Sausage splitting equipment

A kind of enema and equipment technology, which is applied in sausage making, separated and connected sausages, metal processing, etc. It can solve the problems of hidden dangers in production safety, high labor intensity, cutting fingers, etc., and achieves the effect of easy maintenance and simple equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

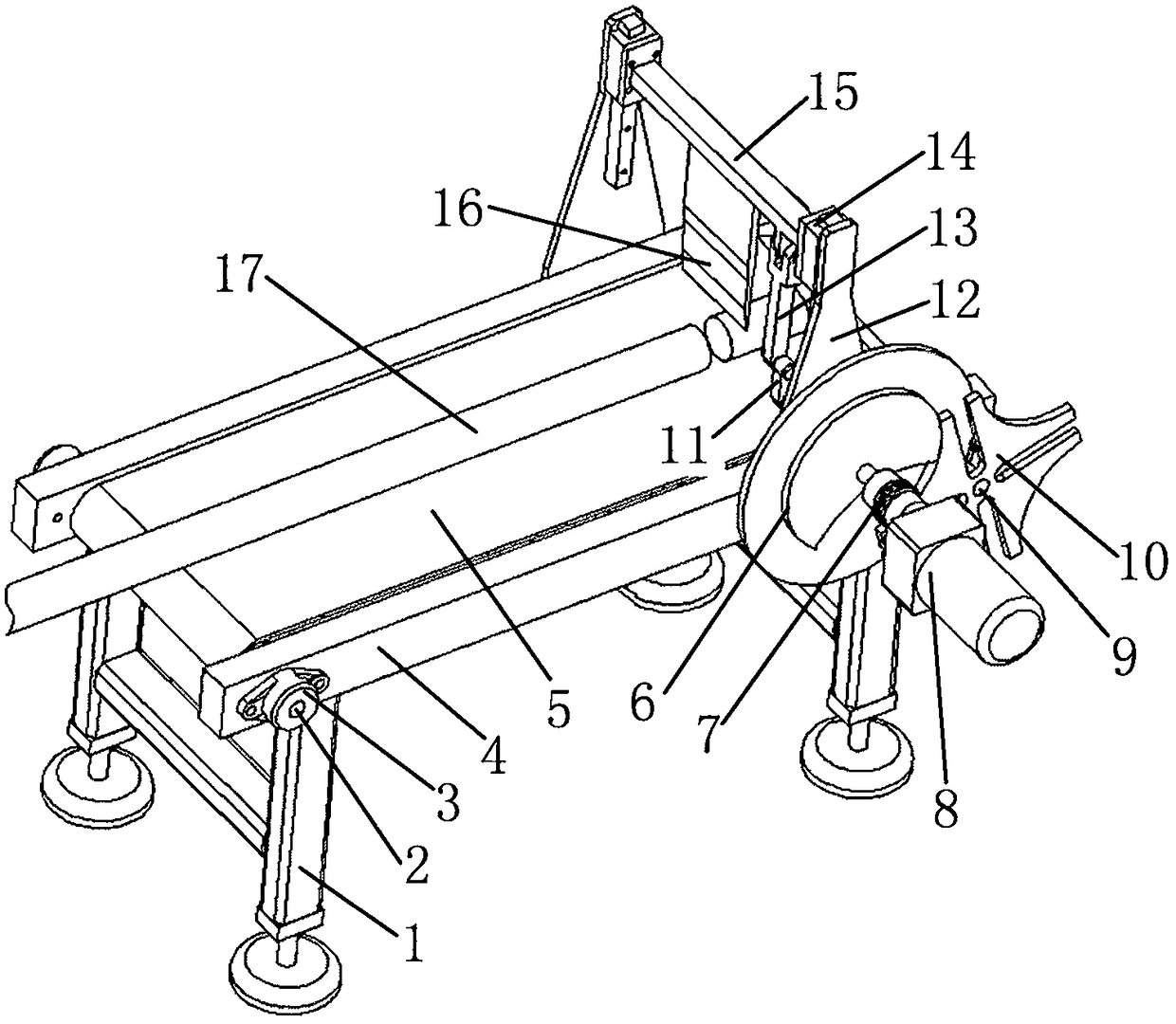

[0016] A sausage cutting device, comprising two side plates 4 arranged in parallel, the two side plates 4 are fixed by legs 1, the front and rear ends of the side plates 4 respectively pass through the driving shaft 9 and the driven shaft 2, the driving shaft 9 A conveyor belt 5 is arranged in the middle of the driven shaft 2, one end of the driving shaft 9 protrudes from the side plate 4 along its axial direction, connects the sheave 10 along the protruding part, and fixes a support plate 12 on the outside of the two side plates 4, wherein The lower part of the support plate 12 on which the sheave 10 is installed is arranged with a driving short shaft 7, one side of the driving short shaft 7 protrudes from the side plate 4, and a notched turntable 6 and a motor 8 are respectively installed, and the other side of the driving short shaft 7 passes through Support plate 12, is fixed with one end of crank 11, and slide rail assembly 14 is all installed in two support plate 12 inner...

