Porcelain plastic decorative plate and its processing method

A decorative board and porcelain-plastic technology, applied in the field of decorative boards, can solve the problems of inability to produce three-dimensional effects, having radioactive harmful substances, and low flexural strength of gypsum boards, achieving colorful patterns, saving resources, and high flexural strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

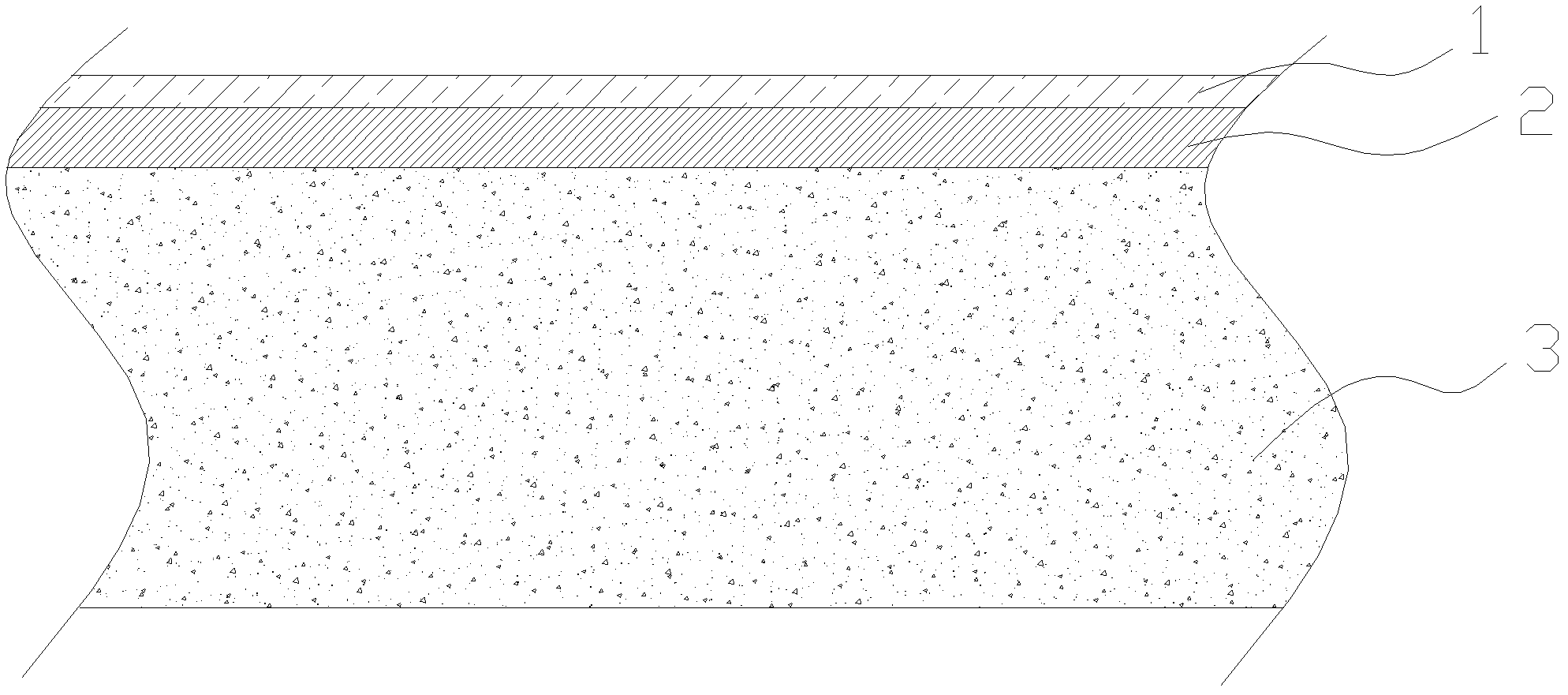

[0027] Such as figure 1 , a porcelain-plastic decorative board, comprising a PVC transparent wear-resistant layer 1, a PVC pattern printing layer 2, and a primer layer 3 laminated sequentially from top to bottom; wherein the primer layer 3 includes the following components by weight: 100 parts suspension Polyvinyl chloride resin, 20 parts of diisononyl phthalate, 2.5 parts of barium stearate, 2.5 parts of zinc stearate, 70 parts of 80 mesh ceramic beads, 30 parts of glass fiber, 10 parts of ACR anti Impact modifier, 30 parts of 325 mesh calcium carbonate stone powder, 1.5 parts of rosin and appropriate coloring agent.

[0028] The method for processing the above-mentioned porcelain-plastic decorative board includes the following process steps:

[0029] (1) Process the bottom material layer; put the components of the bottom material layer into the high-speed mixer according to the weight ratio and mix them uniformly for 5-7 minutes, and send the uniformly mixed mixture into th...

