Patents

Literature

76results about How to "Unique production process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

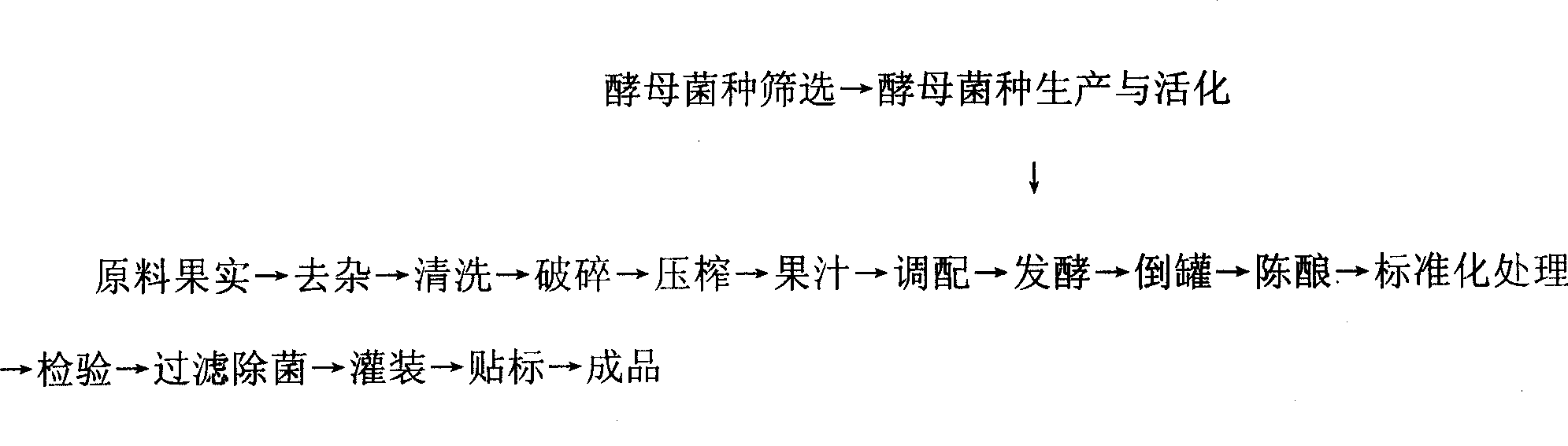

Aroniamelanocarpa fruit wine and brewing method thereof

InactiveCN101481643ARaw materials are uniqueFull of nutritionAlcoholic beverage preparationFruit juiceAntioxidant

The invention relates to an aroniamelanocarpa fruit wine and a brewing method thereof. The fruit of aroniamelanocarpa is taken as raw material and is made into fruit juice, fruit wine microzyme is selected for use and put into the fruit juice according to the proportion being 5-10% of the weight of the fruit juice, and the aroniamelanocarpa fruit wine is brewed with the alcohol content of 5-13% (v / v) and the total sugar content of 4.0-80.0g / L. The brewing technique of the invention comprises preparing the fruit juice, inoculation and fermentation, aging and store maturity, purifying wine body as well as filtration and sterilization, and the most advanced fermenting and purifying technique can be adopted by the production. The product of the invention has unique flavor, slightly acerbic and fresh taste, mellow mouthfeel, pleasing aroma and wide applicable people. The fruit wine contains multiple nutritional functional components such as anthocyanin, flavone, polyphenol active substance, vitamins antioxidant, mineral composition, polyoses, organic acid and the like which are rich in the fruit of aroniamelanocarpa, and has good effects of oxidation resistance, ageing prevention, blood pressure regulation, vessel relaxing, blood-fat reduction, anti-inflammation and detoxification, radiation resistance, etc.

Owner:辽宁省干旱地区造林研究所

Method for producing microecological preparation of bdellovibrio bacteriourus

ActiveCN101338293AUnique production processGuaranteed preservation qualityBacteriaMicroorganism based processesFreeze-dryingMicrobiology

The invention discloses a production method for a bdellovibrio micro-ecological preparation. The production method includes the following steps: A, preparing freezing-drying host bacteria powder; B, preparing the culture medium of the bdellovibrio; C, inoculating the seeds of the bdellovibrio with 2 to 5 percent into a fermentation pot loaded with the culture medium of the bdellovibrio, ventilating and culturing for 20 to 24 hours under 30 to 33 DEG C, namely obtaining the bdellovibrio micro-ecological preparation. The production technique of the host bacteria of the bdellovibrio micro-ecological preparation adopts the freezeing-drying technique to ensure the preservation quality of the host bacteria and provides a stable reliable proliferation nutrition source for the growing and proliferation of the bdellovibrio.

Owner:SHANDONG SINDER TECH

Silicone-acrylate emulsion and production process thereof

The invention relates to a silicone-acrylate emulsion which includes the materials of the following weight portions: 2.7 to 3.3 portions of SDBS, 4.5 to 5.5 portions of OP-10, 1.35 to 1.65 portions of ammonium sulphate, 3.6 to 4.4 portions of KH-570, 54 to 66 portions of methyl methacrylate, 69.3 to 84.7 portions of butyl acrylate, 28.8 to 35.2 portions of methacrylic acid, 9 to 11 portions of TT935 and 280 to 320 portions of deionized water. The invention also relates to the production technique of the silicone-acrylate emulsion which includes the preparation for the nuclear of an organic silicon acrylate polymer and the synthesis of the silicone-acrylate emulsion. The invention has the characteristics of high bonding performance, high resistance to elements, high water resistance, high dirt-resistance, anti-aging, no pollution, unique production technique, short production period, simple operation, low production cost and being suitable for the industrial production in large scale. The dopes manufactured by using the silicone-acrylate emulsion of the invention as basic materials are broadly applied to the indoor and outdoor walls.

Owner:四川伟才高新材料有限公司

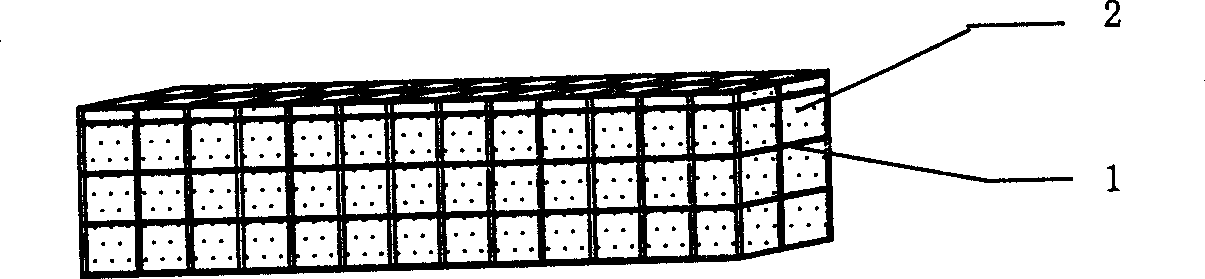

Mesopore activated carbon fiber and manufacturing method thereof

ActiveCN101824669AReasonable structureLarge proportion of mesoporeFibre chemical featuresActivated carbonFiber

The invention discloses mesopore activated carbon fiber and a manufacturing method thereof. The product comprises fiber body; the surface of the fiber body is provided with adsorbing holes; part of mespores with 2-20nm of bore diameter of exist in the adsorbing holes; the specific area of the fiber body is 1500-1700cm2 / g; the gross capacity of the adsorbing holes are 0.8-1cm2 / g; the volume of the middle holes is 0.3-0.4cm2 / g; and the manufacturing method comprises the steps of dipping, extruding, drying, charring and activating. The product has reasonable structure, big mespore proportion, good adsorption effect, stable quality, unique productive technology and easy operation.