Embodiment 2

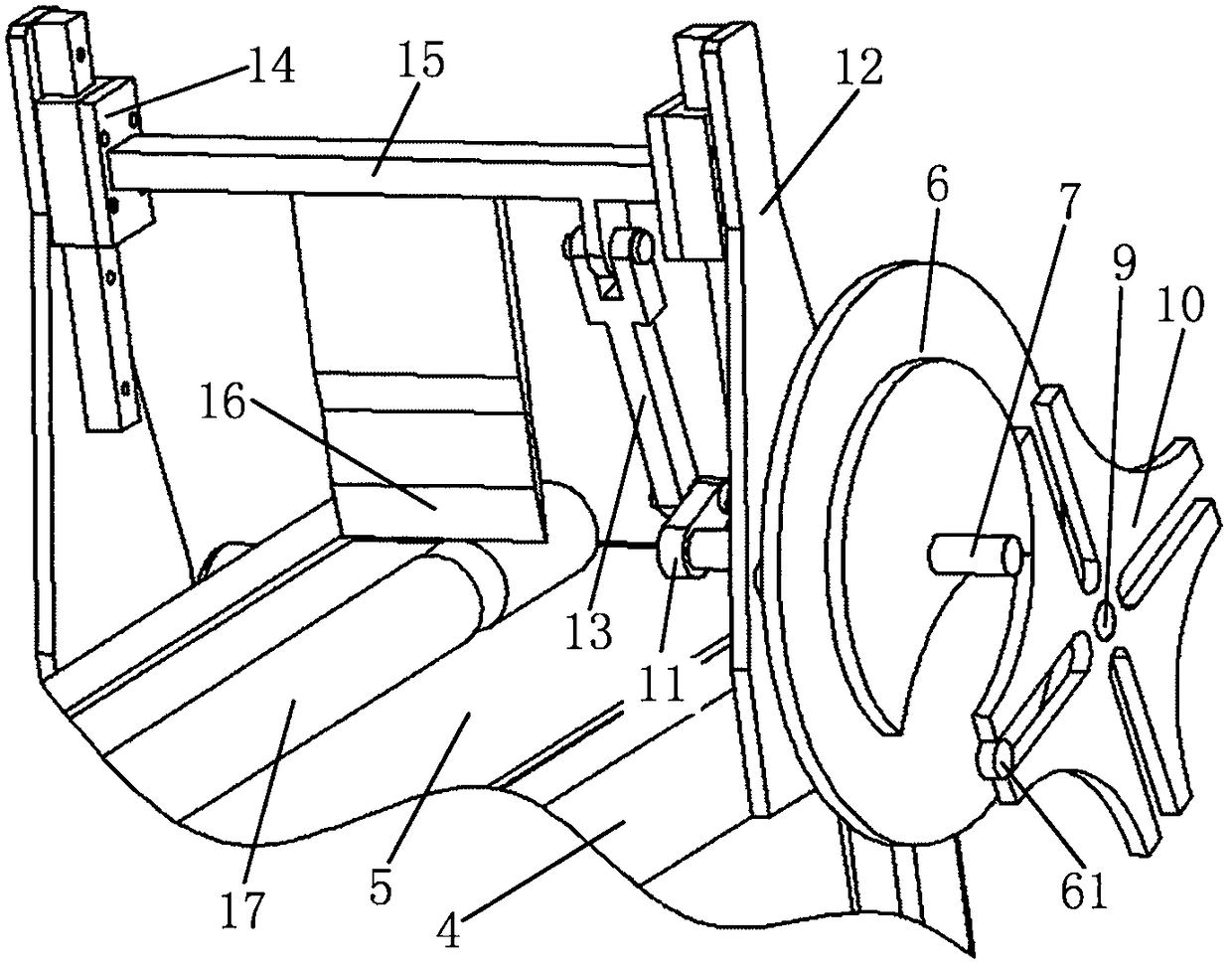

[0022] Such as figure 2 As shown, after the cutter 16 completes the cutting of the enema 17, under the drive of the crank 11, the cutter frame 15 drives the cutter 16 to move upward until it leaves the enema. At this time, the cylindrical block 61 on the notch turntable 6 just enters the groove of the sheave 10, thereby driving the sheave 10 to rotate, thereby making the conveyor belt 5 drive the enema 17 to move forward.

