Patents

Literature

59results about "Sausage twisting/linking machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

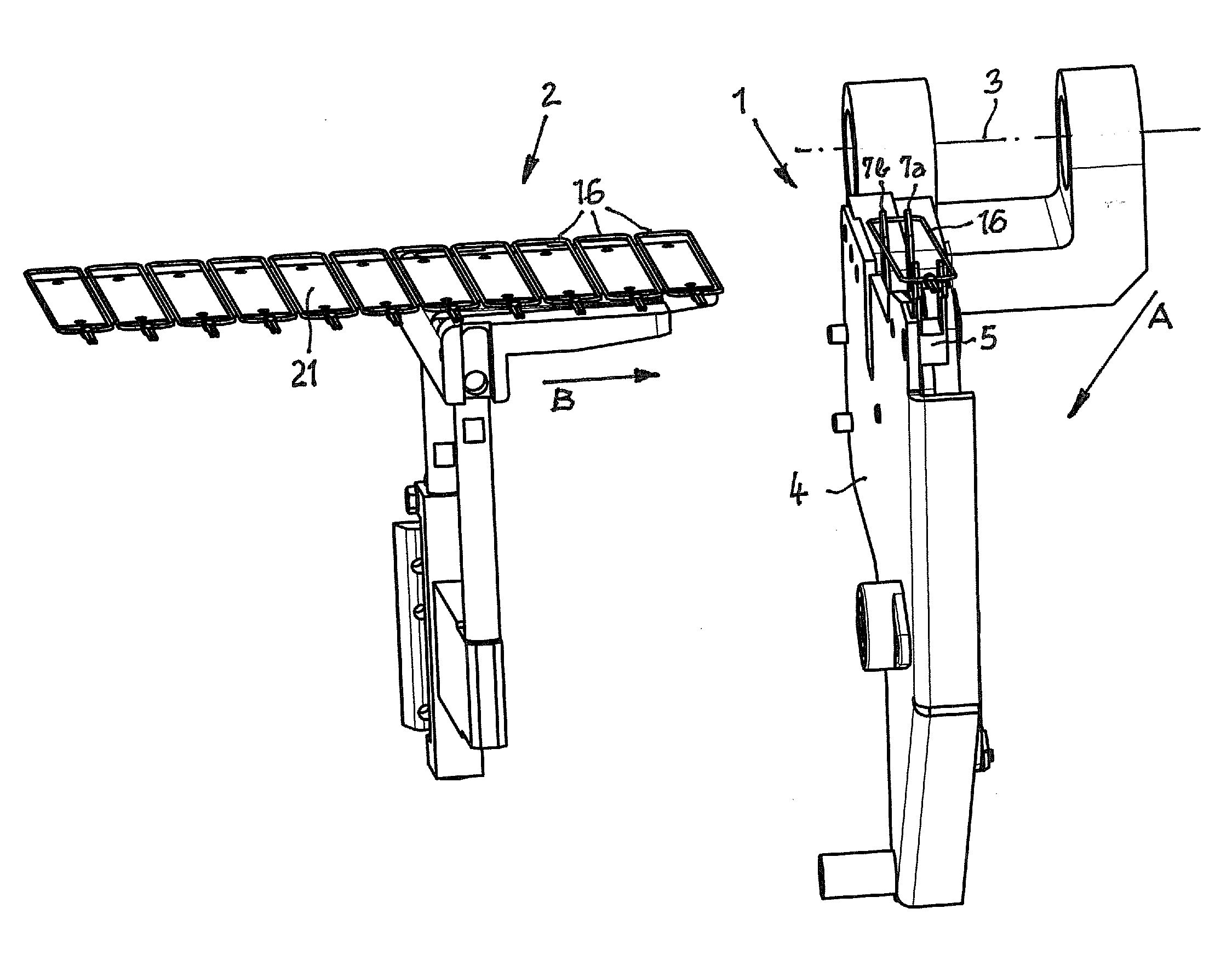

Apparatus and method for setting a casing to a nozzle feeding food-material of sausage or the like into the casing

ActiveUS20080311835A1Improve accuracyReduce idle timeSausage filling/stuffing machinesSausage twisting/linking machinesRotational axisFood material

