Steel rail and production method of steel rail

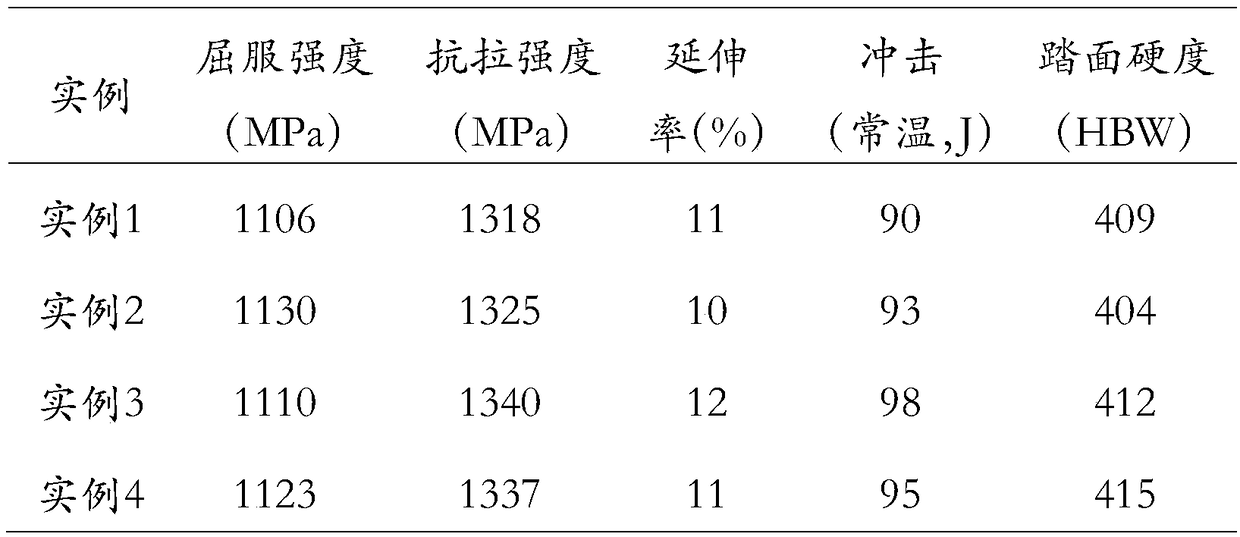

A production method and rail technology, applied in the field of metallurgy, can solve the problems of pearlitic rail wear, increased peeling, unsatisfactory, etc., and achieve good promotion value, high production efficiency, good wear resistance and contact fatigue resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

