A sausage energy-saving and environment-friendly production process and production equipment

An energy-saving, environmentally friendly, production equipment technology, applied in the direction of meat processing equipment, sausage production, sausage stuffing machine, etc., can solve the problems of low degree of automation, insufficient efficiency, and precision that cannot meet the requirements, so as to achieve low error rate and reduce Labor cost, simple and applicable effect of production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

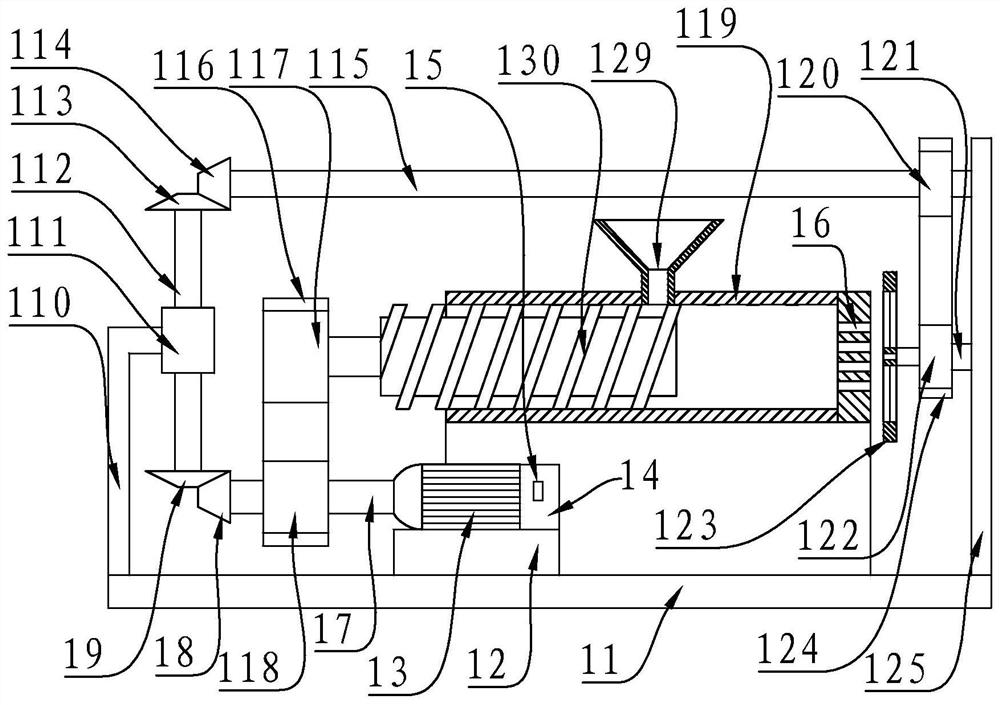

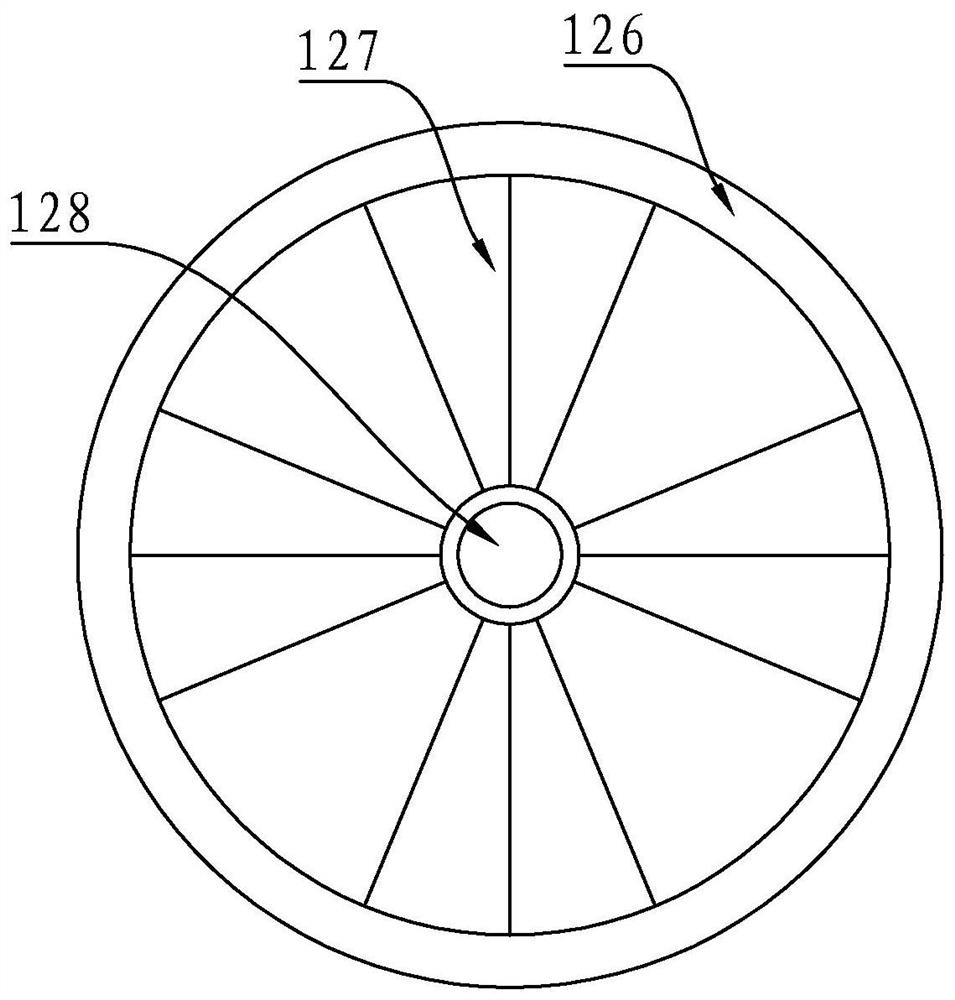

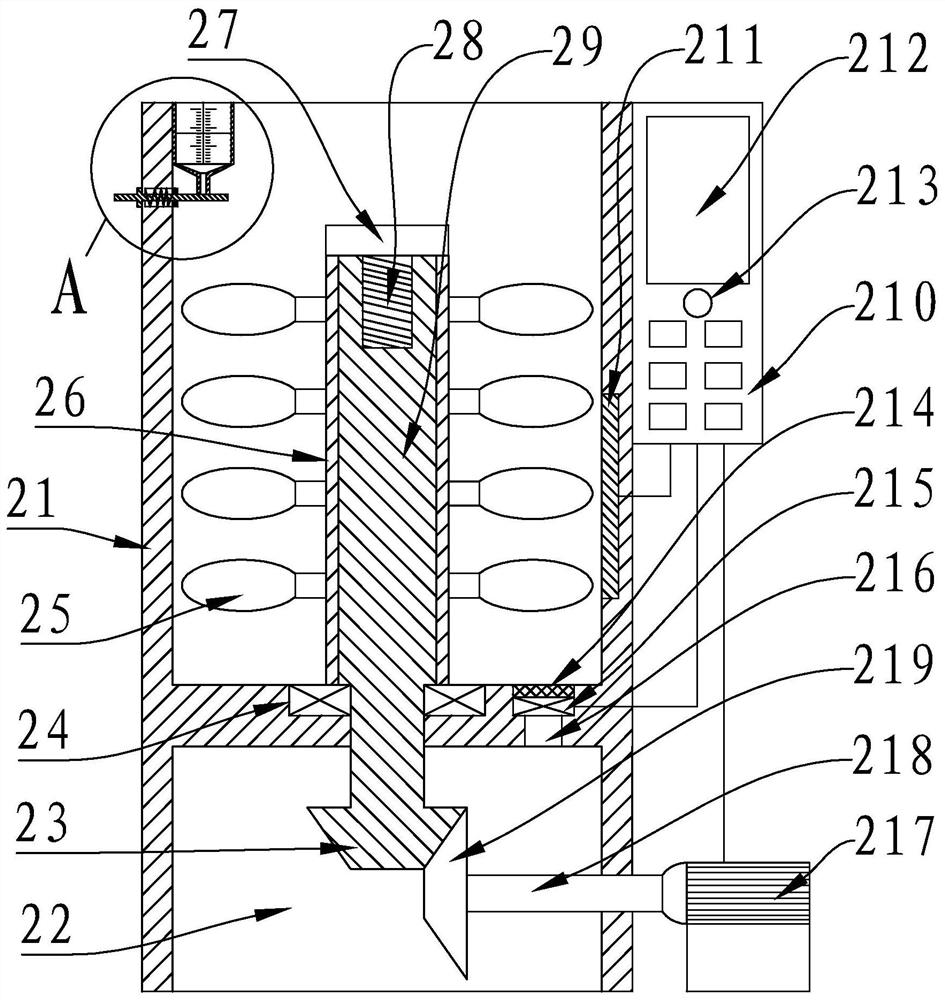

[0050] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

[0051] The invention provides an energy-saving, environment-friendly and high-quality production process for sausages, which comprises the following steps: 1) minced meat: crushing larger meat pieces into granular meat materials; 2) rinsing: washing the meat obtained in step 1) 3) Stir stuffing: Add sodium nitrite, salt, white sugar, monosodium glutamate and pigments and other condiments to the meat material rinsed in step 2) and stir to mix evenly; 4) Pickle: Stir step 3) to obtain 5) Weighing: Weigh the meat fillings obtained by rolling and kneading in step 4) respectively; 6) Enema: Enema the meat fillings obtained in step 5) respectively to obtain several connected sausages ; 7) Fumigation: fumigate the surface of the sausage body obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com