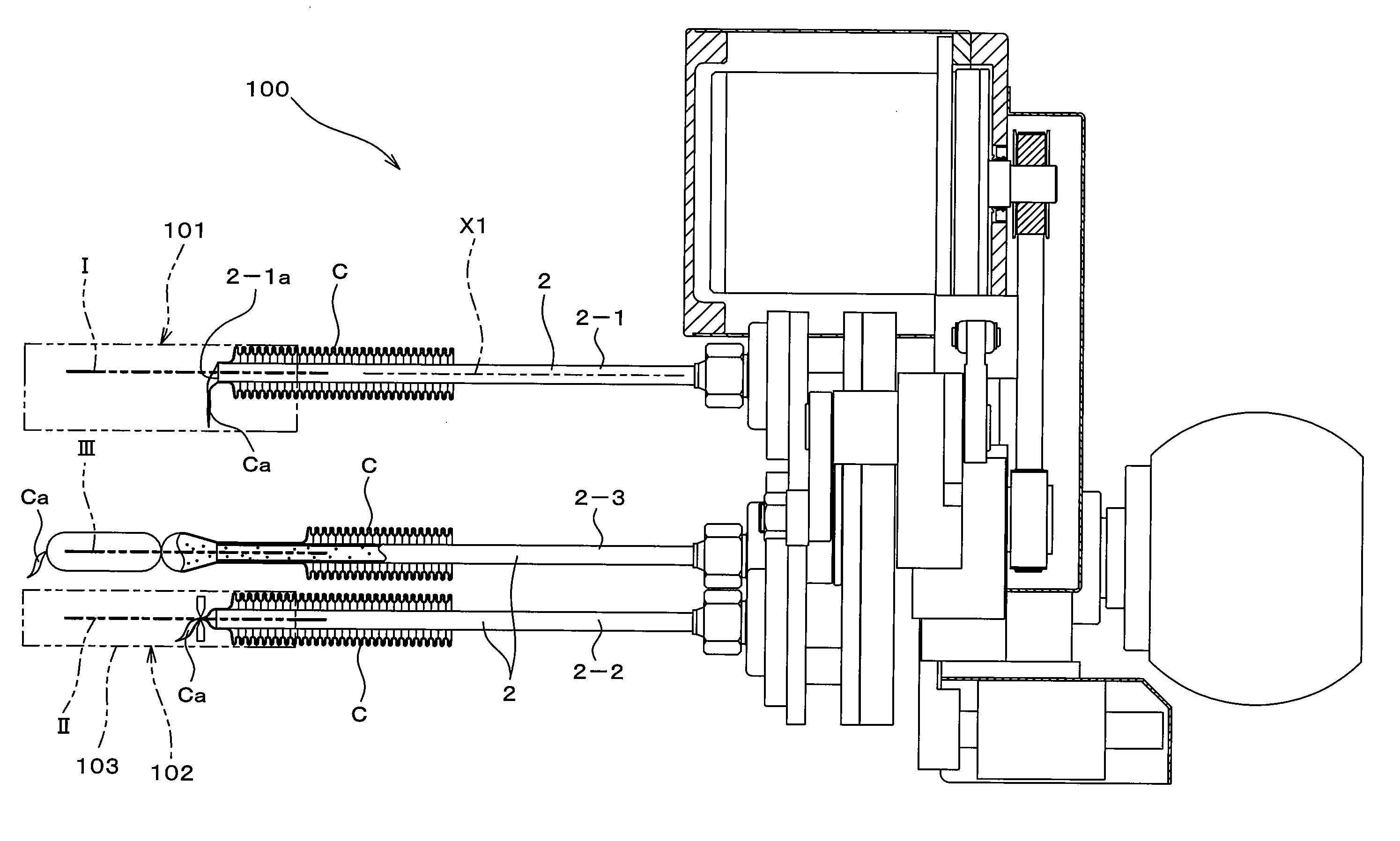

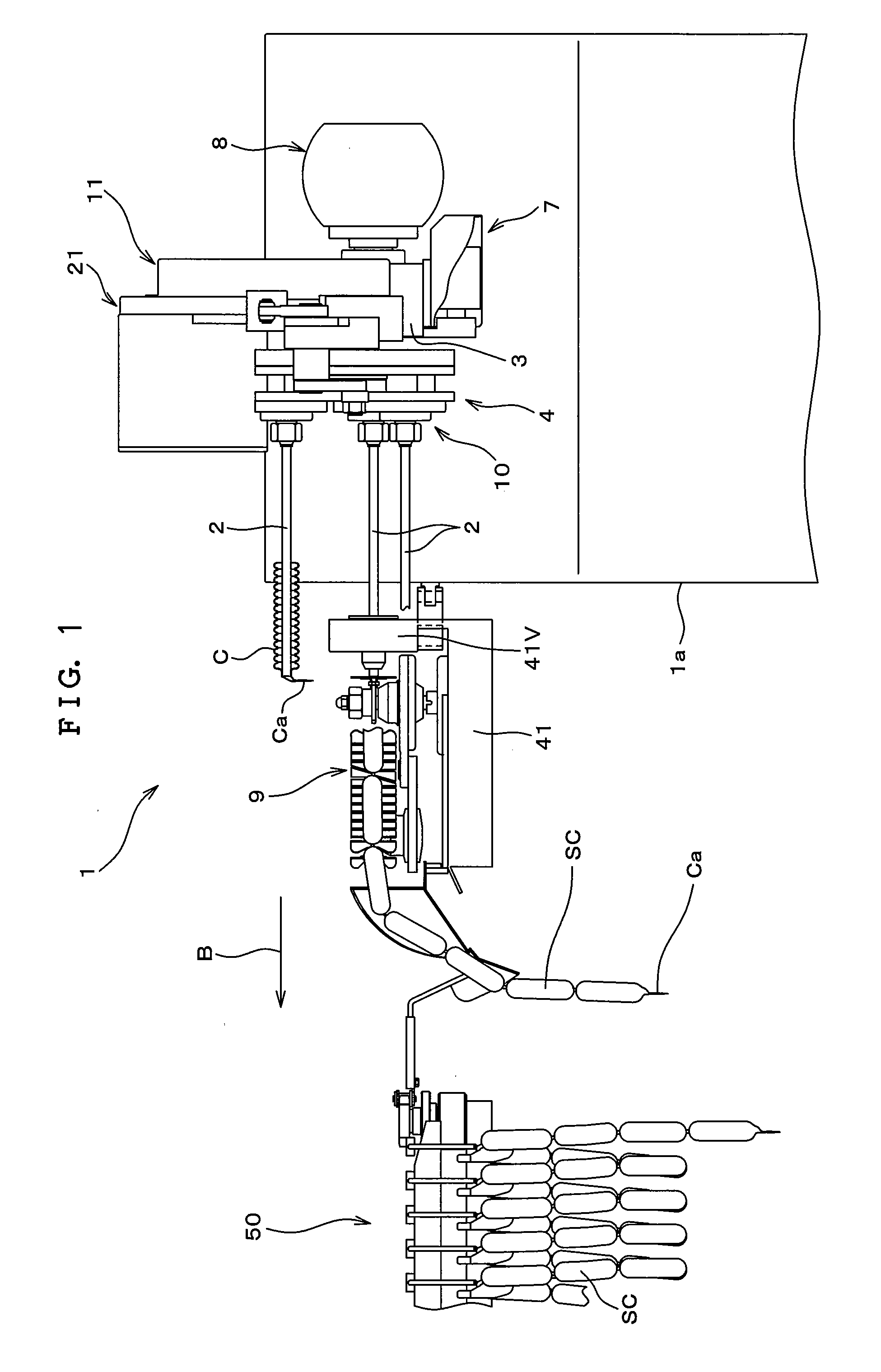

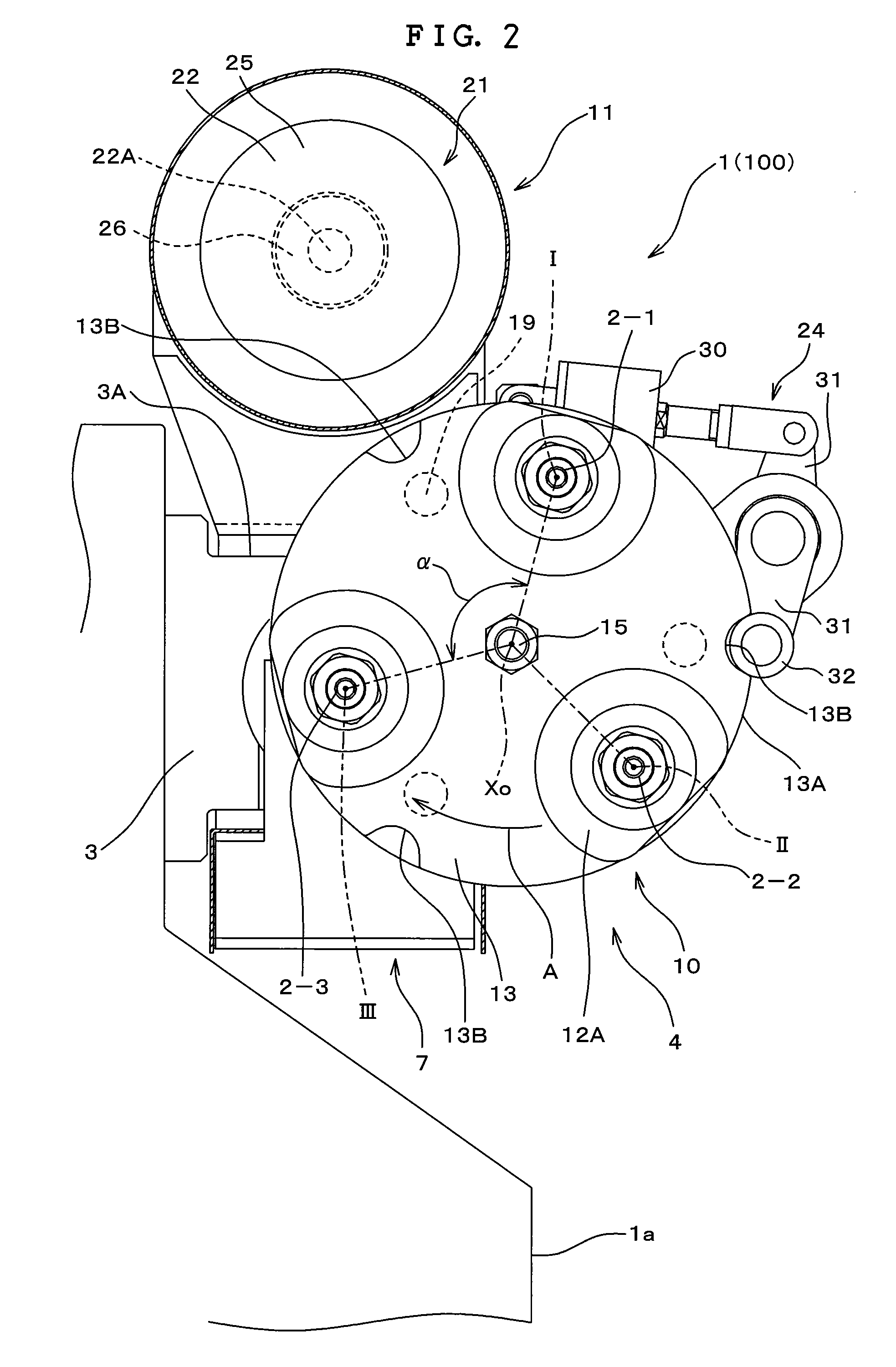

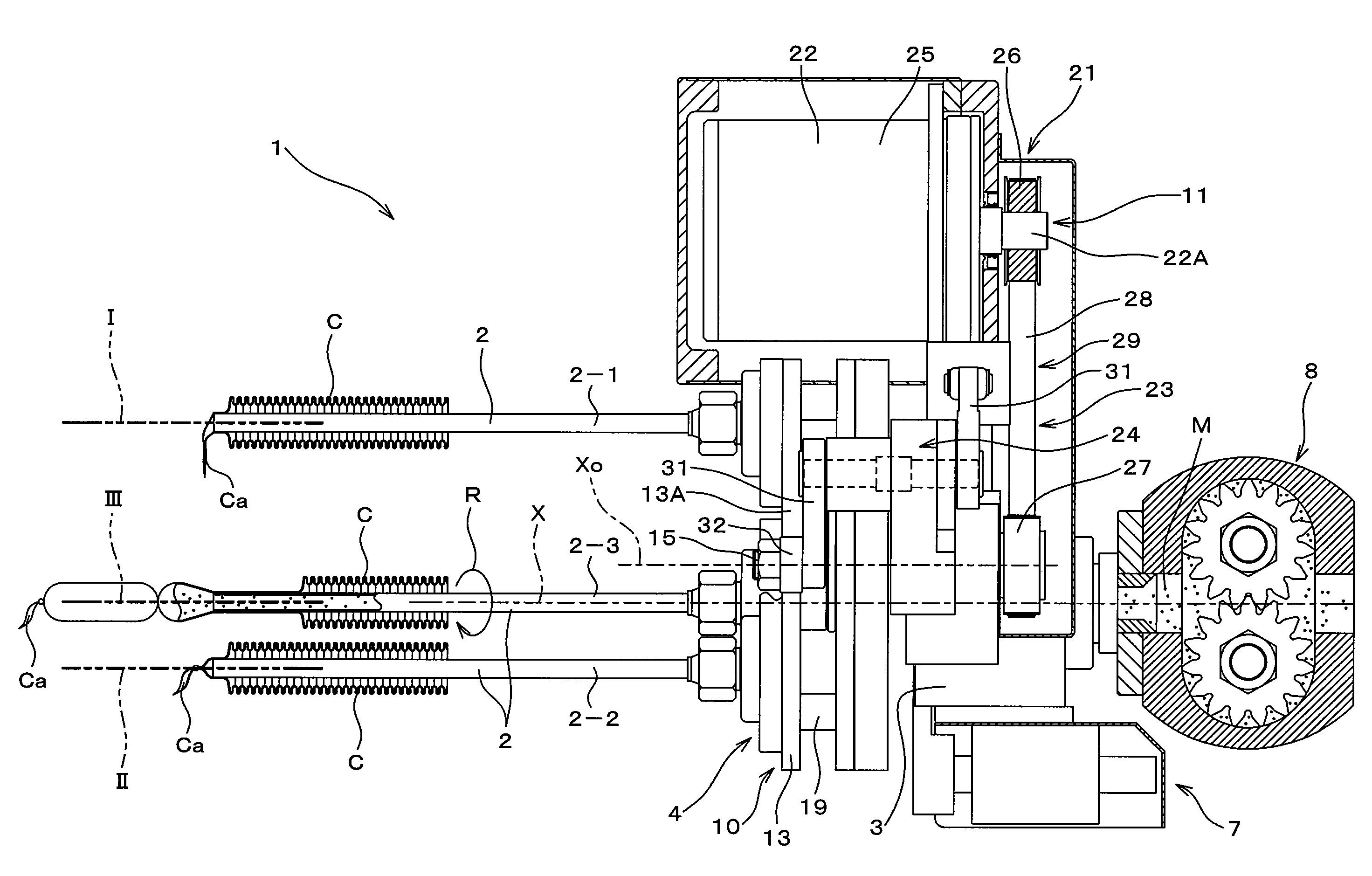

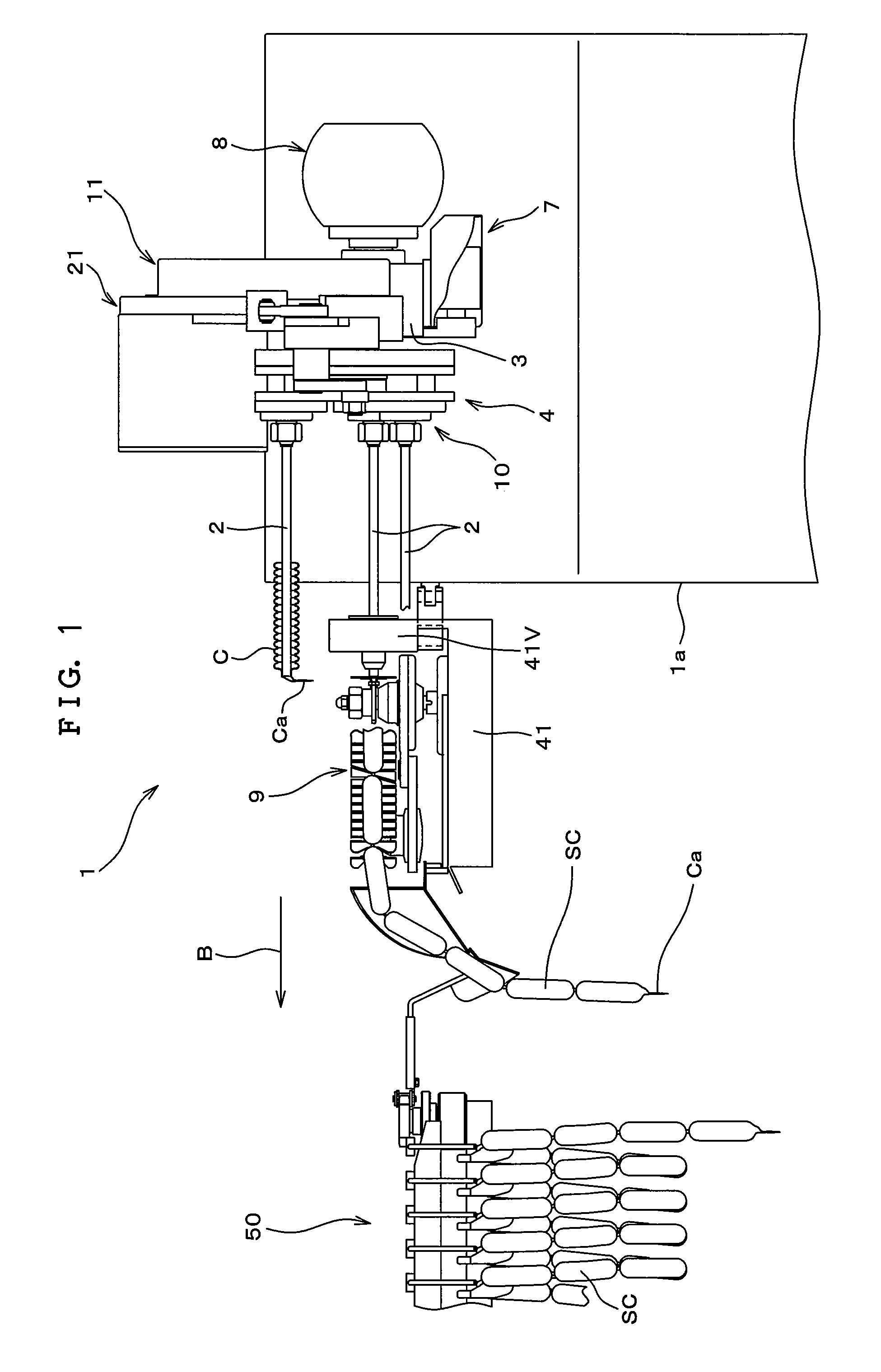

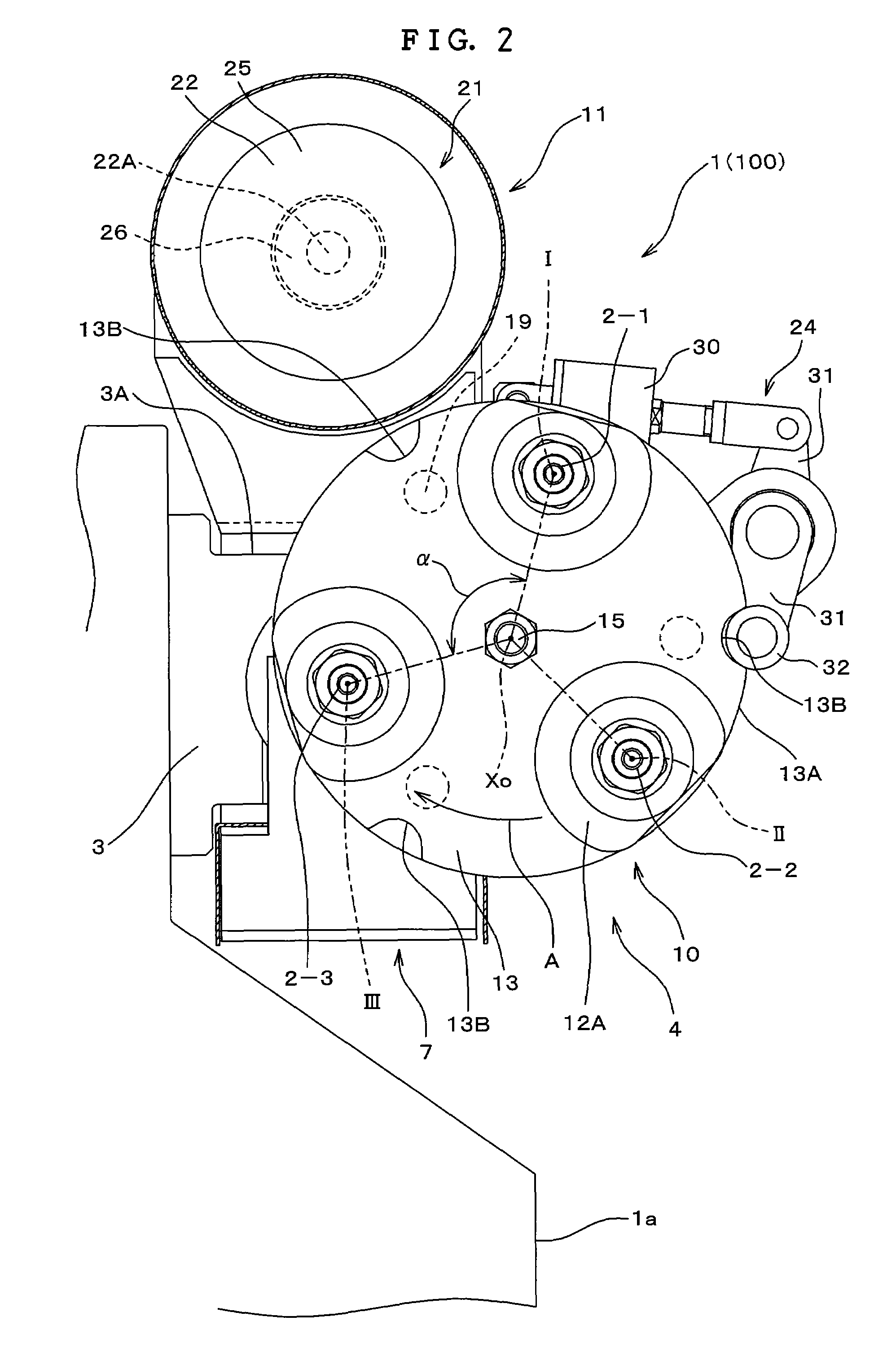

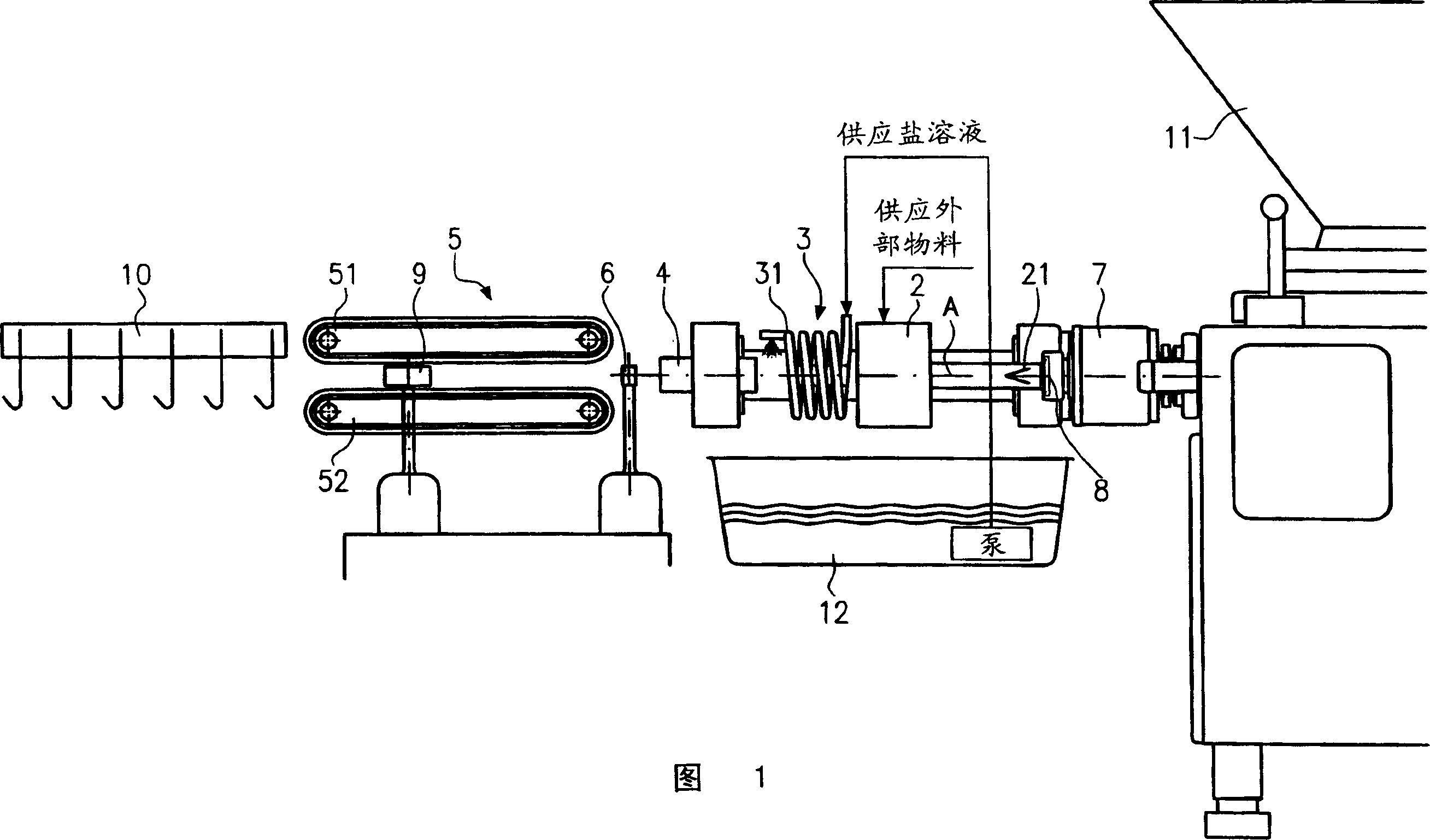

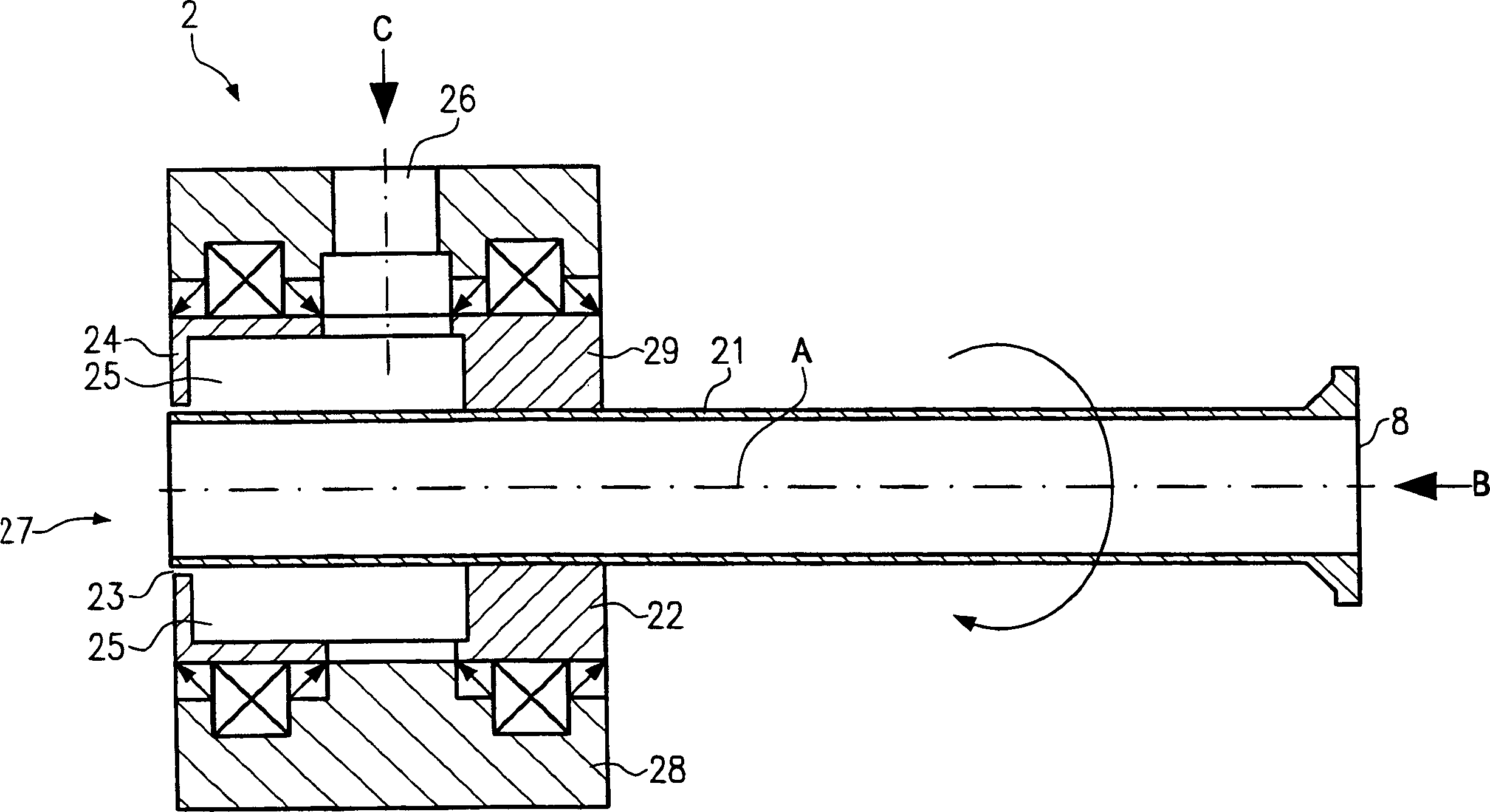

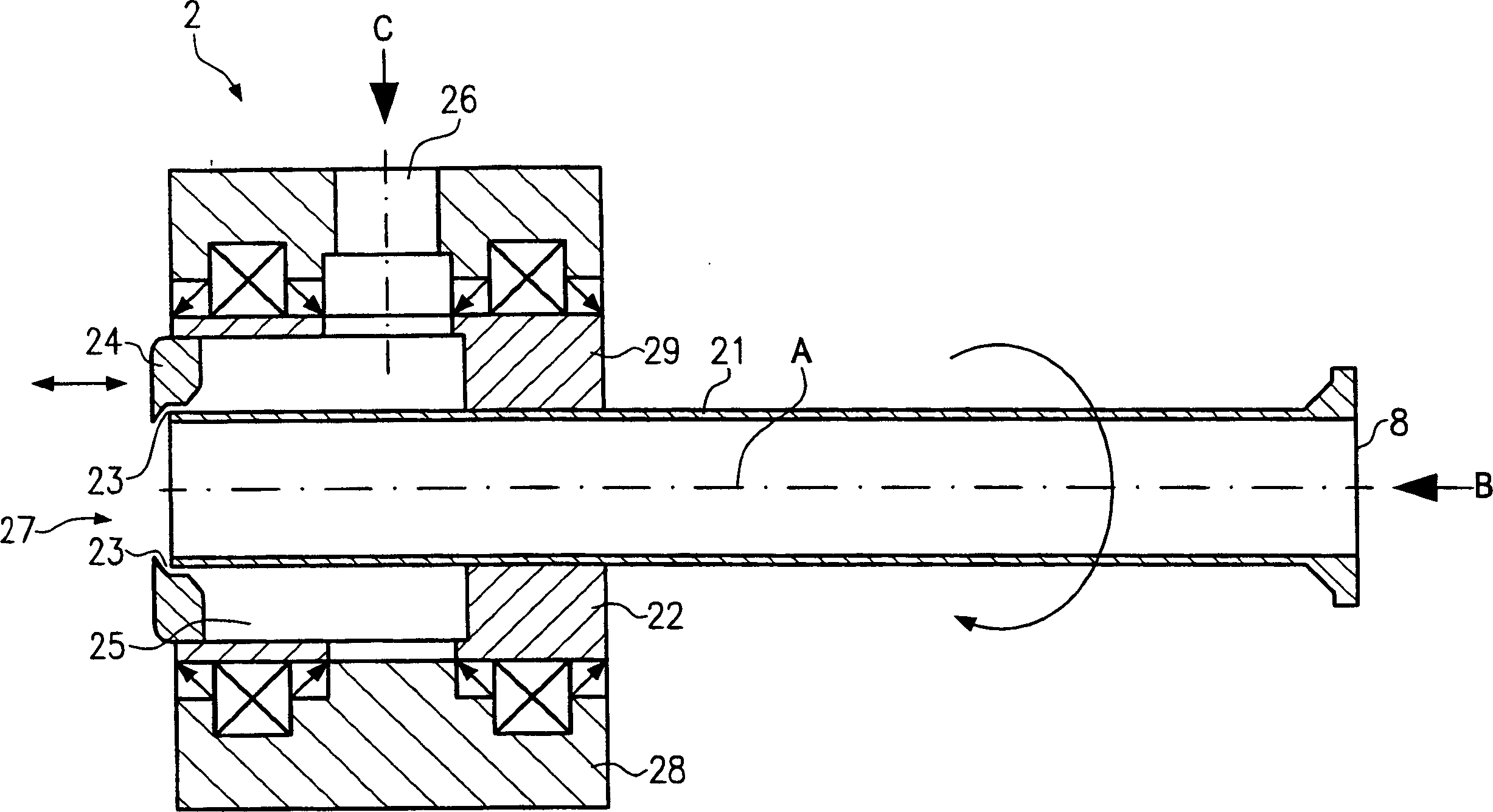

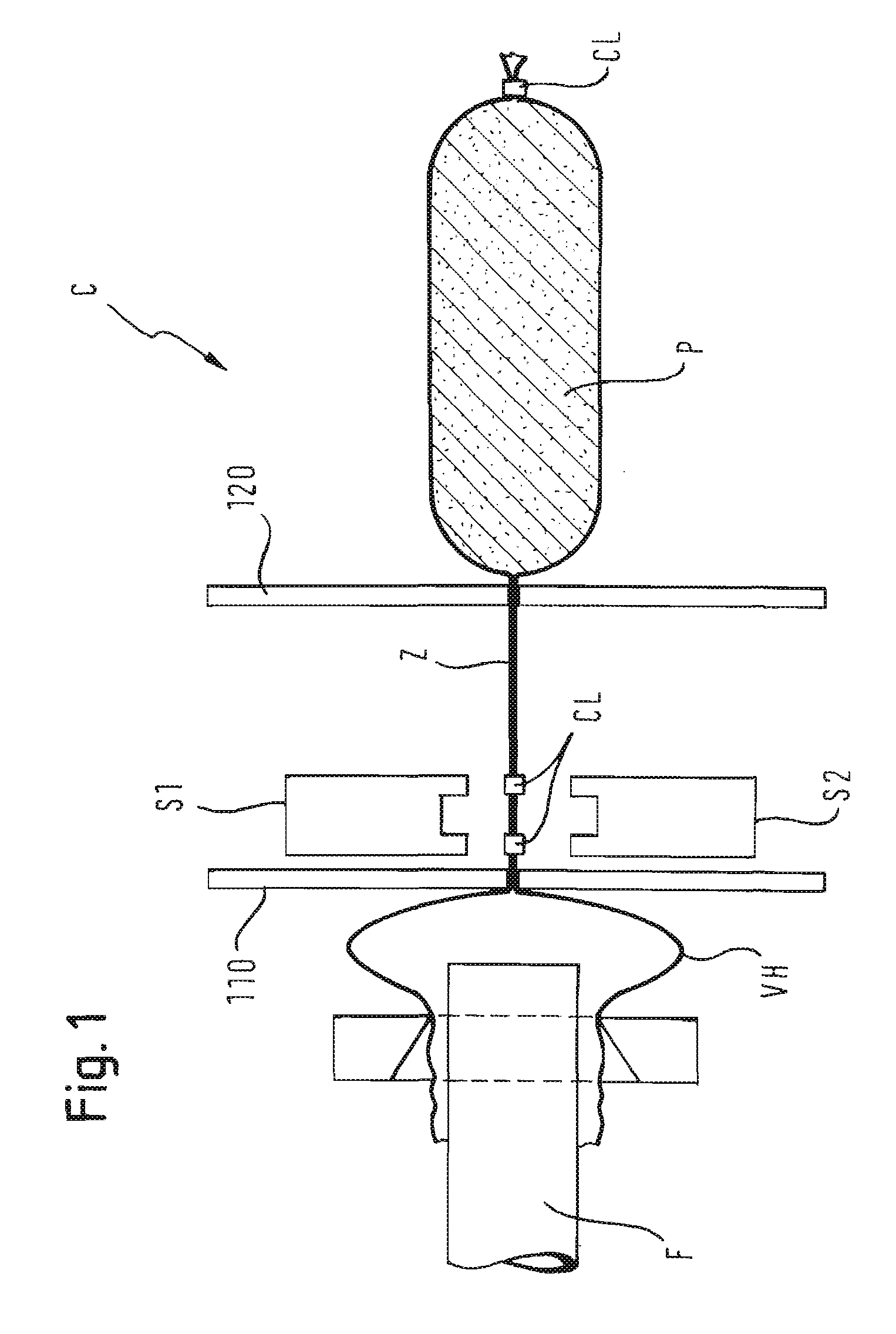

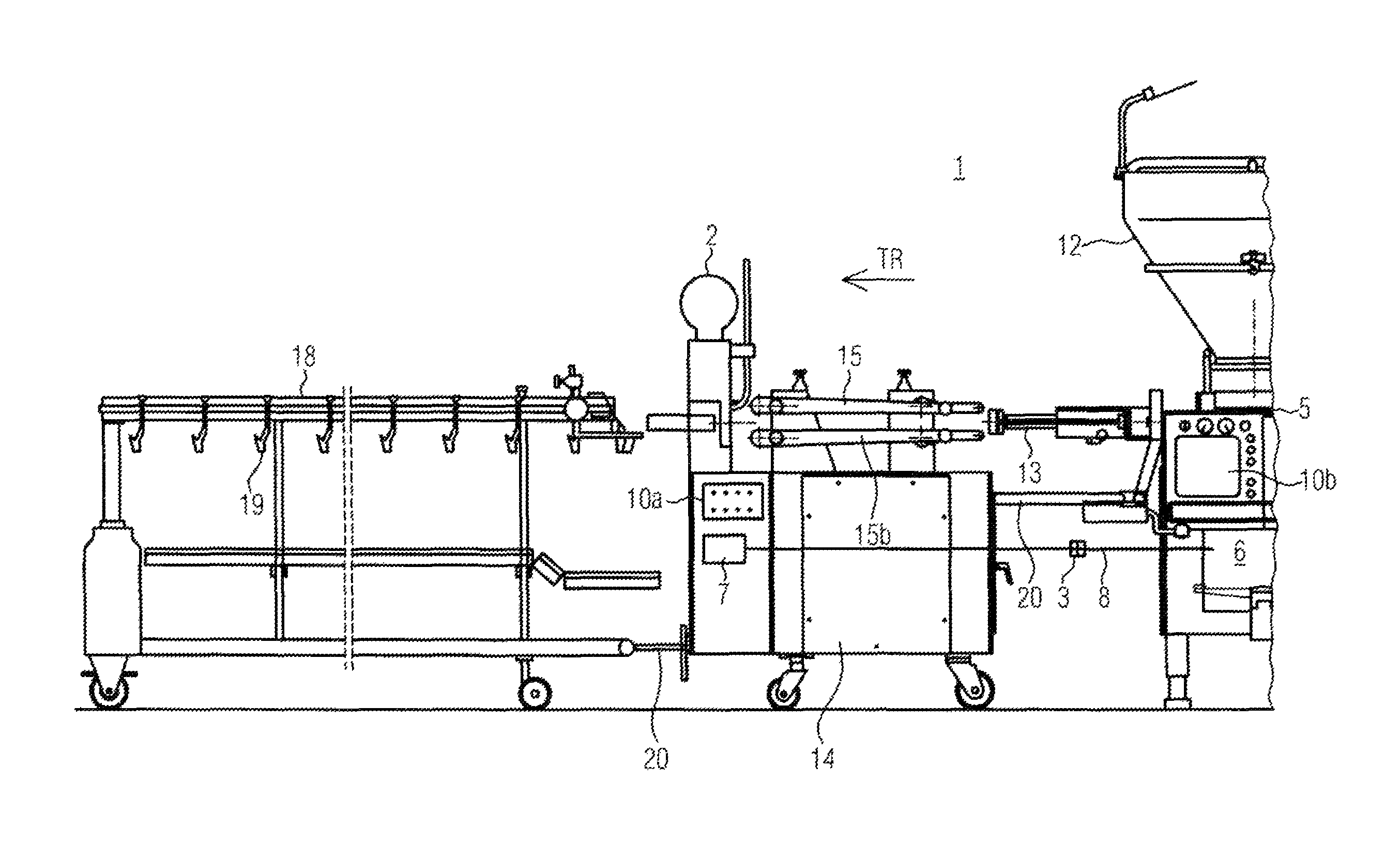

An apparatus for manufacturing chains of linked food products such as sausages with twisted portions and having a plurality of stuffing tubes, includes a plurality of stuffing tubes 2 provided at equal intervals about a rotational axis Xo; a stuffing tube moving body 4 which rotates through predetermined angles about the rotational axis Xo so that the respective stuffing tubes 2 sequentially move to a filling position III; and a stuffed casing conveying means 50 which conveys in a suspended state a stuffed casing C formed by the stuffing tube 2 positioned at the filling position III.

Owner:HITEC

Apparatus for manufacturing chains of linked food products such as sausages with twisted portions and having a plurality of stuffing tubes and method of manufacturing the same

