Rare earth-containing nuclear seamless steel tube material and preparation method thereof

A technology of seamless steel pipe and nuclear power, which is applied to the material and preparation of seamless steel pipe for nuclear power containing rare earth, and the field of seamless steel pipe for nuclear power containing rare earth, can solve the problems of aggravating environmental pollution, increase power generation cost, etc., and achieve energy saving in production process The effect of environmental protection, high production efficiency and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

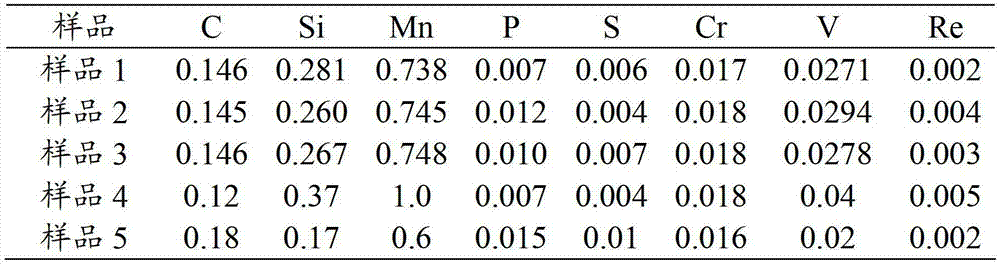

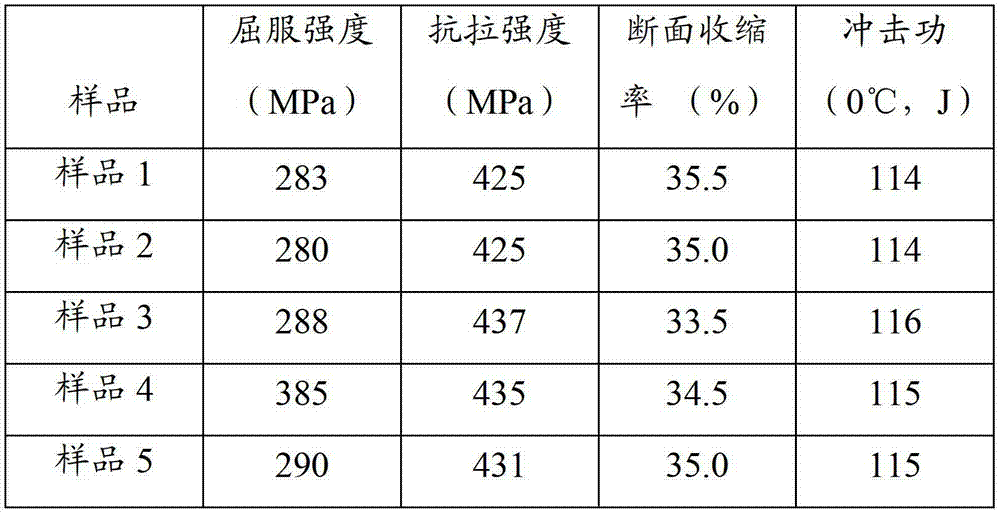

[0019] The invention adopts Baotou Steel's own ore as raw material, and the ore contains rare earth elements. The rare earth elements include La and Ce.

[0020] The steelmaking production process of steel is:

[0021] The steel smelting and continuous casting process is molten iron pretreatment→converter smelting→LF refining→VD degassing→round billet continuous casting. The smelting uses a 100-ton top-bottom combined blowing converter, using desulfurized molten iron, ferrosilicon, ferromanganese and other alloys using deoxidation alloying, single slag process, and the final slag alkalinity is controlled at 3.0. The composition of the end point of the converter is controlled to be no less than 0.03% carbon, no more than 0.01% phosphorus, the temperature of the molten steel in the converter is controlled above 1600°C, and 100-300kg of limestone is added during the tapping process. LF refining adopts single refining production, and the whole process is blown argon according to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com