Owner:JIANGSU TONGKANG SPECIAL ACTIVATED CARBON FIBER &GARMENTS

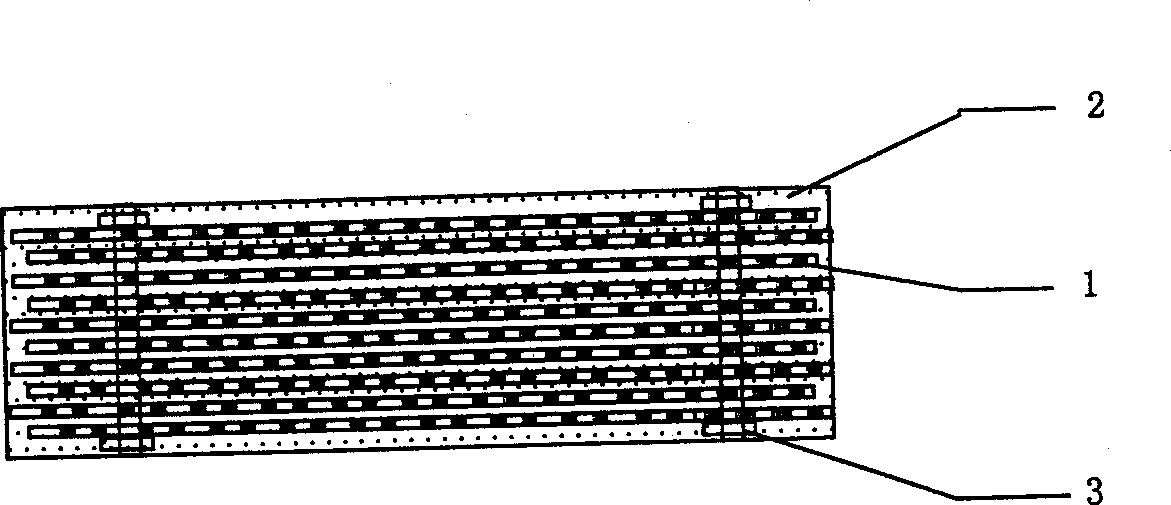

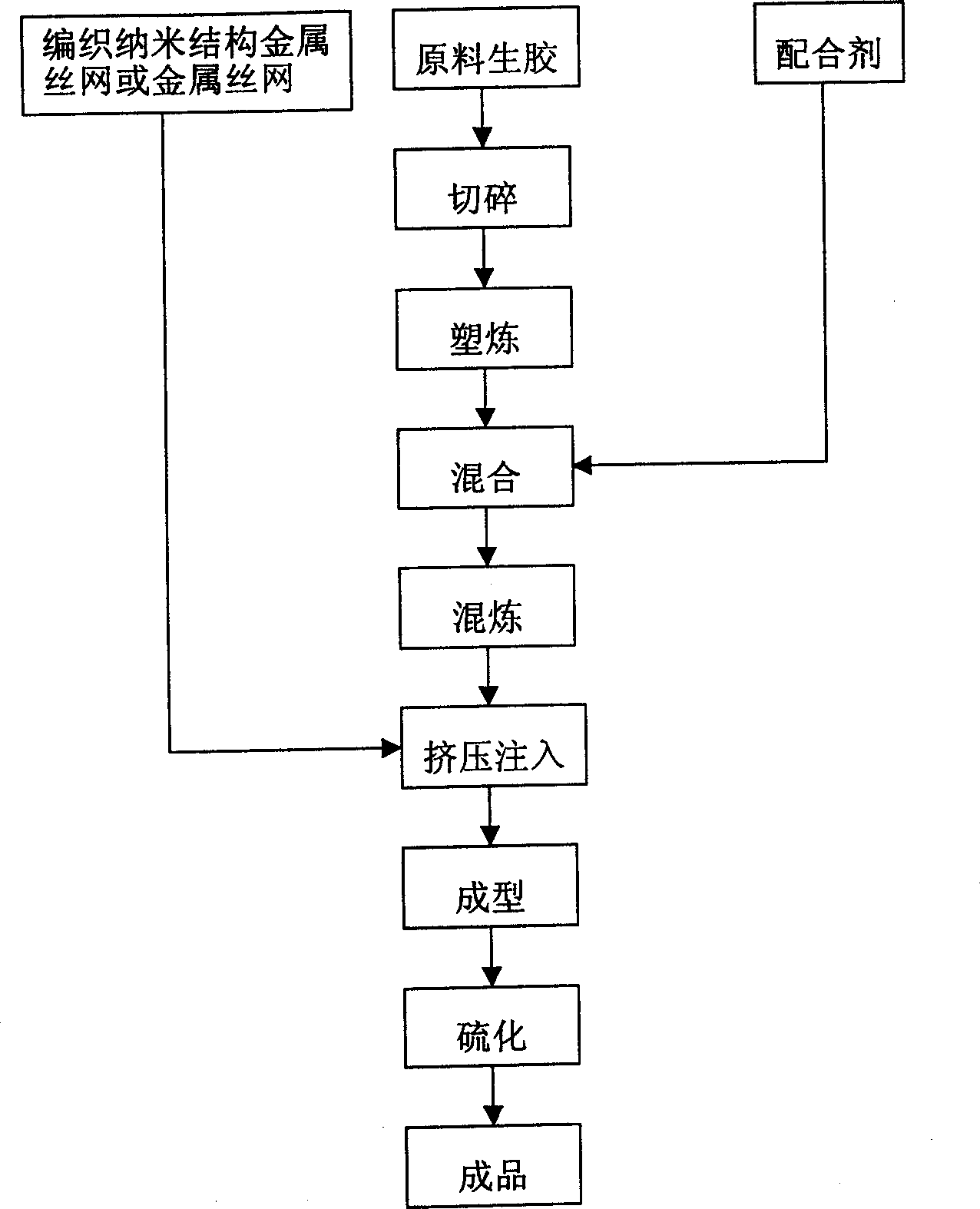

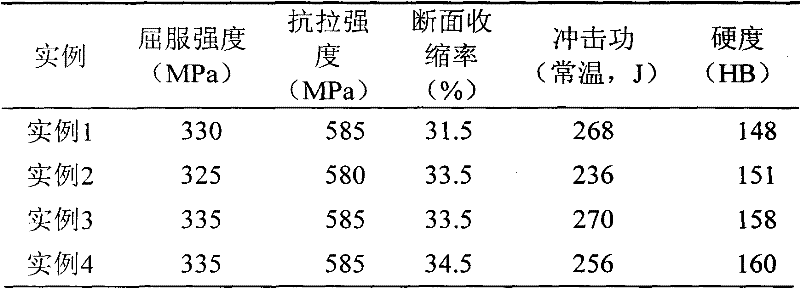

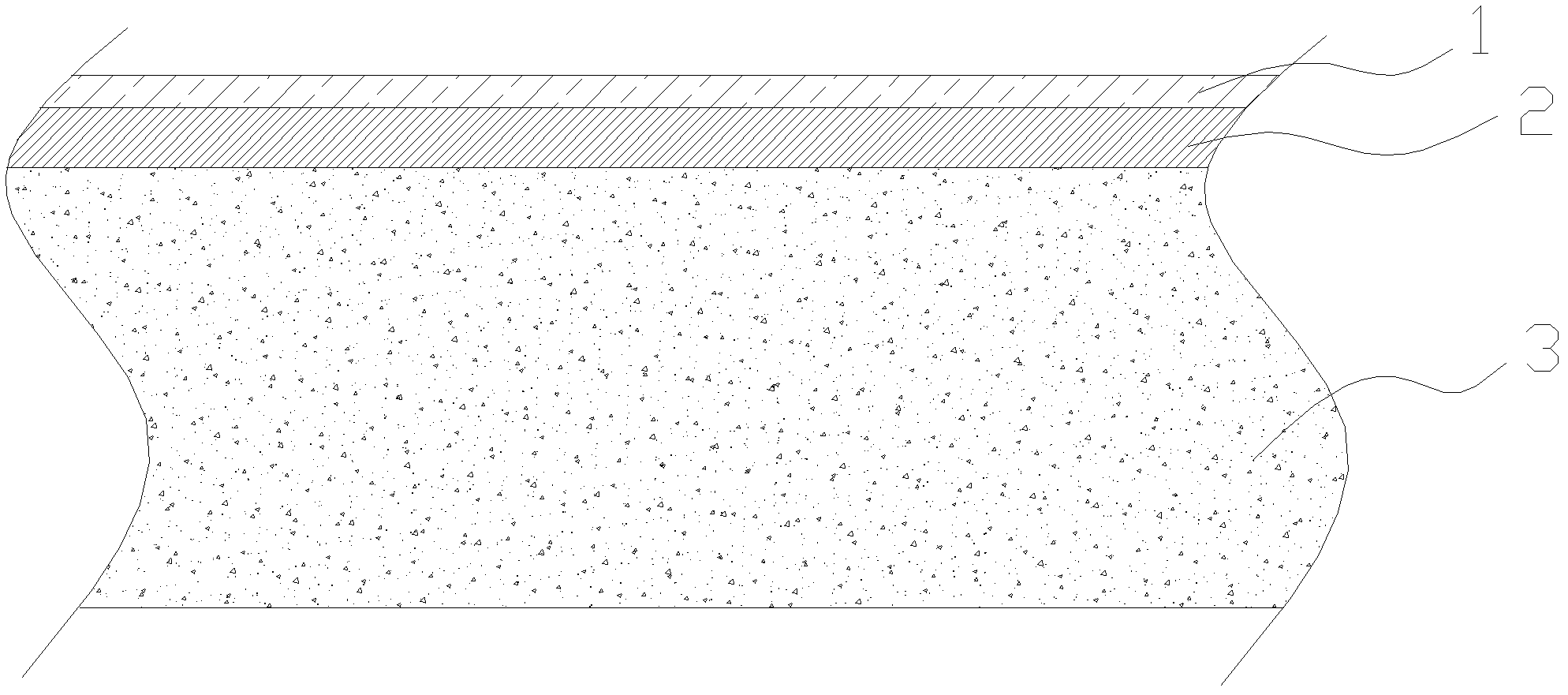

Composite lining with metal wire screen in nanometer structure and its production process

The present invention discloses a kind of nano structure wire gauze composite lining plate and its preparation process. Said lining plate is made up by using wire gauze and compounded filing materialthrough a compositive process. Said wire gauze can be integrally braided, also can be a multilayer structure pieced by using single-layer of wire gauze, said wire gauze can be placed in the interior of compounded filling material, then they are combined into a whole body. Said composite lining plate possesses high wear-resistance, water-resisting property, vibration-absorbing property and corrosion-resisting property, etc..

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

High concentration compound fertilizer

InactiveCN102276362AHigh nutrient contentLess side ingredientsFertilizer mixturesAmmonium sulfateSoil science

The invention provides a high-concentration compound fertilizer which is prepared from the following components in parts by weight, namely 35 parts of ammonium phosphate, 30 parts of ammonium hydrogen carbonate, 20 parts of calcium superphosphate, 15 parts of potassium chloride, 40 parts of potassium sulfate, 50 parts of urea, 10 parts of ammonium sulfate, 10 parts of ammonium chloride and 10 parts of kaolin (nucleating agent) through multiple chemical reactions. The high-concentration compound fertilizer has a special formula design, wherein the ratio of N to P to K reaches 40.625:23.4:21.0,the content of N and P and K reaches 85.625 percent which greatly exceeds 45 percent, and the exceeding value is 40.625 percent; and the high-concentration compound fertilizer has the characteristicsof no acidization and alkalization to soil and does not harden soil. A production process of the high-concentration compound fertilizer comprises the steps of: guniting through a high tower, granulating through a rotary hub, drying for two times and cooling for two times, wherein in processes of drying and cooling, a chemical reaction process of a composite material is further promoted and perfected.

Owner:吴金华

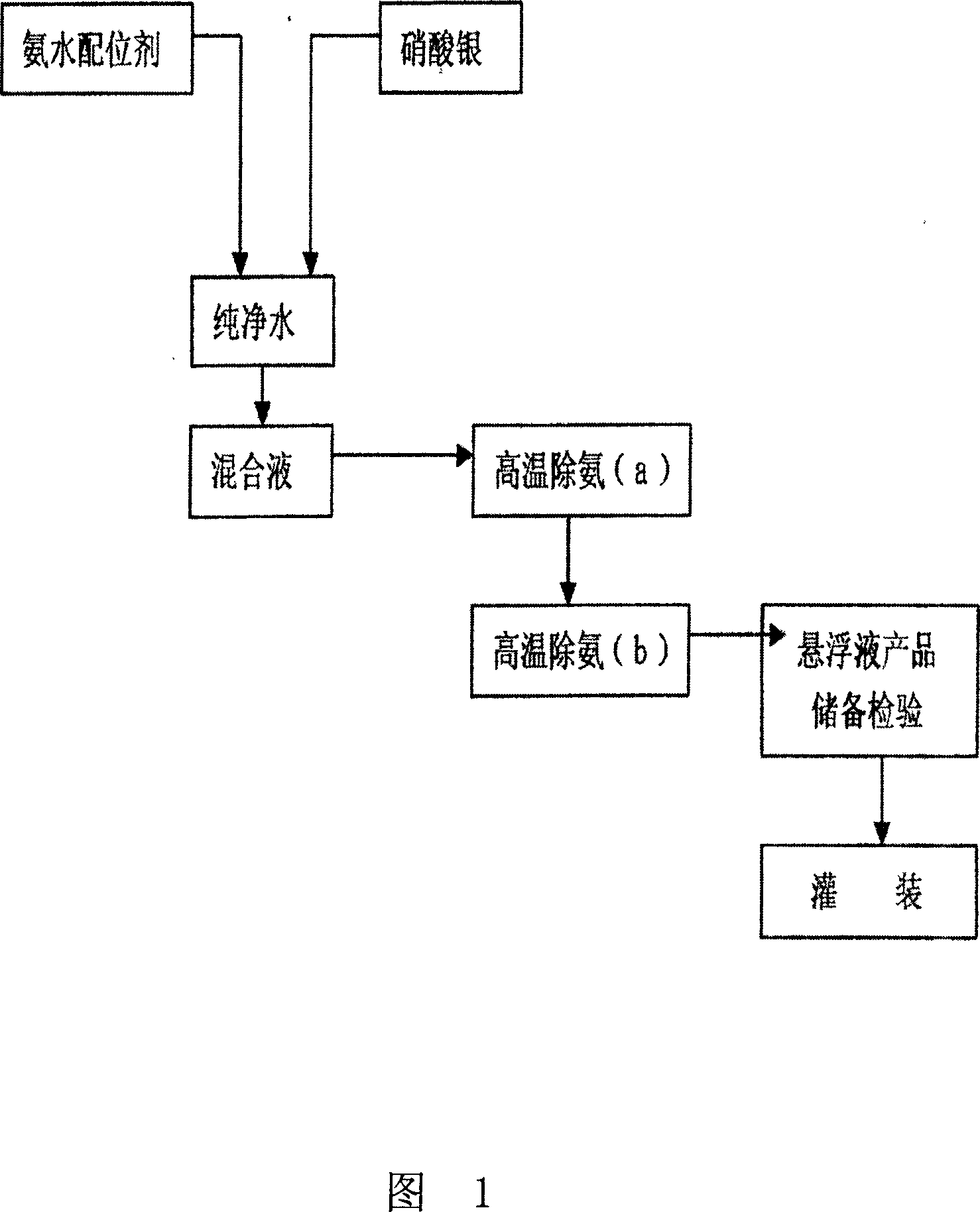

Preparation method of nano silver suspending liquid

InactiveCN1918998AStable in natureImprove sterilization efficiencyBiocideAnimal repellantsIonSilver particles

The invention discloses a preparing method of nanometer silver suspension, which comprises the following steps: adding silver nitrate solution in the purified water to dilute, putting certain quantity of ammonial solution (coordination agent) in the silver nitrate solution within regulated time, proceeding silver ammino complex reaction and ion coordination, heating the mixing solution sequently to remove ammonium, obtaining ball-shaped nanometer silver ionic suspension (the silver content scale is 5-1000ppm, the silver particle size is 0.1-20nm ).

Owner:张宝荣 +1

Low carbon hydrate beer and manufacturing method thereof

The invention relates to low carbohydrate beer, which comprises water, alcohol, carbohydrate, protein, carbon dioxide, mineral composition and other compositions, wherein, the carbohydrate is equal to or less than 1.6 percent (m / m), and the heat is equal to or less than 108KJ / 100ml. The manufacturing method of the beer is that: crushing malt, carrying out saccharification and fermentation, filtering and packaging, wherein, the selected raw material is two-rowed malt; the saccharification temperature is 62-65 DEG C and the saccharification time is 60-100 minutes, efficient enzyme preparation is added in the process of saccharification, thereby the fermentation degree of the beer reaches a higher value; maltogenic amylase and pullulanase can be separately selected or selected in a blending way as the efficient enzyme preparation. Compared with the traditional beer, the carbohydrate of the beer is reduced by more than 56 percent, the heat is reduced by more than 36 percent, the rate of dilution can be enlarged to 70 percent, and the main fermentation time is shortened, thereby reducing grain consumption, improving production efficiency, saving production cost and improving product quality.