ActiveUS7666071B2Reduce idle timeSignificant differenceSausage filling/stuffing machinesSausage twisting/linking machinesRotational axisEngineering

An apparatus for manufacturing chains of linked food products such as sausages with twisted portions and having a plurality of stuffing tubes, includes a plurality of stuffing tubes 2 provided at equal intervals about a rotational axis Xo; a stuffing tube moving body 4 which rotates through predetermined angles about the rotational axis Xo so that the respective stuffing tubes 2 sequentially move to a filling position III; and a stuffed casing conveying means 50 which conveys in a suspended state a stuffed casing C formed by the stuffing tube 2 positioned at the filling position III.

Owner:HITEC

Shaping device and shaping method for forming rounded tips on the ends of sausages

ActiveUS7762874B2Facilitates the tying off and/or partingUniform formatSausage skin tying apparatusSausage filling/stuffing machinesEngineeringMechanical engineering

Owner:ALBERT HANDTMANN MASCHFABRICK

Automatic spreading adjustment

ActiveUS7575506B2Simple structureSimple of stroke movementSausage filling/stuffing machinesSausage twisting/linking machinesLinear motionFilling materials

Owner:POLY CLIP SYST

Apparaus and method for producing paste material and extrusion head separately used for the apparatus and method

InactiveCN1468540AHigh normal sclerosisIncrease distanceSausage skin tying apparatusSausage casing manufactureMechanical engineeringExtrusion

Owner:ALBERT HANDTMANN MASCHFABRICK

Automatic spreading adjustment

ActiveUS20080220704A1Simple structureSimple of stroke movementSausage filling/stuffing machinesSausage twisting/linking machinesEngineeringMechanical engineering

Owner:POLY CLIP SYST

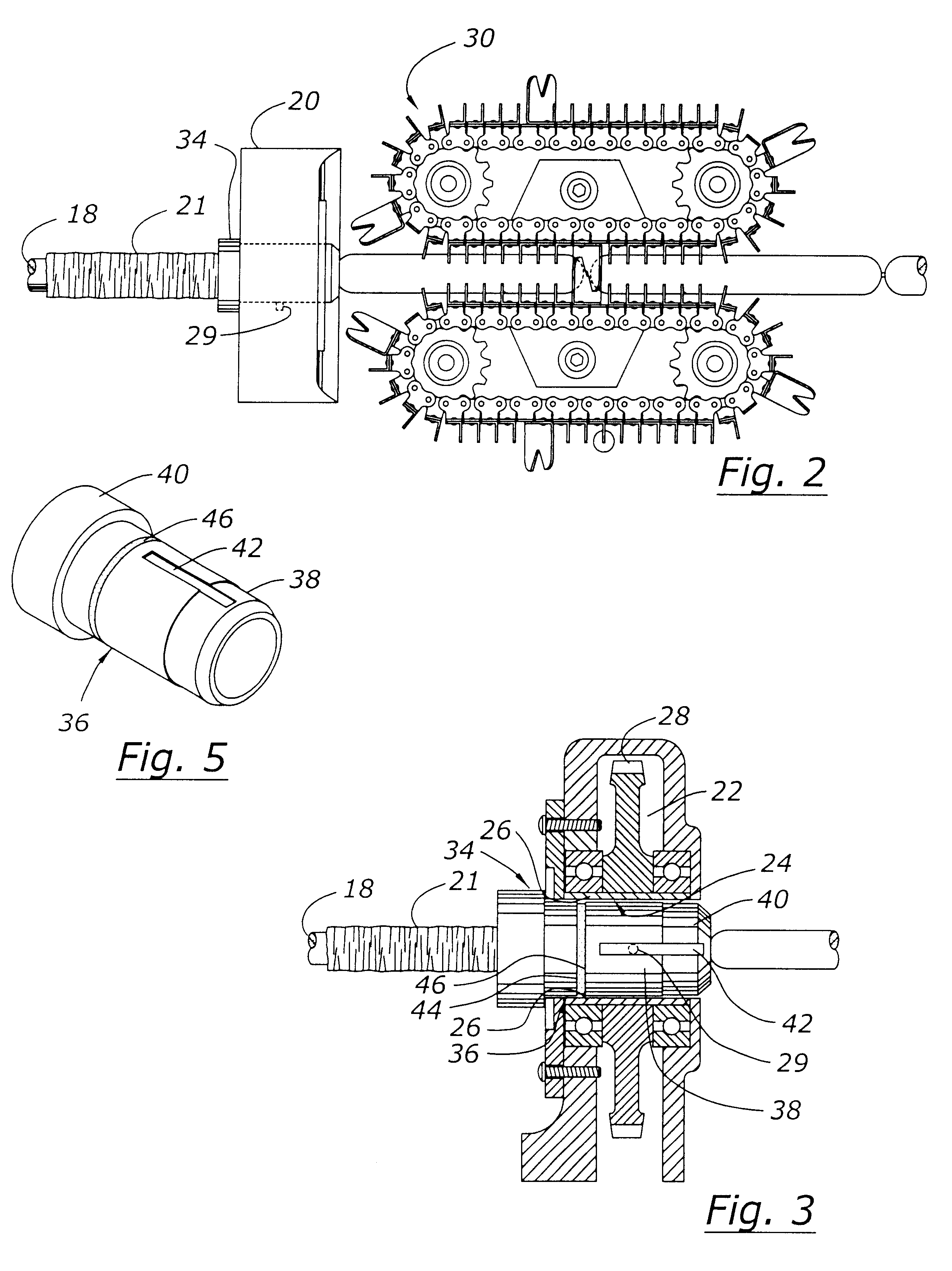

Chuck for meat encasing machines

InactiveUSRE37883E1Sausage filling/stuffing machinesSausage twisting/linking machinesMechanical engineering

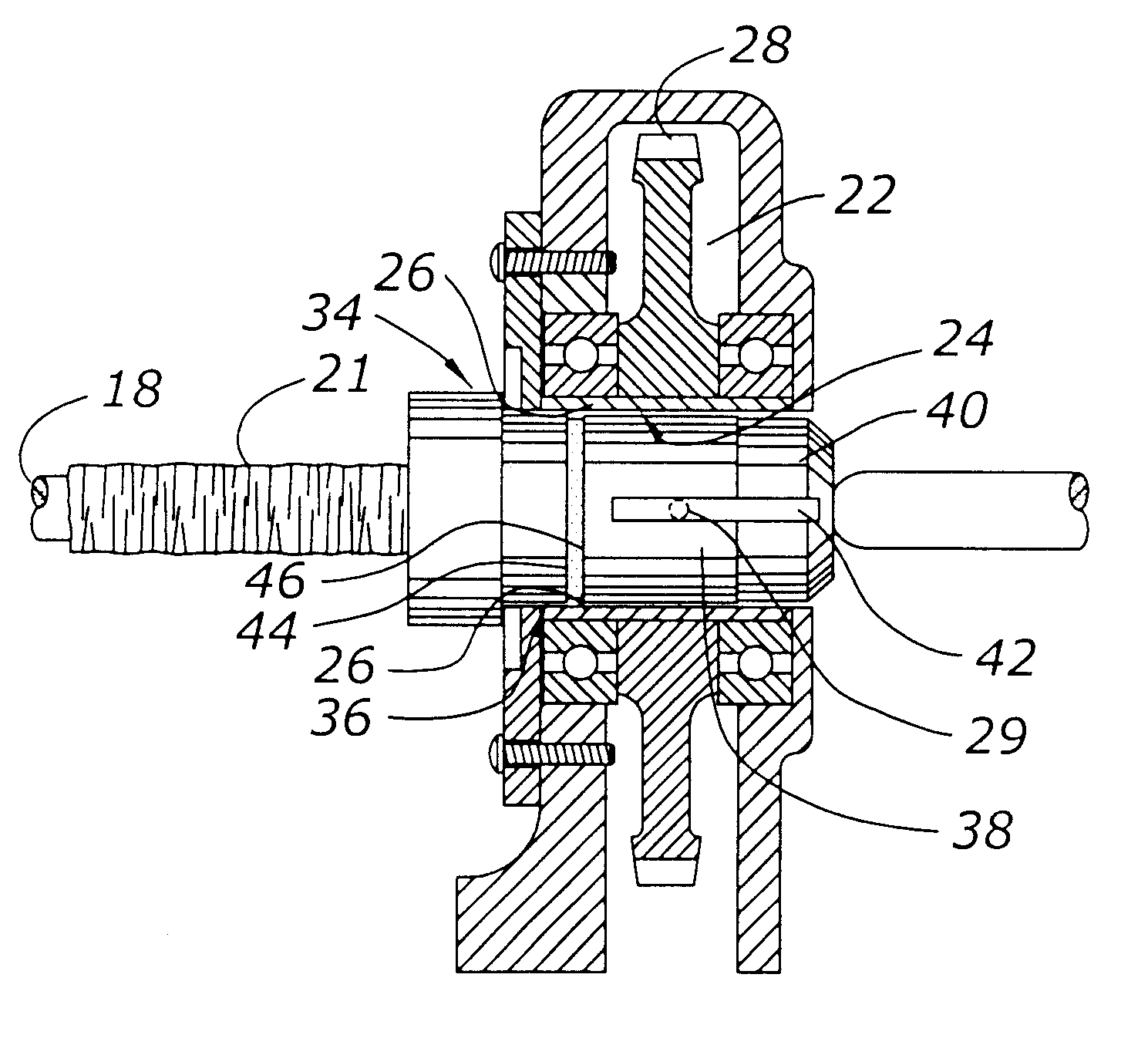

A chuck for a meat encasing machine has an elongated body having an inlet end and a discharge end. The body has an elongated hollow bore extending therethrough and an exterior cylindrical surface. A plurality of radially extending flutes are in the bore of the body for purposes of grasping and imparting rotational motion to a filled meat casing. An annular groove extends around the exterior cylindrical surface of the body member. A resilient O-ring is mounted in the groove and slightly projects outwardly from the groove to frictionally engage a socket into which the chuck is inserted.

