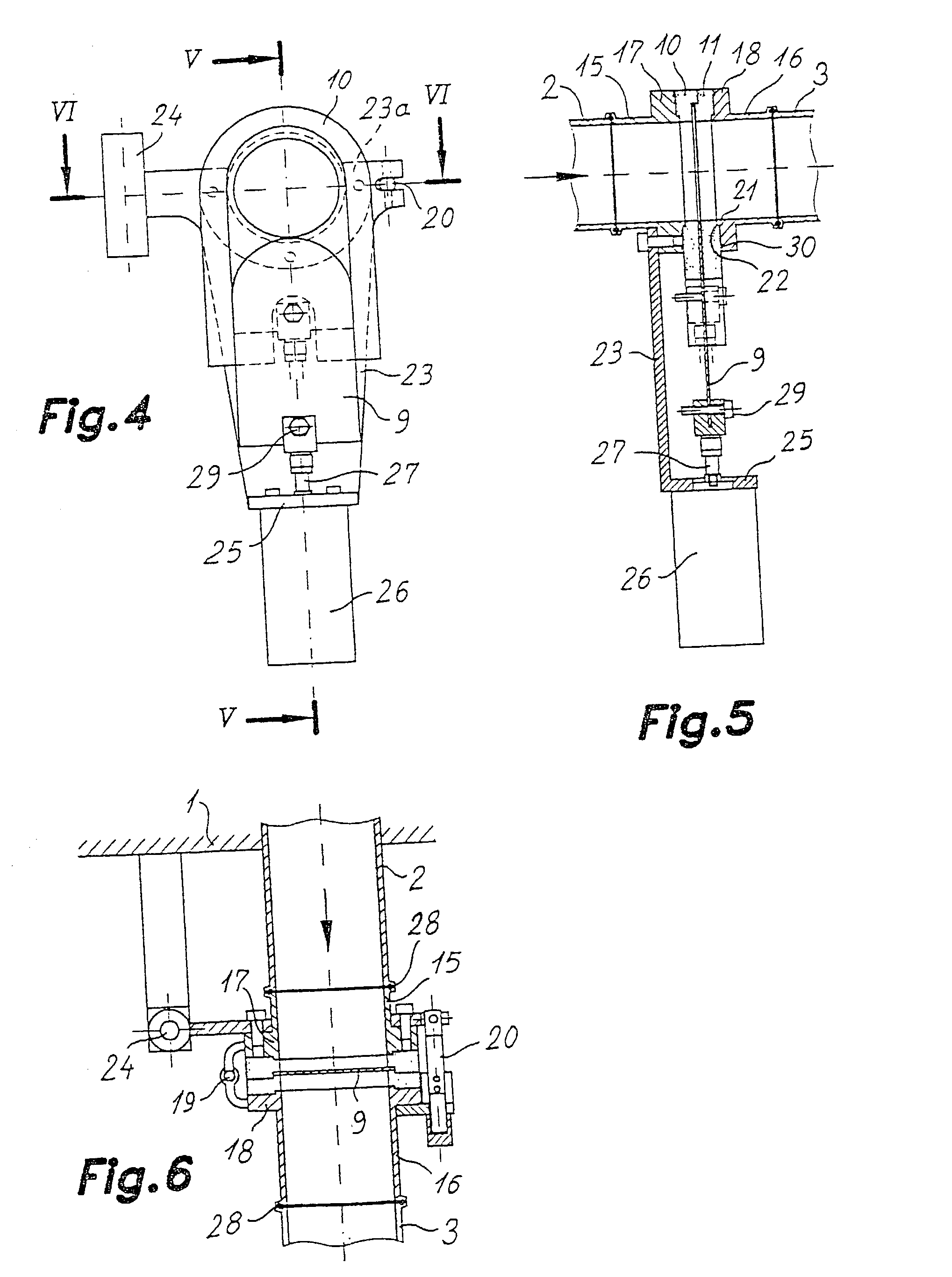

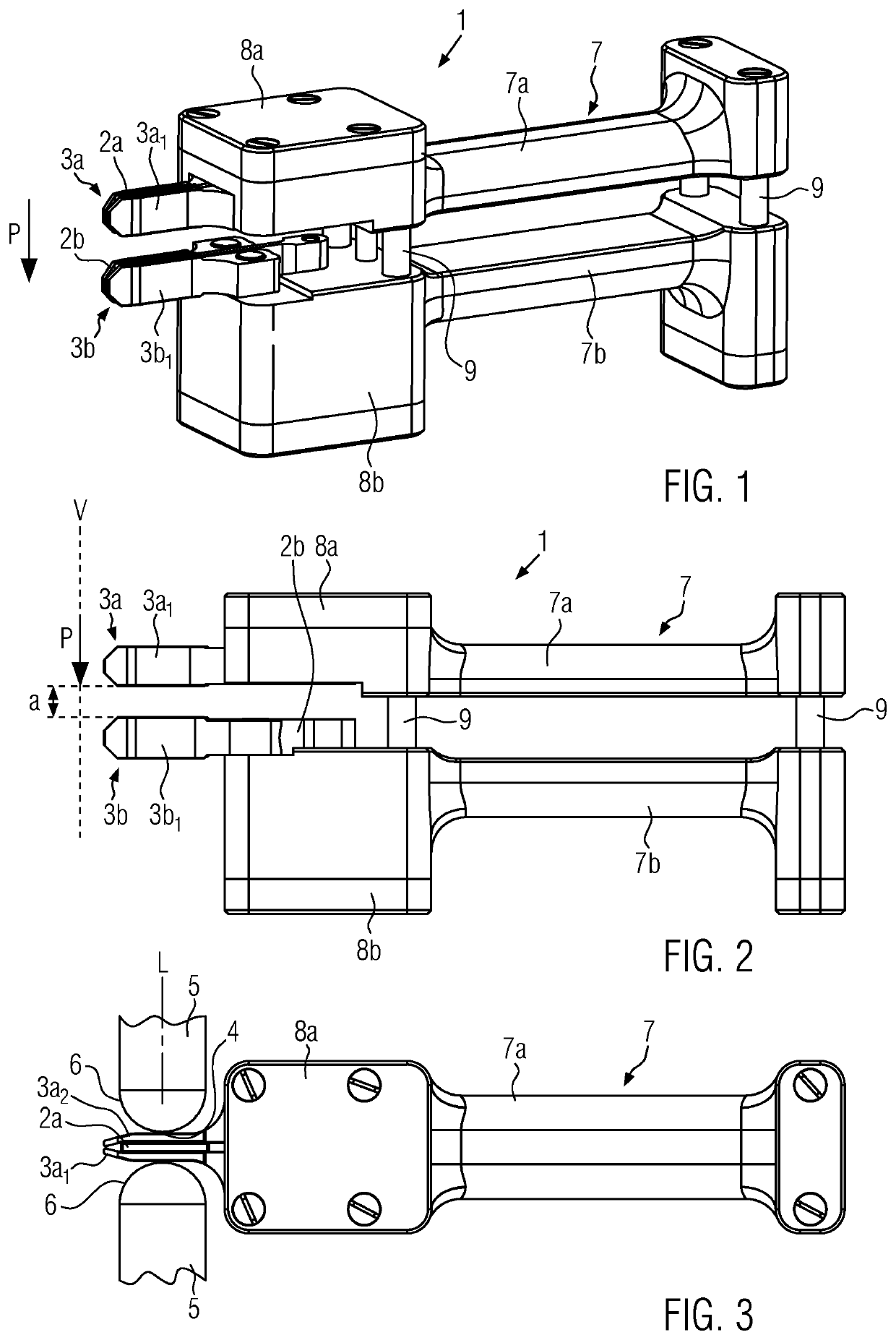

Apparatus for severing the link between two sausages

InactiveUS6932689B2Improve guidanceLinked sausage separationSausage skin tying apparatusEngineeringMechanical engineering

In an apparatus for severing a link between two sausages, in particular for cutting out a clip at a twisting point by means of a cutting device which has a cutting edge, comprises at least two cutting edges lying opposite one another and movable toward one another when the twisting point is located between them.

Owner:STIMPFL & GIESELER SONDERMASCHEN F LEBENSMITTELIND

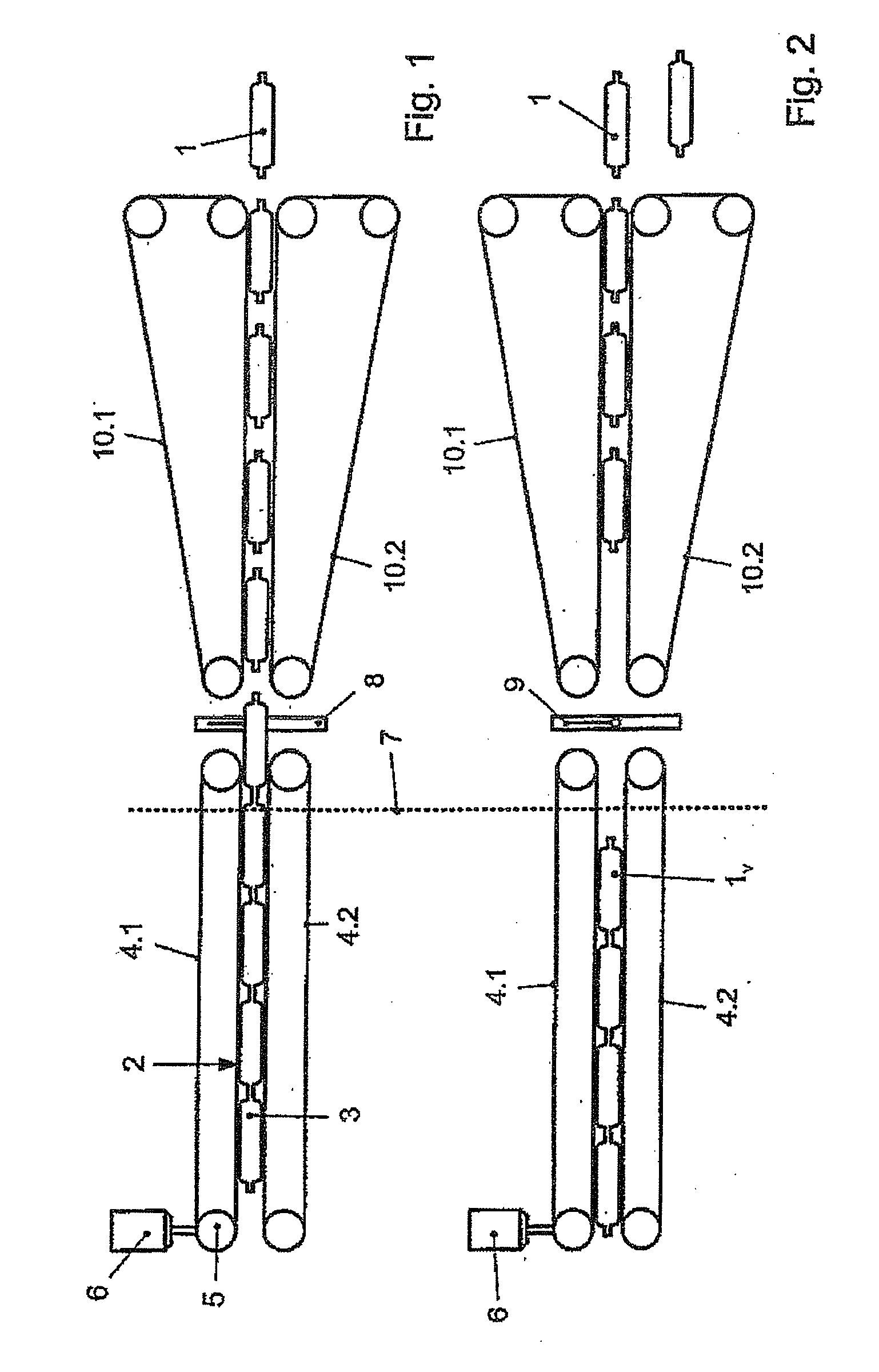

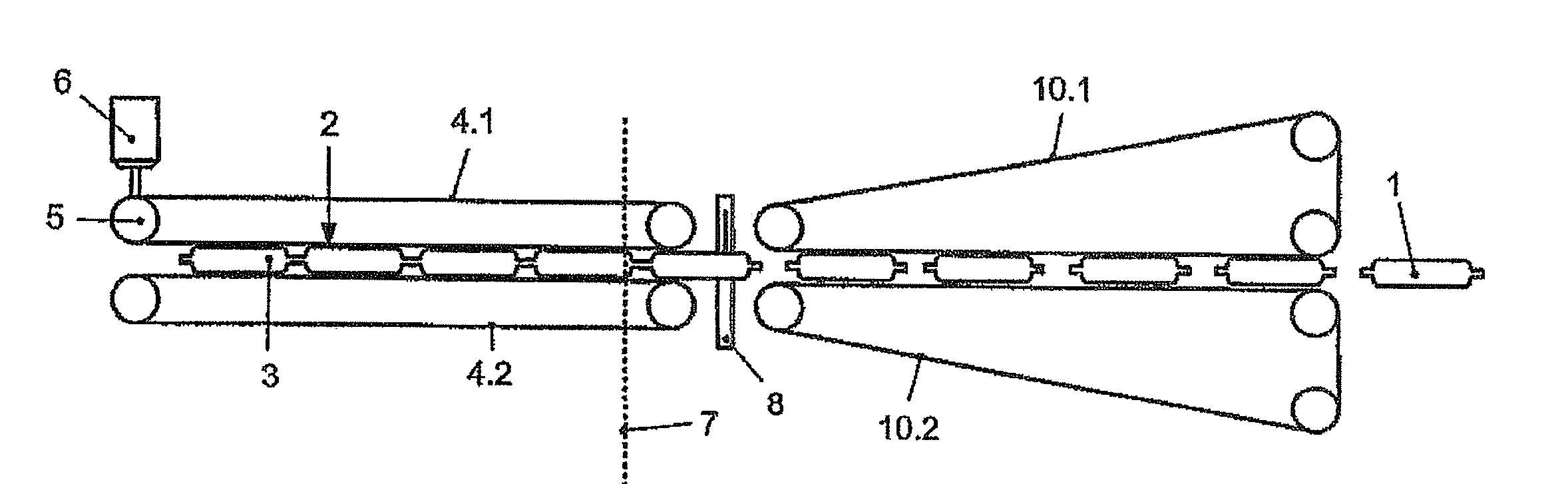

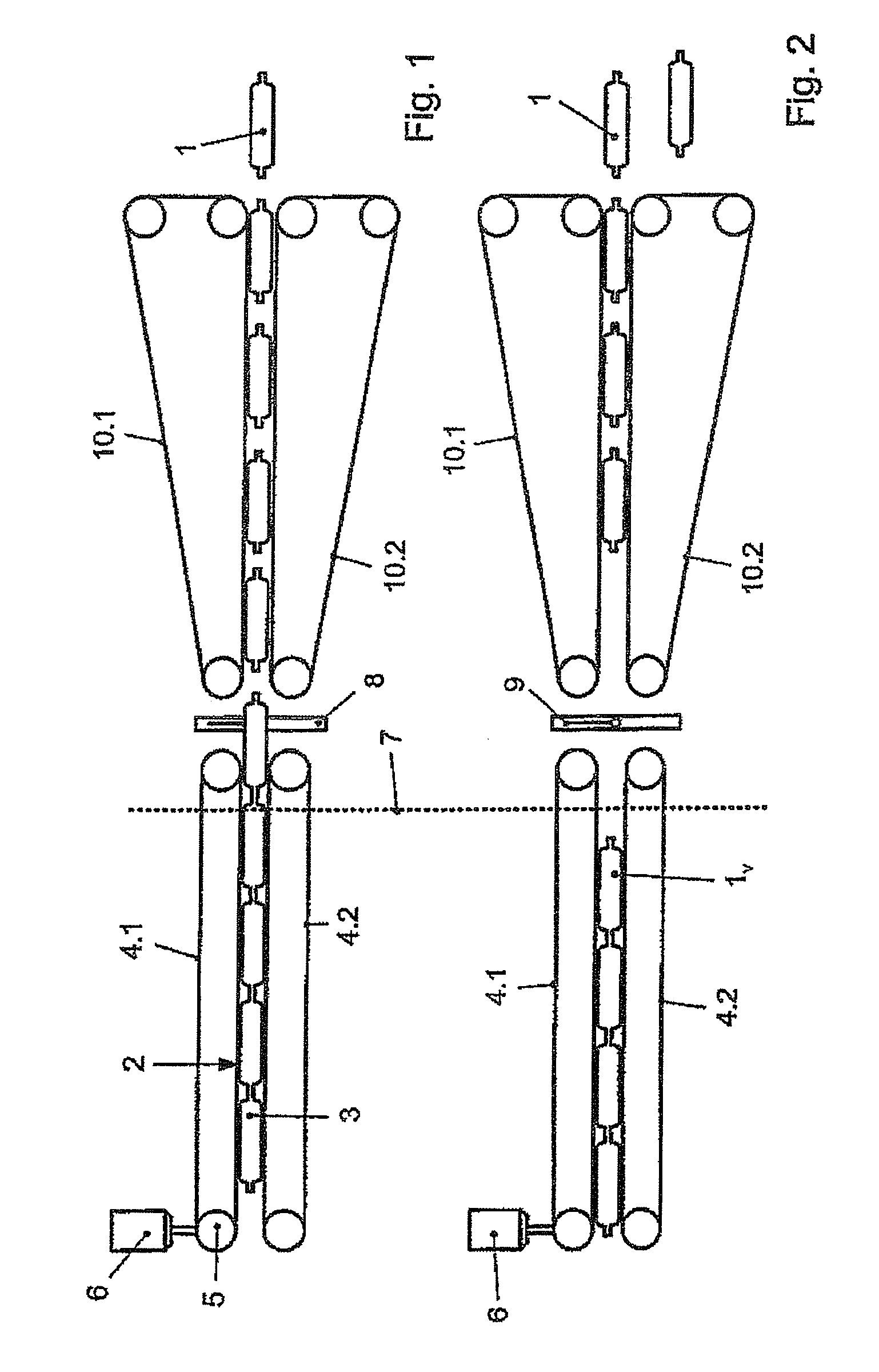

Process and device for cutting sausage

A process for cutting sausages from a sausage link by a cutting device to which the sausages in the sausage link are conveyed together and a cutting site between two successive sausages is recognized by a sensor device, the sausage link being retracted with the front most sausage behind the sensor device after a predetermined number of sausages has been cut. This permits a specific indexing of the sausages in the sausage link after the sensor device and prevents bottlenecks between the cutting machine and the packaging machine.