Owner:TSINGTAO BREWERY

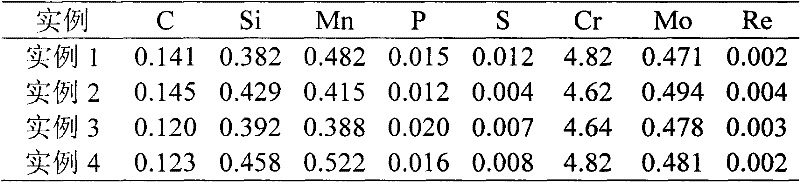

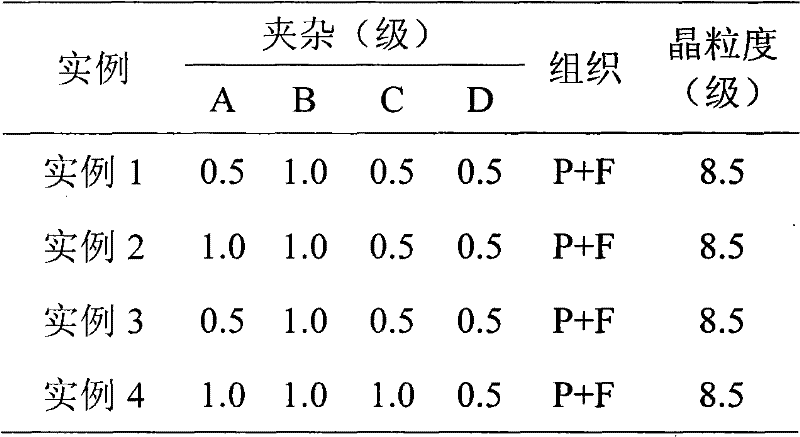

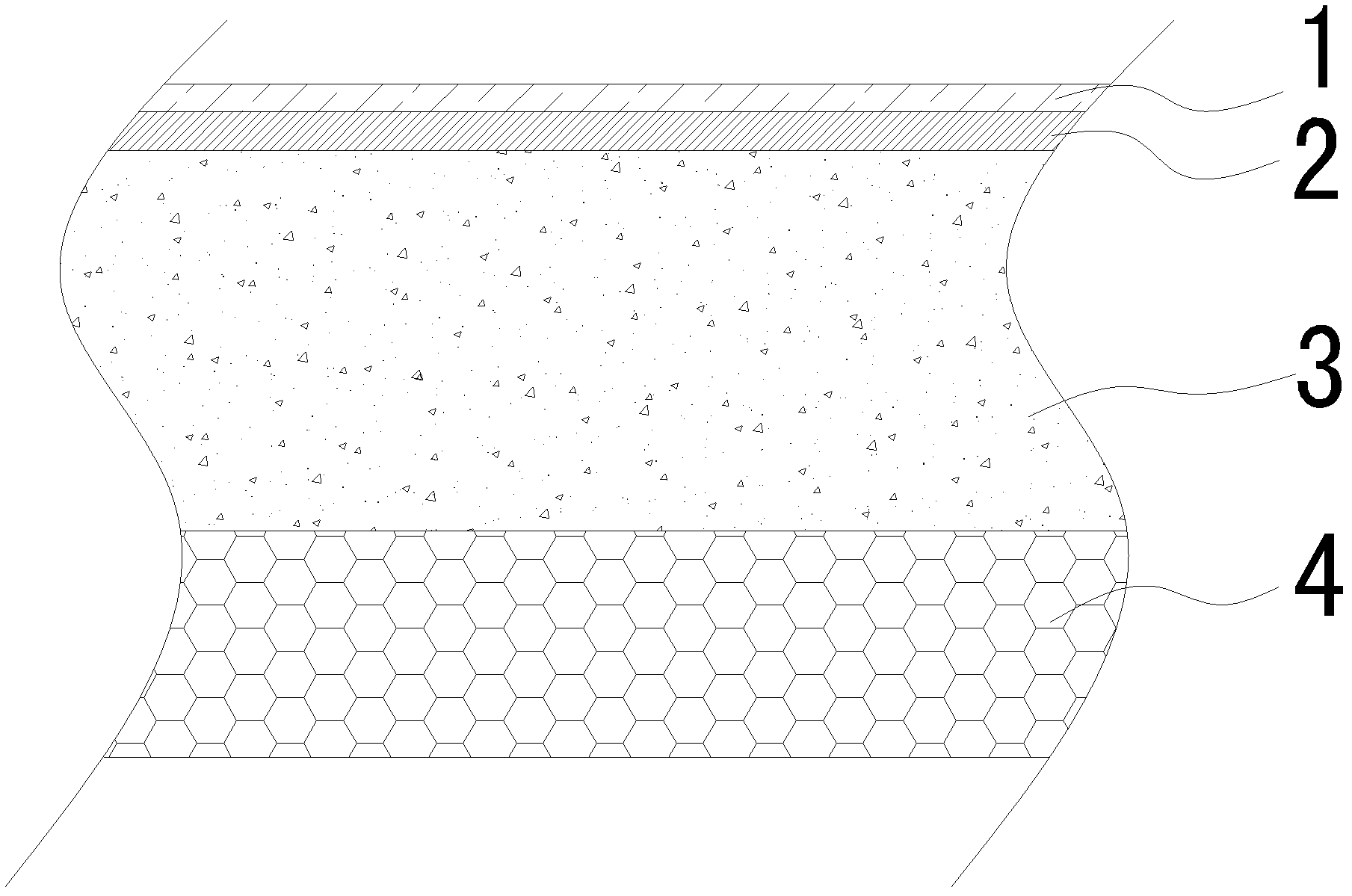

Method for preparing rare earth-containing seamless steel tube for petroleum cracking

The invention relates to a method for preparing a rare earth-containing seamless steel tube for petroleum cracking. The method is characterized in that: a steel material of the seamless steel tube comprises the following chemical ingredients in percentage by mass: 0.09 to 0.15 percent of C, 0.22 to 0.50 percent of Si, 0.31 to 0.60 percent of Mn, 4.00 to 6.00 percent of Cr, 0.45 to 0.65 percent of Mo, less than or equal to 0.02 percent of P, less than or equal to 0.02 percent of S, 0.002 to 0.005 percent of Re and the balance of Fe, wherein the total mass fraction of all the ingredients is 100 percent; continuous casting blank rounding punching temperature of the material is between 1,250 and 1,280 DEG C; the tube rolling temperature is between 1,180 and 1,220 DEG C; the sizing / stretch-reducing temperature is between 820 and 860 DEG C; a heat treatment process of normalizing and tempering is adopted, and the normalizing temperature is between 860 and 880 DEG C and is kept for 70 to 80 minutes; and the tempering temperature is between 730 and 750 DEG C and is kept for 90 to 100 minutes. The method has the advantages that: the prepared seamless steel tube has extremely high compression strength and corrosion resistance, and each performance meets the requirement of the seamless steel tube for the petroleum cracking under rigorous conditions.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

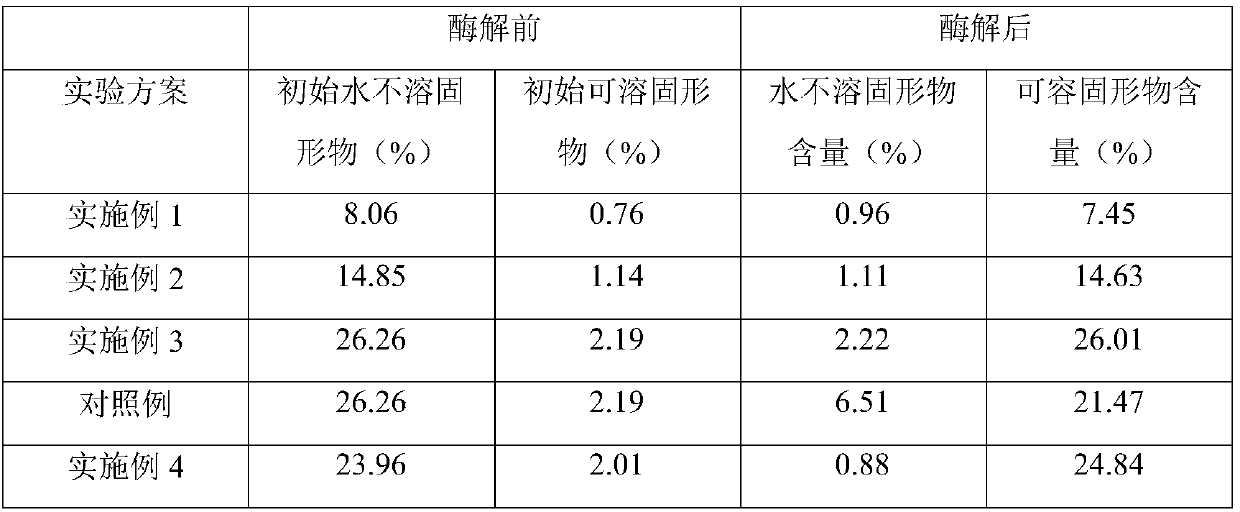

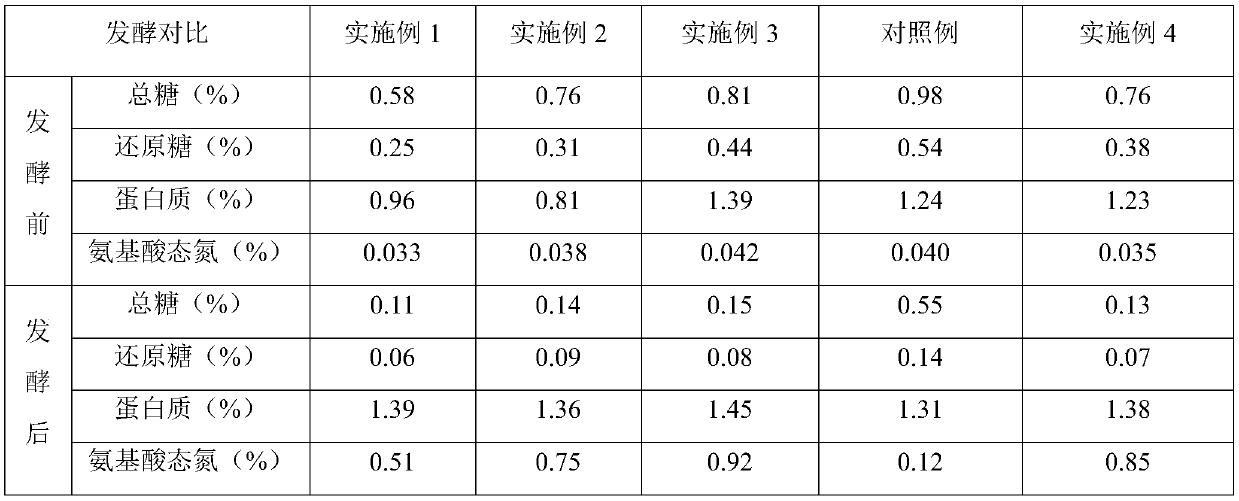

Process for preparing selenium yeast protein peptide powder from selenium-rich yeast

InactiveCN106520875APromote digestion and absorptionImprove immunityCosmetic preparationsToilet preparationsUltrafiltrationHydrolysate

The invention provides a process for preparing selenium yeast protein peptide powder from selenium-rich yeast. The process comprises the following steps: (1) with a selenium-rich yeast product as a raw material, dissolving selenium-rich yeast in water to prepare a suspension with a concentration of 10 to 15%; (2) subjecting the suspension containing the selenium-rich yeast to autolysis at a temperature of 53 to 55 DEG C under the condition of a natural pH value and adding plasmolyticum in the phase of autolysis; (3) adjusting the pH value of the suspension having undergone autolysis to 6 to 7 and adding a composite bio-enzyme preparation so as to prepare enzymatic hydrolysate for subsequent usage; (4) subjecting the enzymatic hydrolysate to hydrolysis at a temperature of 55 + / - 2 DEG C for 20 to 24 h, heating hydrolysate to 85 to 90 DEG C after hydrolysis, maintaining the temperature for 2 h, inactivating enzyme in the solution so as to guarantee stable product quality and high yield, then carrying out ultrafiltration and collecting a filtrate so as to obtain a polypeptide filtrate; (5) subjecting the polypeptide filtrate obtained after ultrafiltration to nanofiltration and desalination so as to obtain a desalinized peptide solution; and (6) subjecting the desalinized peptide solution to concentration and drying so as to obtain the selenium yeast protein peptide powder.

Owner:安徽省华信生物药业股份有限公司

Porcelain plastic decorative plate and its processing method

InactiveCN102991069AReduce manufacturing costGood mechanical propertiesSynthetic resin layered productsFiberStone dust

The invention relates to a decorative plate, and discloses a porcelain plastic decorative plate. The porcelain plastic decorative plate comprises, from top to bottom, a PVC transparent abrasion-resistant layer, a PVC pattern printing layer and a substrate layer which are sequentially stacked. The substrate layer comprises the following components, by weight, 100 parts of PVC resin, 15-20 parts of a plasticizer, 2.0-5.0 parts of a stabilizing agent, 60-70 parts of bead powder, 15-30 parts of a fiber, 5-10 parts of an impact improver, 15-30 parts of stone powder, 0.5-1.5 parts of rosin or PE wax, and a proper amount of a coloring agent. The invention also discloses a processing method of the decorative plate. The method comprises the following technological steps: 1, processing the substrate layer; 2, printing a pattern; 3, carrying out hot-press molding; 4, carrying out surface treatment; 5, carrying out heat treatment; and 6, carrying out product inspection and packaging. The decorative plate has the advantages of stable dimensional stability, low water absorption rate, difficult deformation, difficult shedding and foaming of the decorative layer, rich and colorful pattern, and stereoscopic effect.

Owner:SHENZHEN JIANCHEN INDAL

Cotton fiber modifying agent, modified cotton fiber and preparation method thereof

PendingCN108611849AIncrease forceMaintain stability and persistenceUltrasonic/sonic fibre treatmentVegetal fibresTanninCellulose

The invention provides a cotton fiber modifying agent, a modified cotton fiber and a preparation method thereof. The cotton fiber modifying agent comprises a traditional Chinese medicine composition.The traditional Chinese medicine composition is prepared from, by weight, 10-60 parts of flos caryophylli and / or radix astragali, 10-60 parts of rhizoma coptidis and / or cortex phellodendri, 5-50 partsof sophora alopecuroides and 10-70 parts of folium geranii dahurici. By reasonable compatibility of components of the traditional Chinese medicine composition and reasonable content values, the traditional Chinese medicine composition contains antibacterial and mould-proof functional substances and tannin substances, combination of functional components in the traditional Chinese medicine composition and cellulose macromolecular groups in cotton fibers is promoted to realize hydroxyl radical formation, macromolecular interaction is enhanced, functional durability and stability of the traditional Chinese medicine composition are maintained, and antibacterial and mould-proof effects of the cotton fibers are achieved.

