Kipah-level bainite steel with ultrahigh yield ratio and manufacturing method of Kipah-level bainite steel

A technology of bainitic steel and yield ratio, which is applied in the field of Gipa grade bainitic steel and its manufacturing, can solve problems such as unrealizable, achieve good formability, efficient strip temperature control, and green-safety design The effect of ideas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

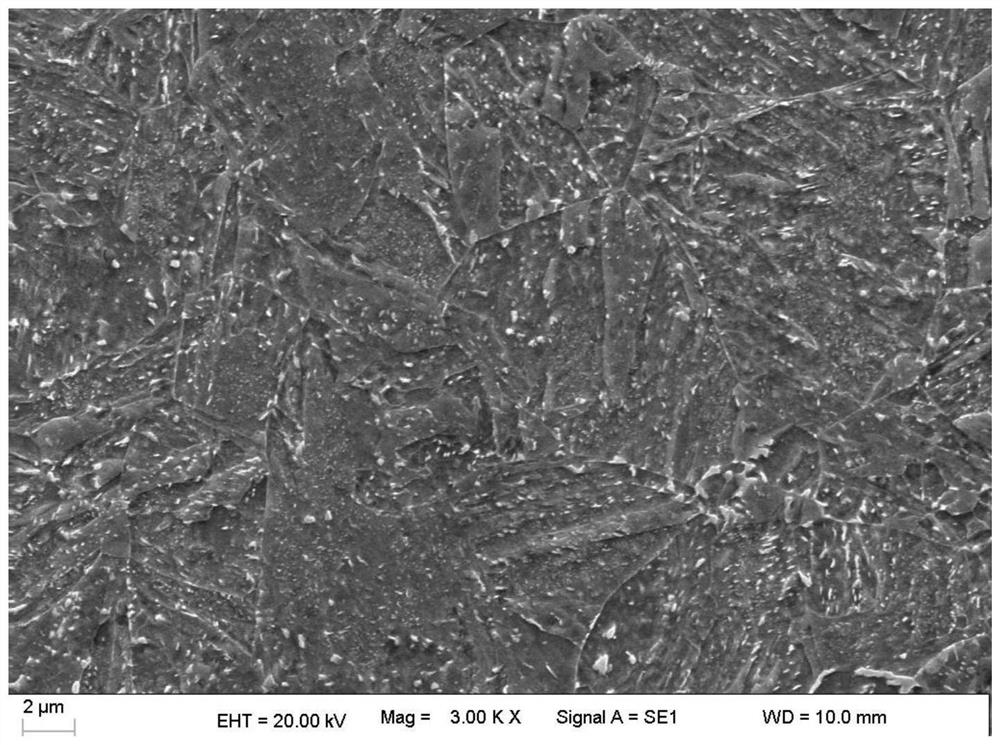

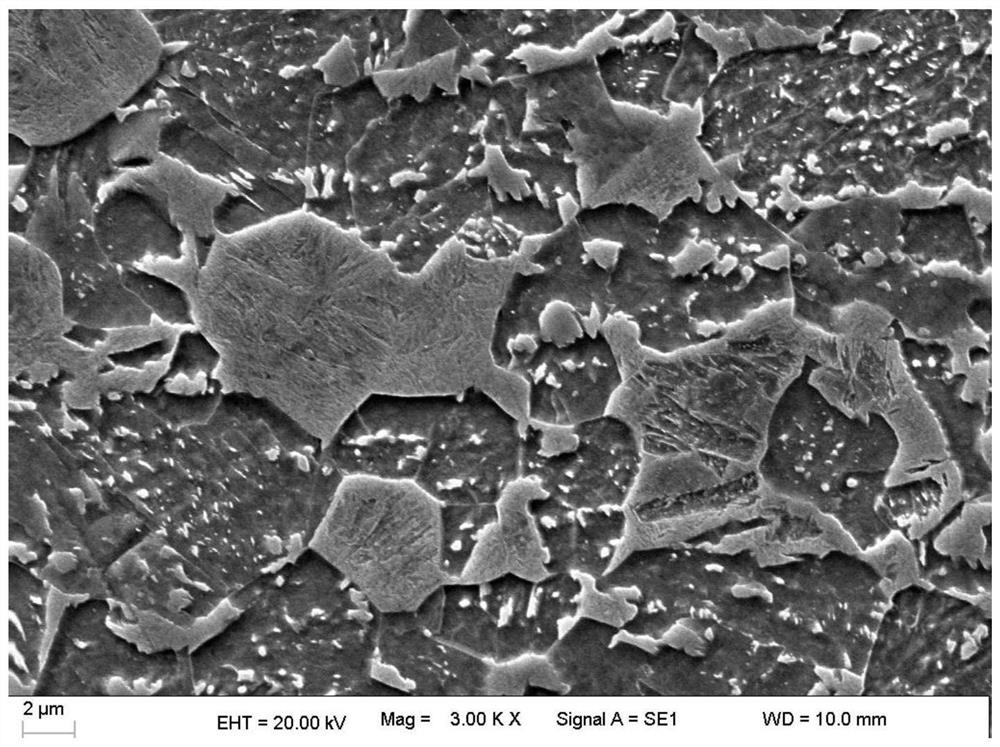

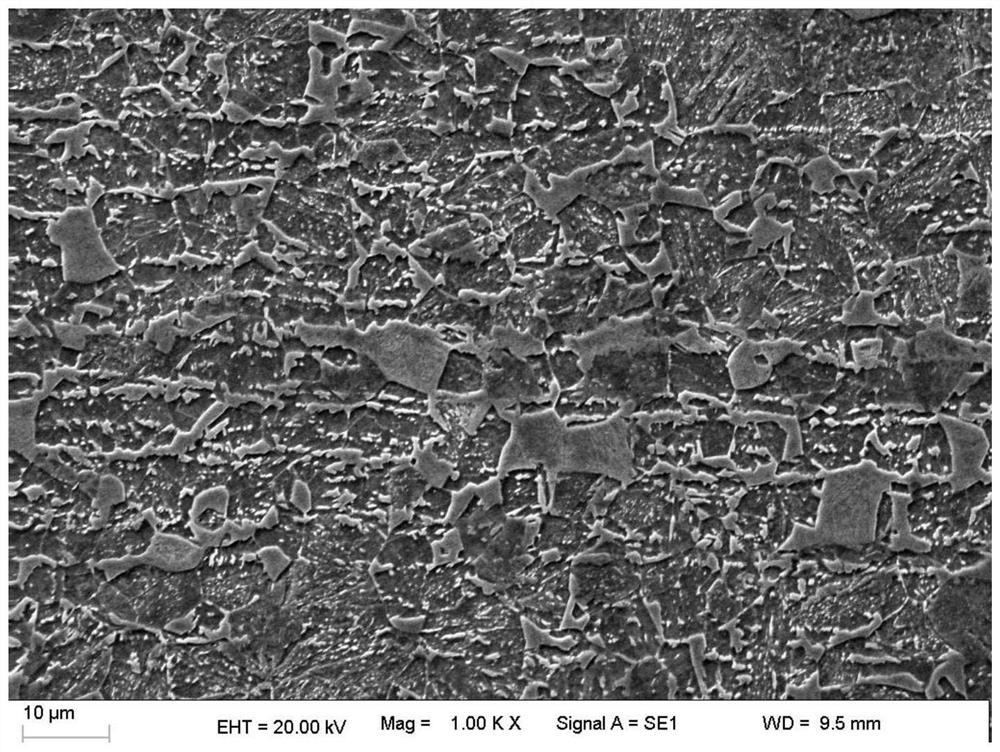

Image

Examples

Embodiment 1-14 and comparative example 1-10

[0095] Examples 1-14 The geka Babyberg steel with ultra-high and flexible ratio is made of the following steps:

[0096] (1) Smelting and casting was carried out in accordance with the chemical composition shown in Table 1.

[0097] (2) Hot rolling: The heating temperature is 1150 to 1260 ° C; the finished rolling temperature is 1100 ~ 1220 ° C, and the finishing rolling temperature is 900 ~ 950 ° C.

[0098] (3) Cooling and winding after rolling: The control cooling speed is 30 to 150 ° C / s, and the controlled volume temperature is 450 to 580 ° C.

[0099] (4) Acid washing and cold rolling: The rate of cold rolling pressure is ≥50%.

[0100] (5) Annealing.

[0101] It should be noted that in step (5), the annealing process comprises the following steps:

[0102] (a) Heating to a heated temperature TS at a heating rate of ≤ 50 ° C / s at a heating section, wherein Ts is 840 to 900 ° C.

[0103] (b) The temperature TS is 10 min or less in a warming section.

[0104] (c) Cool (TS-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com