Owner:STORK TOWNSEND BV

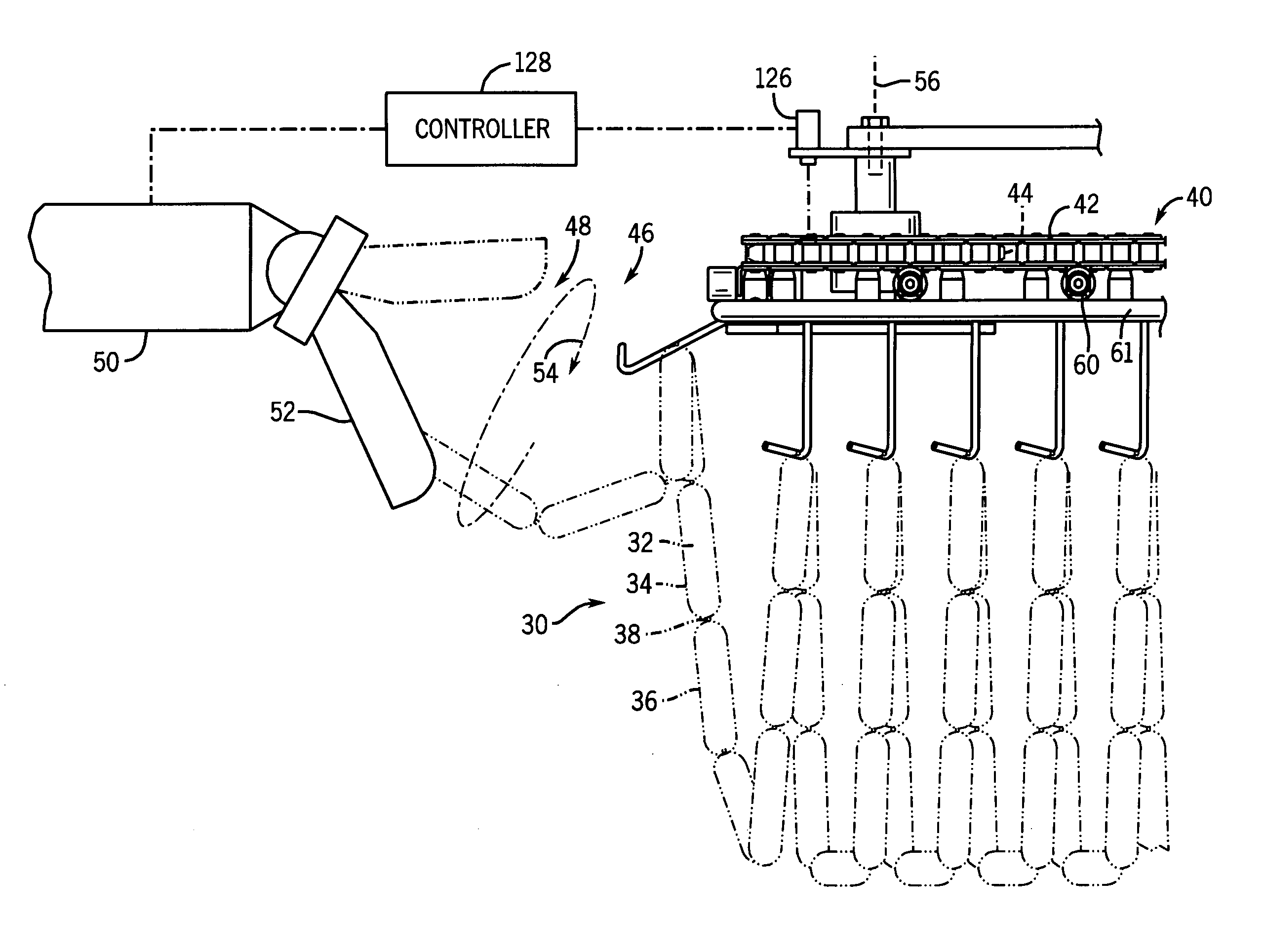

Conveyor chain

InactiveUS7195552B1Meat/sausage hanging-upMeat/fish preservation by heatingArrival timeMechanical engineering

A food processing system for an elongated strand of food product, such as hot dogs or sausage links, provides aligned orientation of conveyor hooks and identical arrival time spacing between adjacent hooks at a reference loading point at a strand producing machine discharge station.