Owner:顾翚

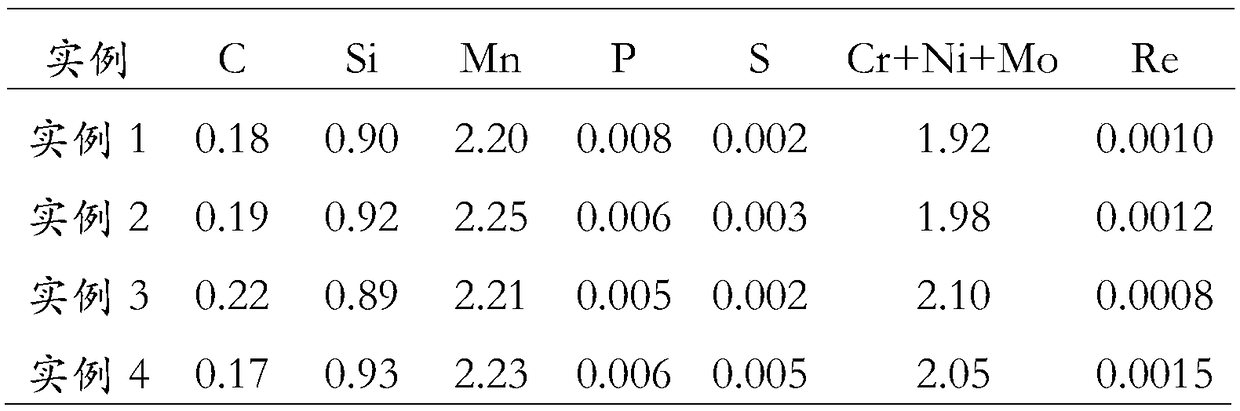

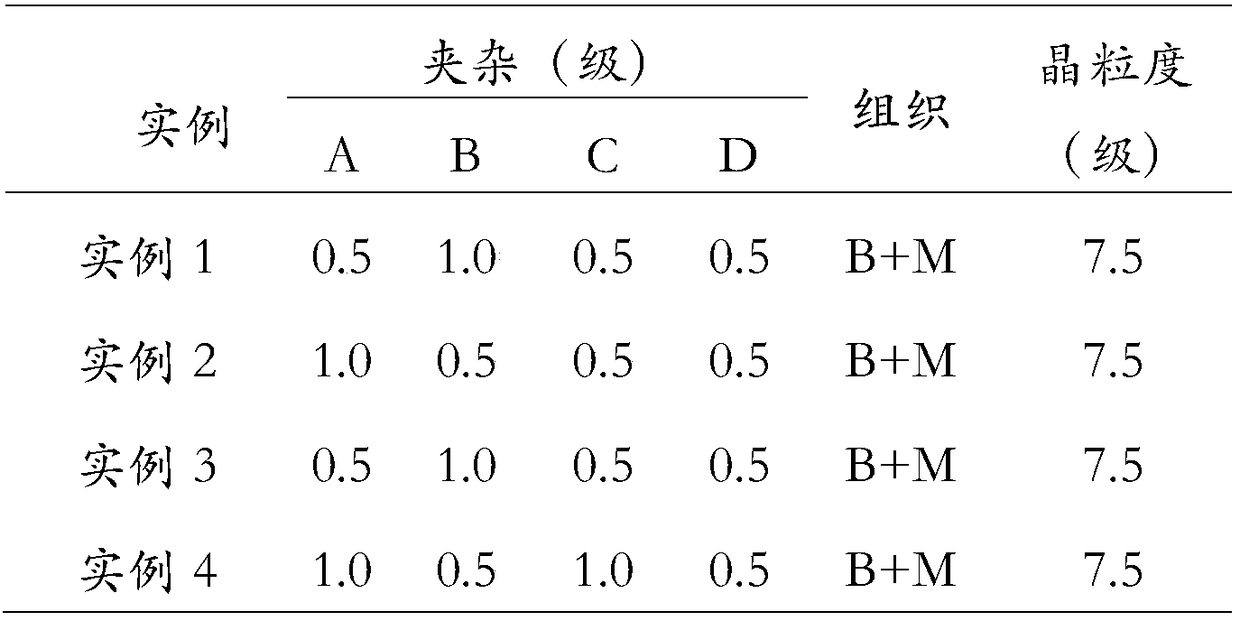

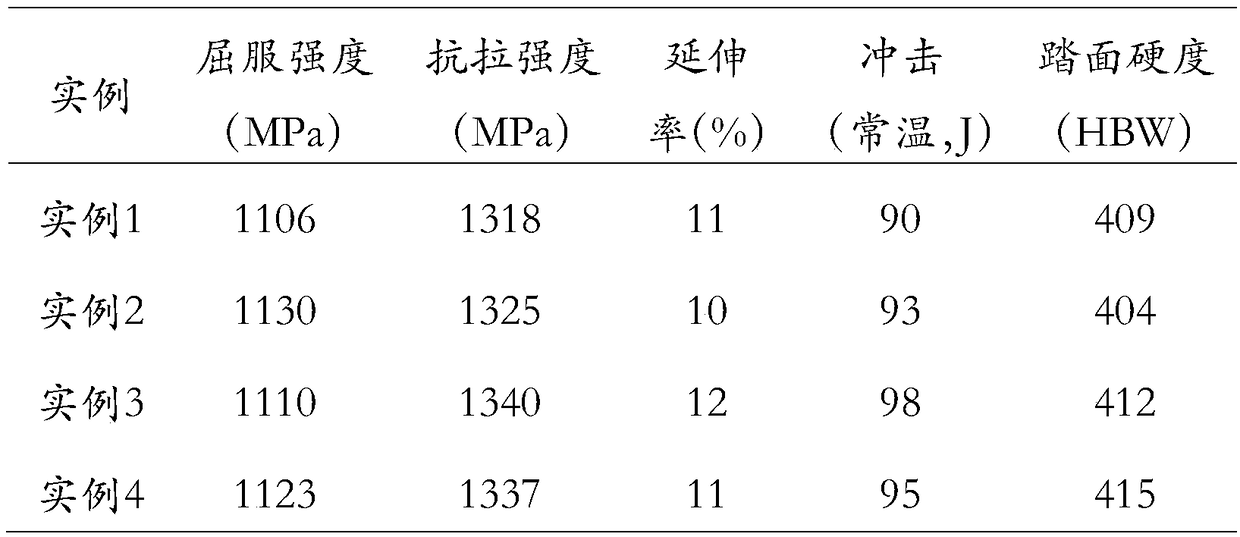

Steel rail and production method of steel rail

The invention provides a steel rail and a production method of the steel rail. The steel rail is prepared from chemical components in percent by weight: 0.16-0.25% of C, 0.70-1.20% of Si, 1.60-2.45% of Mn, smaller than or equal to 0.022% of P, smaller than or equal to 0.015% of S, smaller than or equal to 0.030% of Al, smaller than or equal to 2.30% of Cr+Ni+Mo, 0.0005-0.0020% of RE and the balance being a matrix Fe and microimpurity elements incapable of being detected. By means of the technical scheme, rolled steel made from Cr, Ni and Mo high-alloy low-carbon steel and containing Re has good strength, toughness and mechanical performance, and the steel rail prepared from the rolled steel has good abrasion resistance and contact fatigue resistance. The rare-earth-containing high-strengthhigh-toughness bainite steel rail has a special production process, is high in production efficiency, low in cost and suitable for large-scale production, and has good economic benefits and good promotional value, and energy saving and environmental protection are achieved.

Owner:BAOTOU IRON & STEEL GRP

Green high-efficiency processing method for roxburgh rose fruit powder

InactiveCN107212227APromote digestion and absorptionImprove immunityFood homogenisationFood dryingIce waterFruit juice

The invention provides a green high-efficiency processing method for roxburgh rose fruit powder. The method comprises the following steps: (1) storing mature roxburgh rose fruit in a fresh-keeping storehouse for 6 to 8 h; (2) taking the roxburgh rose fruit out from the fresh-keeping storehouse, soaking the roxburgh rose fruit in ice water for 30 to 60 min, then adding a proper amount of edible salt in the ice water, carrying out stirring every 15 min or so during soaking, then cleaning the surface of the roxburgh rose fruit and draining the roxburgh rose fruit for subsequent usage; (3) crushing and juicing the cleaned roxburgh rose fruit, collecting roxburgh rose fruit juice with a container, adding purified water accounting for 1.5 times the weight of the roxburgh rose fruit juice, carrying out uniform mixing under stirring, and then adding a bio-enzyme preparation so as to obtain enzymatic hydrolysate for subsequent usage; (4) subjecting the enzymatic hydrolysate to hydrolysis at 55 + / - 2 DEG C for 20 to 24 h, carrying out enzymatic hydrolysis, heating the obtained enzymatic hydrolysate to 55 to 70 DEG C, maintaining the temperature for 2 h to inactivate enzymes in the enzymatic hydrolysate, then carrying out filtering and collecting a filtrate for subsequent usage; (5) homogenizing the filtrate with a high-pressure homogenizer and carrying out filtering with a 200-mesh sieve so as to obtain a stock solution of the roxburgh rose fruit juice; and (6) subjecting the stock solution of the roxburgh rose fruit juice to concentration and drying so as to obtain the roxburgh rose fruit powder.

Owner:ANHUI FINDSHE BIOLOGICAL PHARMA CO LTD

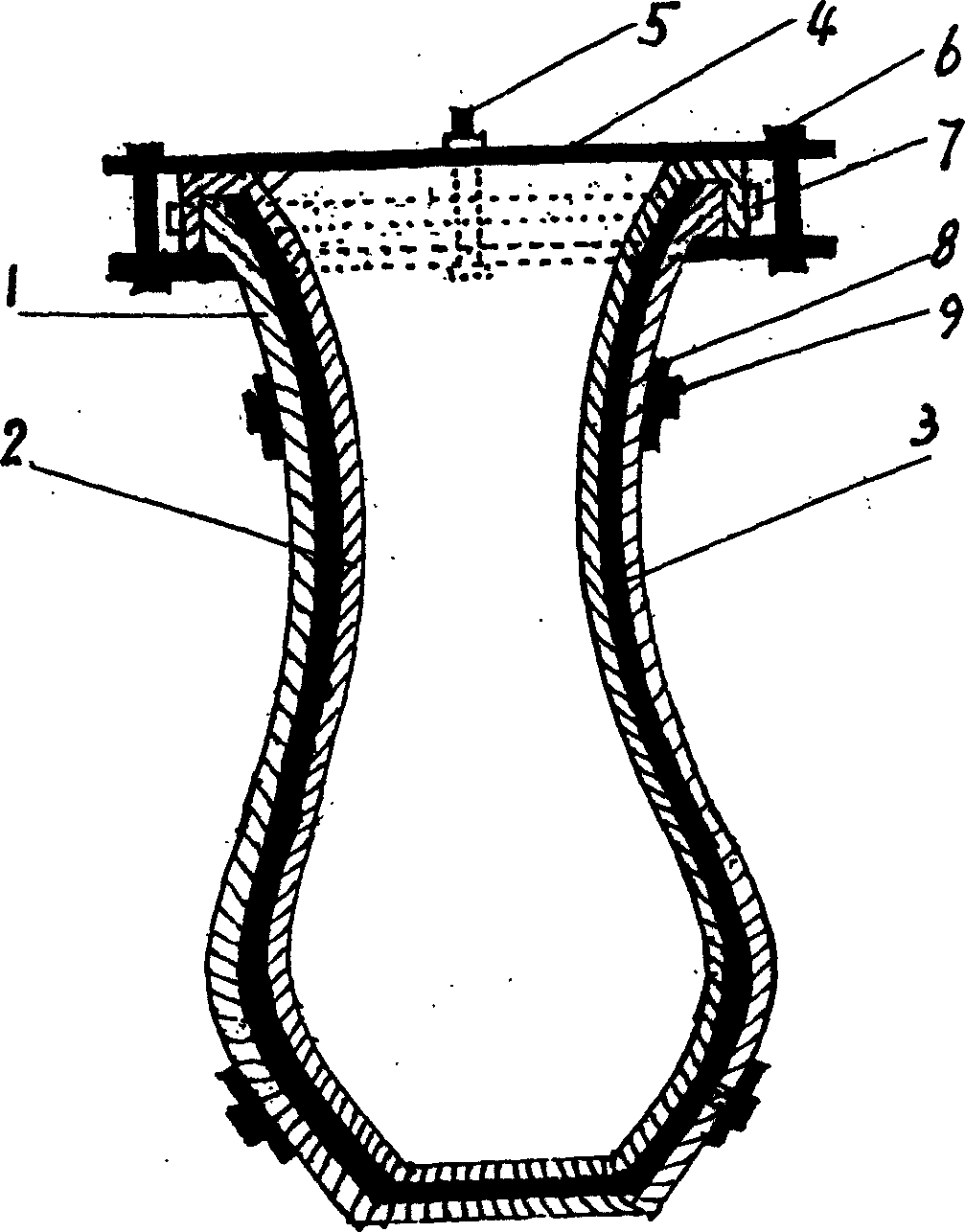

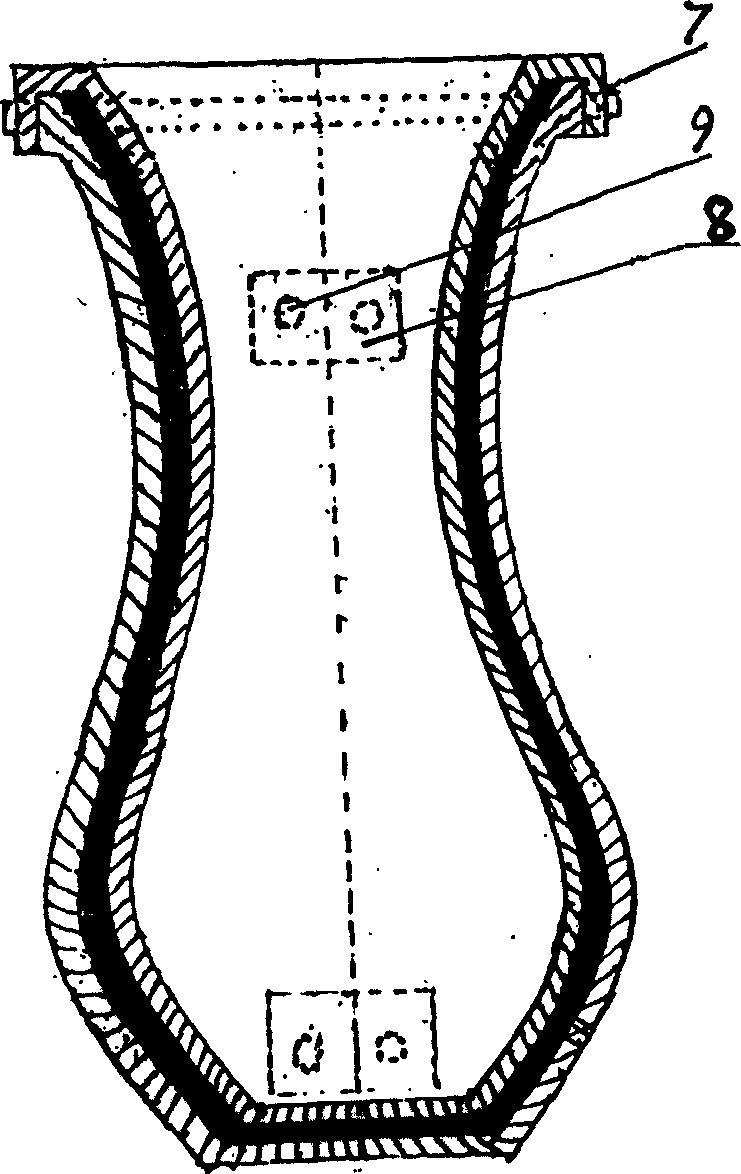

Air pressure forming method for producing glass fibre reinforced plastic

The invention relates to a glass reinforced plastics air pressure forming manufacturing method. It can effectively solve the problem that both sides of the glass reinforced plastics product is gabrous, especially the big internal mold cavity, and small collar extension. The technical proposal are that resin and fiber are coated between the hard outer mold and the soft inner mold; after sealing the mold gland is fixed and aerated to increase pressure; or after air proof hold down strip is sealed, the inner and outer mold are set in the pressure container to aerate, increase pressure, and solidify. The invention can solve the pressing problem which can not be solved by the existing pressure forming technology, which means no matter how complicate the shape of the product is, it still can make the both sides of the product be gabrous. Its advantages are that the manufacturing technique is unique; the effect is good; the quality of the product is good; the appearance is beautiful; the market is wide; and the economic benefit is notable.

