Steel rail, smelting method thereof and rolling method thereof

A smelting method and rail technology, applied in the field of rail rolling, to achieve the effects of improving tensile strength, good tread hardness, and good promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

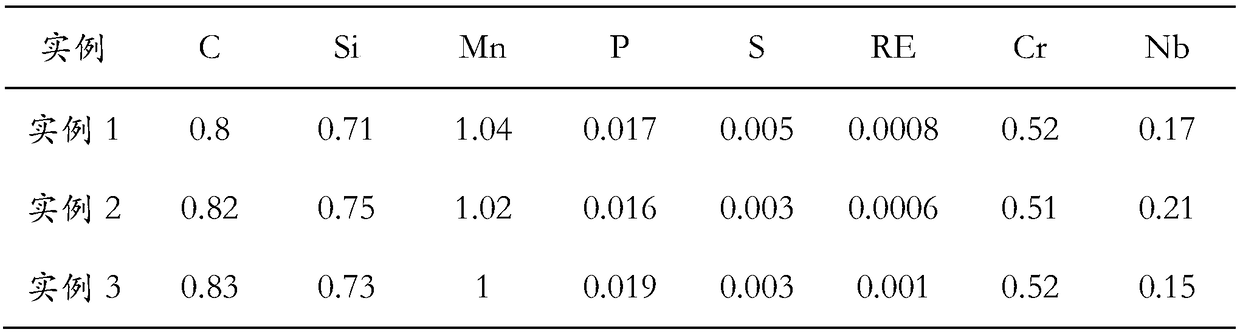

[0016] The steel rail according to the embodiment of the present invention is used for train transportation, and its chemical composition is: C0.75%~0.90%, Si 0.55%~0.85%, Mn0.95%~1.15%, Cr0. 40%-0.70%, Nb0.01%-0.25%, P≤0.025%, S≤0.025%, the addition of RE alloy is 0.02-0.08%, and the rest is Fe.

[0017] The main alloying elements Si, Mn, Cr, and Nb added to the material are aimed at improving the strength and phase transition temperature of the rail to suit the heat treatment line. The C component in the steel is designed to have a large solid solubility with Fe, which has a solid solution strengthening effect and improves the strength and hardness of the steel. Mn expands the austenite phase region, increases the stability of the supercooled austenite of the steel, and significantly improves the hardenability of the steel. Si reduces the transformation speed from austenite to ferrite and improves the strength, elasticity and tempering stability of the steel; the addition o...

Embodiment 2

[0019] The steel rail smelting method according to the embodiment of the present invention includes: molten iron; converter smelting; LF refining; VD; 0.10KPa, deep vacuum time ≥ 15min, superheat ΔT ≤ 30℃, rare earth alloy is added at VD station.

Embodiment 3

[0021] The rolling method of the steel rail according to the embodiment of the present invention includes: billet; sawing; heating; BD1 rolling; BD2 rolling; CCS universal rolling mill continuous rolling; online waste heat quenching; sawing; cooling; Straightening, wherein, the temperature of the billet heating preheating section is not higher than 900°C, and the heating time is not less than 3 hours and 15 minutes; ~940°C; the on-line waste heat quenching cooling medium is a mixture of aerosol and wind, the starting heat treatment temperature of the rail after final rolling is 720°C to 770°C, and the rail is transformed within the pearlite transformation temperature range through the cooling equipment, and the on-line heat treatment is 100~770°C. After 120s, it exits the heat treatment production line, and the rail outlet temperature is 520°C-600°C. After exiting the heat treatment production line, it is naturally air-cooled to room temperature.

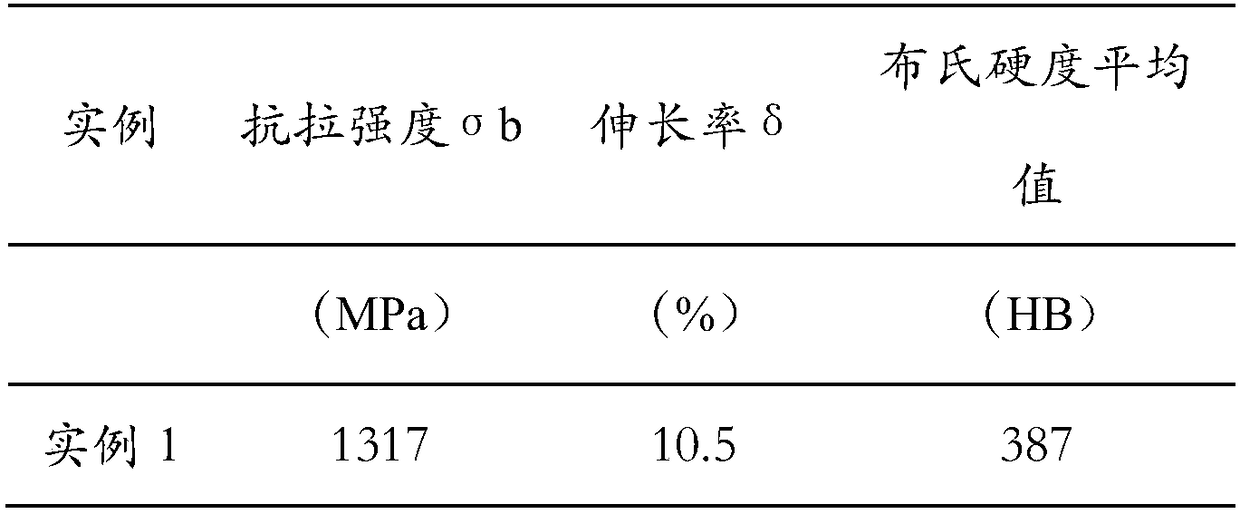

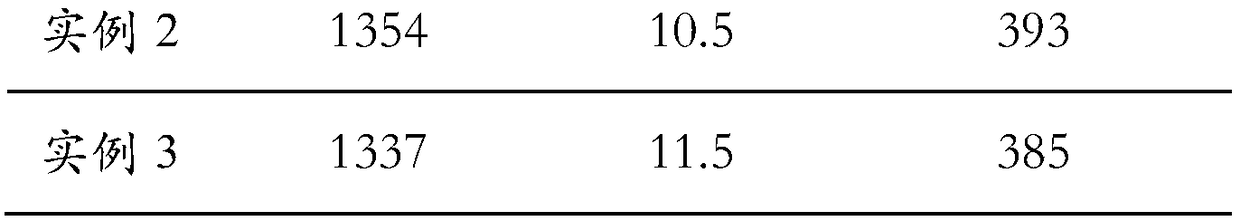

[0022] This embodiment provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com