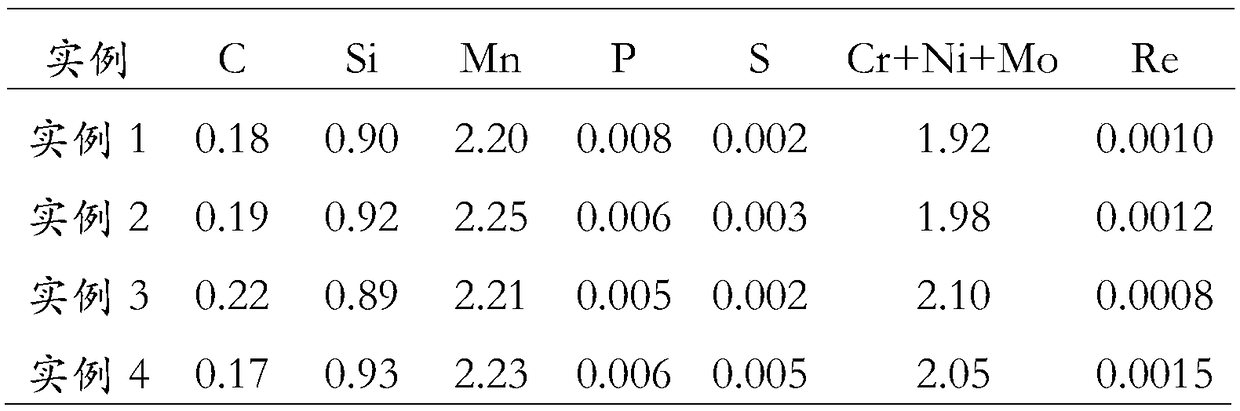

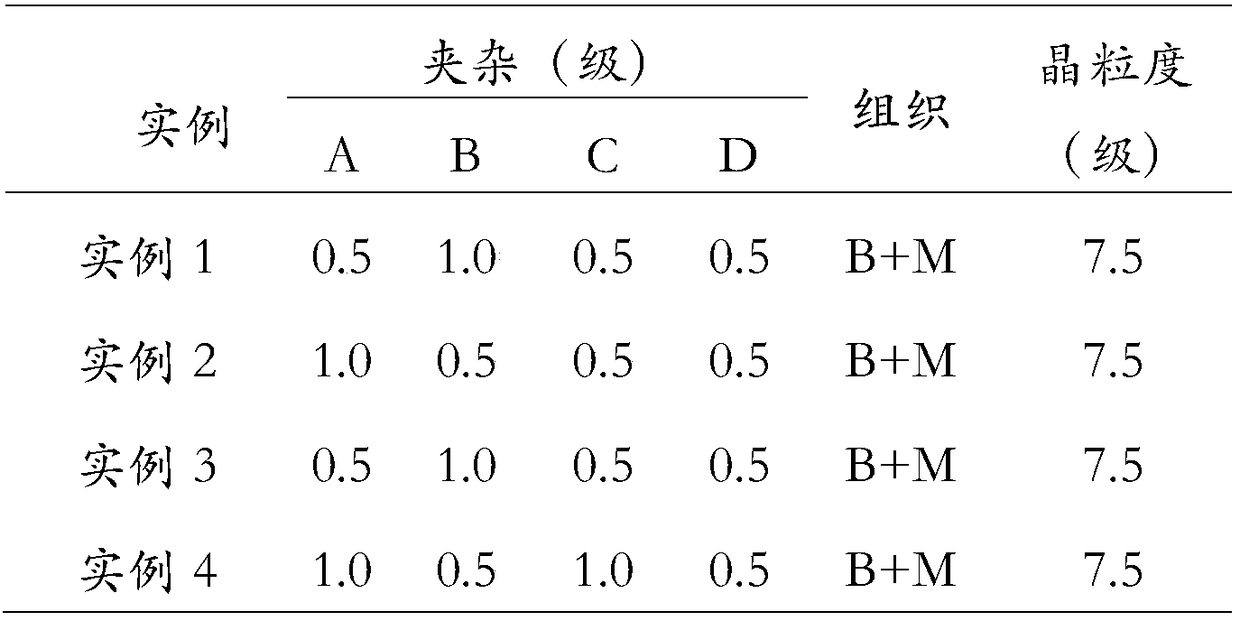

[0020] According to the steel rail of the embodiment of the present invention, its chemical composition is: C 0.16-0.25, Si 0.70-1.20, Mn 1.60-2.45, P≤0.022, S≤0.015, Al≤0.030, Cr+Ni+ Mo≤2.30, RE 0.0005-0.0020, the balance is matrix Fe and undetectable trace impurity elements.

[0021] Mn, Cr elements depress bainite transformation point, improve bainite hardenability and strength, Ni element stabilizes austenite, refines bainite structure, improves impact toughness, Mo stabilizes bainite transformation and strengthens bainite Structure, RE elements mainly strengthen grain boundaries, refine grains, effectively modify inclusions, and increase elongation.

Embodiment 2

[0023] The production method of the steel rail according to the embodiment of the present invention includes: pretreatment of molten iron; smelting in a 90-ton top-bottom combined blowing converter; refining in an LF furnace; VD vacuum treatment; continuous casting of blooms; heating in a walking heating furnace; Phosphorus; BD1 blanking; BD2 medium rolling; high pressure water phosphorus removal; CCS universal rolling; straightening; cooling; flaw detection; sawing.

[0024] Further, the raw materials are (wt%) 90% blast furnace hot metal and 10% scrap steel, and the blast furnace hot metal is pretreated by KR desulfurization, so that the S content in the molten iron is ≤0.005%, and the P content is ≤0.110%.

[0025] Further, the molten iron and steel scrap after the pretreatment of the molten iron are blended into the top-bottom combined blowing converter according to a certain proportion, and are smelted by the double slag-leaving slag process, and the end point temperature ...

specific Embodiment approach

[0032] A smelting production process for rare earth-containing high-strength and high-toughness rails, including: molten iron pretreatment → 90-ton top-bottom double-blowing converter smelting → LF furnace refining → VD vacuum treatment → bloom continuous casting. Corresponding technological measures shall be taken during molten iron pretreatment, converter smelting, LF, VD external refining, and continuous casting, including: blast furnace molten iron undergoes KR desulfurization pretreatment, so that the S content in molten iron is ≤0.005%, and the P content is ≤0.110%; Then the pretreated molten iron and high-quality steel scrap are mixed into the top-bottom double-blowing converter according to the proportion, and the double slag-leaving slag process is used for smelting. Low aluminum silicon calcium barium is used for deoxidation, the addition amount is 2.6kg / ton of steel, and the slag stopper is used to stop the slag, and 3kg / ton of top slag lime is added after tapping; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com