Owner:封明信

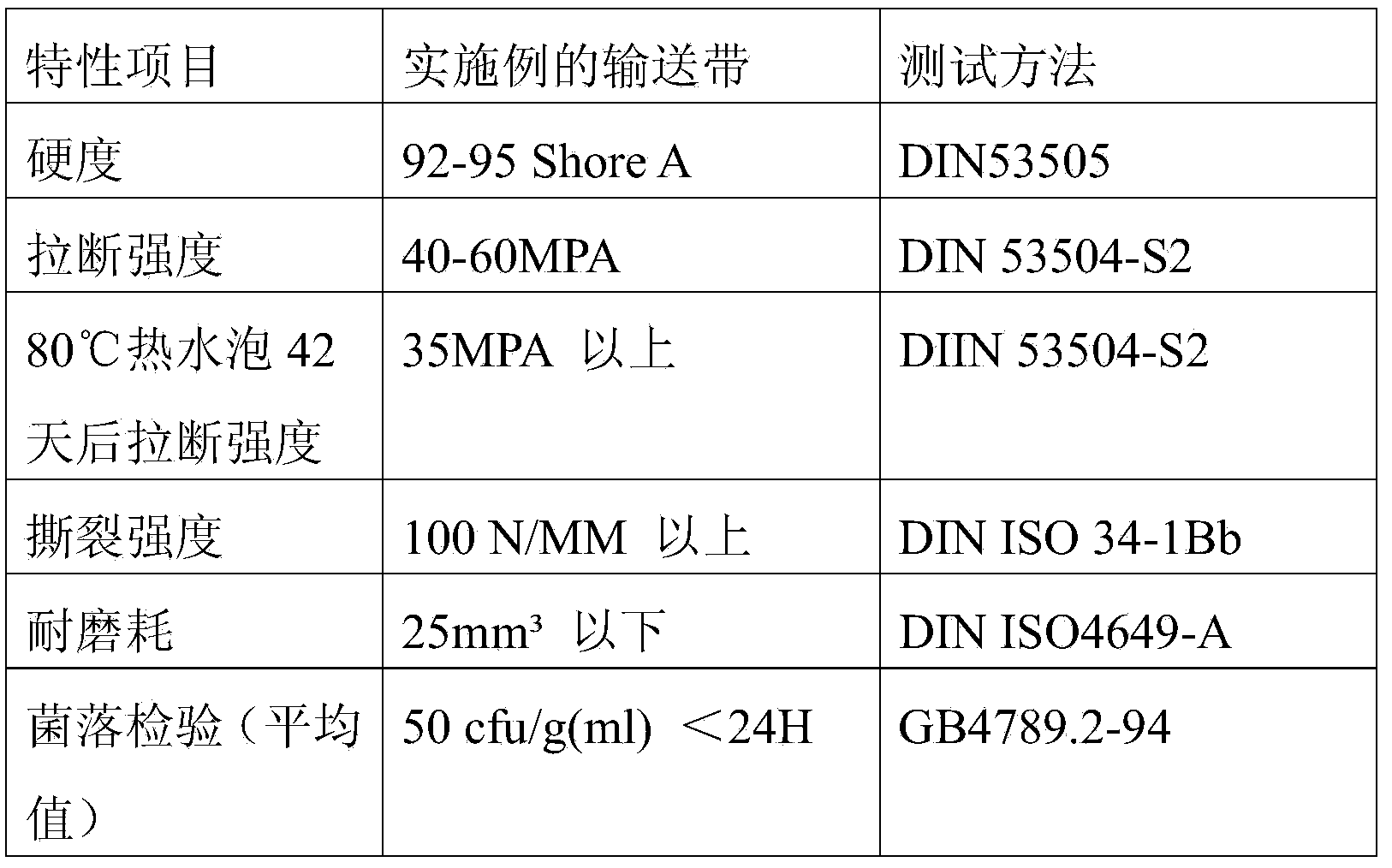

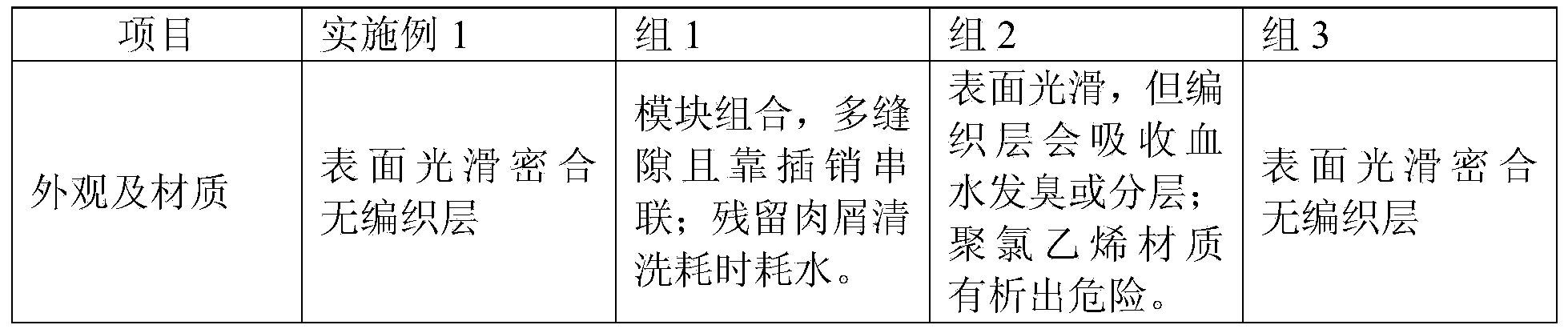

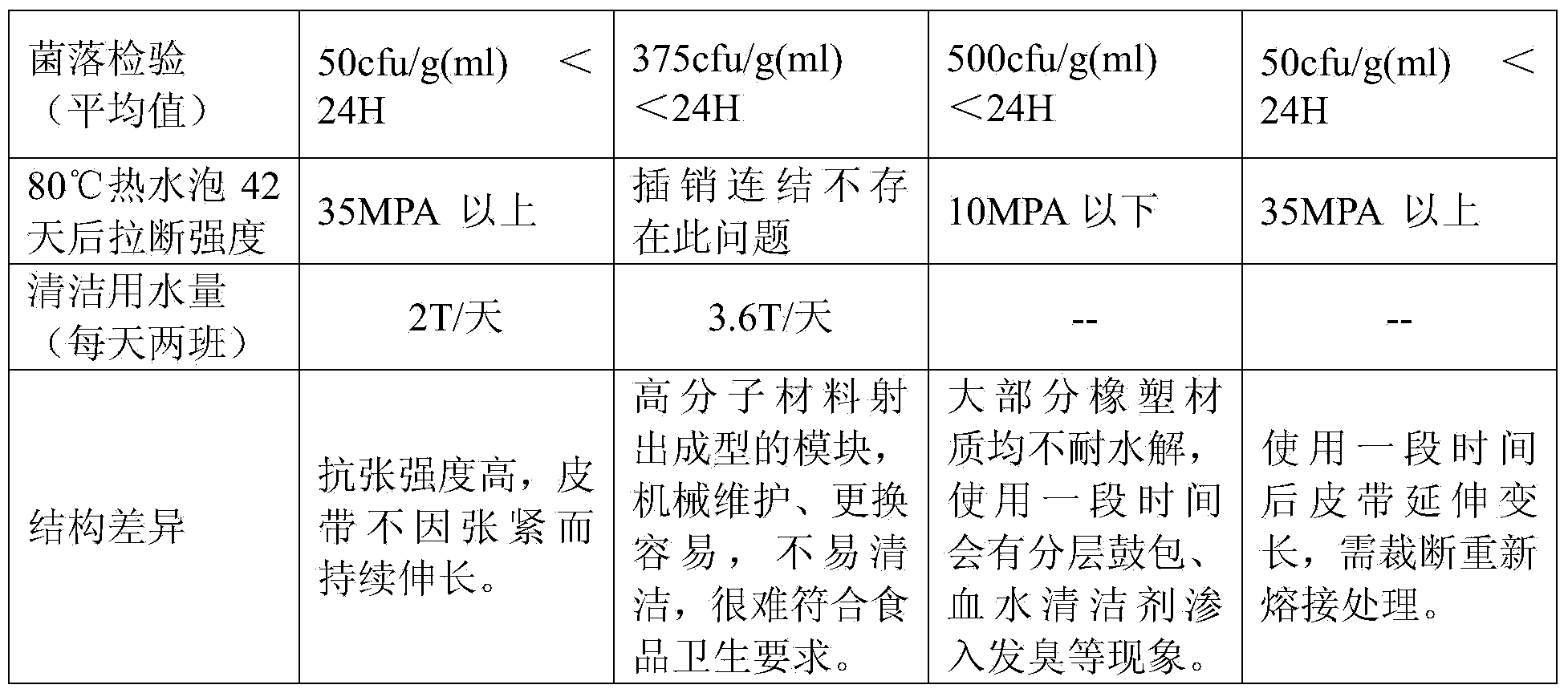

Conveying belt and preparation method thereof

The invention discloses a conveying belt and a preparation method of the conveying belt. The method comprises the following steps of (1) arranging para-position aramid yarns in parallel, wherein the interval between the para-position aramid yarns is 7-10mm, and each para-position aramid yarn is stretched by force of 2.94N-4.9N; and (2) mixing, calendering, extruding, and integrally forming the arranged para-position aramid yarns and polyether-type thermoplastic polyurethane. The conveying belt provided by the invention conforms to the food hygiene and safety requirement, is high in hardness, is abrasion resistant, does not generate burr phenomenon, and is durable in stretching.

Owner:AA IND BELTING (SHANGHAI) CO LTD +1

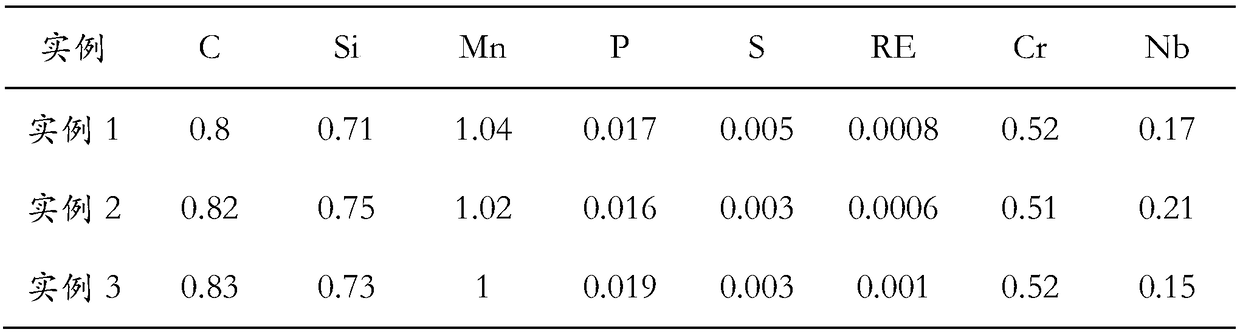

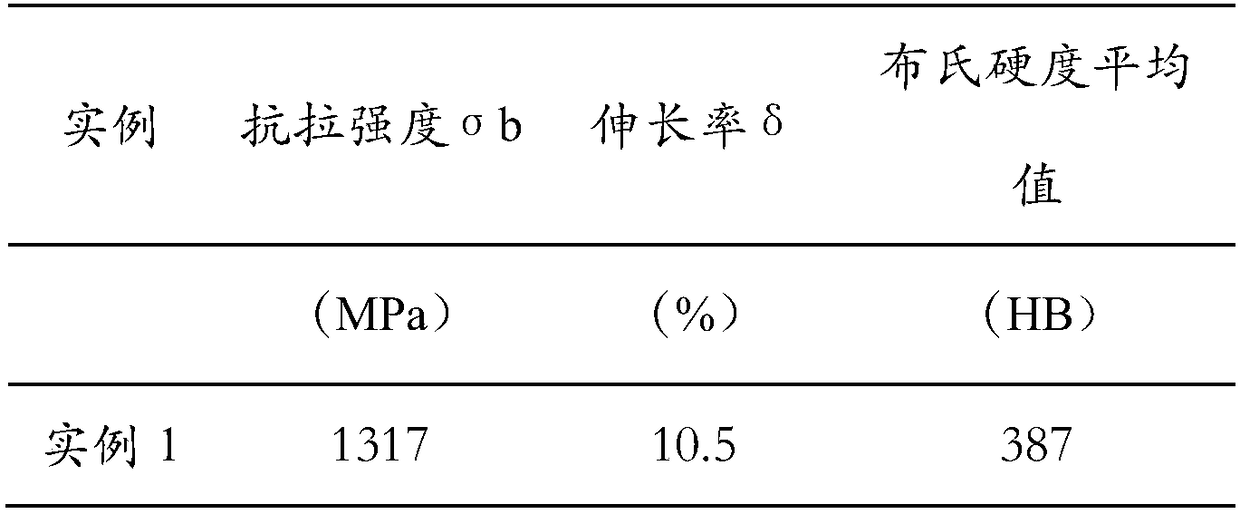

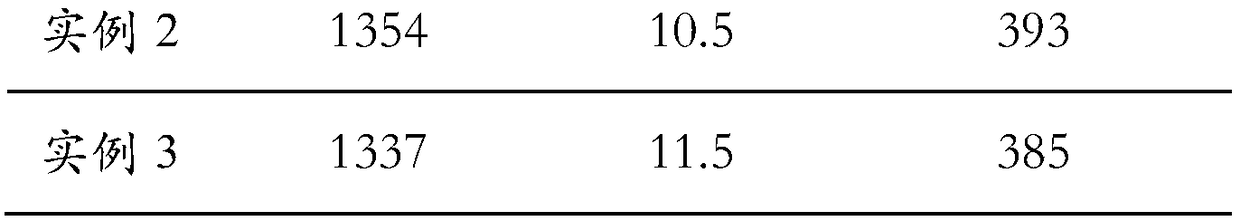

Steel rail, smelting method thereof and rolling method thereof

InactiveCN109234611AIncrease productivityHigh tensile strengthMetal rolling arrangementsChemical compositionWear resistant