Owner:STIMPFL CHRISTOF

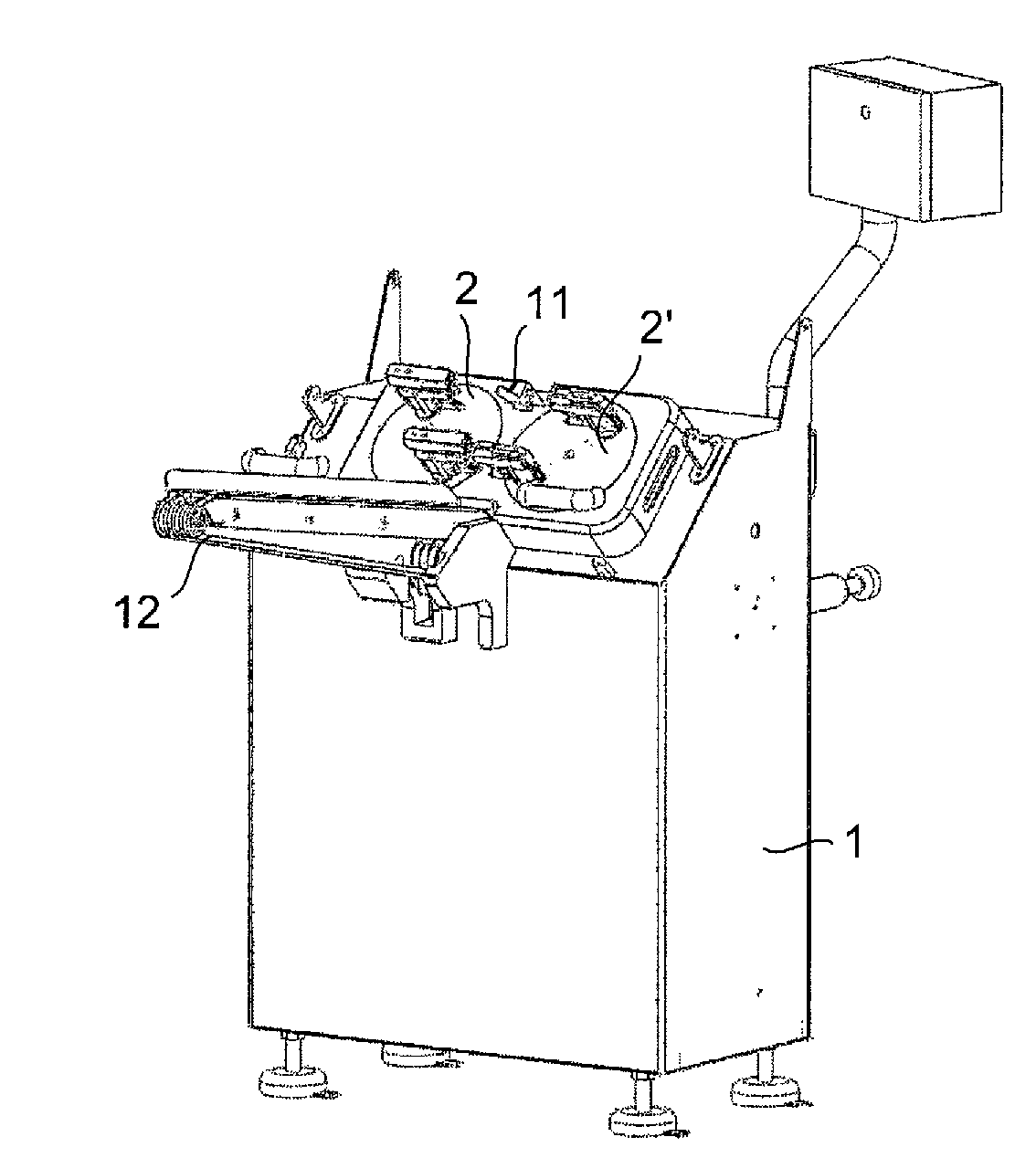

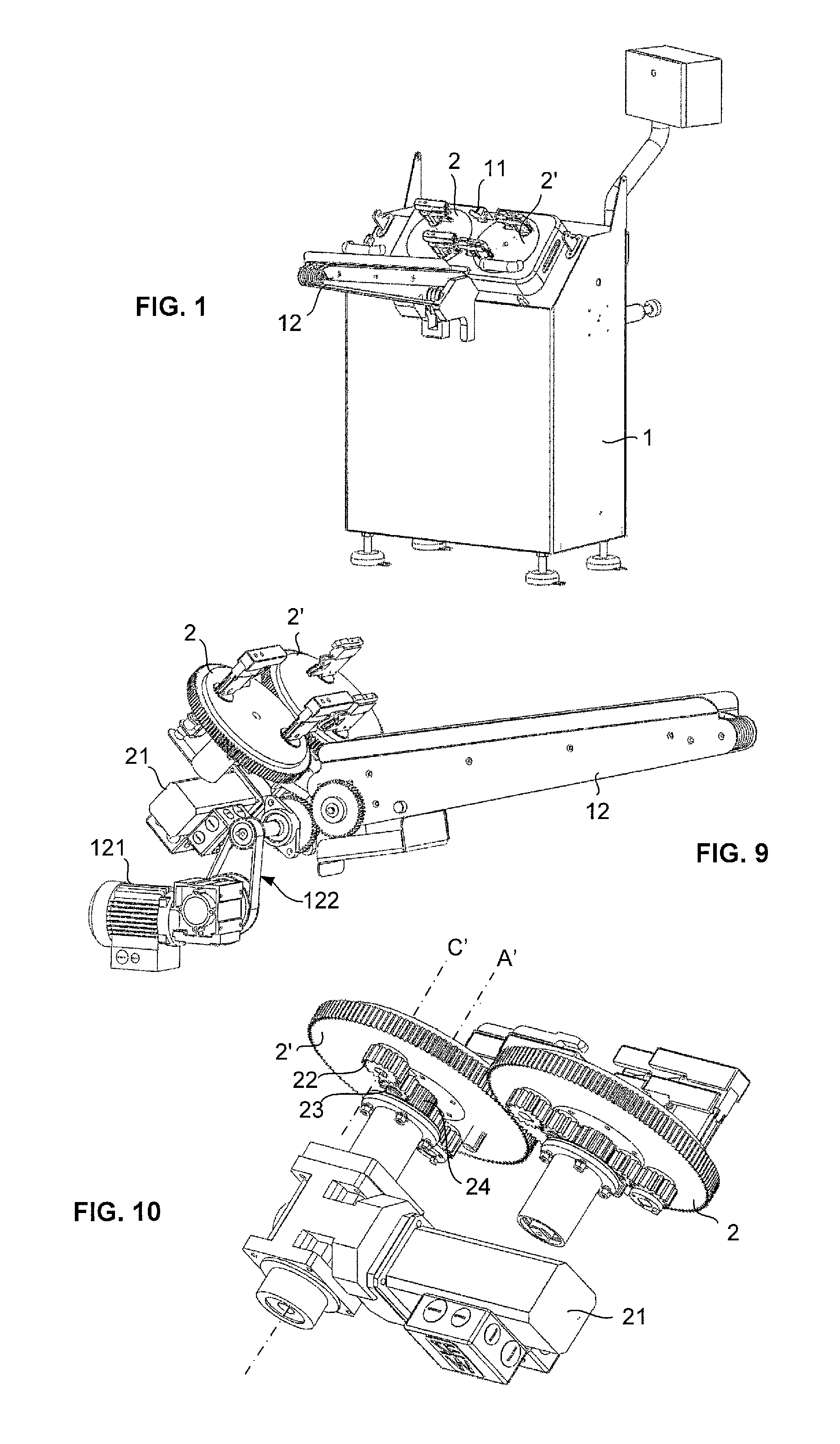

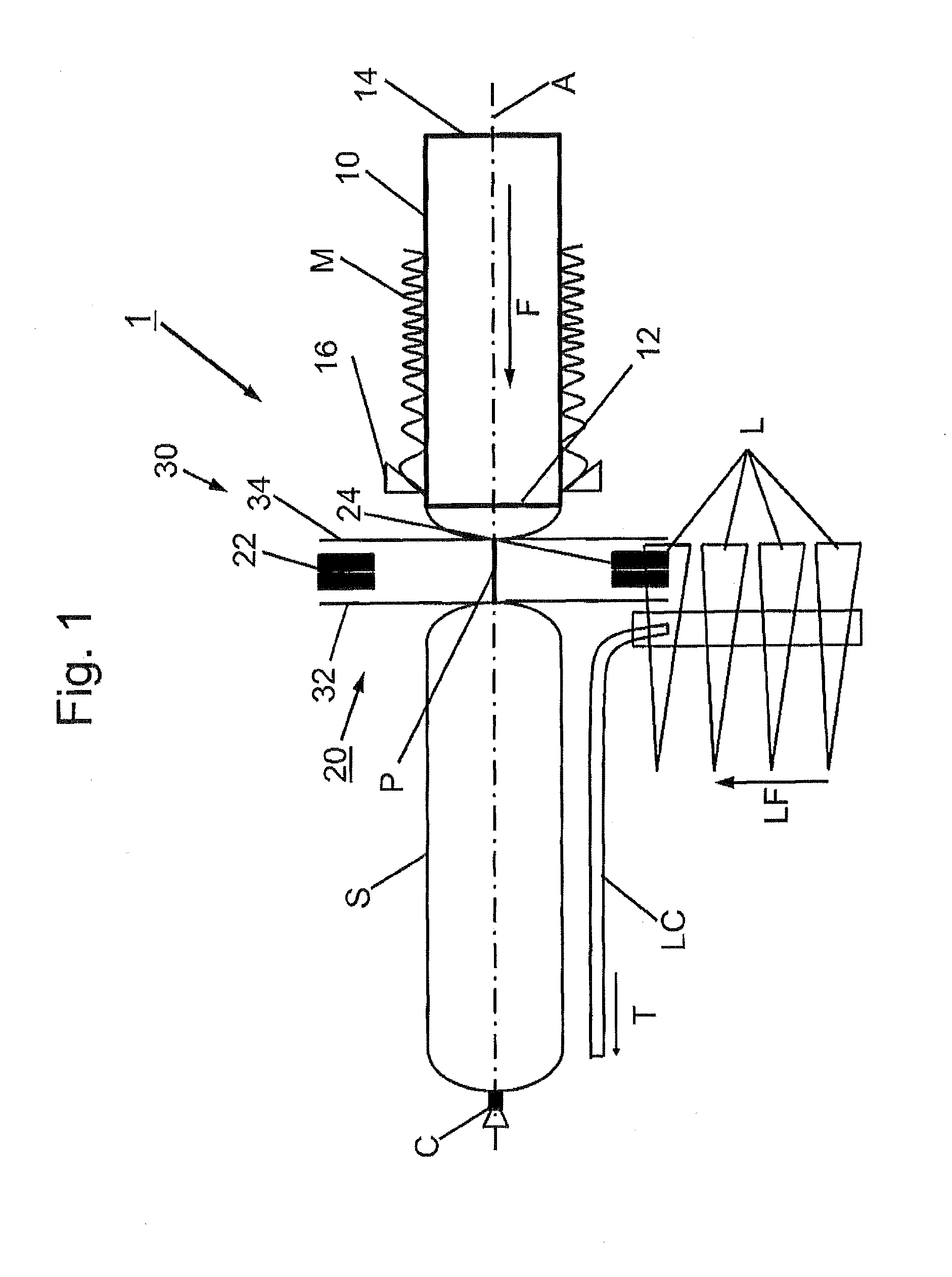

Suspension apparatus and method for suspending sausages, in particular sausage chains

ActiveUS8795038B2Easily identifiableAccurate and reliable operationMeat/sausage hanging-upLinked sausage separationEngineeringMechanical engineering