Embodiment 2

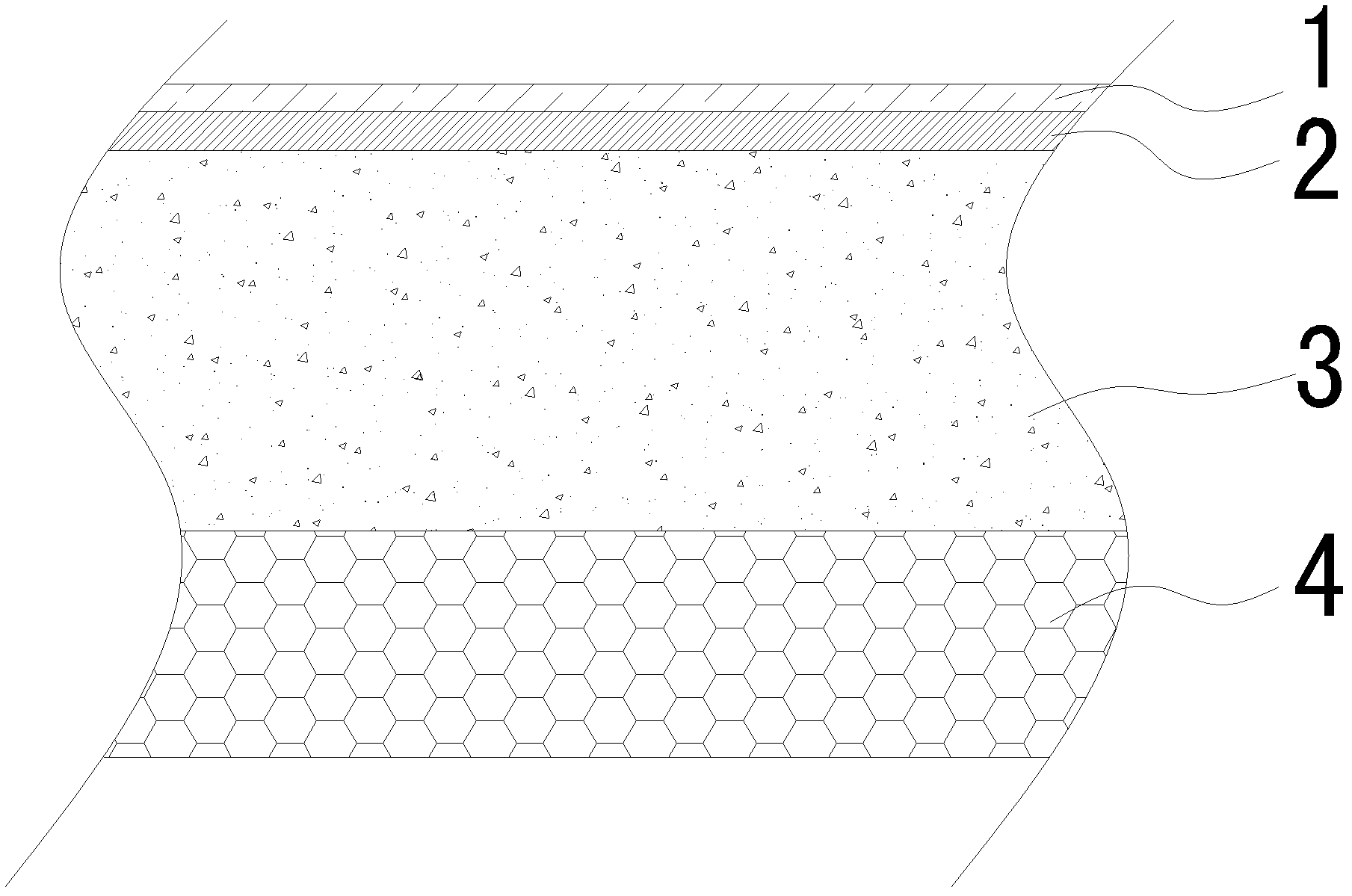

[0036] Such as figure 2 , a sound-absorbing porcelain-plastic decorative board, comprising a PVC transparent wear-resistant layer 1, a PVC pattern printing layer 2, a primer layer 3 and a sound-absorbing layer 4 sequentially stacked from top to bottom; the primer layer 3 includes the following components by weight : 100 parts of suspension polyvinyl chloride resin, 15 parts of diisononyl phthalate, 1 part of barium stearate, 1 part of zinc stearate, 60 parts of 150 mesh ceramic beads, 15 parts of glass fiber, 5 parts Parts of CPE impact modifier, 30 parts of 600 mesh calcium carbonate stone powder, 0.5 part of PE wax and appropriate amount of coloring agent.

[0037] The method for processing the above-mentioned porcelain-plastic decorative board includes the following process steps:

[0038] (1), processing the bottom material layer; put each component of the bottom material layer into the high-speed mixer according to the weight ratio and mix it uniformly for 5-7 minutes, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com