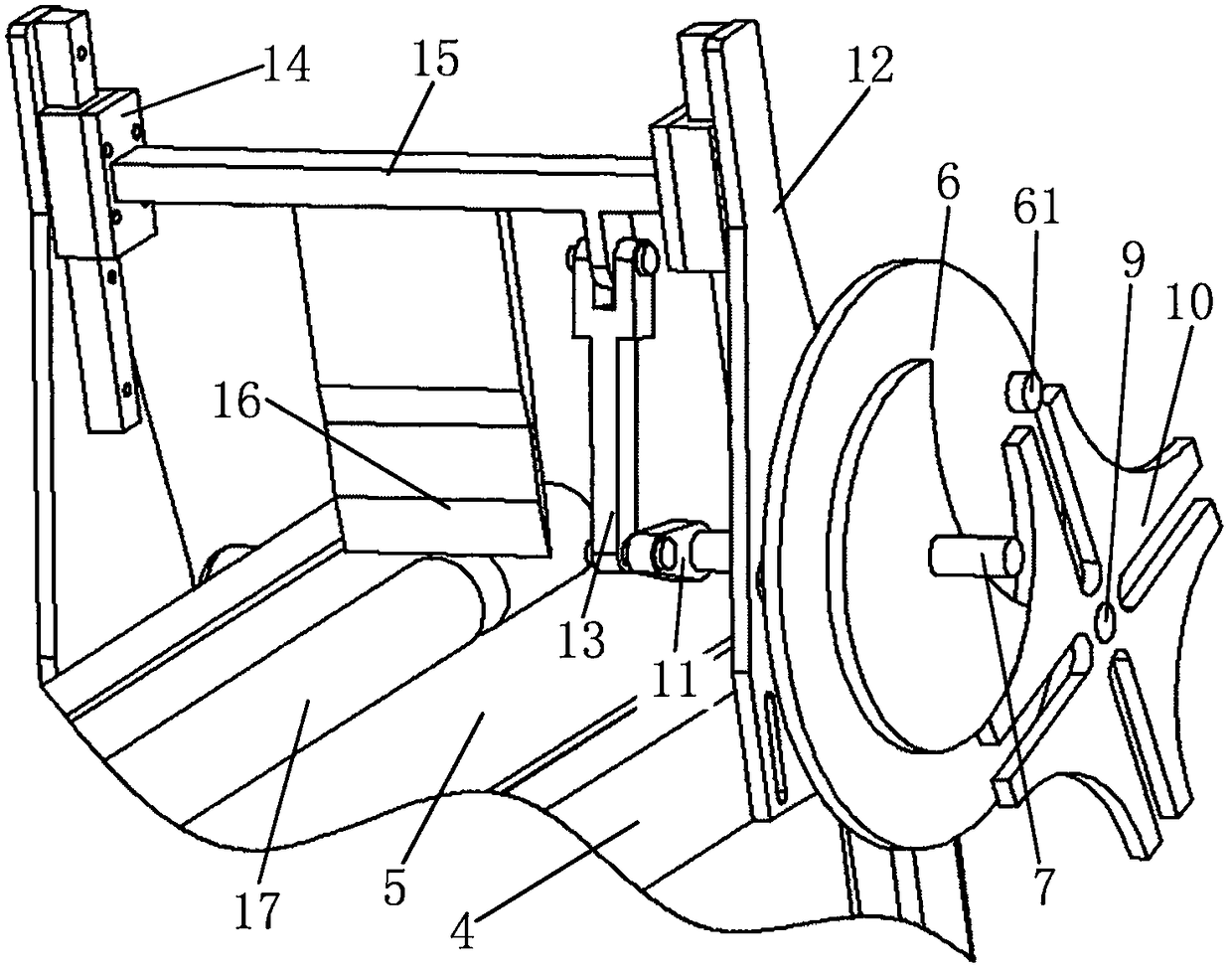

[0023] Such as image 3 As shown, the cylinder block 61 on the notch turntable 6 leaves the groove of the sheave 10, and the conveyor belt 5 no longer drives the enema 17 to move. At this time, under the drive of the crank 11 , the cutter frame 15 drives the cutter 16 to move downward to cut the enema 17 . After the cutting is completed, the cutter 16 moves upwards, and the previous step is repeated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com