Owner:ALBERT HANDTMANN MASCHFABRICK

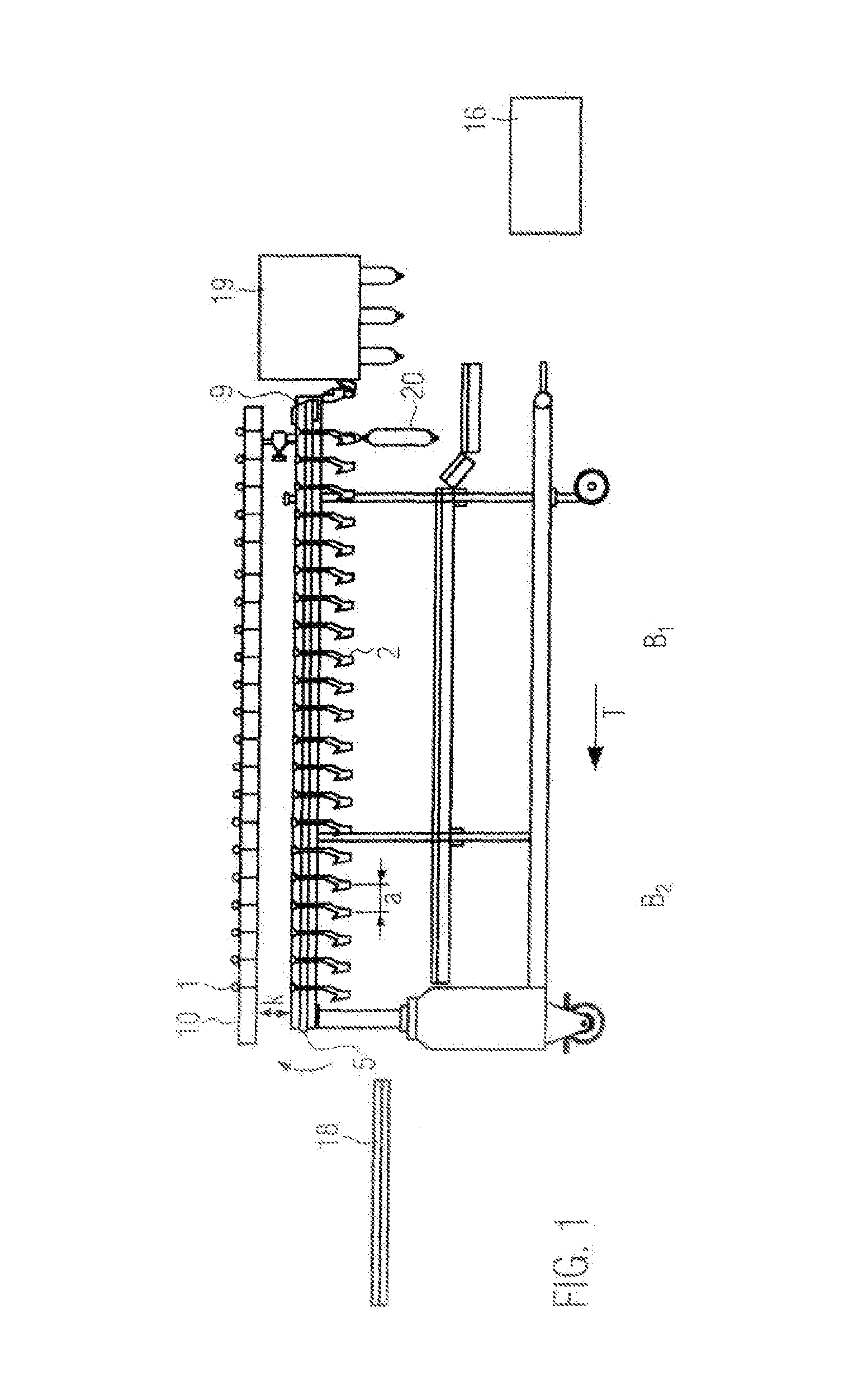

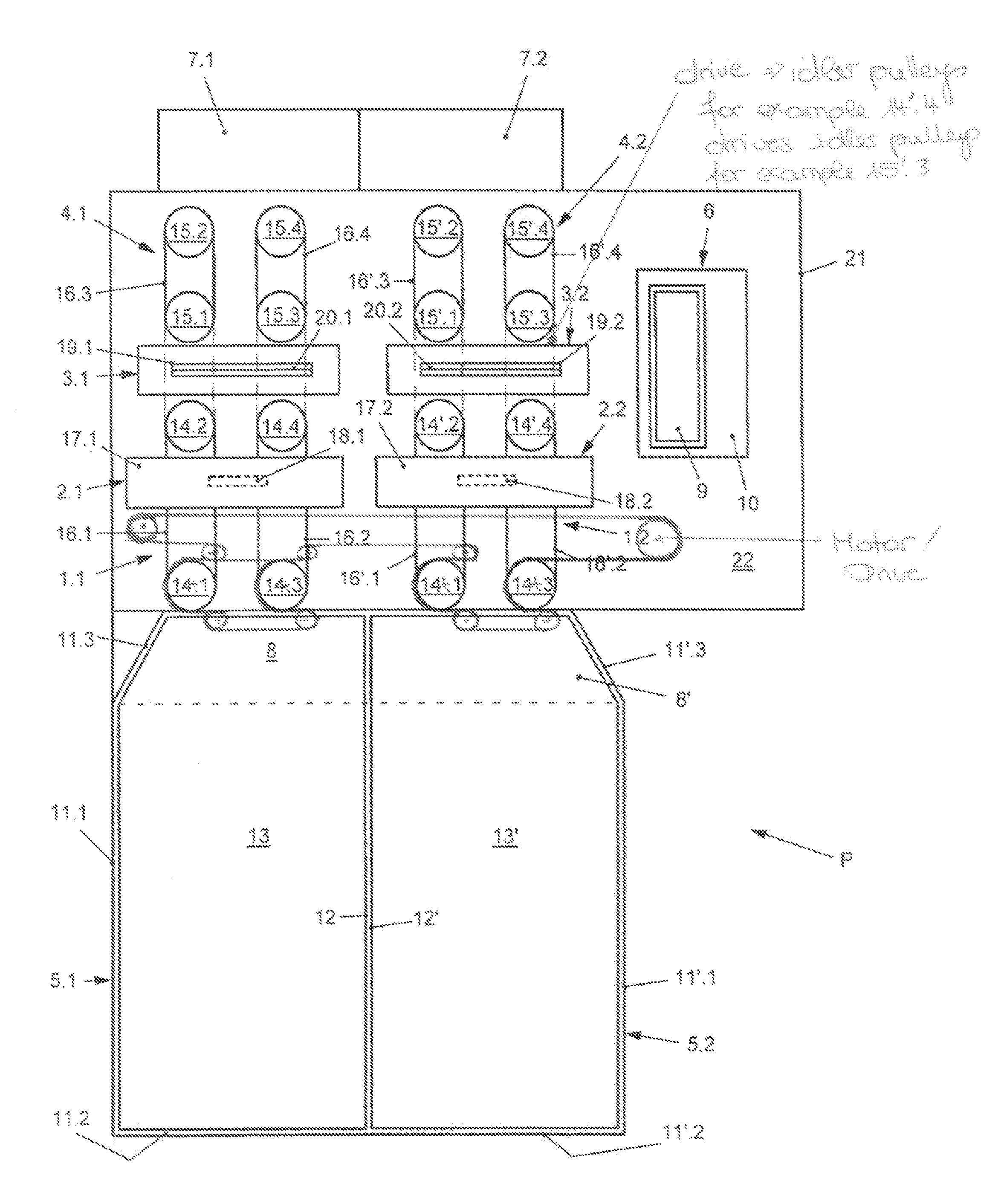

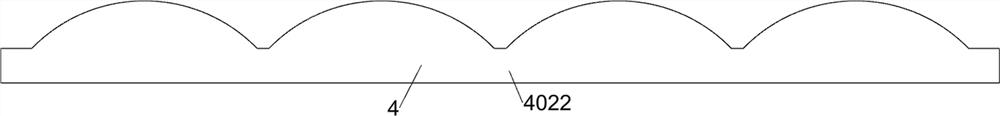

Production line for continuously cutting off and packing meat sausages

ActiveCN108077387AUniform lengthImprove work efficiencyPackaging meatLinked sausage separationProduction lineEngineering

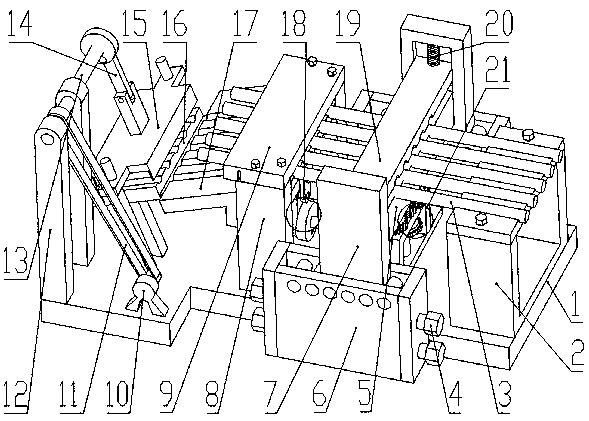

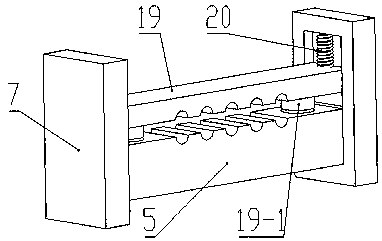

The invention provides a production line for continuously cutting off and packing meat sausages. The production line also comprises a first supporting plate, a cutting off device and a packing device,wherein the first supporting plate is fixedly arranged on the upper end surface of a bottom plate and used for supporting the meat sausages to move; the cutting off device which is arranged on the front side of the first supporting plate and can cut off the meat sausages; the packing device is used for packing the cut-off meat sausages; the cutting off device comprises a clamping mechanism for clamping the meat sausages to move forwards, a driving mechanism for driving the clamping mechanism to move and a cutting mechanism which is driven by the driving mechanism and can cut the meat sausages; and the cutting mechanism is connected with the packing device. Through the adoption of the production line disclosed by the invention, a plurality of the meat sausages which are arrayed in parallelcan be cut off at the same time, and the meat sausages of which the length is uniform are obtained; the working efficiency is improved; and the labor intensity of workers is reduced.

Owner:NEW HOPE LIUHE

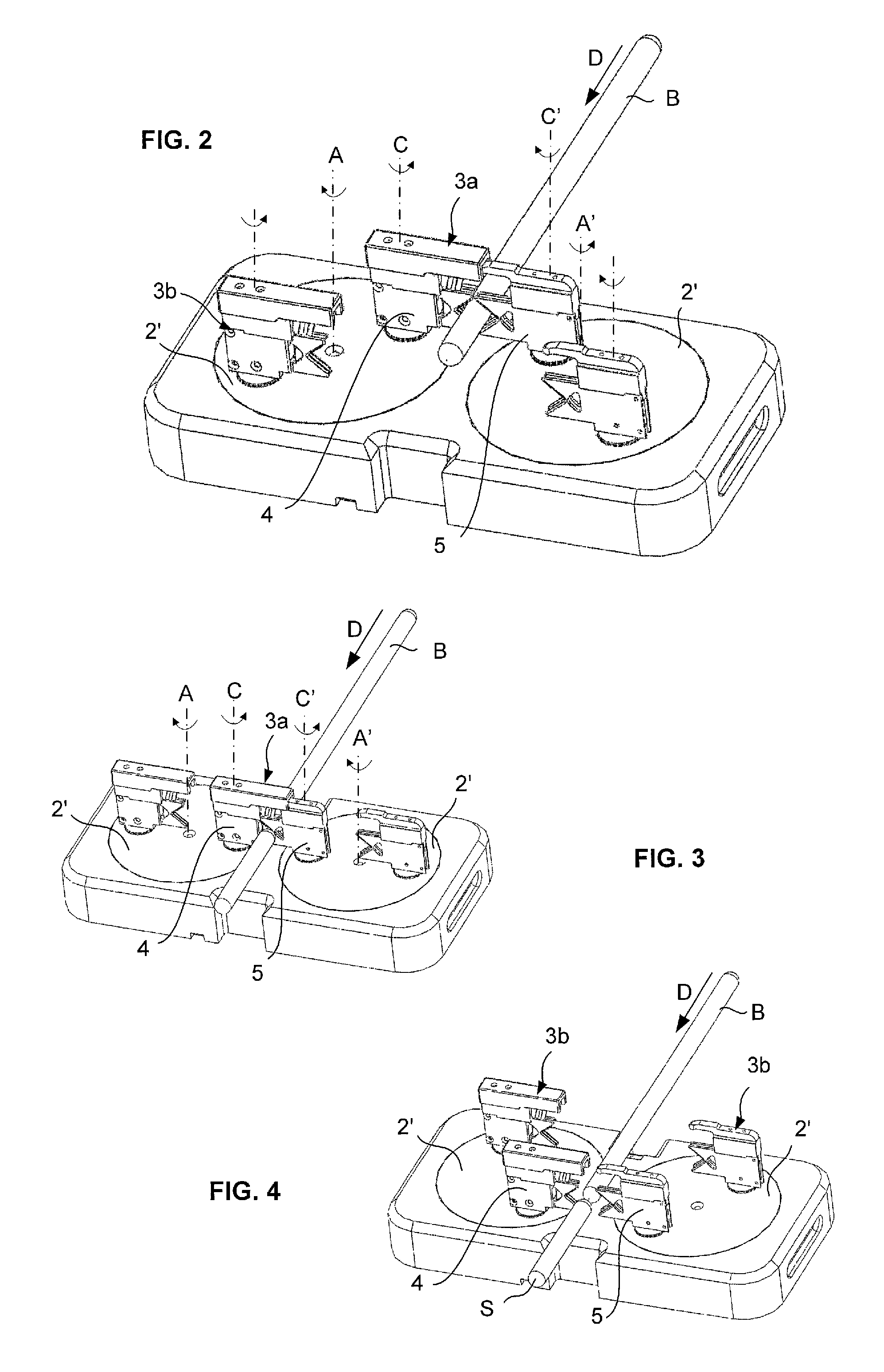

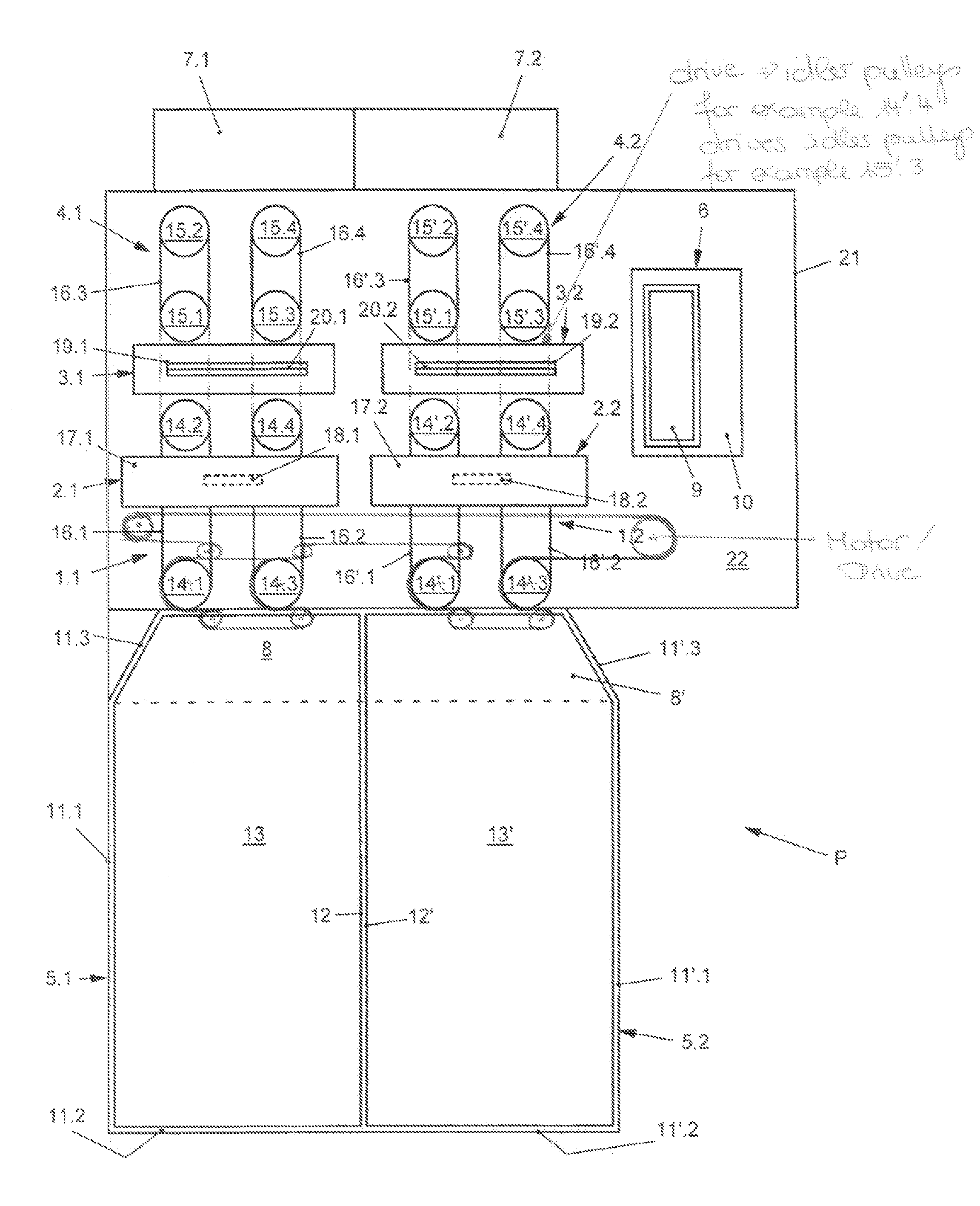

Portioning device including clamps and a cutting blade

The invention relates to a device for dividing a continuous sausage into portions, in particular sausage links. The invention includes at least one pair of opposing clamps which can be moved towards one another by actuation means in order to crush the sausage. Each clamp includes at least a first plate (141, 151) and a second plate (142, 152), each of said plates having front clamping edges (141a, 151a; 142a, 152a) and being arranged such that the front edge of the first and second plates form respectively first (181) and second (182) variable-cross-section passages. The invention also includes at least one blade associated with the pair of clamps, which can be moved transversely to the plates between the first passage and the second passage in order to cut the sausage.

Owner:MAREL FRANCE

Process and device for cutting sausage

A process for cutting sausages from a sausage link by a cutting device to which the sausages in the sausage link are conveyed together and a cutting site between two successive sausages is recognized by a sensor device, the sausage link being retracted with the front most sausage behind the sensor device after a predetermined number of sausages has been cut. This permits a specific indexing of the sausages in the sausage link after the sensor device and prevents bottlenecks between the cutting machine and the packaging machine.

Owner:STIMPFL CHRISTOF

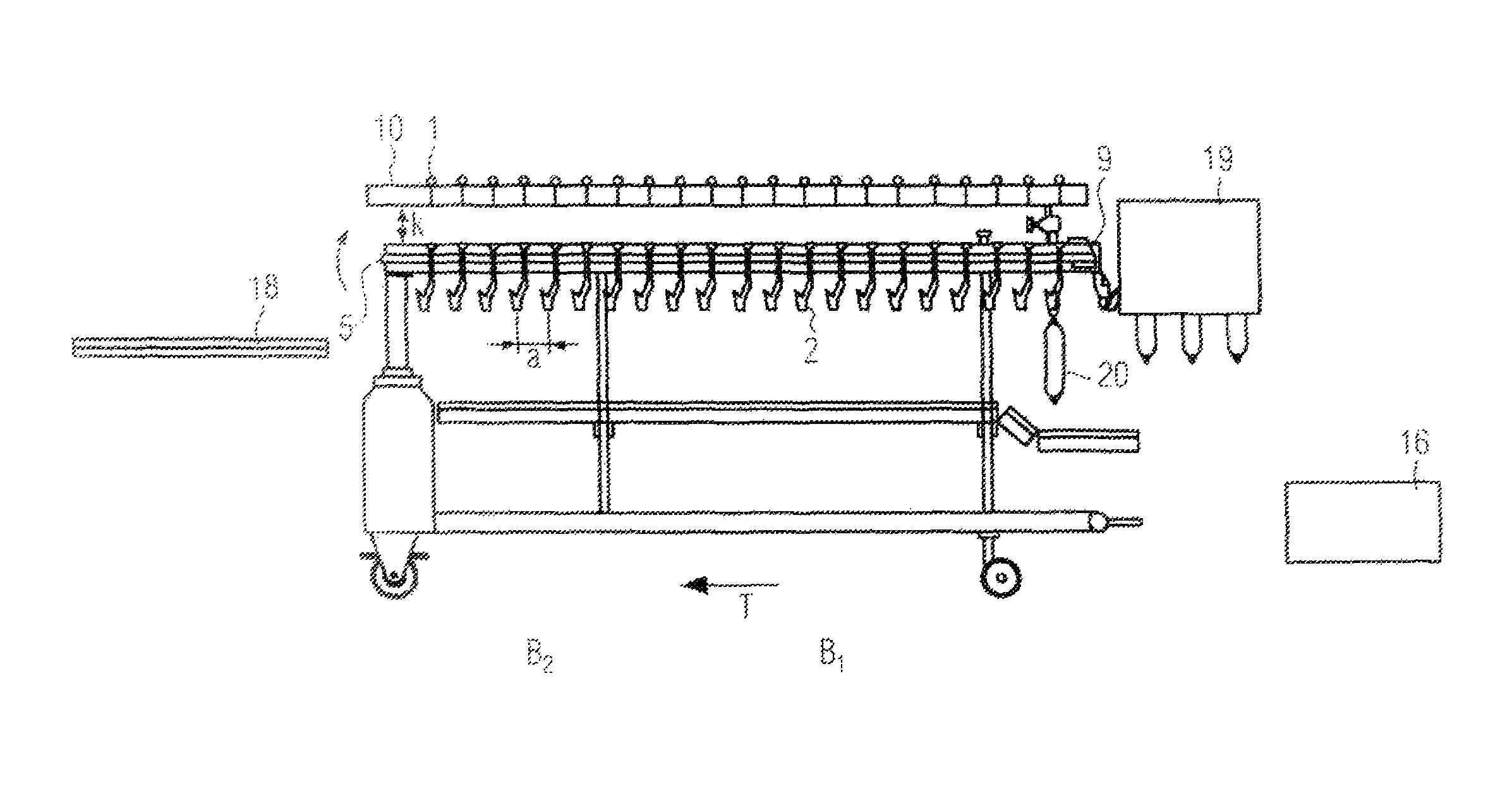

Device for treating a string of sausages

InactiveCN104604998AMonitor fireEasy to cleanMeat/fish preservationLinked sausage separationEngineeringRadiation

Device for treating a string of sausages composed of a plurality of sausages which are disposed so as to be behind one another, having a sausage casing from an organic material which in the region between two sausages displays in each case a twist, wherein at least one microwave applicator which has at least one application chamber and is assigned at least one microwave generation unit for generating the microwave radiation to be supplied to the application chamber, and which has at least one conveying unit for conveying the string of sausages through the at least one application chamber is provided, wherein at least one measuring unit (28, 29) for identifying at least one measured value which represents a measure of the temperature prevailing in the application chamber (11) is provided.