The invention provides a steel rail. The steel rail is applied to train transportation, and comprises the following chemical components in percent by mass: 0.75-0.90% of C, 0.55-0.85% of Si, 0.95-1.15% of Mn, 0.40-0.70% of Cr, 0.01-0.25% of Nb, smaller than or equal to 0.025% of P, smaller than or equal to 0.025% of S, 0.02-0.08% of RE alloy and the balance of Fe. According to a technical scheme adopted by the invention, by using the effect of improving the strength of the steel rail by C element, and adopting on-line residual heat quenching technology, and through reasonable design of the components and addition of optimal Si, Mn, Cr and Nb alloy elements into the steel rail, the tensile strength, the elongation, the tread hardness, the wear resistance and other performance of the steel rail can be improved by a rolling technology; the wear-resistant steel rail produced thereby has very good tensile strength and tread hardness.

Owner:BAOTOU IRON & STEEL GRP

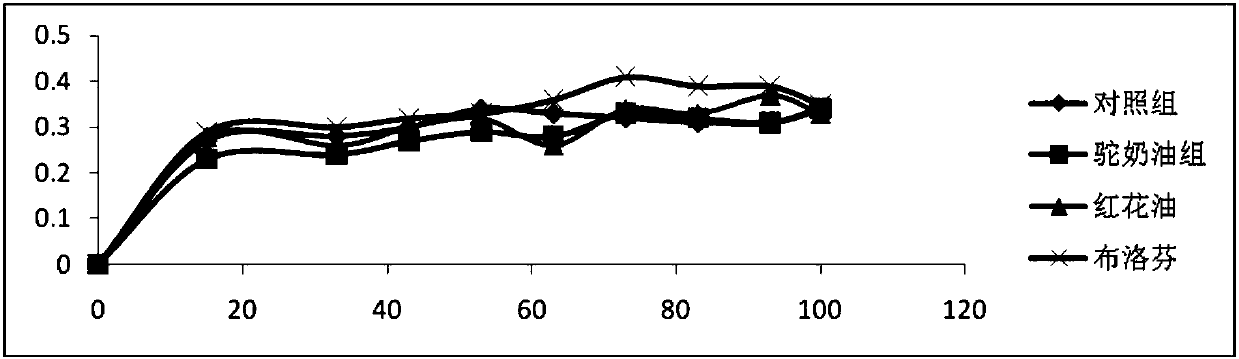

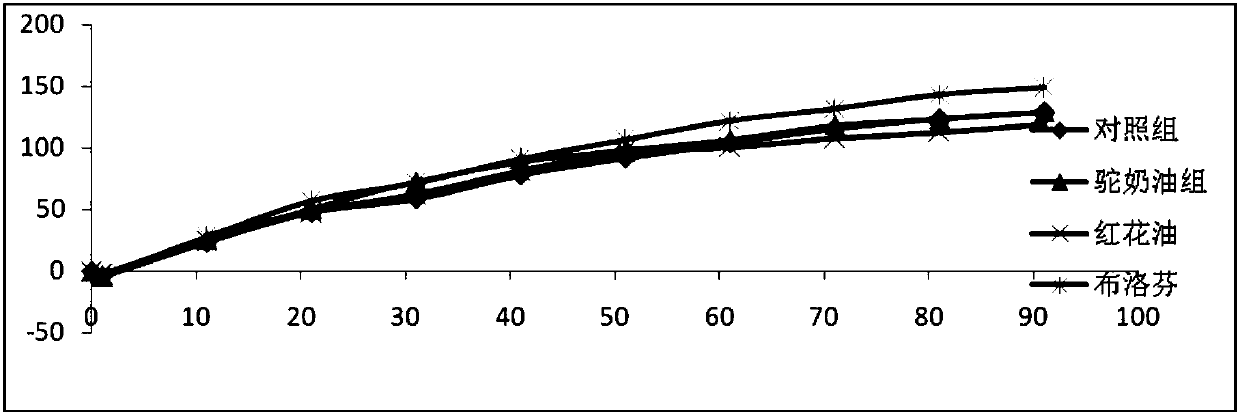

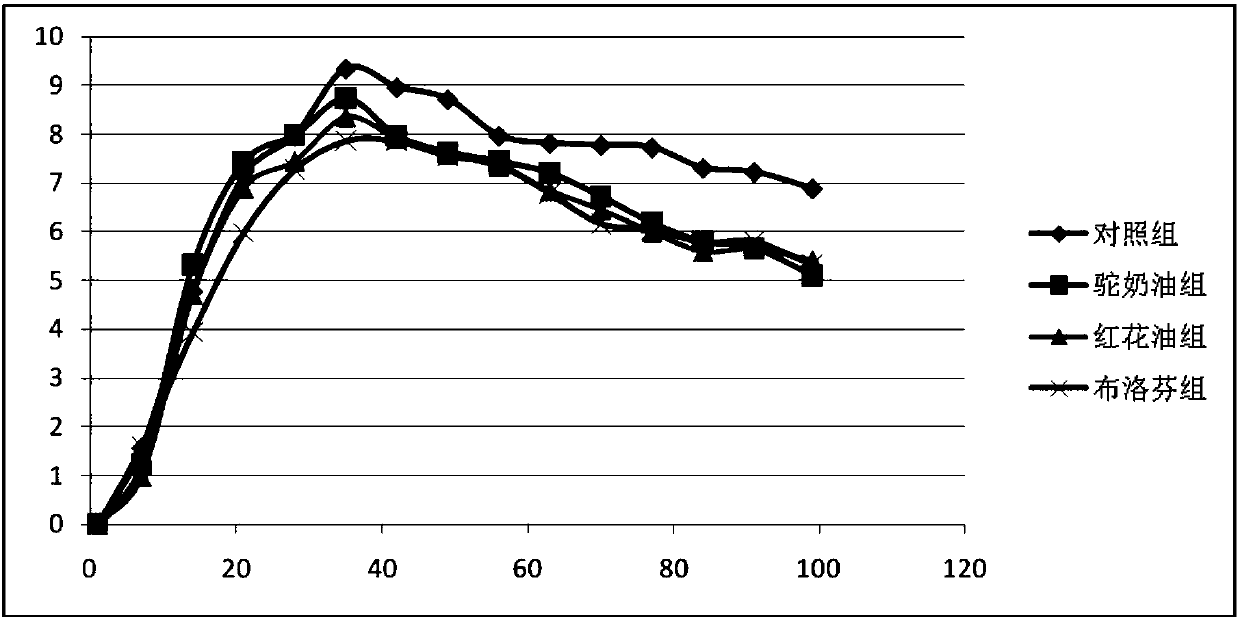

Anti-rheumatic-arthritis emulsifiable paste composition and preparation method thereof

ActiveCN105943557AGood moisturizing effectUnique formulaCosmetic preparationsAntipyreticMentholPreservative

The invention relates to an anti-rheumatic-arthritis emulsifiable paste composition, and also relates to a preparation method of the anti-rheumatic-arthritis emulsifiable paste composition. The composition contains camel oil, menthol, seabuckthorn oil, an emulsifying agent, an emollient, a humectant, a preservative, a thickening agent, essence and the like. The anti-rheumatic-arthritis emulsifiable paste has the advantages that the paste color is light yellow and glossy; the texture is fine; no irritation is generated on the skin; the release effect is achieved in the aspects of antiinflammation, swelling subsidence, pain ease, wind dispelling, dampness eliminating and the like; the auxiliary treatment function is realized in the aspects of swelling subsidence, pain ease, inflammation diminishing, allergy resistance, wind dispelling and dampness eliminating; good moistening and moisture preserving efficacy are achieved.

Owner:INNER MONGOLIA AGRICULTURAL UNIVERSITY

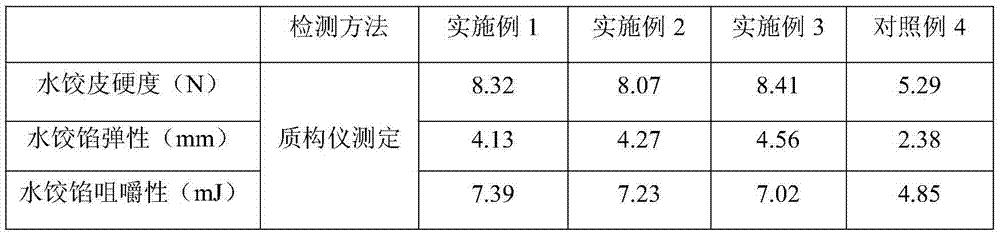

Quick-frozen seaweed crystal dumplings and preparation method

InactiveCN105433210AUnique production processFull of nutritionFood preservationFood ingredient functionsPotato starchNutrient

The invention provides quick-frozen seaweed crystal dumplings and a preparation method. The quick-frozen seaweed crystal dumplings comprise dumpling wrappers and dumpling fillings, wherein the dumpling wrappers are prepared from the following components in parts by weight: 25-35 parts of water, 10-20 parts of flour, 20-30 parts of potato starch, 15-25 parts of tartarian buckwheat starch, 6-12 parts of concentrated kelp powder, and 1-3 parts of sodium alginate; the dumpling fillings are prepared from the following components in parts by weight: 20-30 parts of ground meat, 50-65 parts of vegetables, 10-20 parts of seasoning, and 1-2 parts of an alginate compounding thickening agent. The made quick-frozen crystal dumplings provided by the invention are rich in fucoidin and high in nutrient value, and have the efficacies of improving immunity and the like; besides, the sodium alginate and compounded components are added, so that the mouth feel of the dumpling wrappers is tenacious and smooth, the crystal dumplings can be cooked and fried; the dumpling fillings are good in mass forming performance, are not diverged and are good in quality, so that the technical problems that conventional quick-frozen crystal dumpling wrappers are easy to crack, conventional quick-frozen crystal dumplings are easy to break when being cooked, and conventional dumpling fillings are poor in mass forming performance are effectively solved.

Owner:QINGDAO BRIGHT MOON SEAWEED BIO HEALTH TECH GRP CO LTD

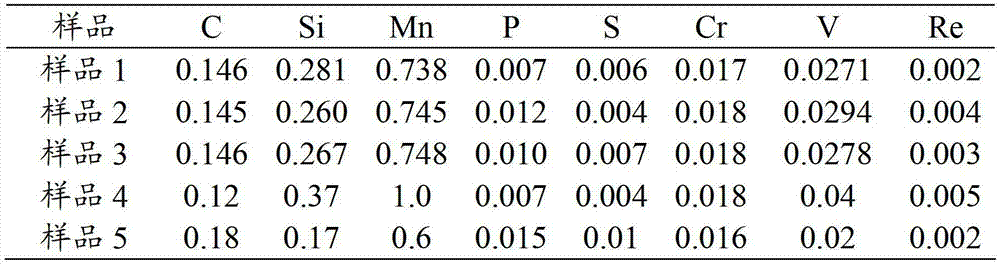

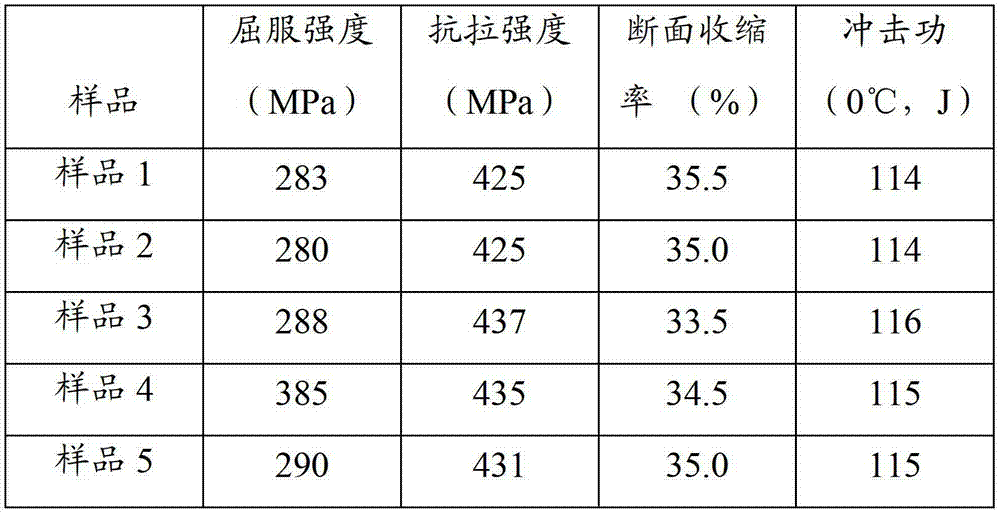

Rare earth-containing nuclear seamless steel tube material and preparation method thereof