Owner:ALKAR-RAPIDPAK INC

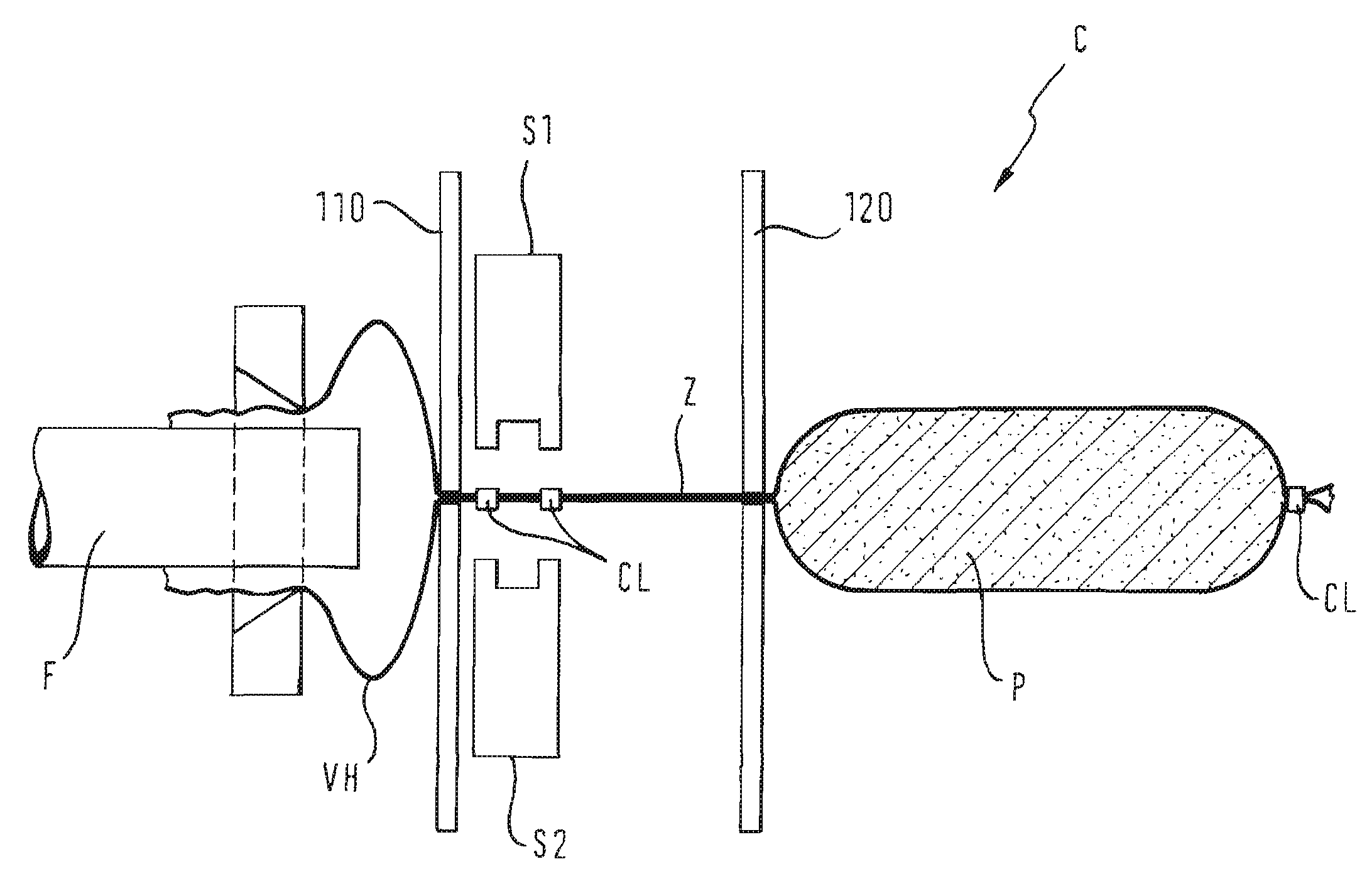

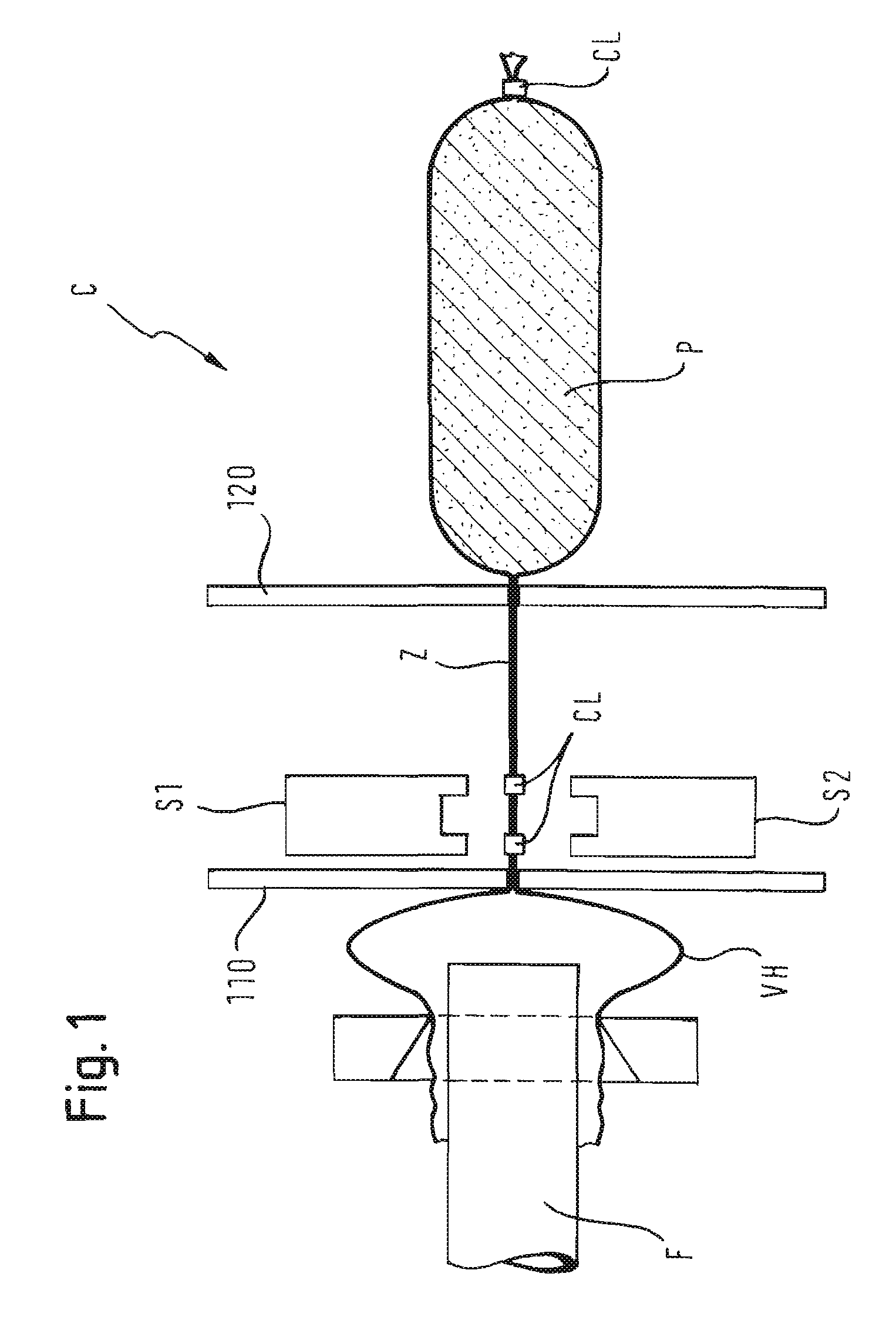

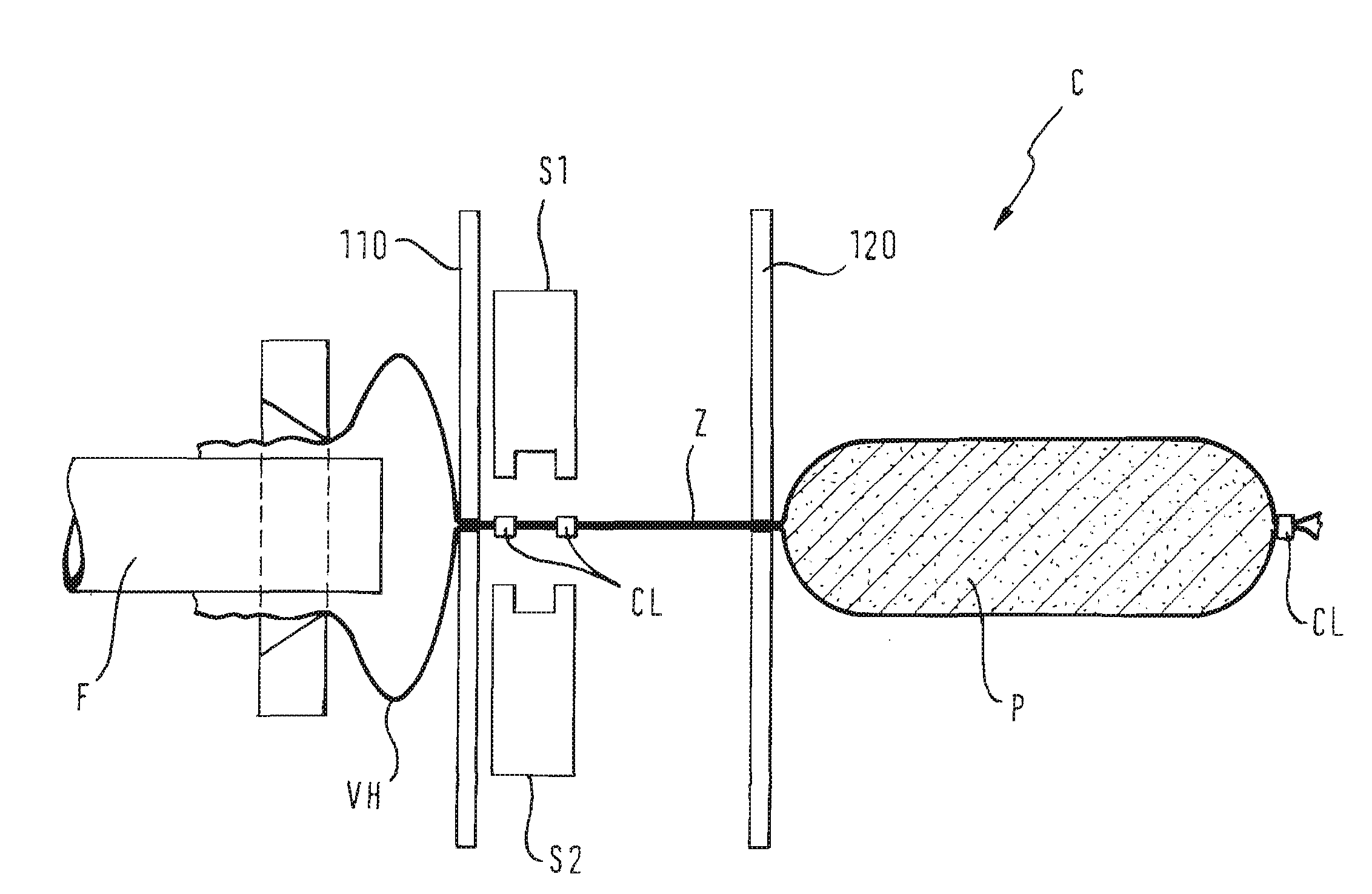

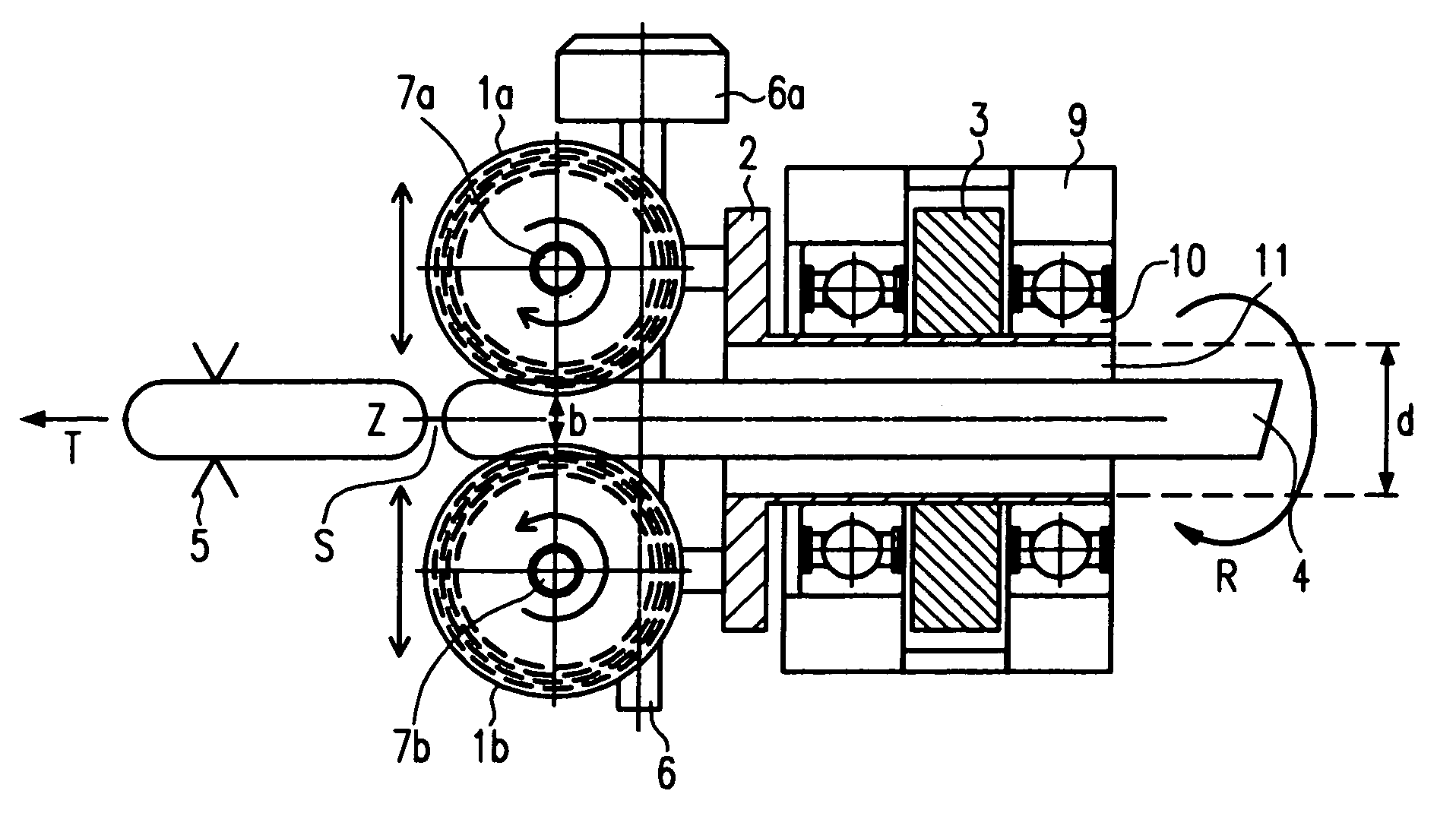

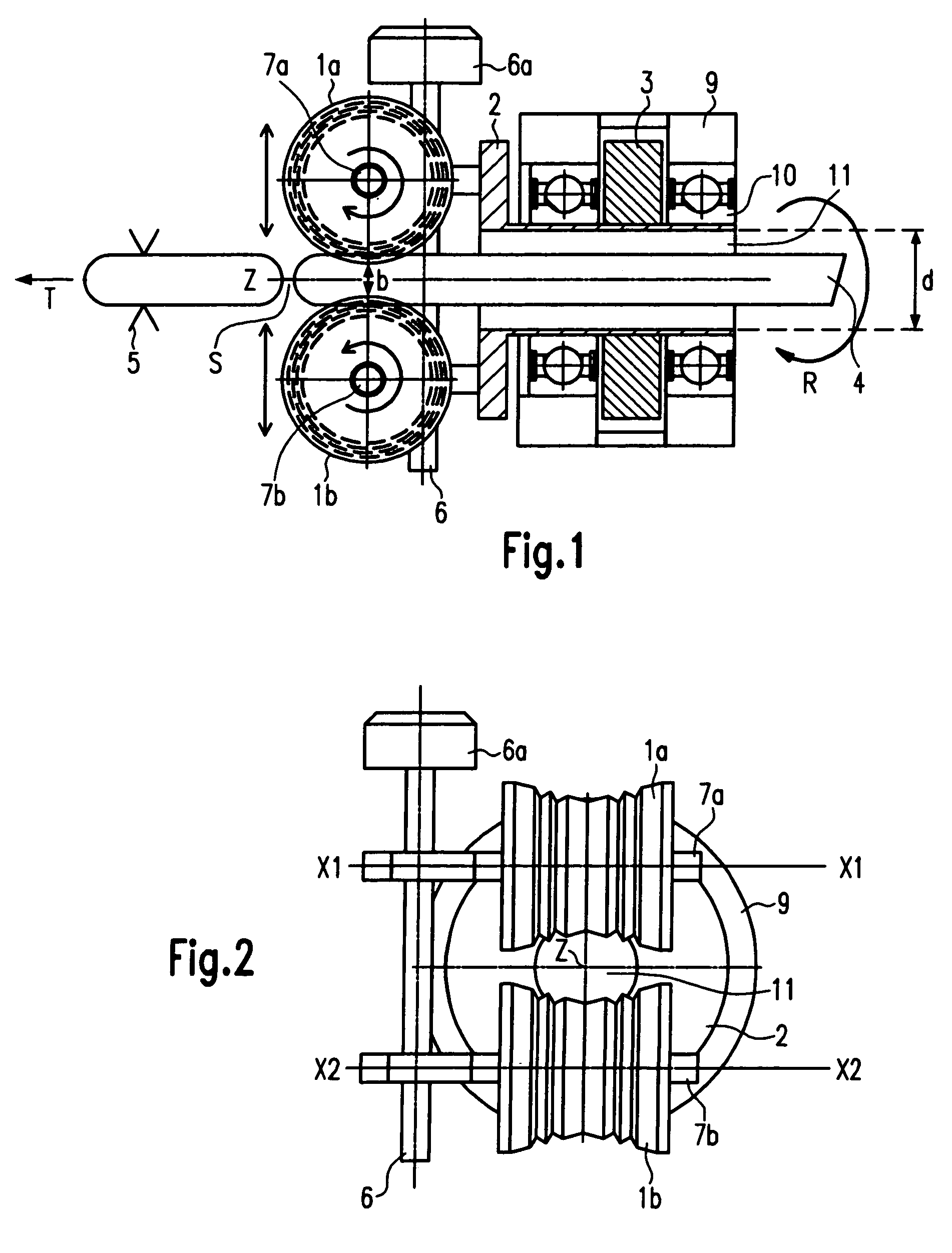