Owner:赫魏香肠公司

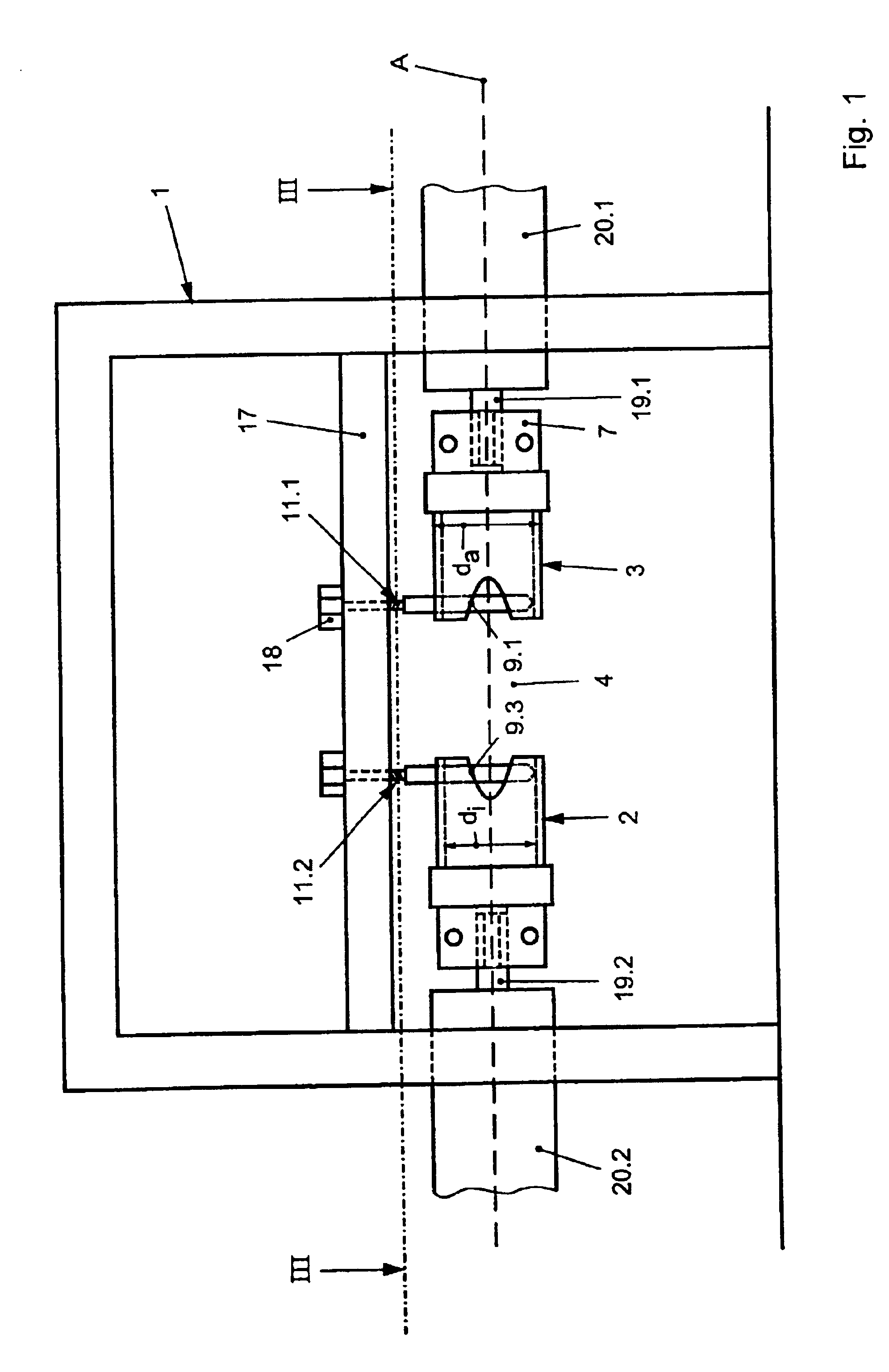

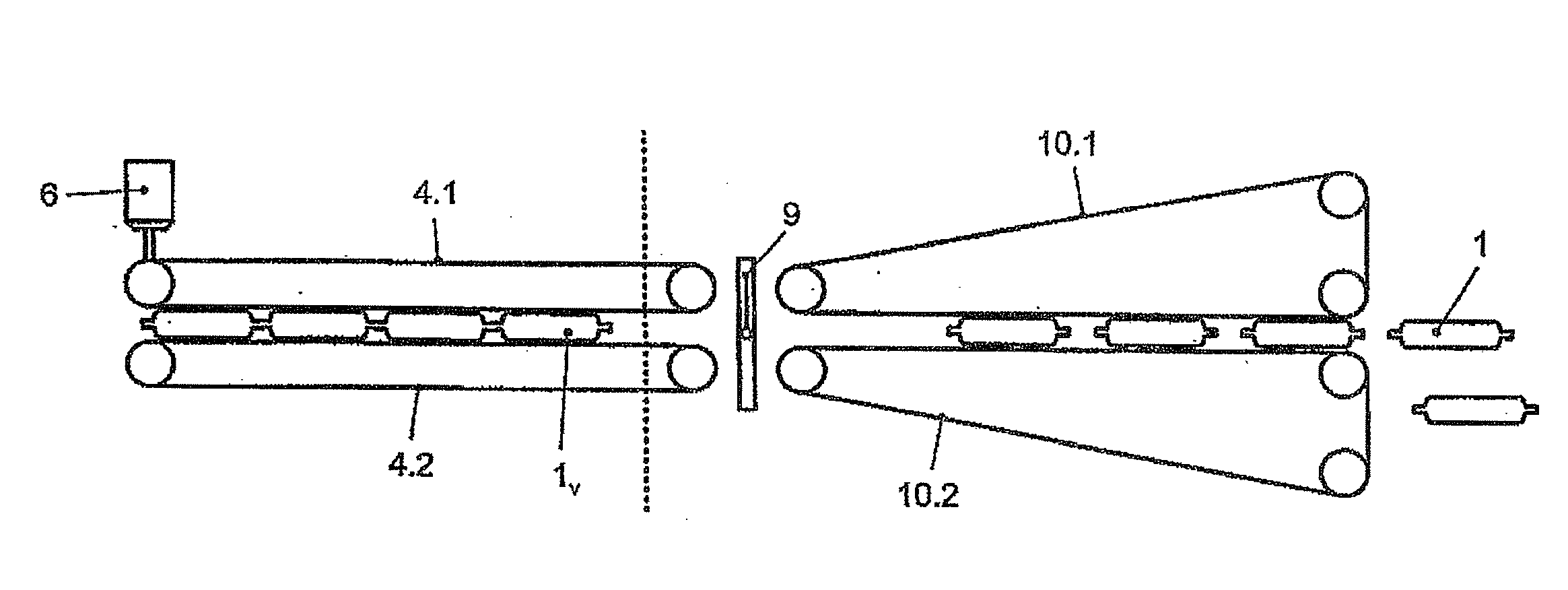

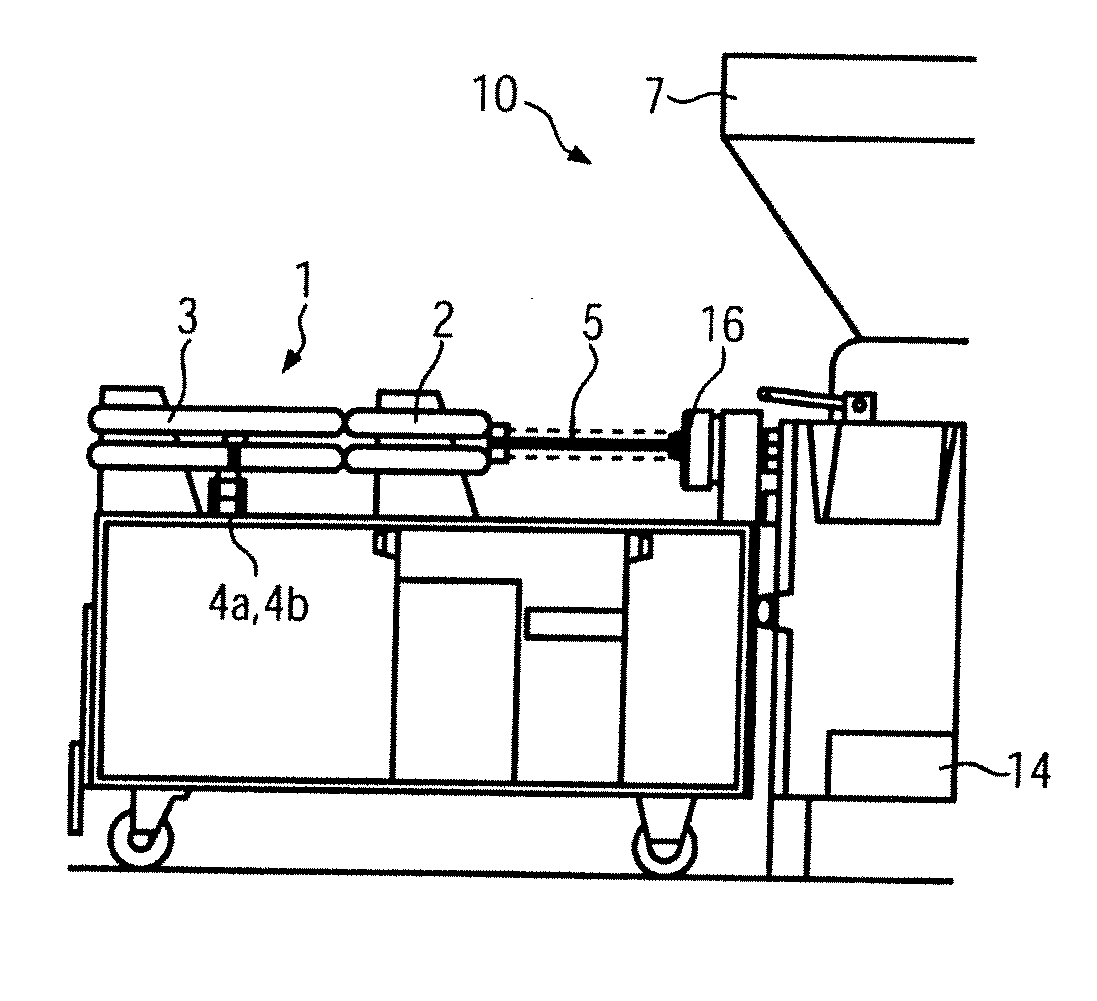

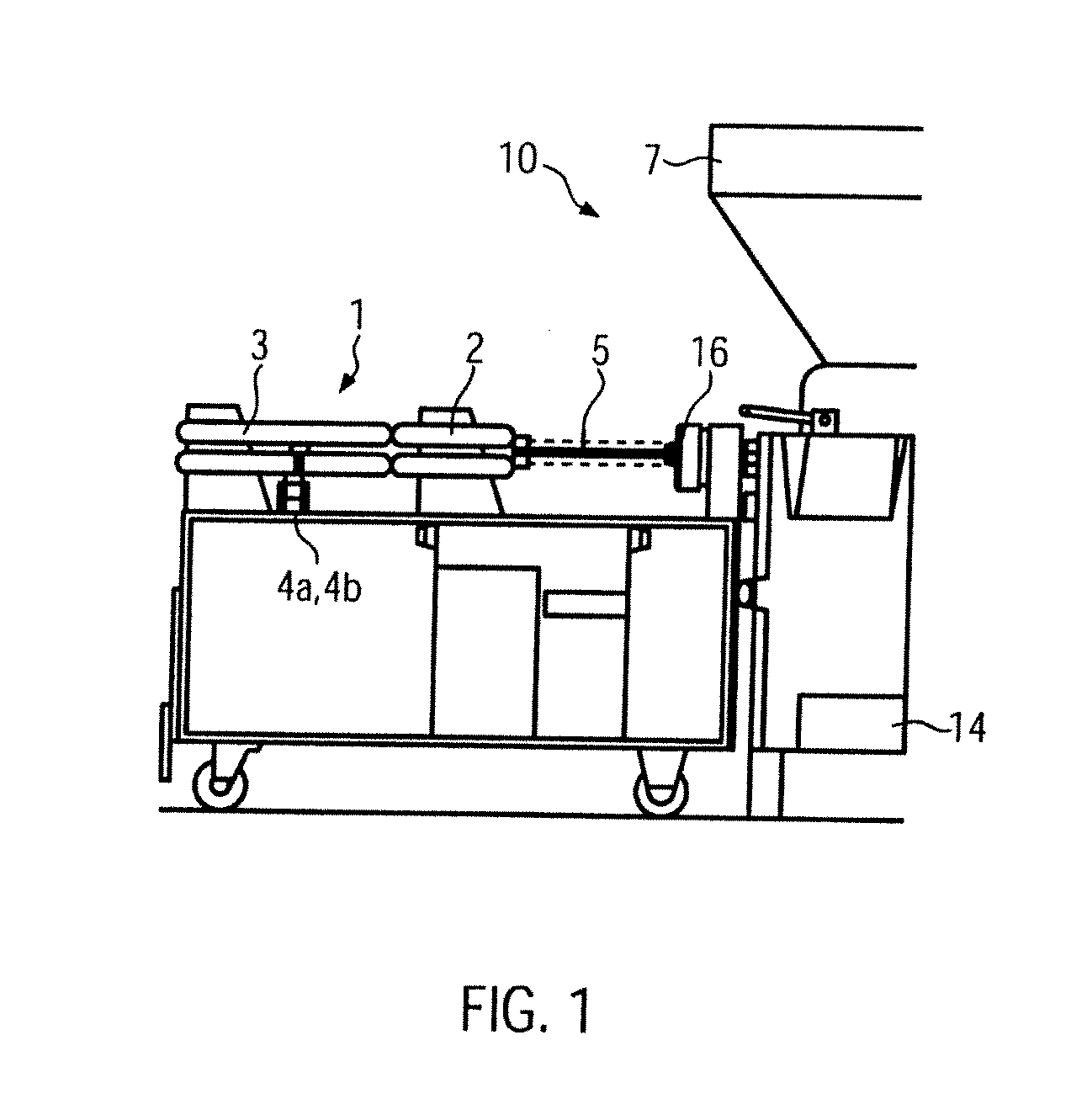

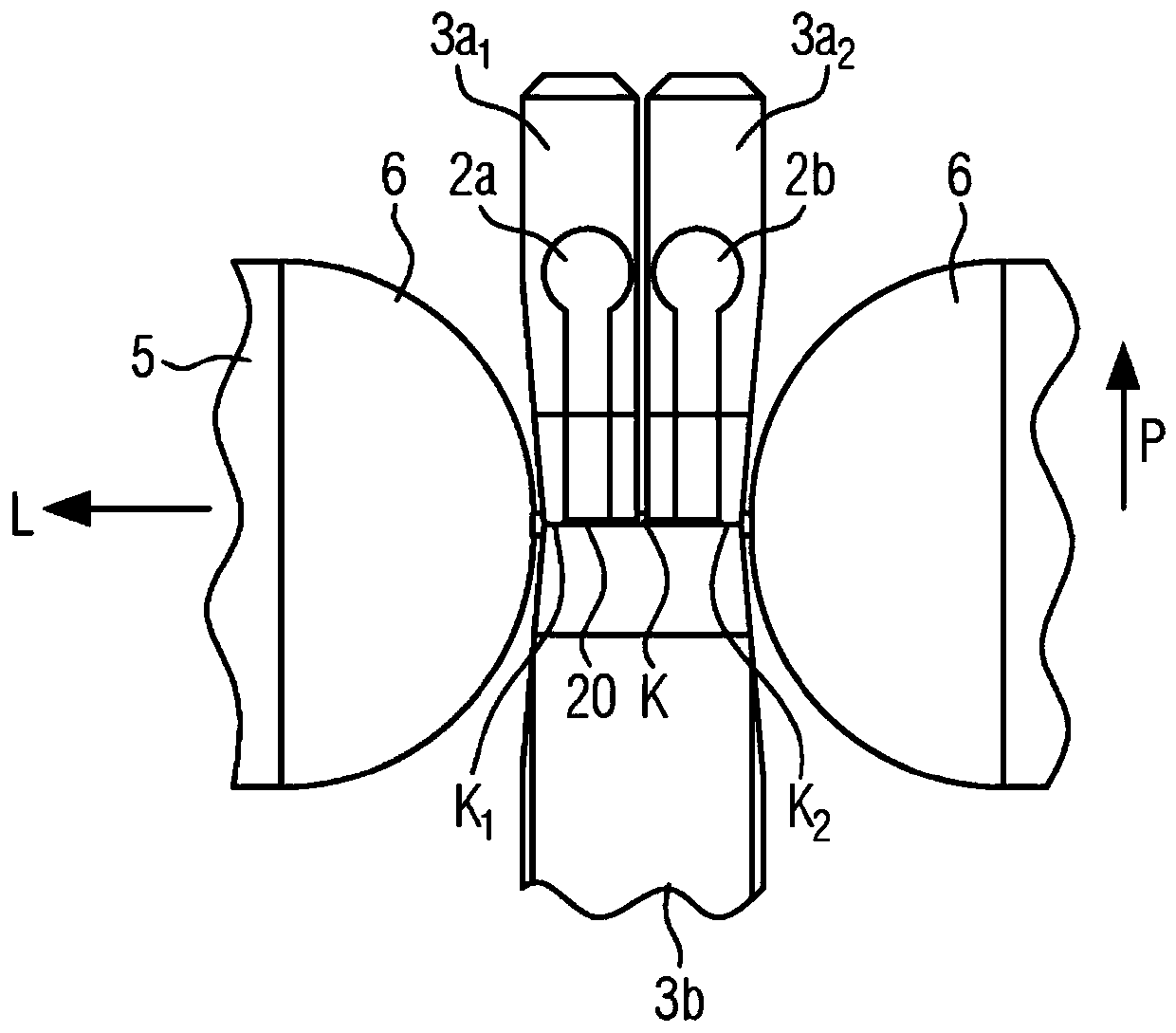

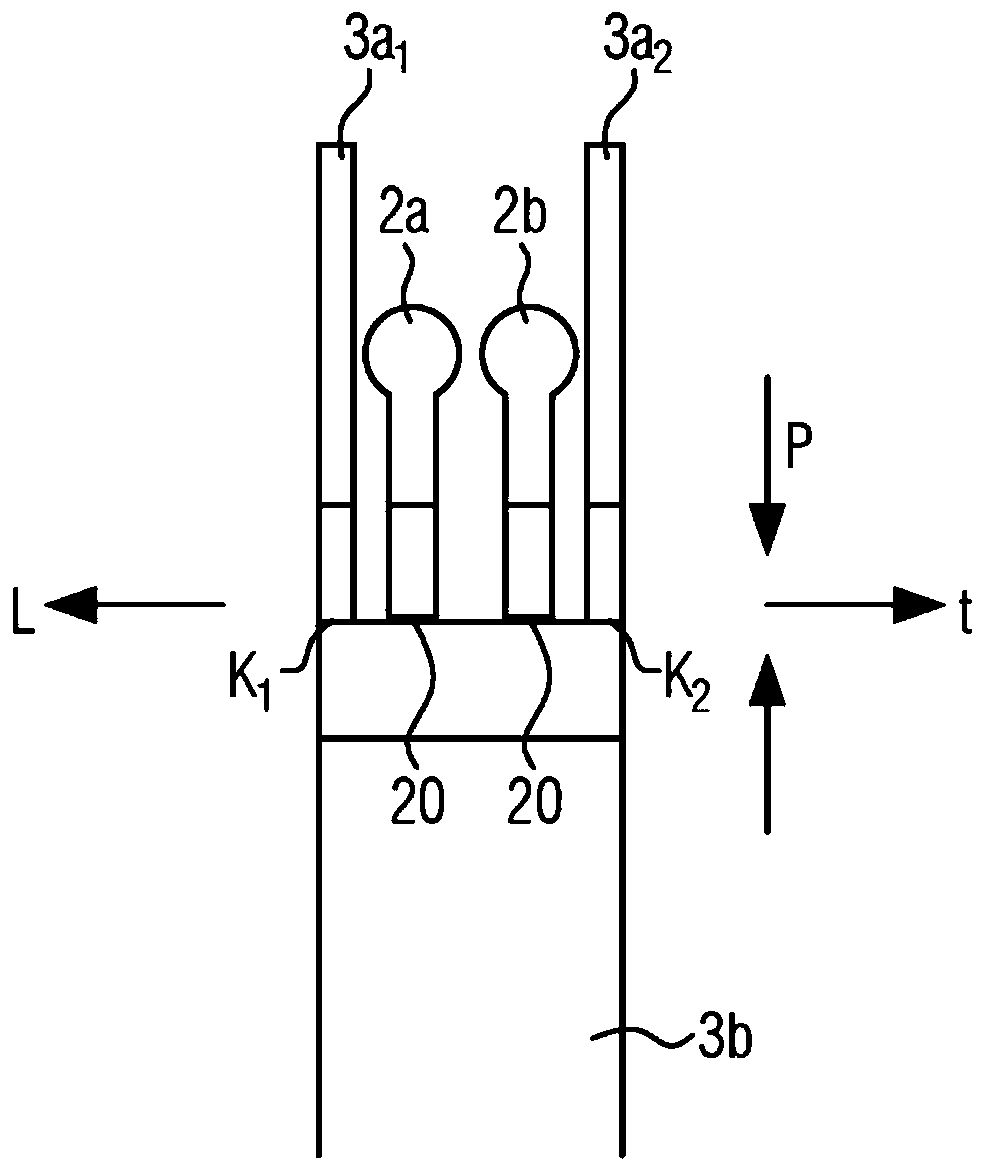

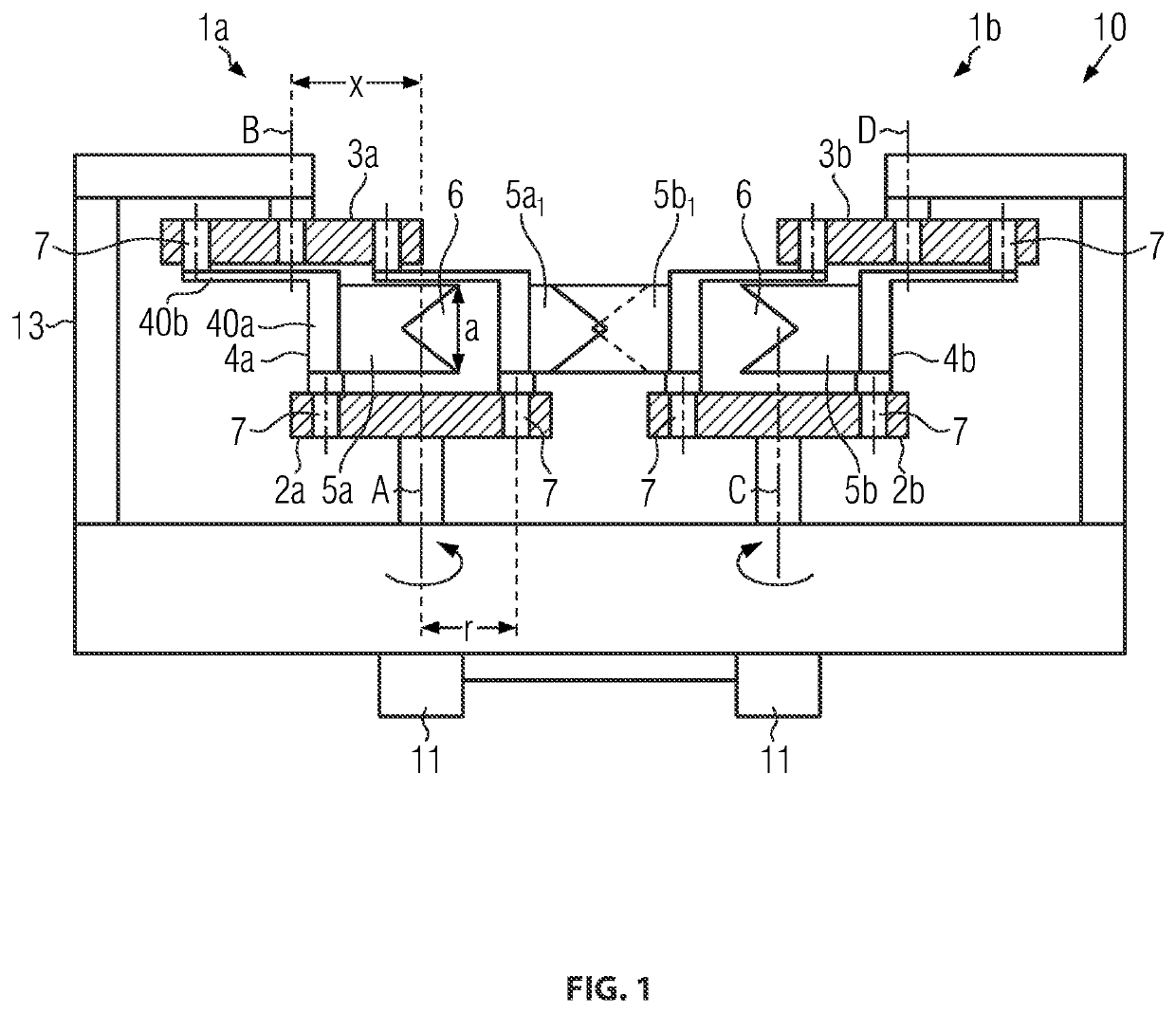