The invention discloses a rare earth-containing nuclear seamless steel tube material. The seamless steel tube material comprises components in percentage by weight: 0.12-0.18 of C, 0.17-0.37 of Si, 0.6-1.0 of Mn, 0.016-0.018 of Cr, 0.02-0.04 of V, no more than 0.015 of P, no more than 0.010 of S, 0.002-0.005 of Re, and the balance of Re, wherein the sum of mass percentage is 100%. The invention further discloses a preparation method of the earth-containing nuclear seamless steel tube material. The preparation method is unique in production technique, high in production efficiency, low in cost and energy-saving and environment-friendly in production technique, the produced seamless steel tube is good in compressive strength and high-temperature resistance property, high in economic benefits, and suitable for large-scale production, and has good popularization values.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Wild mushroom soup and making method thereof

InactiveCN109588673AStrong tasteIncrease percentageLipidic food ingredientsFood ingredient as pH modification agentWild mushroomFermentation

To solve the problem that a conventional mushroom soup product is simple in making method and functions of nutrient substances cannot be taken into play sufficiently, the invention discloses wild mushroom soup which comprises the following raw materials as main materials in parts by weight: 10-90 parts of edible wild mushrooms, 5-30 parts of edible sugar, 0.1-0.6 part of a fermentation agent, 0.01-0.2 part of cellulase, 0.01-0.2 part of papain, 1-10 parts of edible salt, 1-10 parts of animal oil, 1-5 parts of sodium glutamate, 0.1-2 parts of a meat extract and 0.1-1 part of disodium 5'-ribonucleotide. According to the wild mushroom soup disclosed by the invention, types and ratios of raw materials are reasonably matched according to characteristics of various wild mushrooms, the deliciousmushroom soup which is unique in flavor, long-lasting in aftertaste and good in both taste and nutrition is made by using a biological enzymolysis technique and a fermentation technique, moreover, a unique production process is created, and the wild mushroom soup has wide market prospects.

Owner:四川新雅轩食品有限公司 +1

Production method for light transmitting three-dimensional pattern glass

InactiveCN106808877AUnique production processPattern transparentDecorative surface effectsFlat glassHydrofluoric acid

The invention belongs to the technical field of glass deep processing, and in particular relates to a method for producing light-transmitting three-dimensional pattern glass by using chemical acid corrosion method. Printing pattern, the printing ink uses anti-corrosion ink, after drying, cover the back of the glass with anti-corrosion material, emulsify on one side, clean the treated flat glass (retain the ink pattern) and put it in a corrosion box filled with corrosive liquid for immersion 10-20 minutes, the composition and weight ratio of the etching solution are: 65-72 parts of water, 5-10 parts of sulfuric acid, and 21-26 parts of hydrofluoric acid. Rinse the treated flat glass with water to remove ink and stains on the back of the glass. The covering material is made into a finished product after drying. The glass pattern produced is hazy, transparent and interspersed with each other. The production process is unique, the pattern is transparent, and the artistic effect is good. It can be used in indoor and outdoor decoration, vehicle and ship furniture engineering and other fields, and has a strong artistic effect. Effect.

Owner:姜蕾

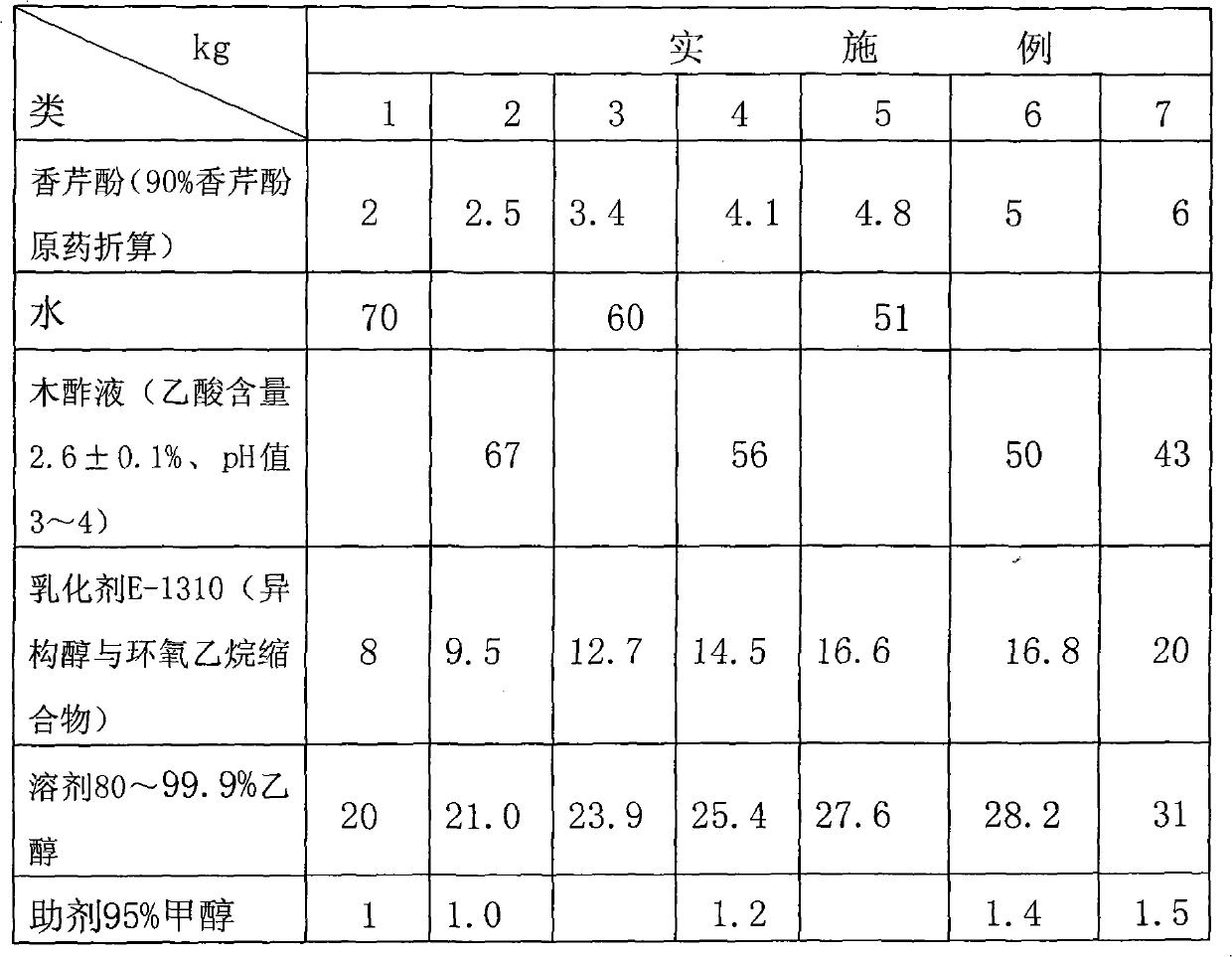

Carvacrol micro-emulsion and production technique thereof

InactiveCN101507432BImprove stabilityImprove the bactericidal effectBiocideFungicidesSocial benefitsEmulsion

The invention relates to a carvacrol microemulsion and a production process thereof, and relates to the technical field of carvacrol microemulsion pesticide. The carvacrol microemulsion comprises the following compositions in portion by weight: 2.0 to 6.0 portions of carvacrol, 43 to 70 portions of pyroligneous liquid (or water), 8.0 to 20 portions of emulsifier and 20 to 31 portions of solvent, and is prepared by mixing, stirring and emulsifying. The carvacrol microemulsion has the advantages that the carvacrol microemulsion has strong stability, good sterilizing effect, good control efficiency, environmental protection and safety, wide range of application, low cost, and high economic benefit and social benefit, and can increase the prophylactic variety; and the production process is simple, unique and pollution-free, and has low cost.

Owner:HEBEI ACAD OF FORESTRY SCI

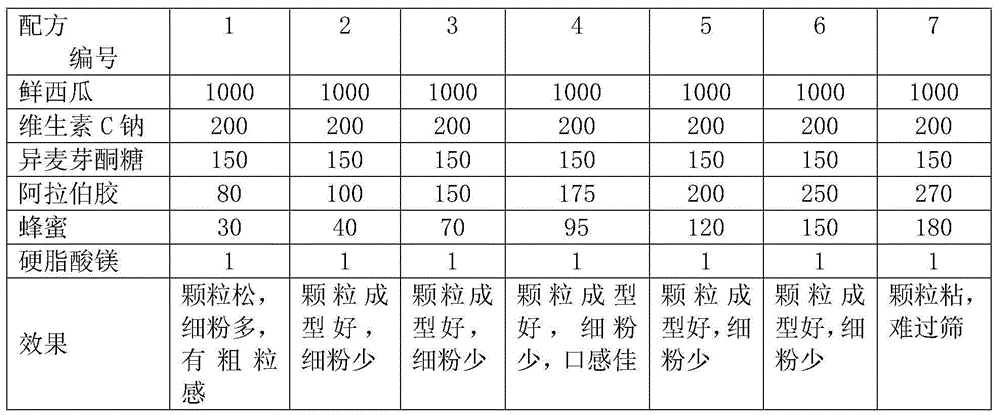

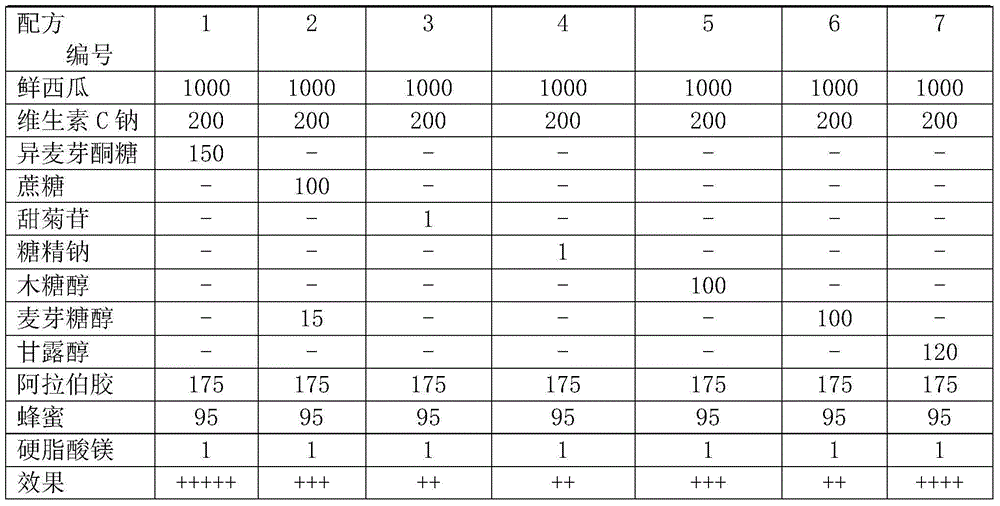

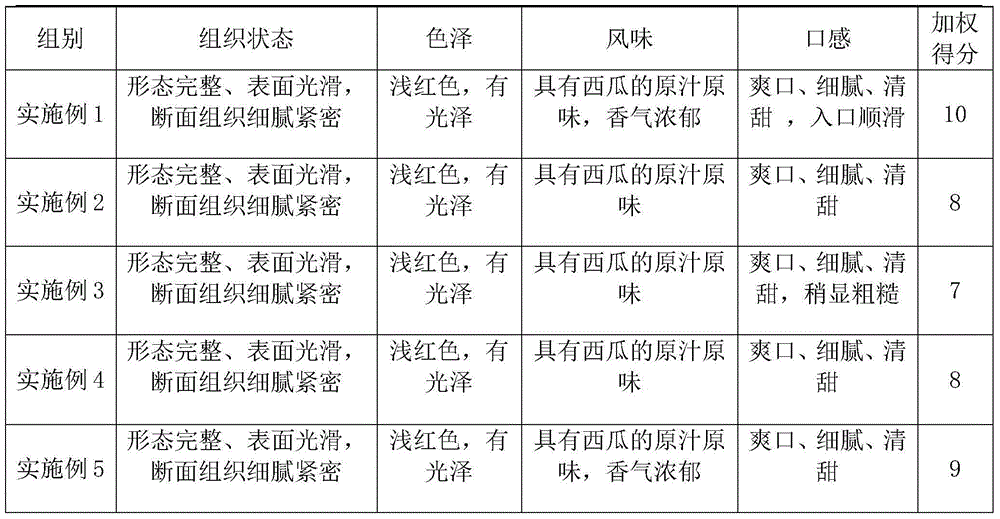

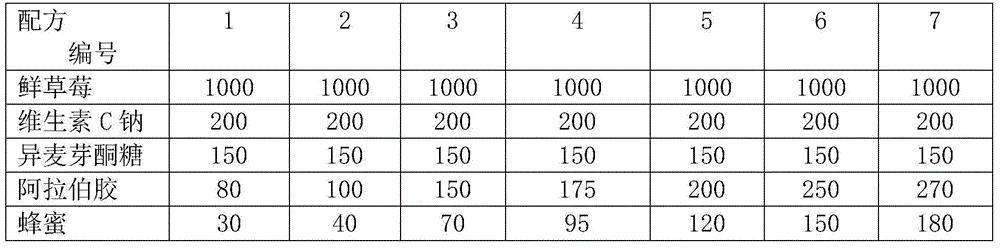

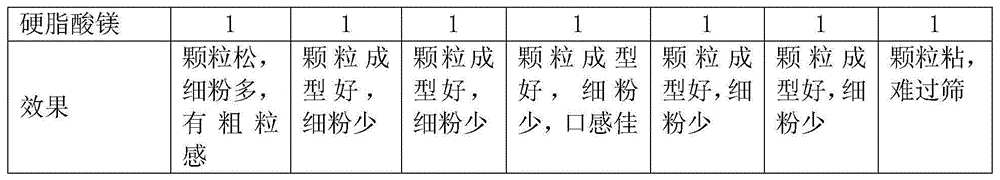

Buccal tablet with composite vitamin C sodium and preparation method thereof

The invention discloses a buccal tablet with composite vitamin C sodium and a preparation method thereof. The buccal tablet comprises the following components in parts by weight: 500-1500 parts of fresh watermelon, 100-300 parts of vitamin C sodium, 150-250 parts of isomaltulose, 100-250 parts of Arabic gum, 40-150 parts of honey and 0.5-2 parts of magnesium stearate. The buccal tablet disclosed by the invention has the beneficial effects that the original juice and the original flavor of the watermelon are retained, the function of the vitamin C sodium is enhanced, so that the buccal tablet is a good vitamin supplement and a health product; and the buccal tablet is unique in production process, good in product forming, simple in process and easy in process operation and is applicable to industrial production.