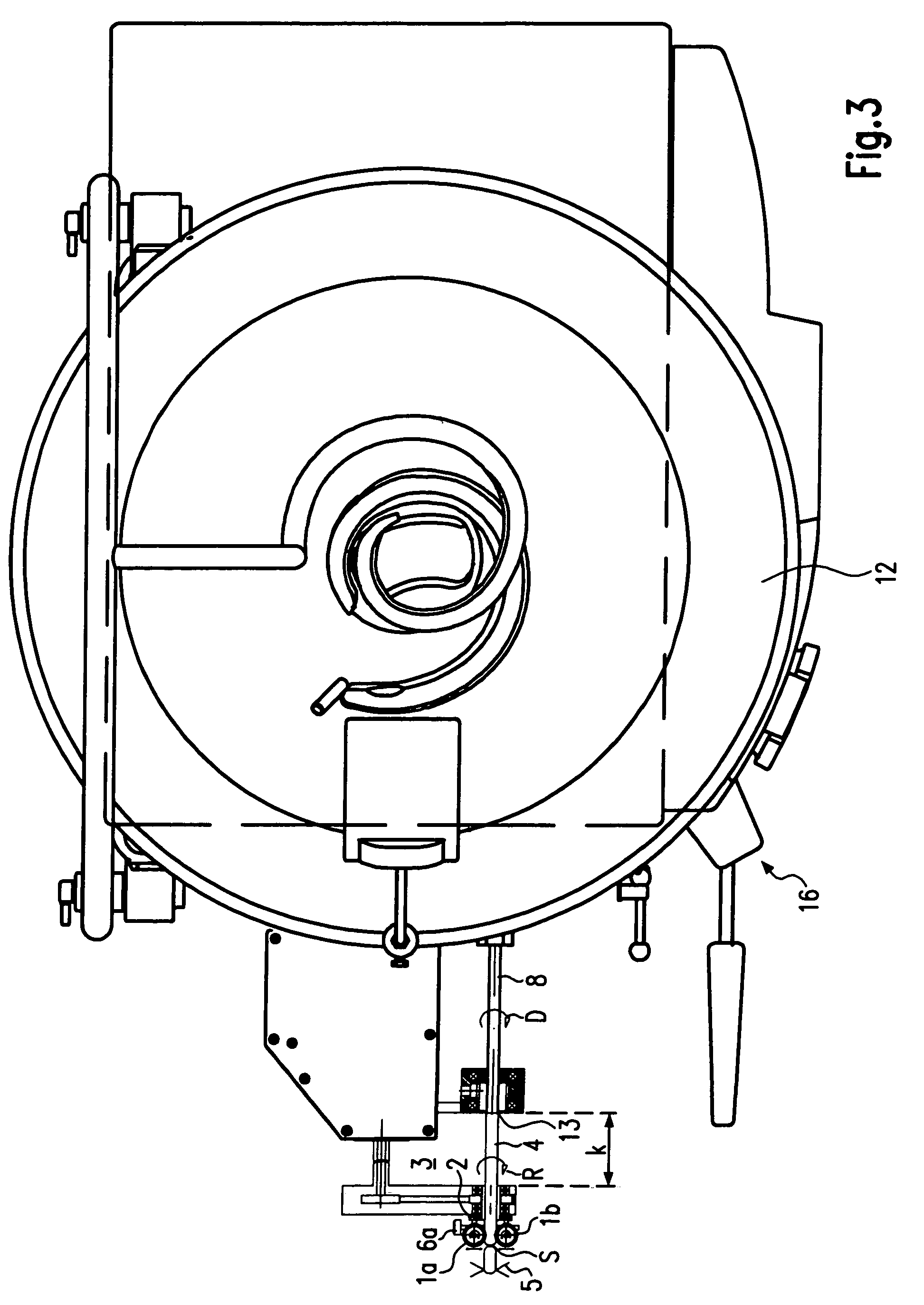

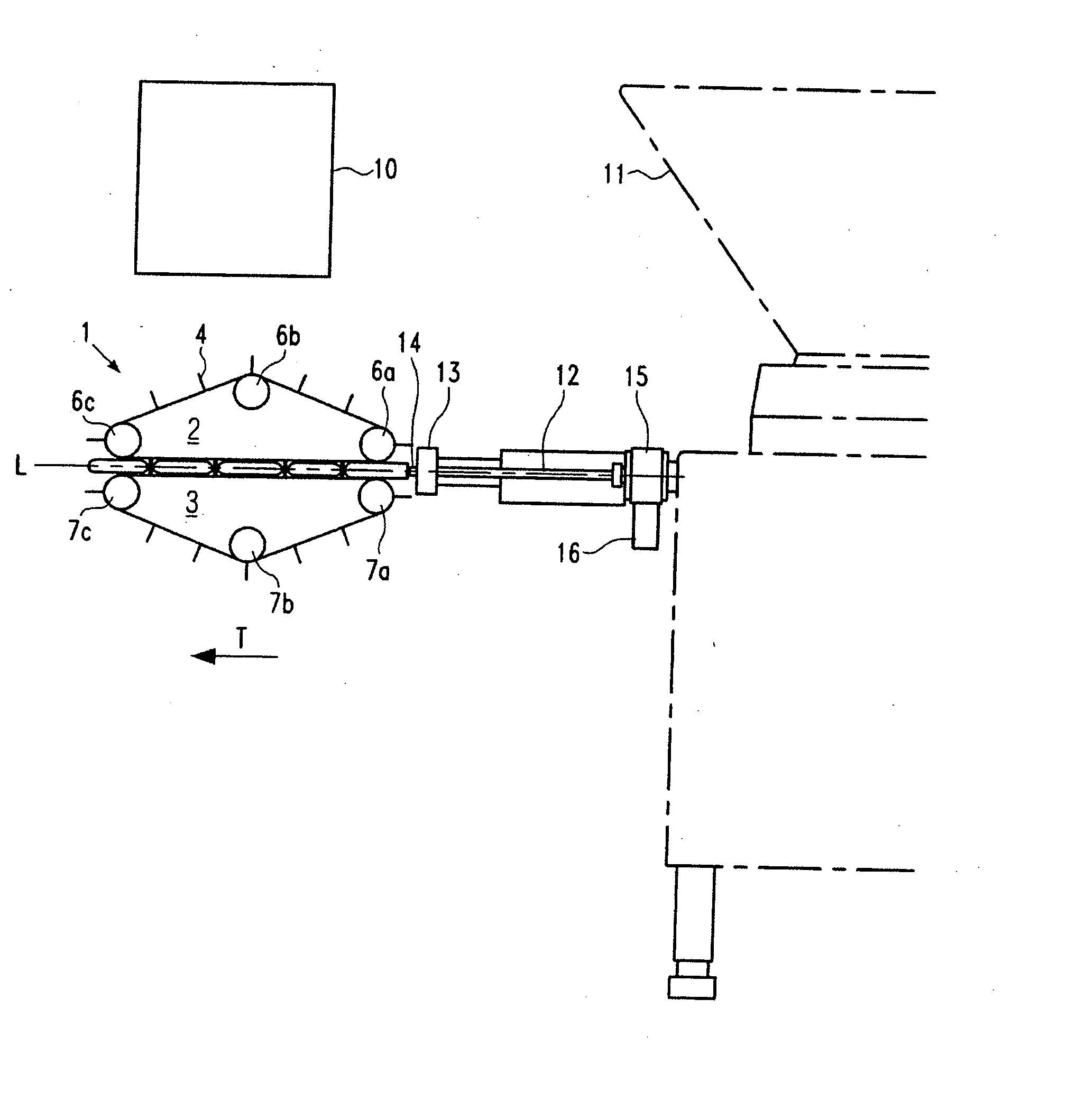

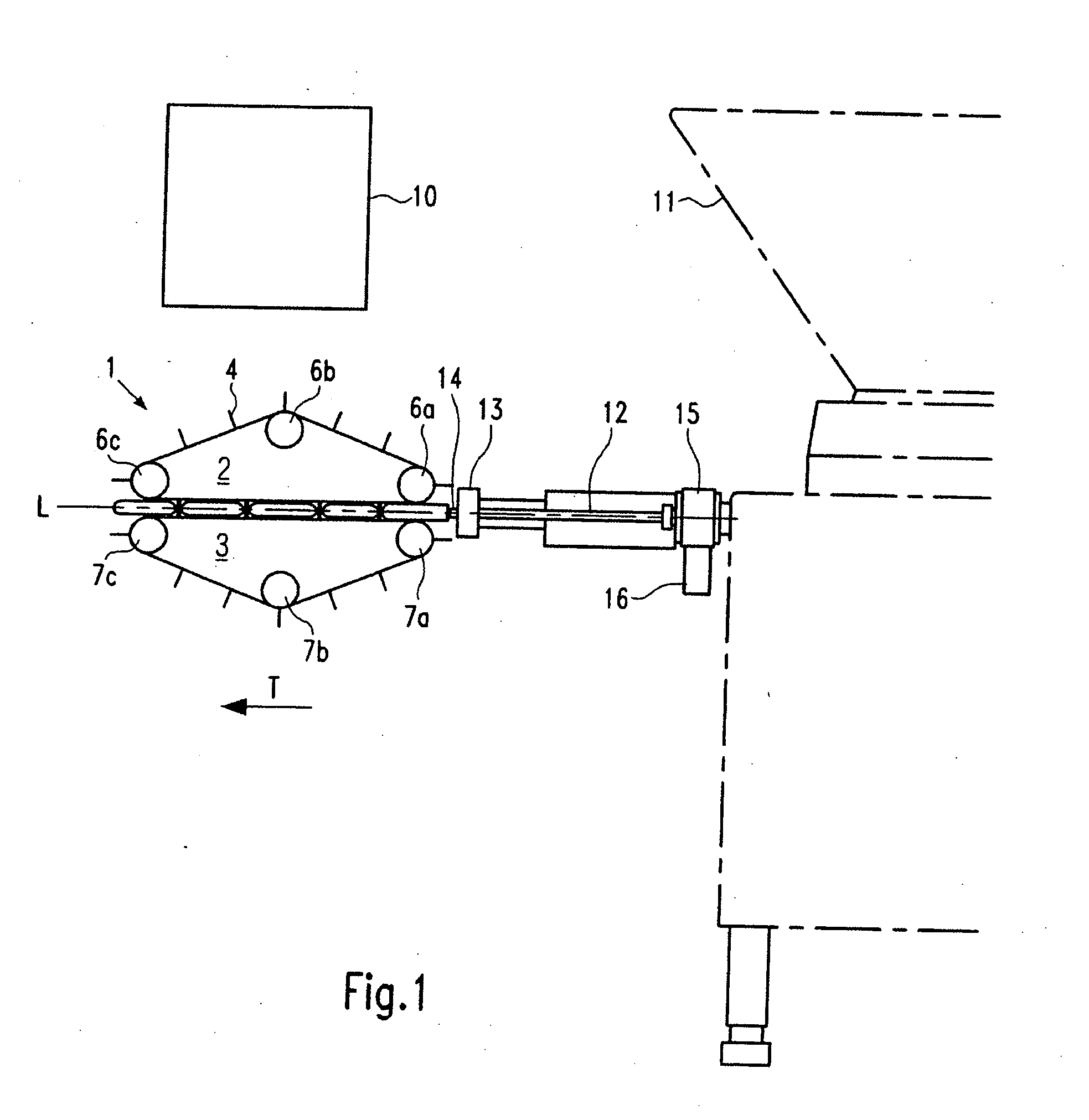

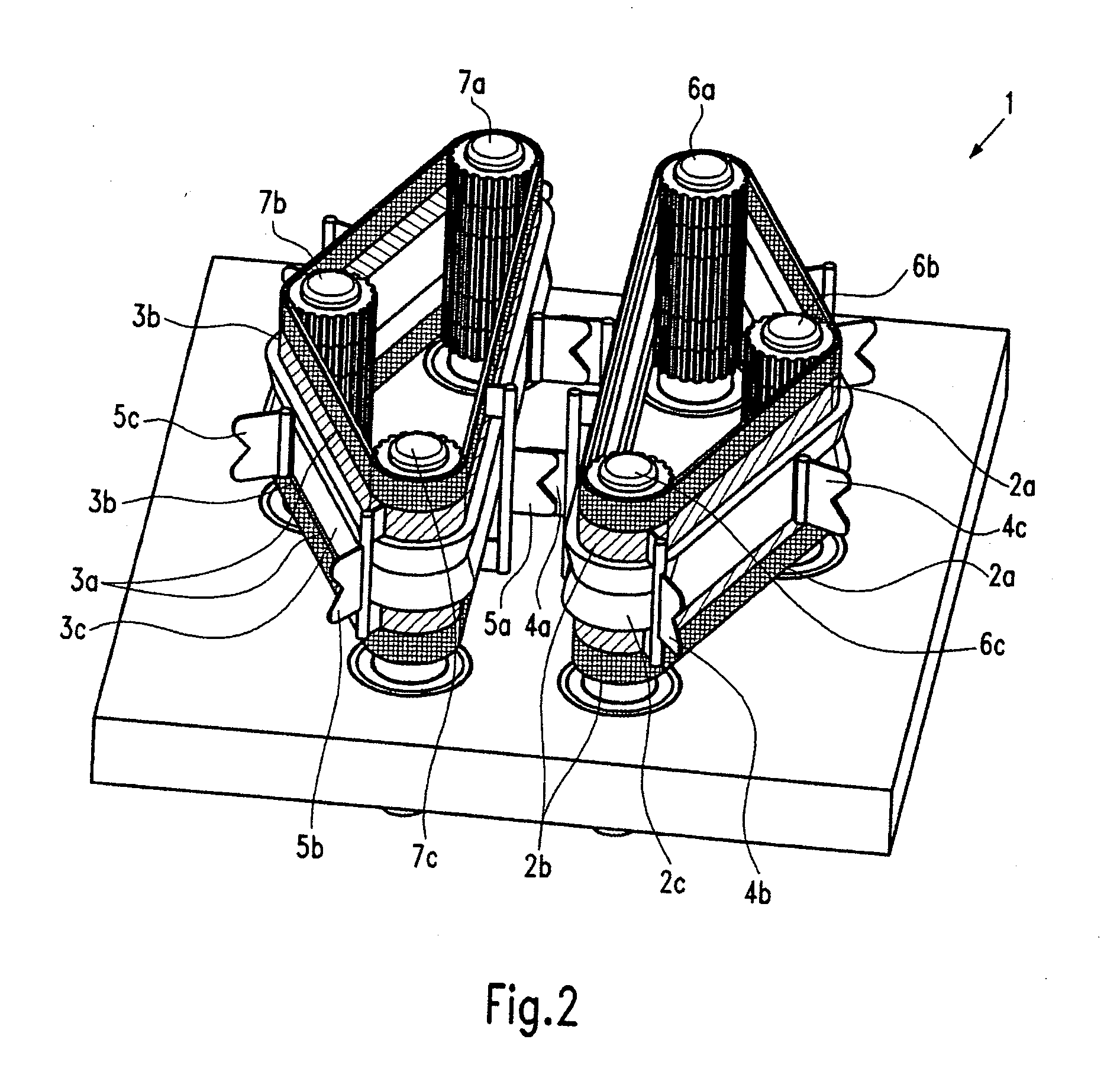

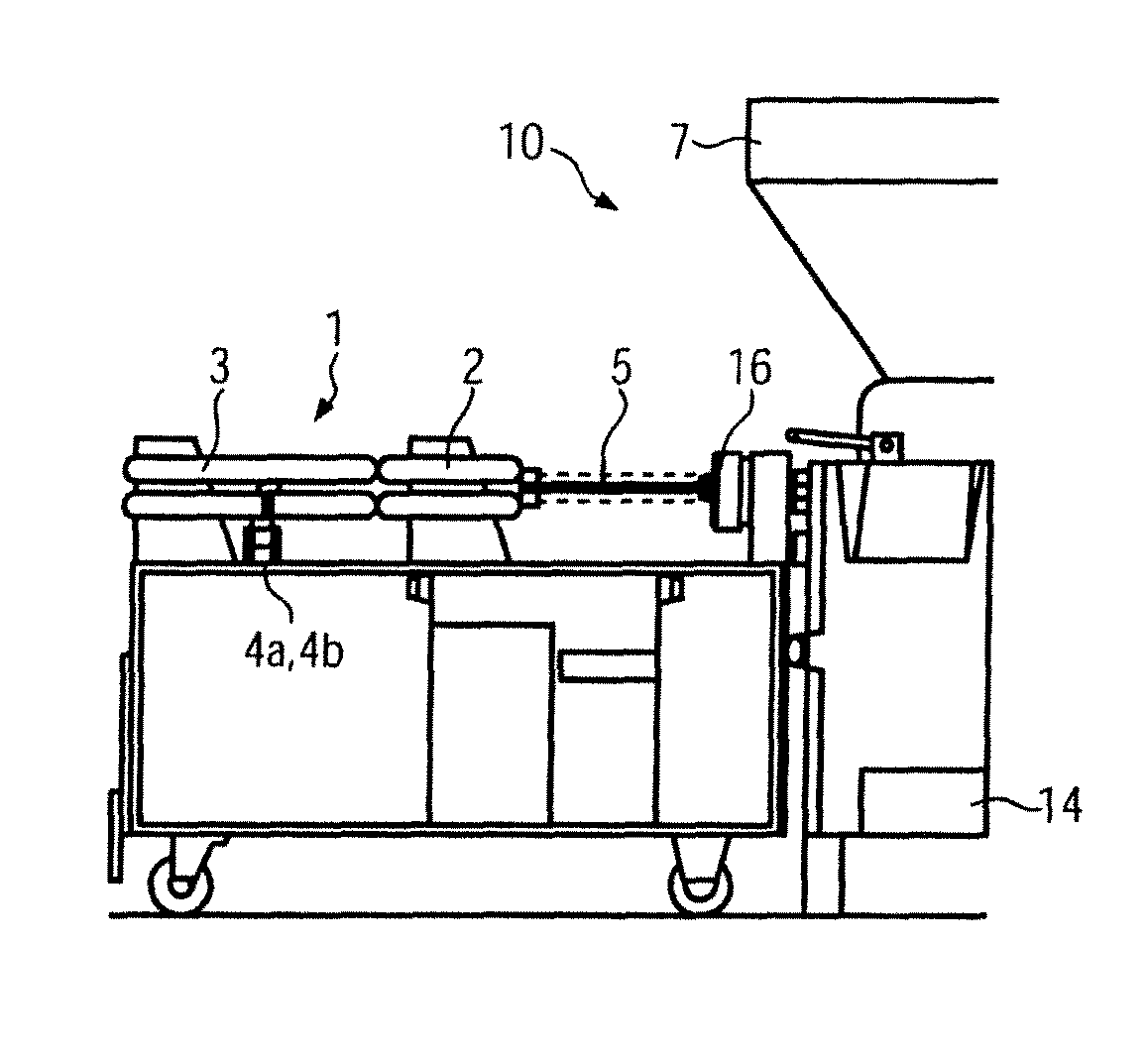

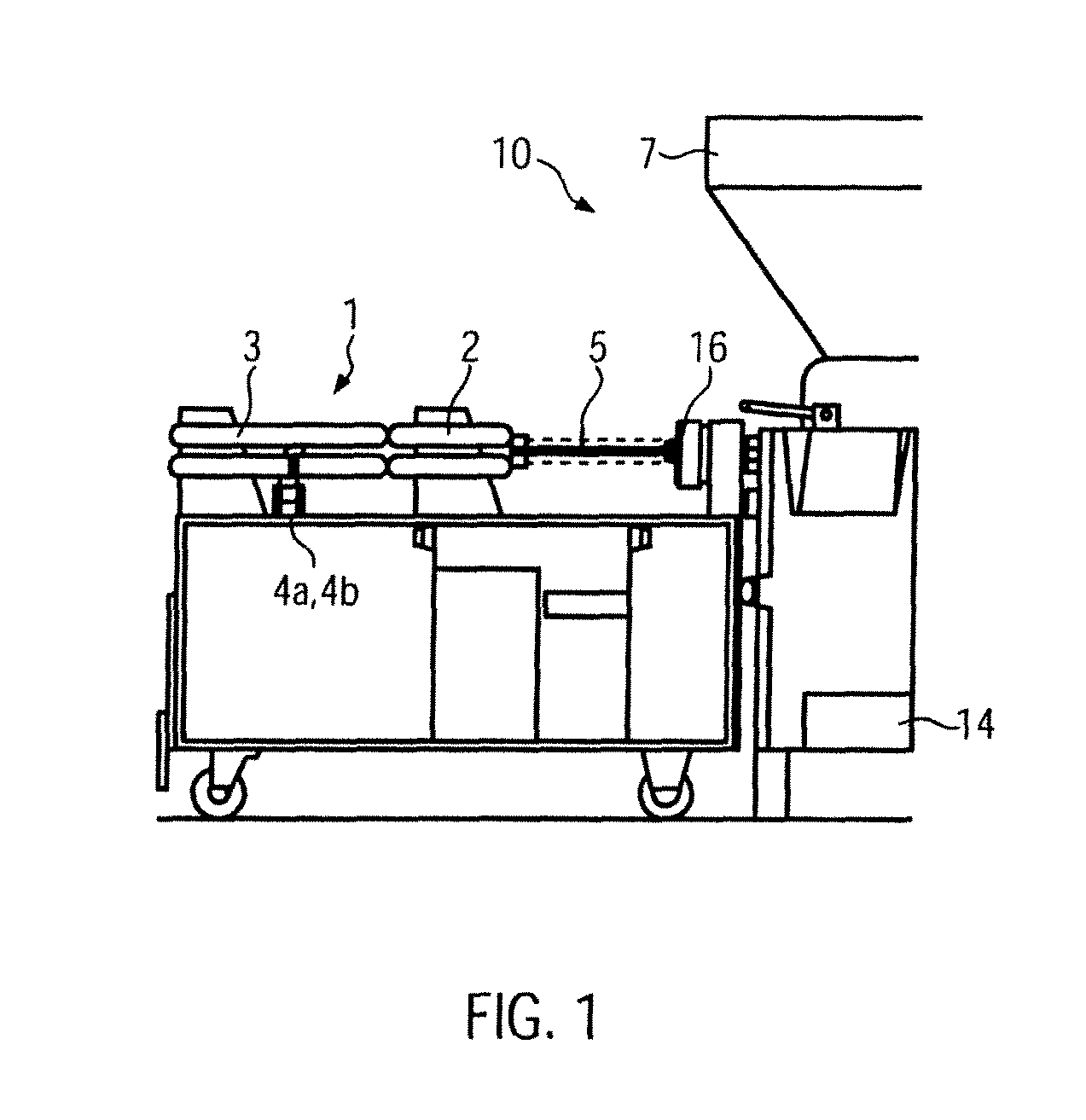