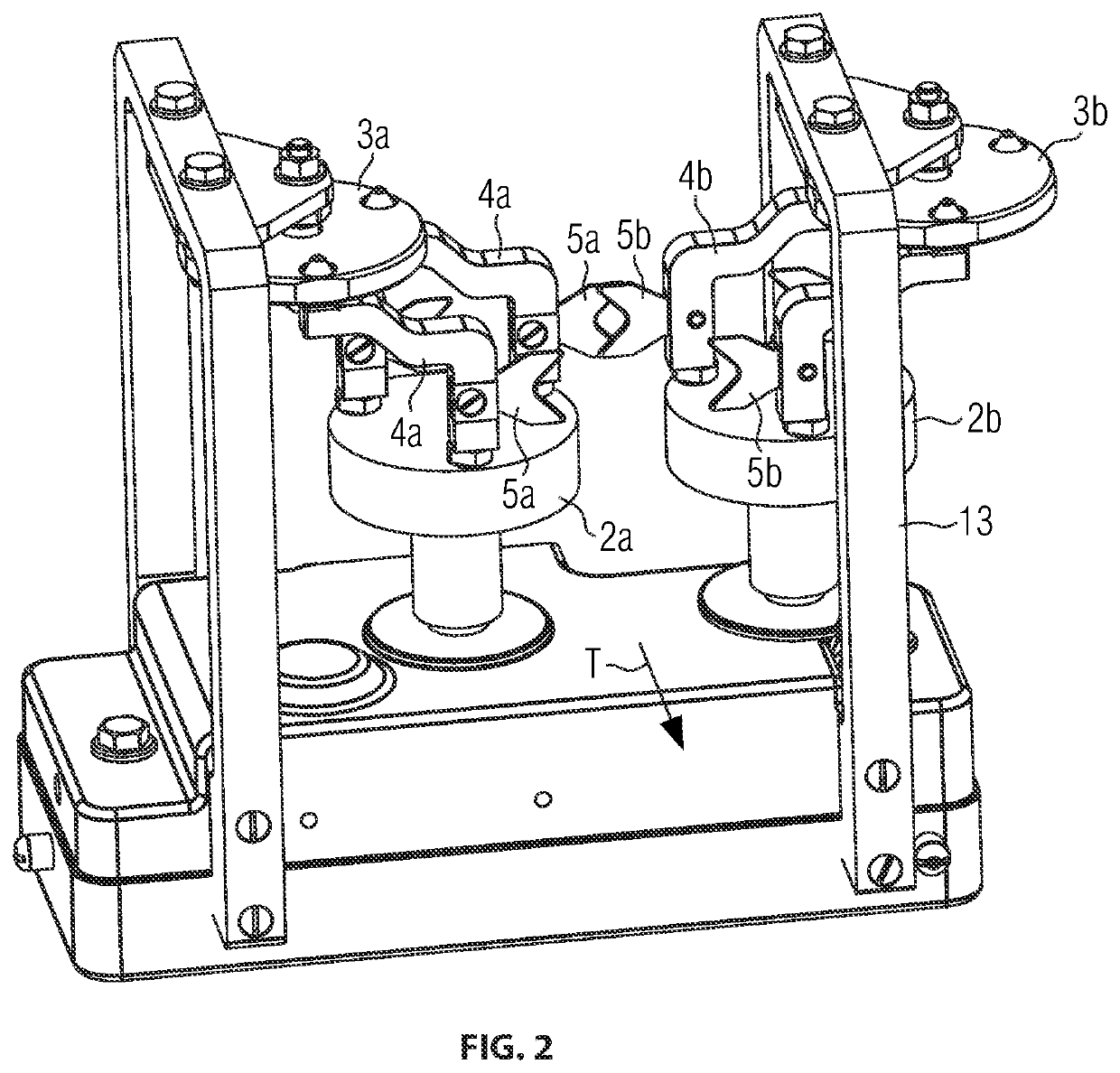

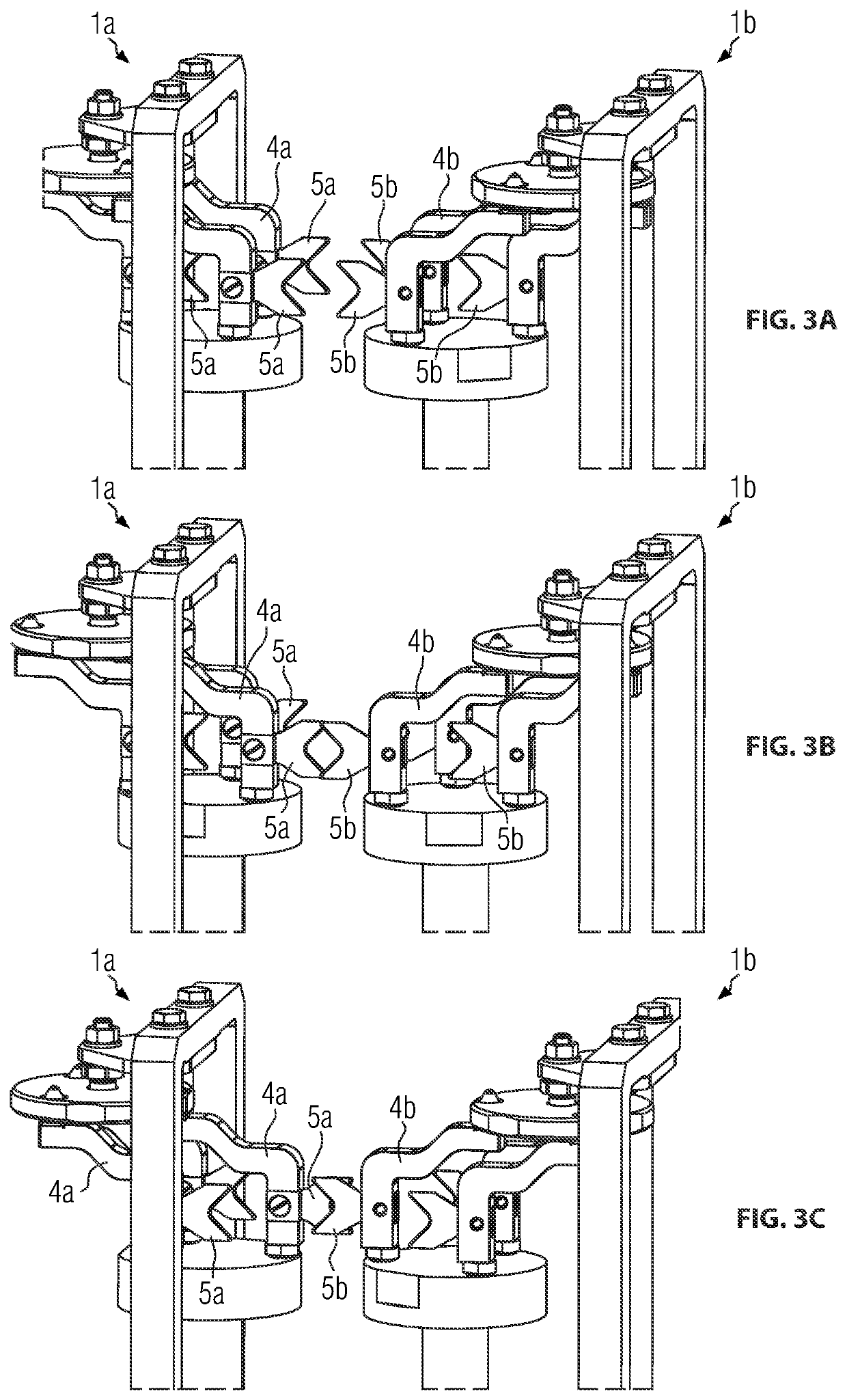

Device and method for parting sausage chains

ActiveUS8231442B2Reliable and simple mannerLess burstingLinked sausage separationSausage twisting/linking machinesTransport engineering