Owner:张莘蔓 +1

PCB (Printed Circuit Board) silver paste and manufacturing method thereof

InactiveCN104036845AUnique production processGood printabilityNon-conductive material with dispersed conductive materialCable/conductor manufacturePolyvinyl alcoholSebacic acid

The invention provides a PCB silver paste. The PCB silver paste is manufactured by the following raw material by weight, glass powder 8 to 10, 10 to 15mum flake silver powder 40 to 50, nanoscale flake silver powder 15 to 20, silver coated nickel powder 10 to 15, bisphenol F-type epoxy resin 8 to 12, isopropyl myristate 1 to 2, tartaric acid 1 to 2, sebacic acid 2 to 3, nano chitin 0.3 to 0.5, polyvinyl alcohol 1 to 2, terpineol 4 to 6, 2-methyl imidazole 0.3 to 0.5, butylcarbitol 4 to 6, methyl cellosolve 3 to 5, and butyl carbitol acet 3 to 5. According to the silver paste of the invention, through using flake silver powder different in particle sizes, contact is tight, and conductive performance is good; the cost is saved through using the silver coated nickel powder; the production technology is unique, and silver powder can be prevented from being aggregated to influence the conductvie performance; and the printing performance is good, the circuit board yield is high, falling is not easy, and the use time is long.

Owner:铜陵市超远精密电子科技有限公司

Original strawberry flavor vitamin C sodium buccal tablet and preparation process thereof

The invention discloses an original strawberry flavor vitamin C sodium buccal tablet and a preparation technology thereof, the original strawberry flavor vitamin C sodium buccal tablet comprises the following raw materials by weight: 500-1500 parts of fresh strawberry, 100-300 parts of vitamin C sodium, 150-350 parts of isomaltulose, 100-250 parts of gum Arabic, 40-150 parts of honey and 0.5-2 parts of magnesium stearate. The original strawberry flavor vitamin C sodium buccal tablet retains strawberry original taste and flavor, improves the function of the vitamin C sodium, and is a good vitamin supplement and health product; the production technology is unique, product molding is good, the process is simple, and the preparation technology is easy to operate and suitable for in industrial production.

Owner:张莘蔓 +1

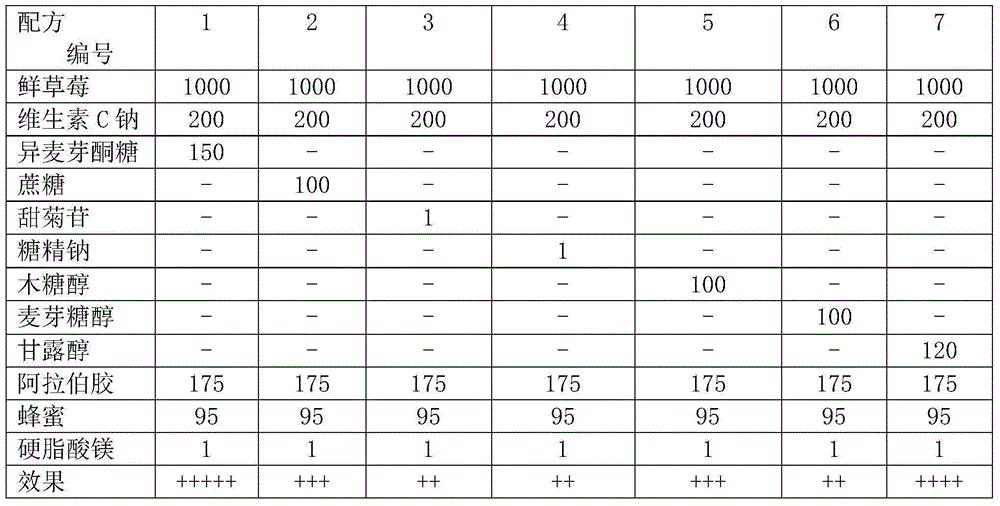

Ferroalloy material for producing golf club ball

InactiveCN102732771AGood compressive strength and hardnessThe combination of strength and hardness is the bestGolf clubsRacket sportsTemperature resistanceHardness

The invention relates to a ferroalloy material for producing a golf club ball and is characterized in that the alloy material is prepared from the following elements of: by weight, 28.01-29.02% of Fe, 14.74-14.85% of Co, 14.70-15.07% of Ni, 15.90-16.10% of Cu, 6.67-6.80% of Al, 18.81-19.91% of Cr and the balance impurity elements, wherein the sum of the mass percentages of each element is 100%; according to molar ratio of each element, the alloy material can be written as Fe2CoNiCuAlCr1.5; and the purity of each element in the alloy material is more than 99.9 at%. The invention has the following advantages: the ferroalloy material of the present invention has good compression strength and hardness; with the rising of the heat treatment and annealing temperature, the compression strength of the material is not obviously reduced, Vickers hardness of the alloy material is raised instead of being reduced; and the alloy material has high temperature resistance. After annealing and insulating at 850 DEG C for 5 hours, the alloy material has the best comprehensive properties of strength and hardness and is suitable for making the golf club ball.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Kipah-level bainite steel with ultrahigh yield ratio and manufacturing method of Kipah-level bainite steel

ActiveCN114107785AReduce consumptionRapid return temperature controlFurnace typesHeat treatment furnacesChemical elementStrip steel

The invention discloses a Gigaba-grade bainite steel with an ultrahigh yield ratio. The Gigaba-grade bainite steel comprises the following chemical elements in percentage by mass besides Fe: 0.12-0.24% of C, 0.12-0.24% of Si, 0.12-0.12% of Cr, 0.12-0.12% of Mo, 0.2 to 0.5 percent of Si; 1.3 to 2.0 percent of Mn; b: 0.001 to 0.004 percent of the total weight of the raw materials; cr is less than or equal to 0.4%, Nb is less than or equal to 0.06%, Ti is less than or equal to 0.1%, and Mo is less than or equal to 0.4%. In addition, the invention further discloses a manufacturing method and an annealing process for the steel. The annealing process comprises the following steps: (a) heating to a soaking temperature Ts of 840-900 DEG C at a heating rate of less than or equal to 50 DEG C / s in a heating section; (b) preserving heat for less than 5 minutes at a temperature Ts in a soaking section; (c) cooling to (Ts-80)-(Ts-140) DEG C at a first cooling rate of less than or equal to 15 DEG C / s in a slow cooling section; (d) cooling to (Ts-490)-(Ts-440) DEG C at a second cooling rate of more than or equal to (130-Q) DEG C / s in a rapid cooling section, Q = C * 180 + Si * 10 + Mn * 30 + Ni * 50 + Cr * 15 + Mo * 15 + B * 2000; the third cooling speed is larger than or equal to [(Q-80) / 12] and smaller than or equal to [(Q-80) / 8]; and (f) the strip steel is air-cooled to the room temperature in the air cooling section.

Owner:BAOSHAN IRON & STEEL CO LTD

Multifunctional organic fertilizer for flowering plants and preparation method thereof

InactiveCN106800474APromote growthPrevent Soilborne DiseasesBio-organic fraction processingExcrement fertilisersDiseaseAdditive ingredient

The invention relates to a multifunctional organic fertilizer for flowering plants and a preparation method of the multifunctional organic fertilizer. The multifunctional organic fertilizer comprises the following ingredients and raw materials by weight: 25-35 parts of corn stalk, 25-35 parts of bone meal, 20-30 parts of chicken manure, 5-15 parts of plant ash, 2-8 parts of trigonella foenum-graecum, 0.05-0.15 part of straw-decomposing inoculant, and 0.1-0.3 part of bacillus subtilis; the multifunctional organic fertilizer is prepared by processing the raw materials, proportioning and fermenting the raw materials, pelleting and processing. The pure natural biomass materials and the beneficial microorganism agent are used, the formula is unique, the production process is advanced, the multifunctional organic fertilizer can immobilize nitrogen and dissolve phosphorus and potassium, the soil fertility is improved, the beneficial microorganism produces phytohormone, antibiotics and the like in the processes of reproduction and metabolism, the growth of the flowering plants is promoted, nutrients are complete, the fertilizer efficiency is good, more than 20 pathogenic bacteria in the soil are controlled and killed, and various soil-borne diseases of the flowering plants are prevented; the added natural plant perfume material is pollution-free, so that the fragrance of the multifunctional organic fertilizer for the flowering plants overflows, and particularly after the multifunctional organic fertilizer is applied to the greenhouse flowering plants, the air is cleaned, and the effect of repelling mosquitos and flies is also achieved.

Owner:东辽县日月星有机肥有限公司

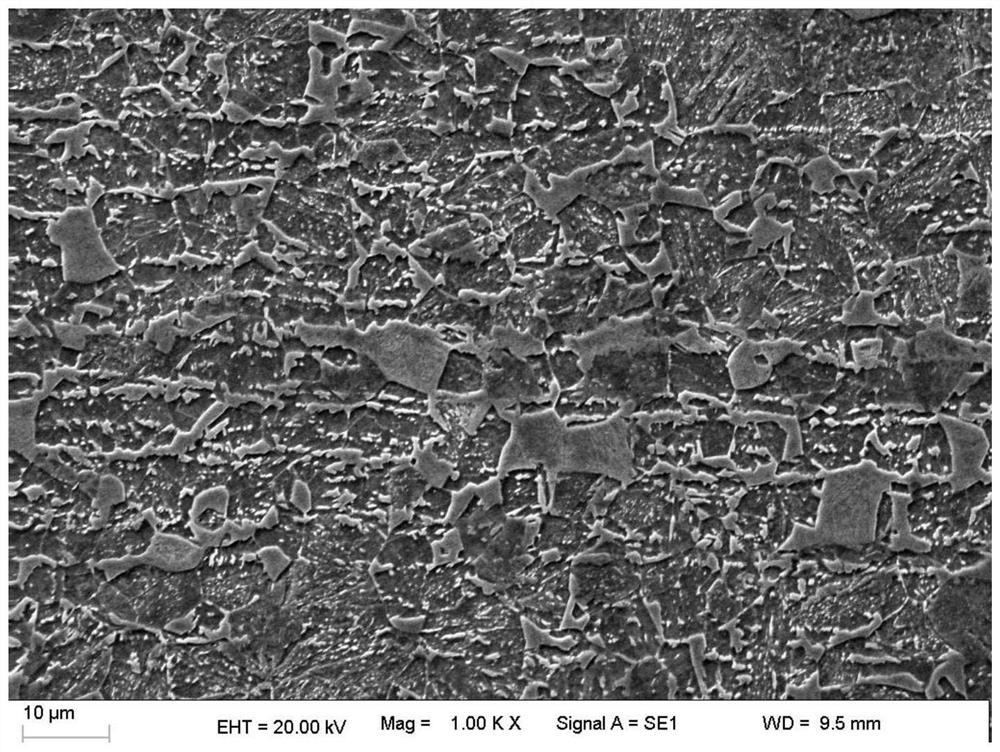

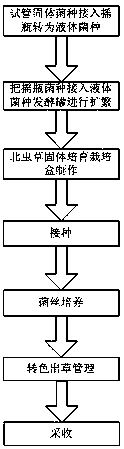

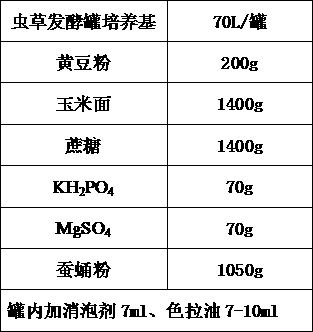

A new method for cultivating Cordyceps militaris

InactiveCN103460981BImprove qualityUnique qualityCultivating equipmentsMushroom cultivationBiotechnologySaccharum

The invention discloses a new method for cultivating Cordyceps militaris, comprising the following steps: connecting solid strains of test tubes into shake flasks and converting them into liquid strains, inserting strains of shake flasks into fermenters for strain propagation, and solid strains of Cordyceps militaris Cultivation box medium production, liquid inoculation, mycelium culture, color change, grass management, and harvesting. Shake flask culture liquid strain formula is as follows: silkworm chrysalis powder 35g; glucose 35g; cornmeal 50g; VB1 2 pieces; KH2PO4 5g; MgSO4 1.7g; water 3500ml; Soybean flour 200g; cornmeal 1400g; sucrose 1400g; KH2PO4 70g; MgSO4 70g; ; MgSO4 1g; VB1 1 piece; soybean meal powder 16.67g; sugar 10g; water 1000ml. The new cultivation method provided by the invention has the advantages of convenient operation, short cultivation period, low cultivation cost, high cultivation success rate and high yield, and the content of cordycepin in adult grass is also greatly improved.

Owner:山西省医药与生命科学研究院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com