Conveying belt and preparation method thereof

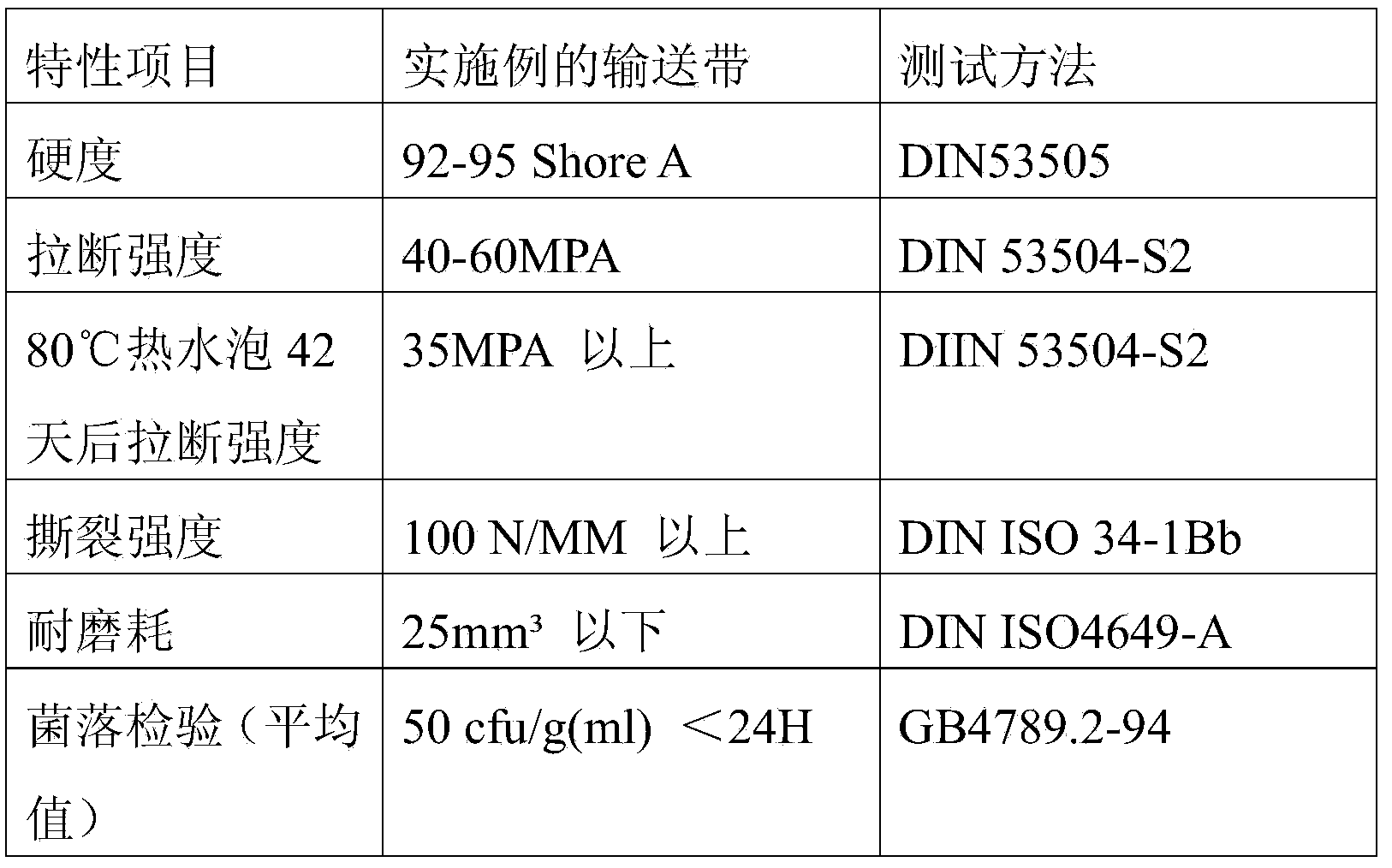

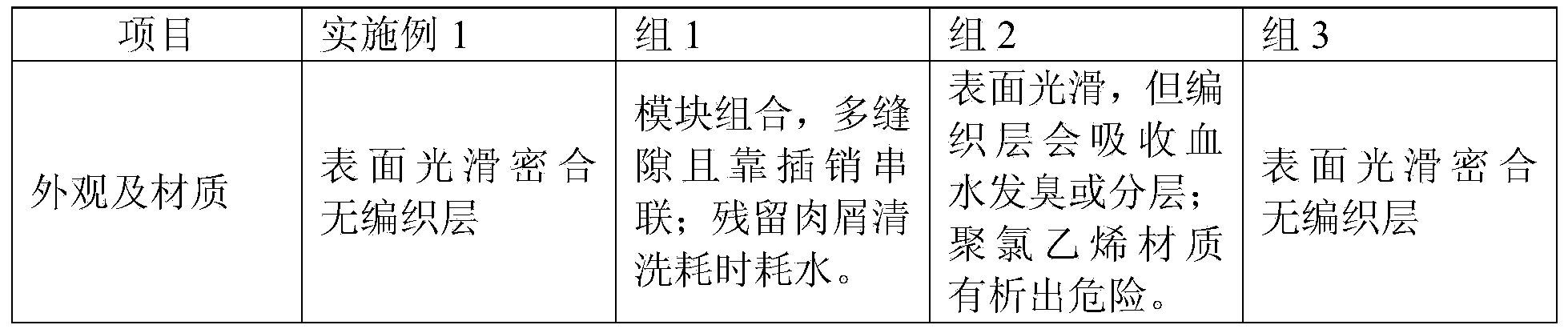

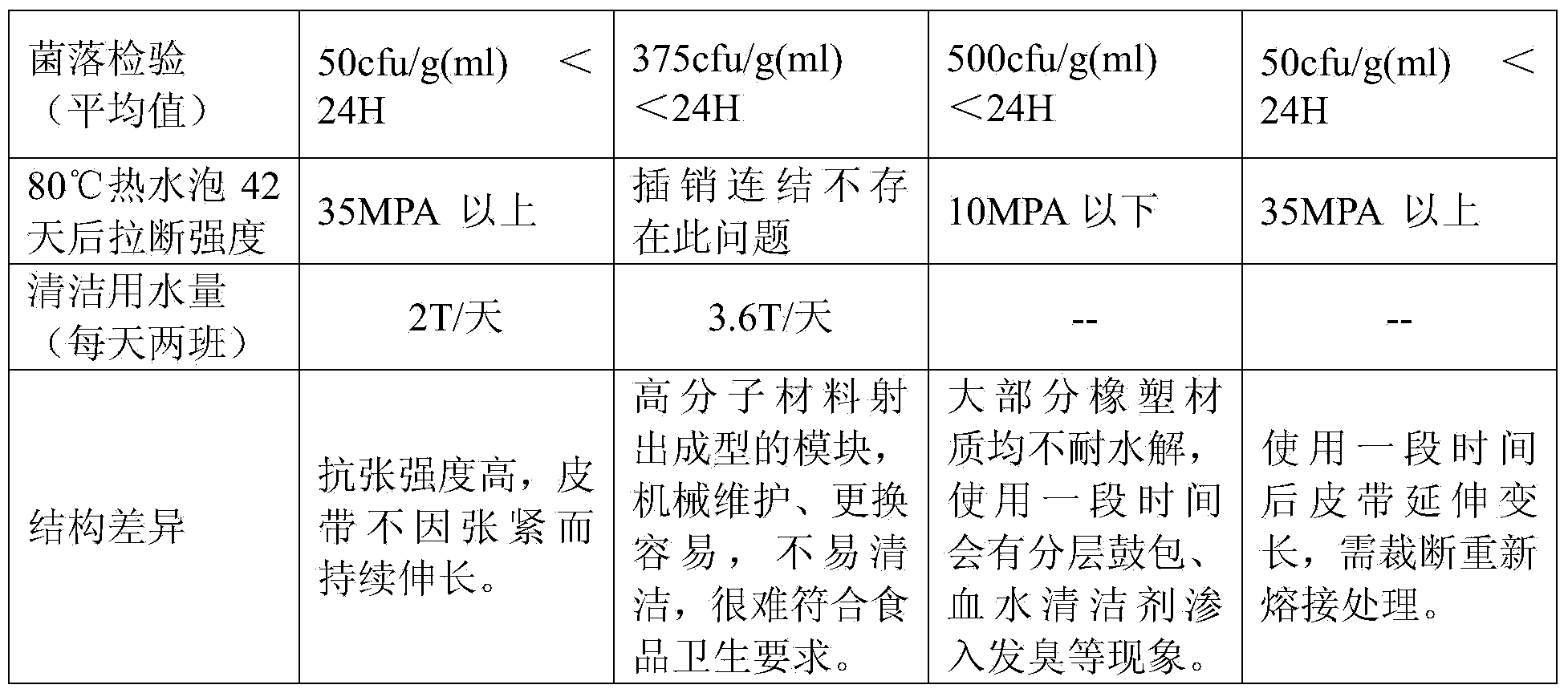

A conveyor belt and para-aramid fiber technology, applied in the field of conveyor belt and its preparation, can solve the problems of insufficient hardness, contaminated food, inconvenient cleaning, etc., and achieve the effects of high hydrolysis resistance, high production efficiency, and convenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A kind of preparation method of conveyor belt comprises the steps:

[0027] (1) Arrange the S-twisted para-aramid yarn and the Z-twisted para-aramid yarn next to each other in parallel; the distance between each para-aramid yarn is 7mm; the S-twisted para-aramid yarn and the Z-twisted pair The para-aramid yarn is twisted by 20 para-aramid spun yarns with an upper diameter of 1000D and a twist of 50. Stretch each para-aramid yarn with a 300g weight;

[0028] (2) The para-aramid yarn enters the extrusion die head through the guide wheel, and the polyether thermoplastic polyurethane is heated and melted at 190°C in the twin-screw extruder, and then extruded into the extrusion die head, mixed evenly and then calendered and extruded Pressing and integral molding in the molding wheel; before the polyether thermoplastic polyurethane enters the twin-screw extruder, it is dried in a dehumidification dryer at a temperature of 100°C for 2 hours, and finally reaches a moisture con...

Embodiment 2

[0030] A kind of preparation method of conveyor belt comprises the steps:

[0031] (1) Arrange S-twisted para-aramid yarn and Z-twisted para-aramid yarn next to each other in parallel; the distance between each para-aramid yarn is 10mm; S-twisted para-aramid yarn and Z-twisted The para-aramid yarn is twisted from more than 20 para-aramid spun yarns with a diameter of 3000D and a twist of 80; each para-aramid yarn is stretched with a 500g weight;

[0032] (2) The para-aramid yarn enters the extrusion die head through the guide wheel, and the polyether thermoplastic polyurethane is heated and melted at 205°C in the twin-screw extruder, then extruded into the extrusion die head, mixed evenly, and then calendered and extruded Pressing and integral molding in the molding wheel; before the polyether thermoplastic polyurethane enters the twin-screw extruder, it is dried in a dehumidification dryer at a temperature of 90°C for 2.5 hours, and finally reaches a moisture content of less ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com