Owner:ALBERT HANDTMANN MASCHFABRICK

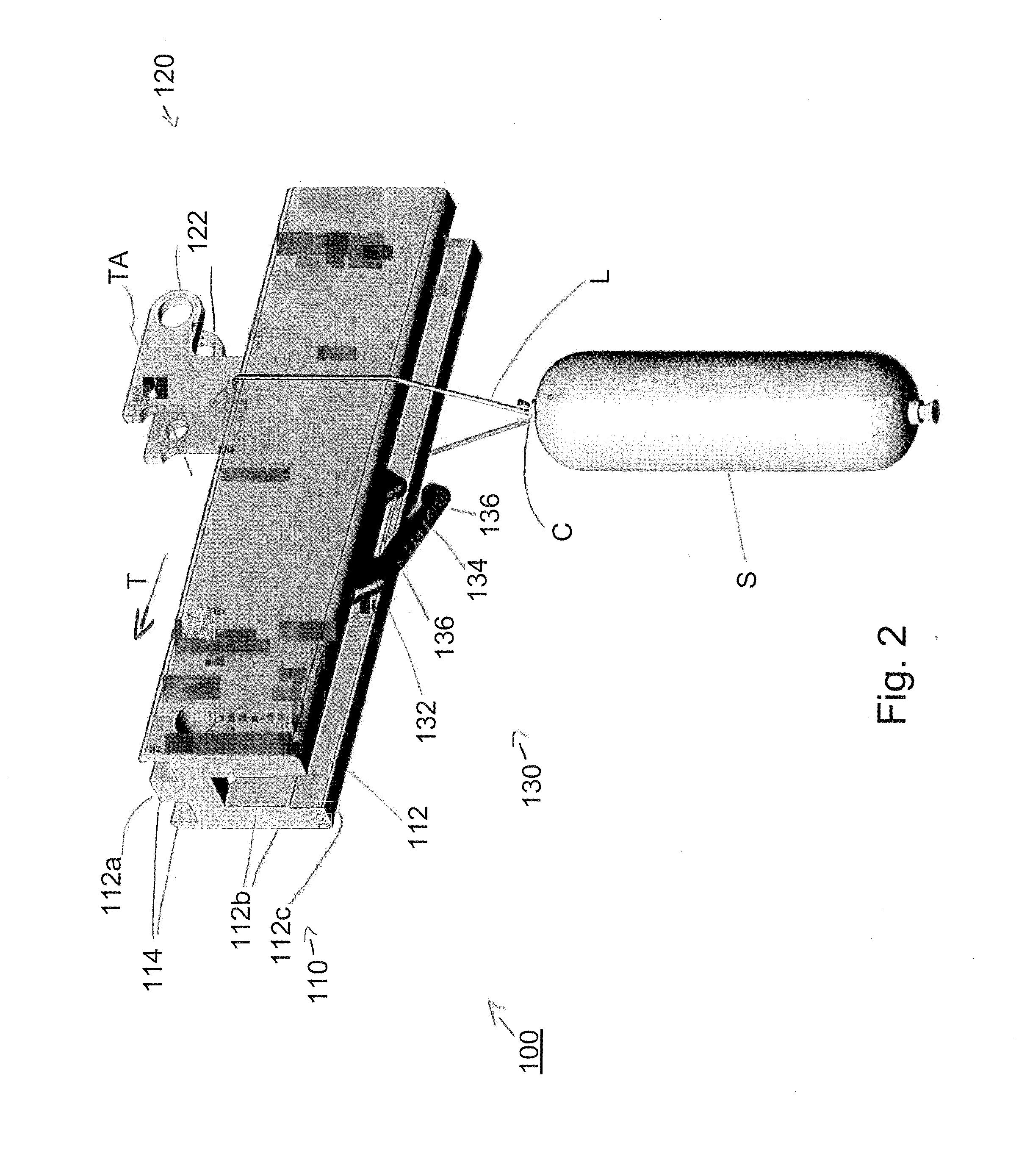

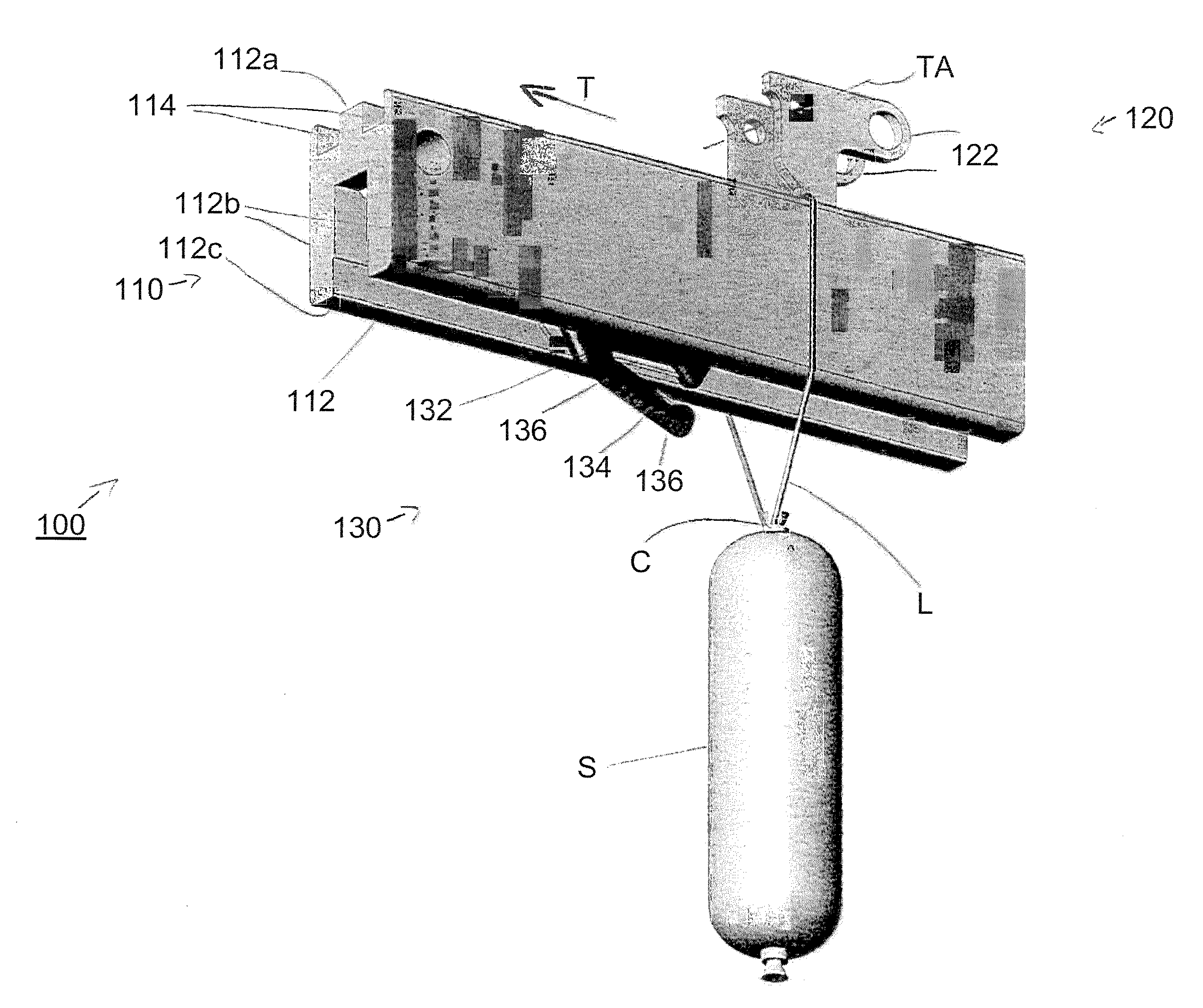

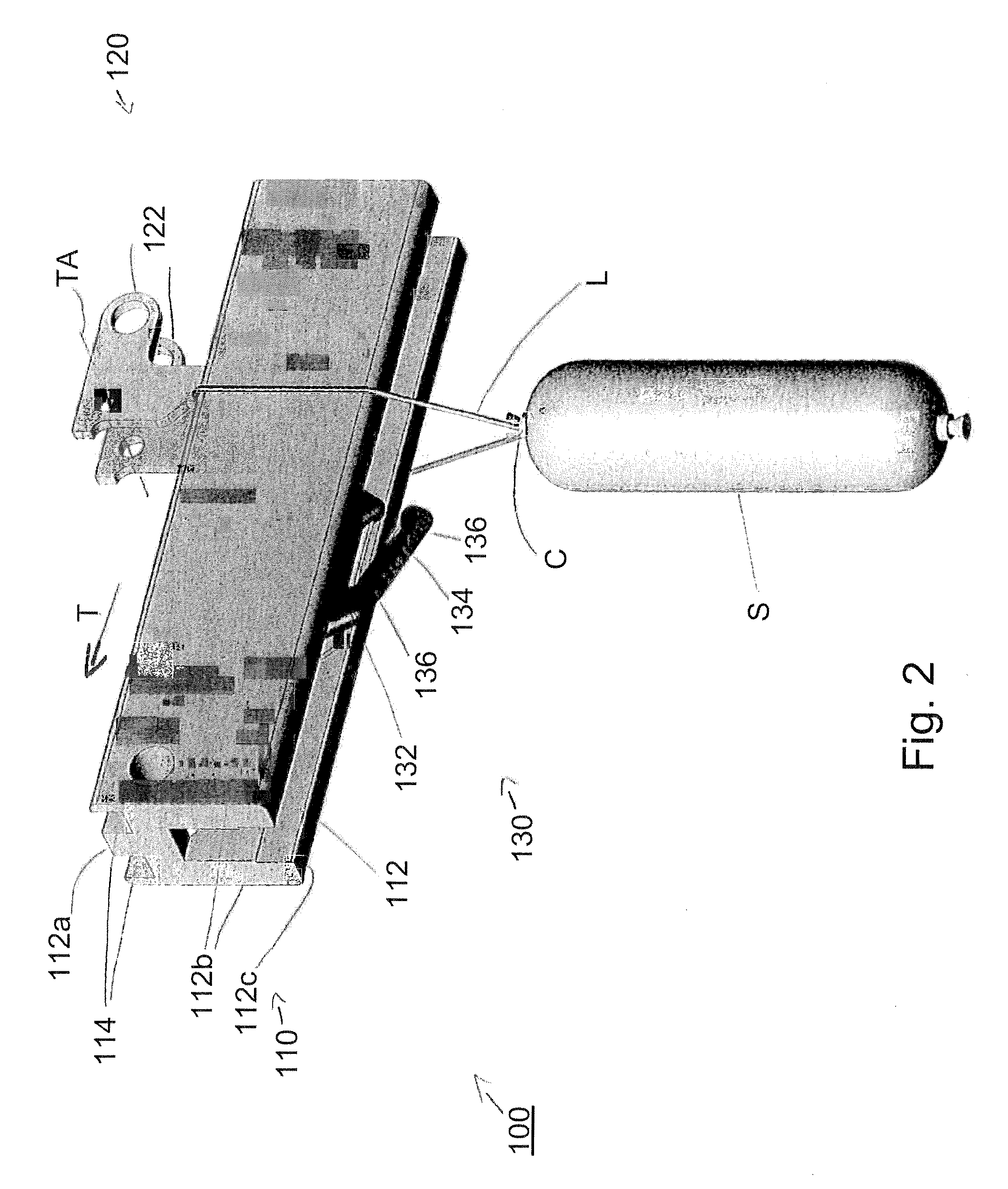

Transportation assembly with separation device

ActiveUS20140194041A1Meat/sausage hanging-upLinked sausage separationEngineeringMechanical engineering

The present invention relates to a transportation assembly for transporting sausage shaped products out of a clipping machine for producing sausage-shaped products in a transportation direction to a rod-like storing element. Each sausage-shaped product comprises a filled tubular or bag-shaped packaging casing closed on at least one end by a closing means and a suspension element attached to the end closed by said closure means, the transportation assembly comprises a guiding device having a bar-shaped guiding element along which the sausage-shaped product is guided by its suspension element, and a transportation device for transporting the sausage-shaped product along the guiding element by engaging the suspension element of the sausage-shaped product.The suspension element is held in an open configuration by the weight of the filled tubular or bag-shaped packaging casing. A separation device is provided at the guide element, for removing a suspension element from the guiding element.

Owner:POLY CLIP SYST

Food processing device

ActiveUS7845271B2Reduce actionImprove cutting performanceLinked sausage separationFood shapingElectricityLine tubing

A food processing device comprises a paste reservoir, a feed pump and a flow divider. The flow divider is provided with outlets to four supply lines all of which receive a substantially equal supply of paste as a result of the operation of the flow divider. Each of the outlets is connected to a nozzle. A pair of knives is located ahead of the nozzles, each being provided with four apertures. The knives are provided with an actuating mechanism and a controller. Controller registers and controls operation of the meatball forming device and is electrically connected to the feed pump, to a servomotor and to a shaft encoder.

Owner:MACHINEFAB GEURTSEN DEVENTER

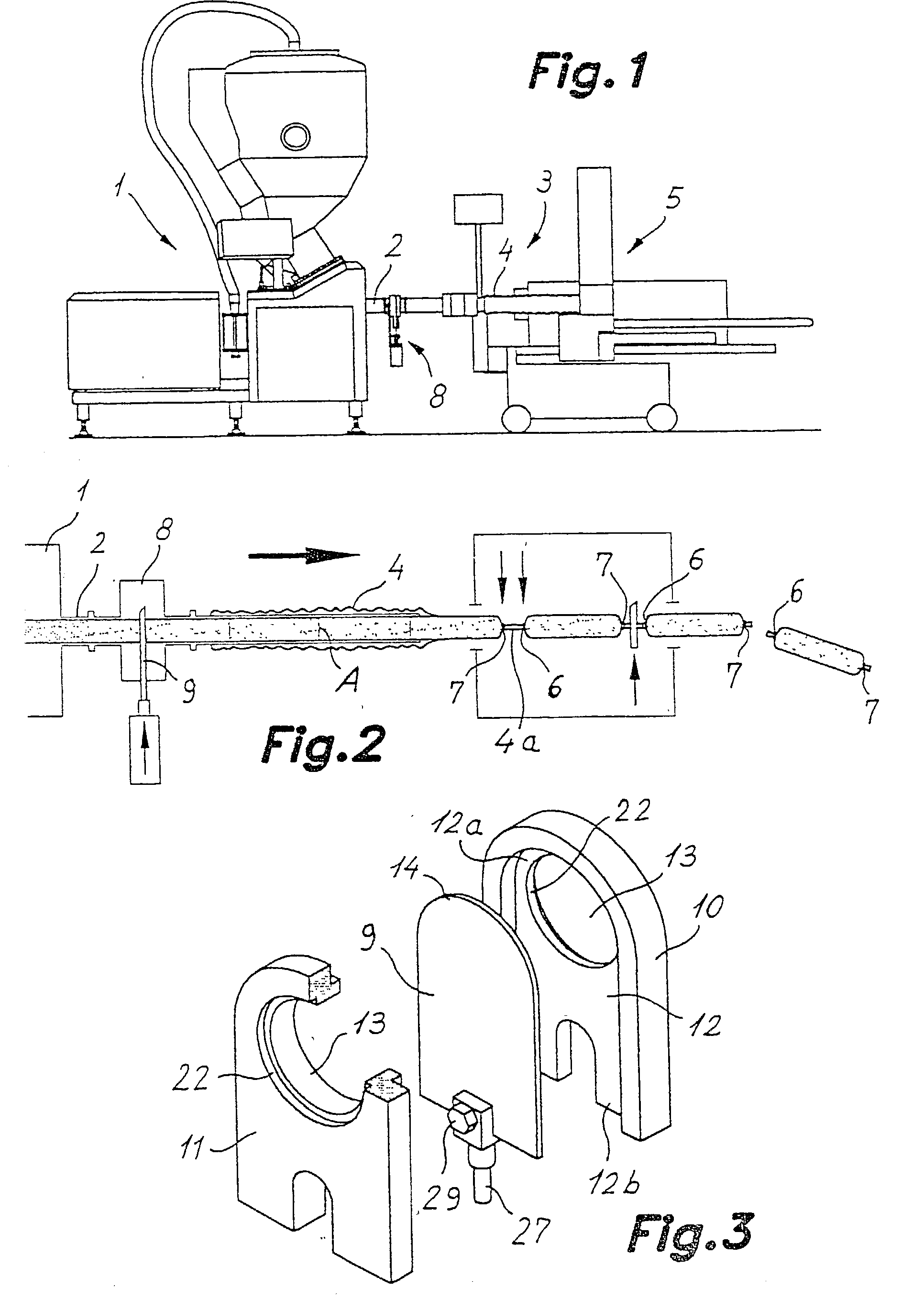

Method and device for stuffing meat product sealed by stapling

InactiveUS20030073398A1Linked sausage separationSausage skin tying apparatusProcess engineeringContinuous flow

The invention relates to a method and device for stuffing meat materials into sausages closed by stapling. The processed meat materials, before their introduction into an endless sleeve (4) having a first closed extremety and further narrowing of the stuffed material at regular intervals by means of spaced staples in order to produce a line of stuffed elements, are previously subjected to a cutting step at regular intervals of the continuous flow of meat material to be stuffed into the sleeve (4), making said cuts coincide with posterior zones of narrowing. The device for implementing the process comprises a stuffing zone (3) with continuous flow of meat materials, from a stuffing machine (1) through an outlet tube (2) introduced into the sleeve (4), having a first closed extremity, and includes between said outlet tube (2) of the stuffing machine (1) and said stuffing zone (3), a guillotine assembly (8) intended to cut transversally the meat material.

Owner:METALQUIMIA SA

Device and method for parting sausage chains

ActiveUS20110223846A1Increase speedReduced first speedLinked sausage separationSausage twisting/linking machinesTransport engineering

Owner:ALBERT HANDTMANN MASCHFABRICK

Transportation assembly with separation device

The present invention relates to a transportation assembly for transporting sausage shaped products out of a clipping machine for producing sausage-shaped products in a transportation direction to a rod-like storing element. Each sausage-shaped product comprises a filled tubular or bag-shaped packaging casing closed on at least one end by a closing means and a suspension element attached to the end closed by said closure means, the transportation assembly comprises a guiding device having a bar-shaped guiding element along which the sausage-shaped product is guided by its suspension element, and a transportation device for transporting the sausage-shaped product along the guiding element by engaging the suspension element of the sausage-shaped product.The suspension element is held in an open configuration by the weight of the filled tubular or bag-shaped packaging casing. A separation device is provided at the guide element, for removing a suspension element from the guiding element.

Owner:POLY CLIP SYST

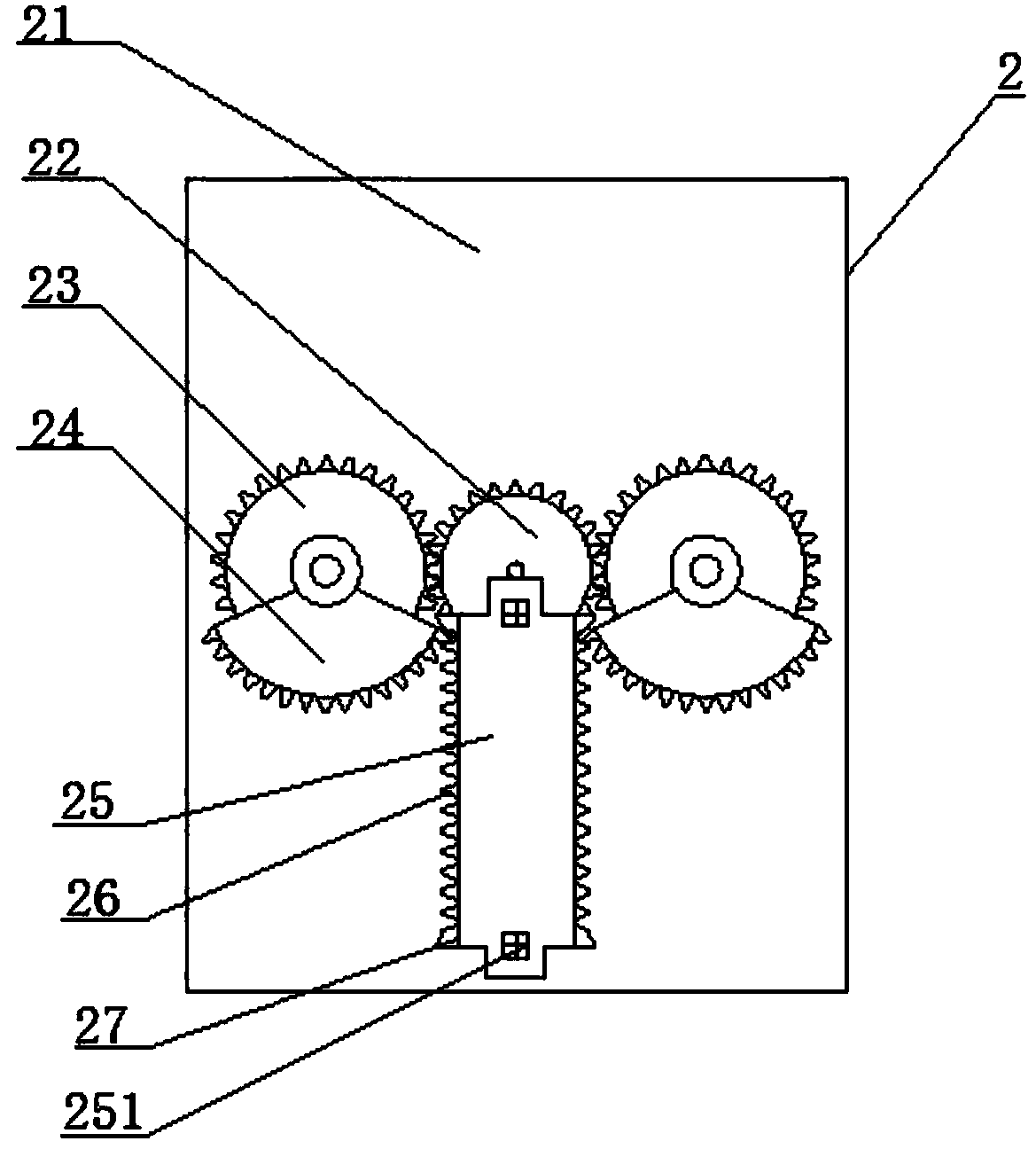

Ham sausage uniform cutting device

InactiveCN107813356AUniform reciprocating motionSimple structureLinked sausage separationMetal working apparatusMotor driveGear wheel

The invention discloses a uniform cutting device for ham sausage, which comprises a cutting tool and a driving device for driving the cutting tool. The output shaft passes through the bottom plate and is connected with the driving gear. Symmetric driven components are arranged on both sides of the driving gear. A moving assembly is arranged between the two groups of guide gears, racks engaged with the guide gears are arranged on both sides of the moving assembly, and the cutting tool is arranged on the upper surface of the moving assembly. In the present invention, the uniform reciprocating motion of the cutting tool is realized only by one motor drive, and the structure is simple and convenient to use.

Owner:SICHUAN HUIQUAN CANNED FOOD

A sausage energy-saving and environment-friendly production process and production equipment

ActiveCN107897743BThe production process is simple and applicableSteady improvement in qualityLinked sausage separationSausage filling/stuffing machinesElectric machineryProcess engineering

The invention provides an energy-saving environment-friendly production process of sausages and a production device of the sausages. The device comprises a weighing and stirring system, a sausage filling system, a smoking system, an air exhaust cooling and shaping system and a cutting system; a meat mincing system comprises a screw cylinder and a first screw rod which are matched with each other;the outer end of the first screw rod is provided with a first belt pulley; a rinsing system comprises a rinsing barrel made of a transparent material, a second motor, a first stirring sleeve and a second controller; a pickling system comprises a top cover and a pickling barrel; and a third rotating shaft is transversely arranged inside the pickling barrel. According to the invention, all importantdevices in sausage production process are improved, the automation degree of the production process is further improved, more mechanized operations are adopted, labor cost is reduced, production efficiency is improved at the same time, the error rate is lower, and the quality of the sausage is improved stably.

Owner:福建舜洋食品有限公司

An energy-saving, environment-friendly, high-quality production process and production equipment for kissing intestines

ActiveCN107996668BThe production process is simple and applicableSteady improvement in qualityLinked sausage separationSausage filling/stuffing machinesProcess engineeringConveyor belt

The present invention provides an energy-saving, environmentally-protective and high-quality production technology and production device of a qinqin sausage (a short and juicy sausage). The processingdevice comprises a base seat. A control table is arranged at one side of the base seat, a meat grinder system is arranged at a left end of the other side of the base seat, a right side of the meat grinder system is successively provided with a stuffing blending system, a pickling tank, a rolling system, a weighing system, a sausage filling system, a steaming and smoking system, a cooling room, acutting system, a secondary sterilization system and a cold storage. Each system transfers the sausage via a conveyor belt, transportation labor is reduced, important devices are improved, automationdegrees of production processes are further improved, more mechanized operations are used, labor costs are reduced, and at the same time, the production device can improve production efficiency, is lower in error rate and steadily improves quality of the qinqin sausage.

Owner:福建舜洋食品有限公司

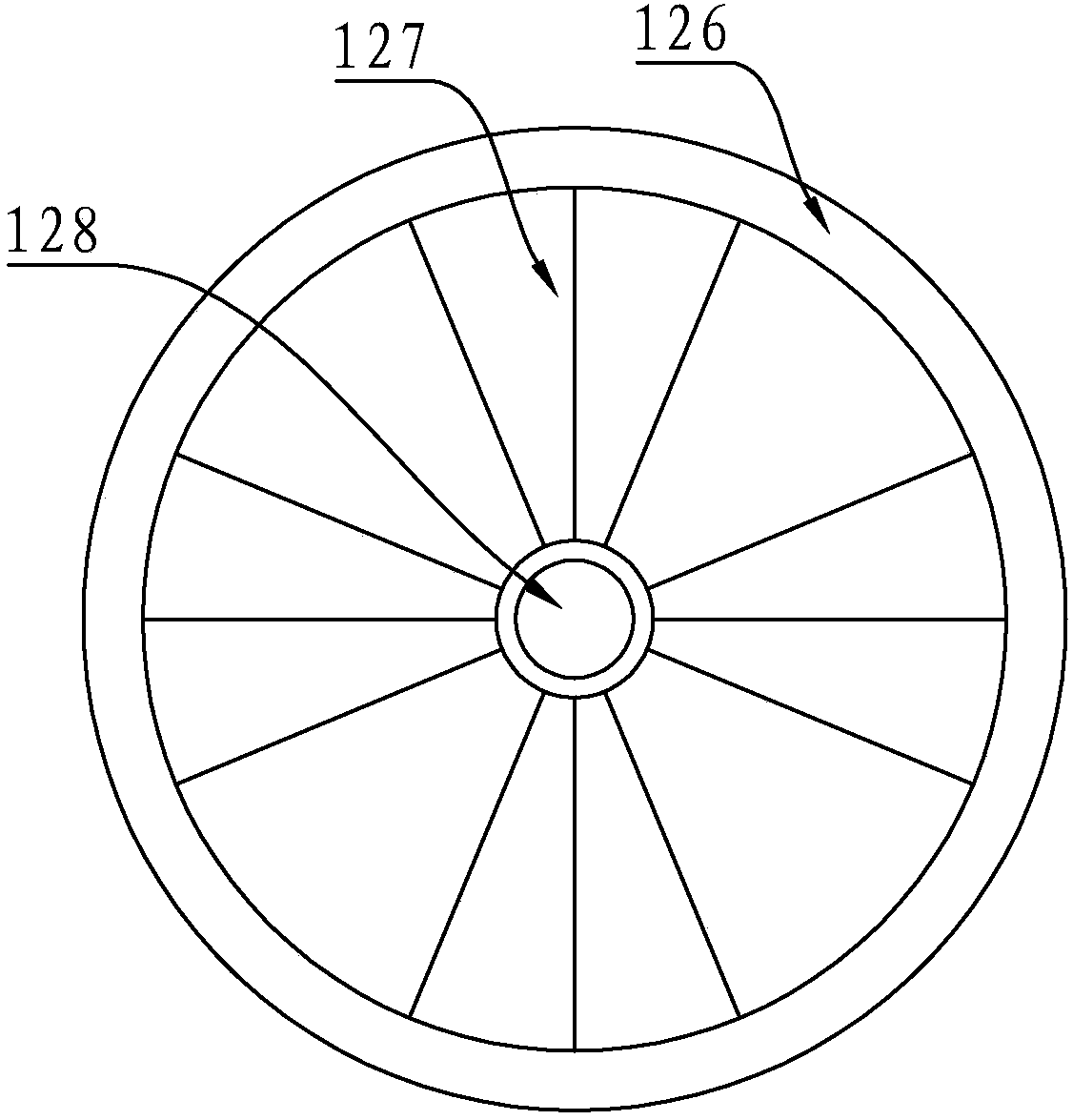

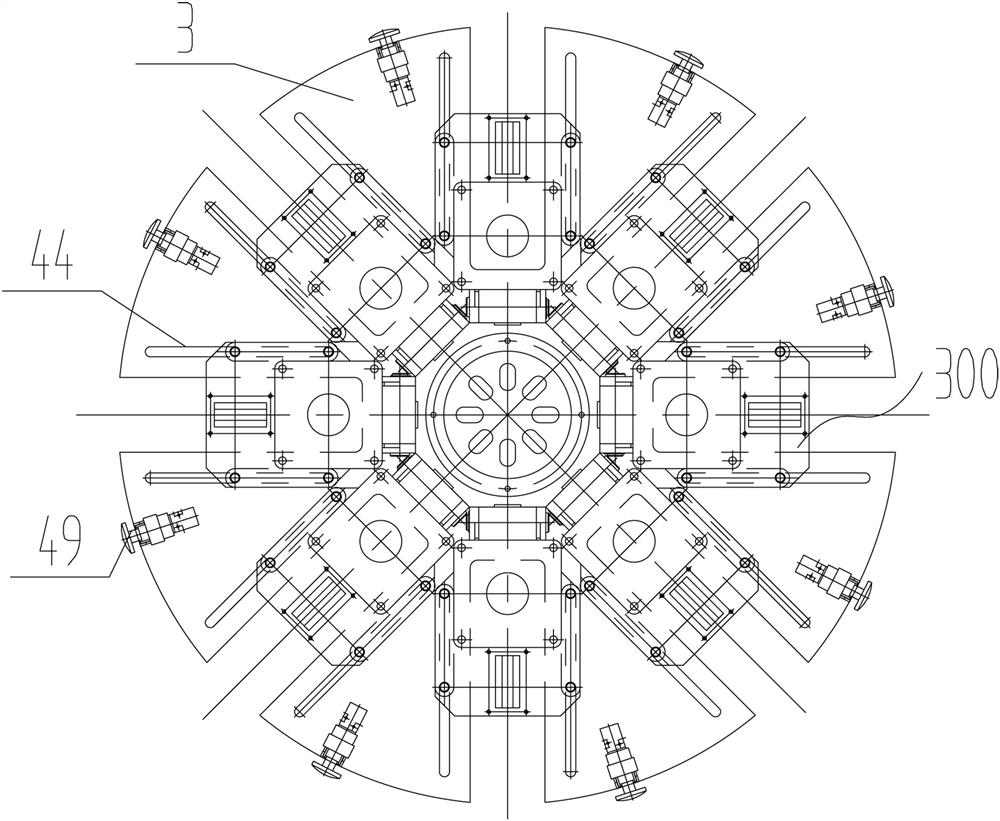

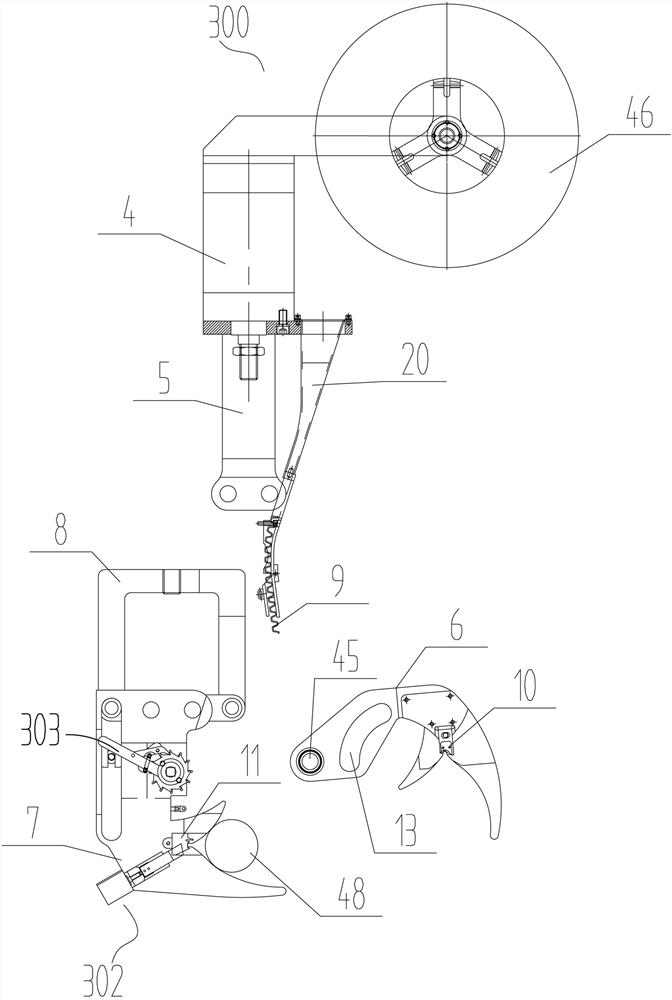

Pneumatic disc type food packaging punch device

InactiveCN112219884ASimple structureReasonable arrangementLinked sausage separationSausage skin tying apparatusEngineeringStructural engineering

The invention relates to a pneumatic disc type food packaging punch device. The pneumatic disc type food packaging punch device comprises a base, a rotary stand column arranged on the base, a power device for driving the rotary stand column to rotate, a control device arranged on the rotary stand column, a rotary disc fixedly arranged on the rotary stand column and a punch machine arranged on therotary disc. The punch machine comprises a punch air cylinder, a fixing frame, a rotary folding claw, a fixed folding claw, a buckle lifting mechanism, a cutting-off assembly, a movable frame, a buckle conveying mechanism and a conveying channel wherein the punch air cylinder and the fixing frame are fixed to the rotary disc; the rotary folding claw is hinged to the fixing frame; the fixed foldingclaw is fixed to the fixing frame; the buckle lifting mechanism and the cutting-off assembly are arranged on the fixed folding claw; the movable frame is driven by the punch air cylinder; the buckleconveying mechanism is driven by the moving frame; and the conveying channel is used for conveying Great Wall Cards; an upper punch head is arranged at the claw center of the rotary folding claw; anda lower punch head is arranged at the claw center of the fixed folding claw.

Owner:石家庄睿普雷健康科技有限公司

Device and method for separating sausage chains

ActiveUS9408401B2Cost effectiveLower requirementLinked sausage separationMetal working apparatusEngineering

Owner:INOTEC MASCHENENTWICKLUNG & VERTRIEB

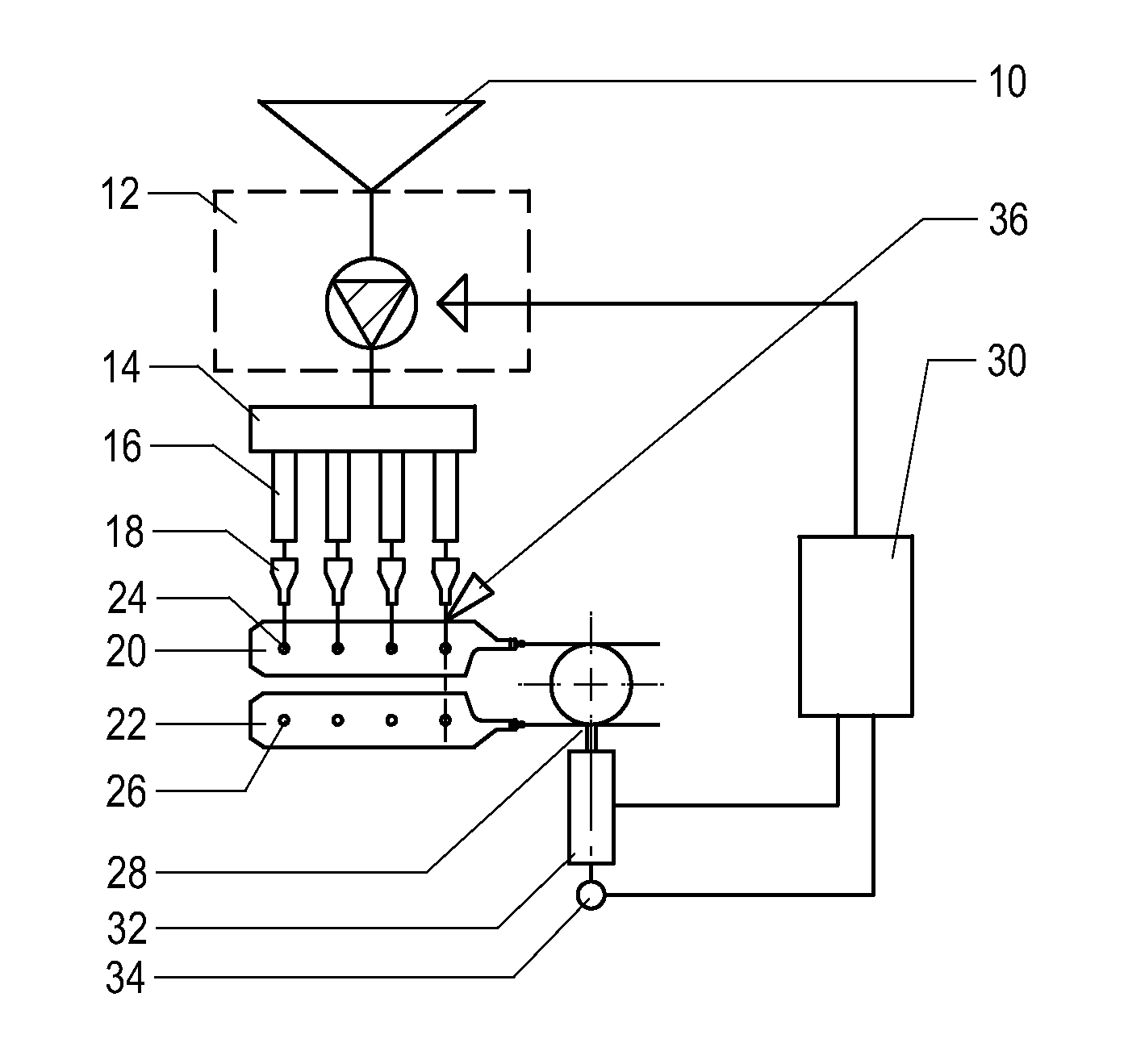

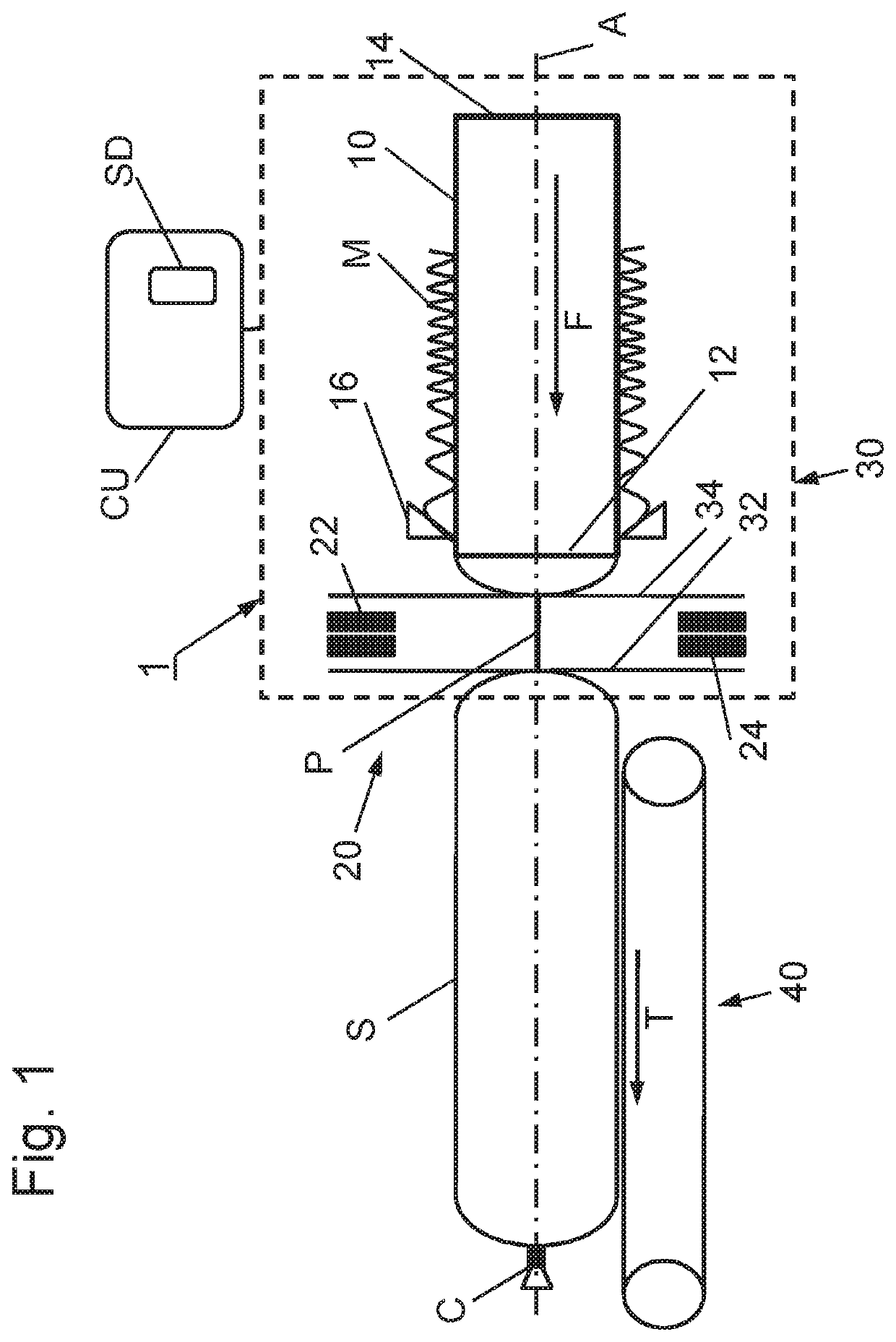

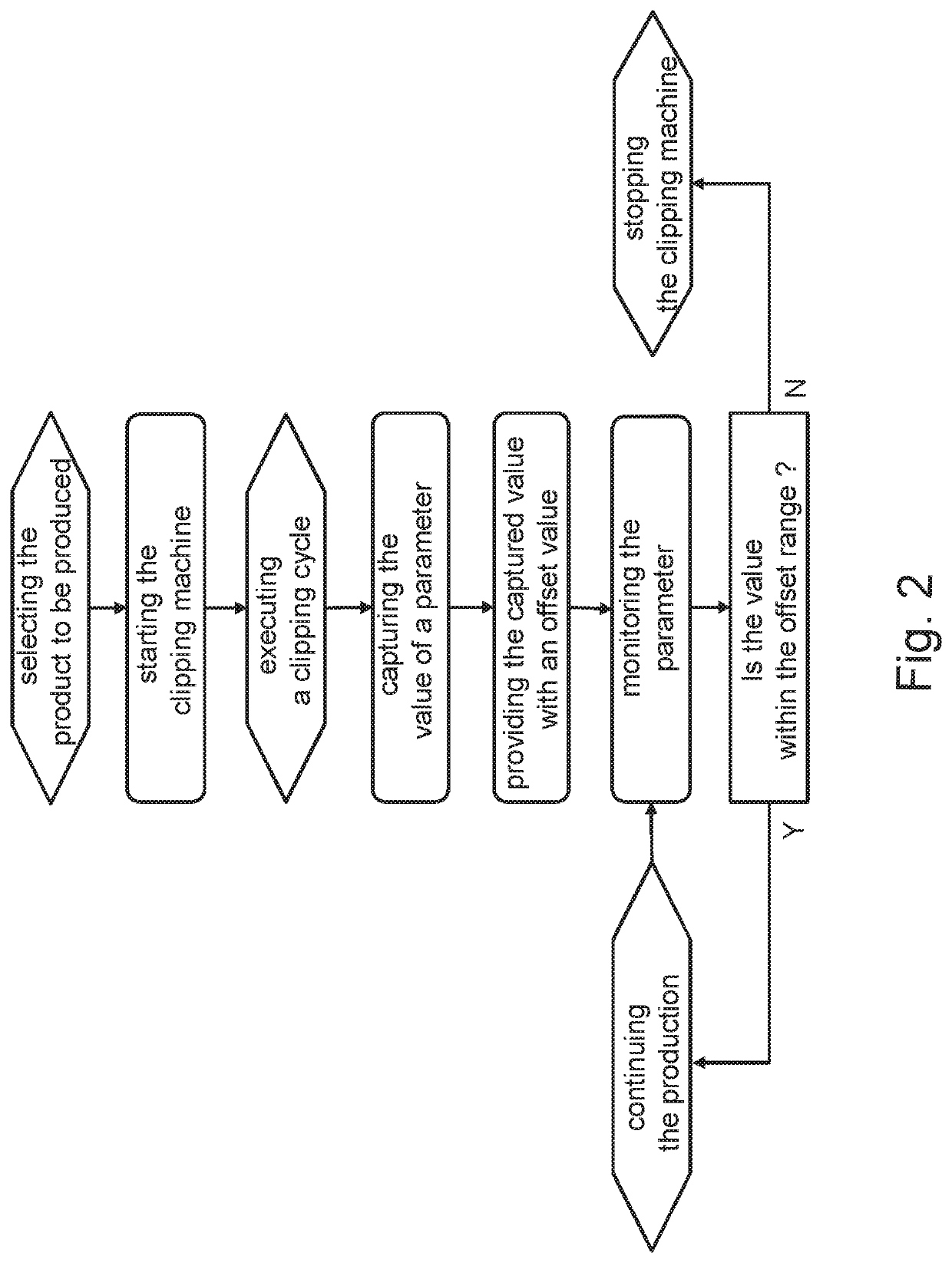

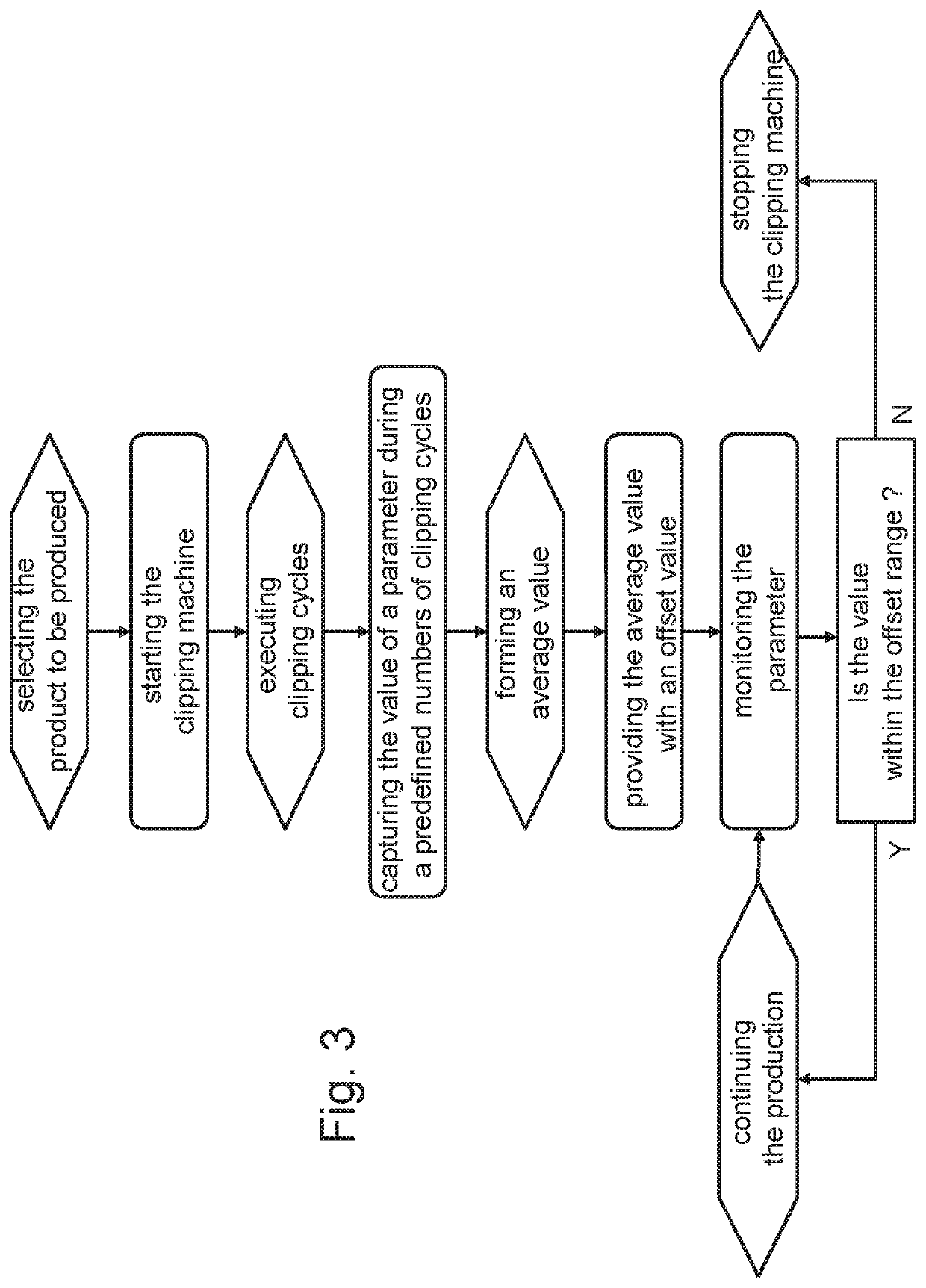

Method for controlling a clipping machine as well as a clipping machine therefor

ActiveUS10750752B2Improve reliabilityIncrease flexibilityLinked sausage separationWrapper twisting/gatheringProcess engineeringMechanical engineering

The present invention relates to a method for producing sausage-shaped products, like sausages, containing a flowable filling material in a tubular or bag-shaped packaging casing, on a clipping machine having a control unit for controlling the clipping machine, the method comprises the steps of feeding the filling material in a feeding direction into the tubular or bag-shaped packaging casing stored on a filling tube and being closed at the front end by a closure means, like a closure clip, gathering the filled tubular or bag-shaped packaging casing by gathering means arranged downstream the filling tube, for forming a plait-like portion thereto, and placing and closing at least one closure means on the plait-like portion for closing the filled tubular or bag-shaped packaging casing. The method includes the steps of starting the production process, automatically capturing at least one value of at least one parameter of the clipping machine and setting the captured value as the target value for said parameter in the further production process. The present invention further relates to a clipping machine on which the inventive method may be executed.

Owner:POLY CLIP SYST

Closure module and method for closing and/or separating filled sausage casings

ActiveCN110663750AReduce consumptionShorten closing timeLinked sausage separationWrapper twisting/gatheringEngineeringMechanical engineering

The invention relates to a closure module and a method for closing and / or separating filled sausage casings connected via a sausage neck, the closure module comprising two stamps movable relative to and towards each other and arranged such that a sausage neck can be placed therebetween, the stamps being capable of clamping the sausage neck in a closed condition, and further comprising a first anda second electrode, through which, in a closed condition of the stamps, a current can flow from the first electrode into the sausage neck and via the sausage neck into the second electrode.

Owner:ALBERT HANDTMANN MASCHFABRICK

Food packaging and pretreatment device for bent sausages

ActiveCN112640944AGood lookingDecrease productivityClimate change adaptationLinked sausage separationBiotechnologyEngineering

The invention relates to the field of food processing and particularly relates to a food packaging and pretreatment device for bent sausages. A technical problem to be solved by the invention is to provide the food packaging and pretreatment device for the bent sausages. A technical embodiment of the invention is as follows: the food packaging and pretreatment device for the bent sausages comprises a supporting framework, a fixed base, an operation control screen and an alignment system, wherein the fixed base and the supporting framework are fixedly connected. According to the food packaging and pretreatment device, the sausages placed in disorder can be arranged in order, can be adjusted to face to the same direction and are stacked in a stack-up manner, the sausages can be in a prepackaged state, and thus, subsequent sausage packaging is facilitated; and meanwhile, multiple groups of sausages are placed and separated side by side, so that the effect of rapid batch-size packaging of the sausages can be achieved.

Owner:重庆好食在农业发展有限公司

Closure module and method for closing and/or separating filled sausage casings connected via a sausage neck

ActiveUS11330823B2Simple and reliable processEasy to handleLinked sausage separationSausage twisting/linking machinesMechanical engineeringComposite material

A closure module and a method for closing and / or separating filled sausage casings connected via a sausage neck, comprising, in at least one example, a first electrode and a second electrode located opposite the first one, the electrodes being arranged such that a sausage neck can be placed therebetween and being adapted to be moved relative to each other and towards the sausage neck to such an extent that a current can flow from the first electrode into the sausage neck and via the sausage neck into the second electrode.

Owner:ALBERT HANDTMANN MASCHFABRICK

Device and method for constricting and/or severing a sausage strand

PendingUS20220192208A1Reliable constrictionReliable separationLinked sausage separationHorizontally conveying sausagesCircular discEngineering

Owner:ALBERT HANDTMANN MASCHFABRICK

Closure module and method for closing and/or separating stuffed sausage casings

ActiveCN110663750BReduce consumptionShorten closing timeLinked sausage separationWrapper twisting/gatheringMechanical engineeringPhysics

The invention relates to a closing module and a method for closing and / or separating stuffed sausage casings connected via a sausage neck, the closing module comprising two dies which can be moved relative to and towards each other and which are held together It is configured so that the sausage neck can be placed between two stampers, the stamper can clamp the sausage neck in a closed state, and the closure module also includes a first electrode and a second electrode, and in the closed state of the stamper, the current can Through the first electrode and the second electrode, the sausage neck flows from the first electrode and flows into the second electrode via the sausage neck.

Owner:ALBERT HANDTMANN MASCHFABRICK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com