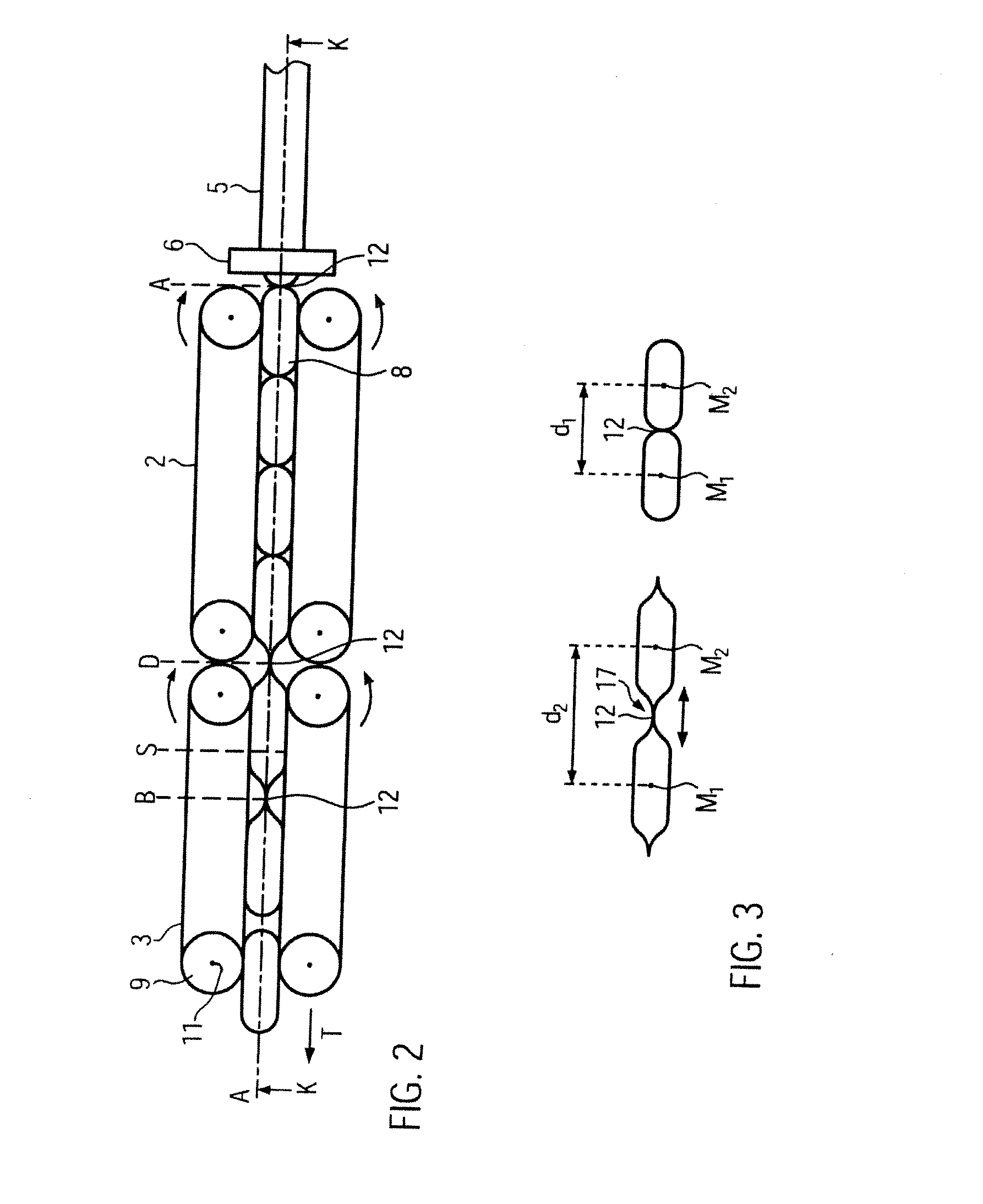

Apparatus and method for dividing a sausage strand

InactiveUS7140958B2Easy to modifyEasy to transformSausage skin tying apparatusSausage filling/stuffing machinesFirst FillEngineering

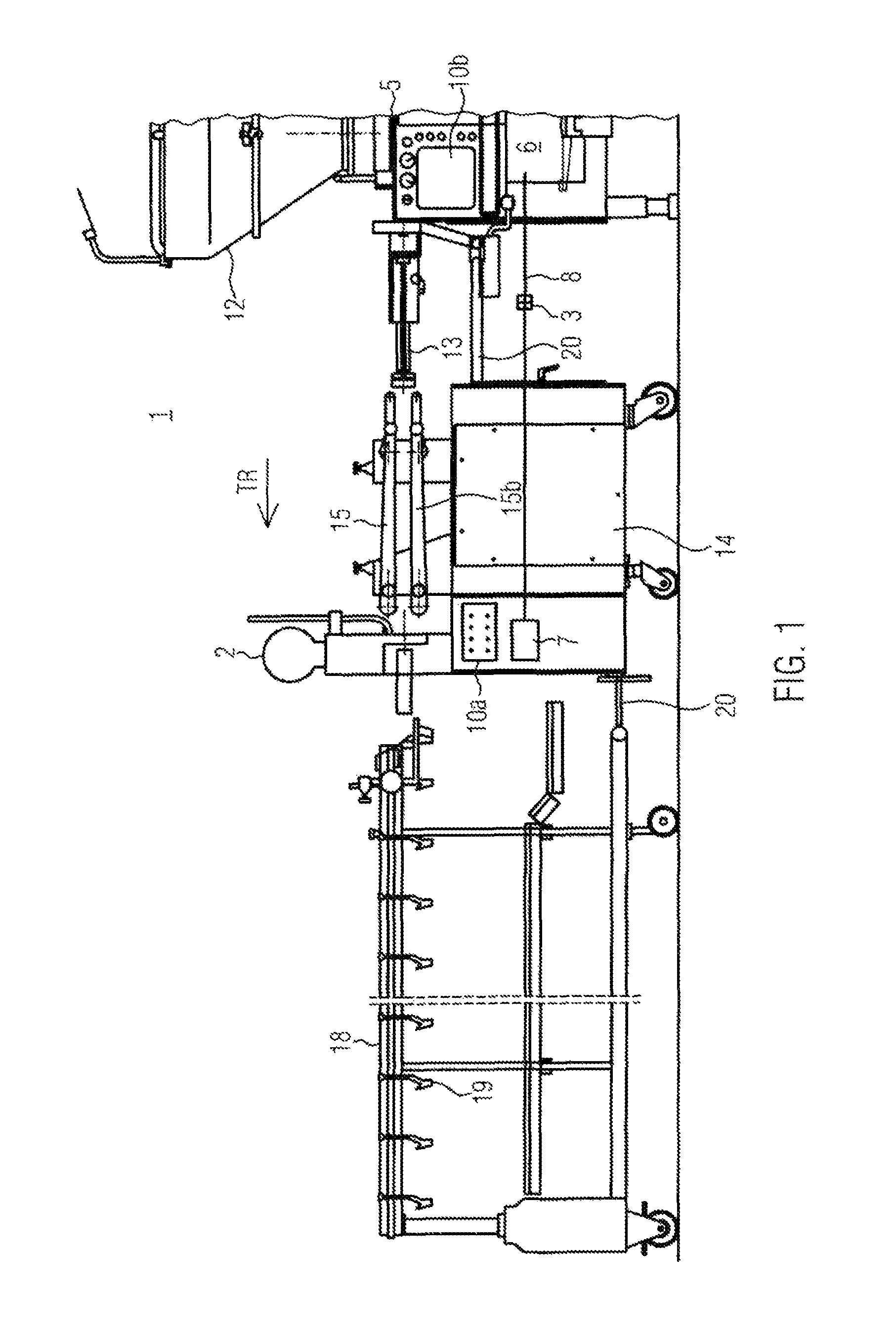

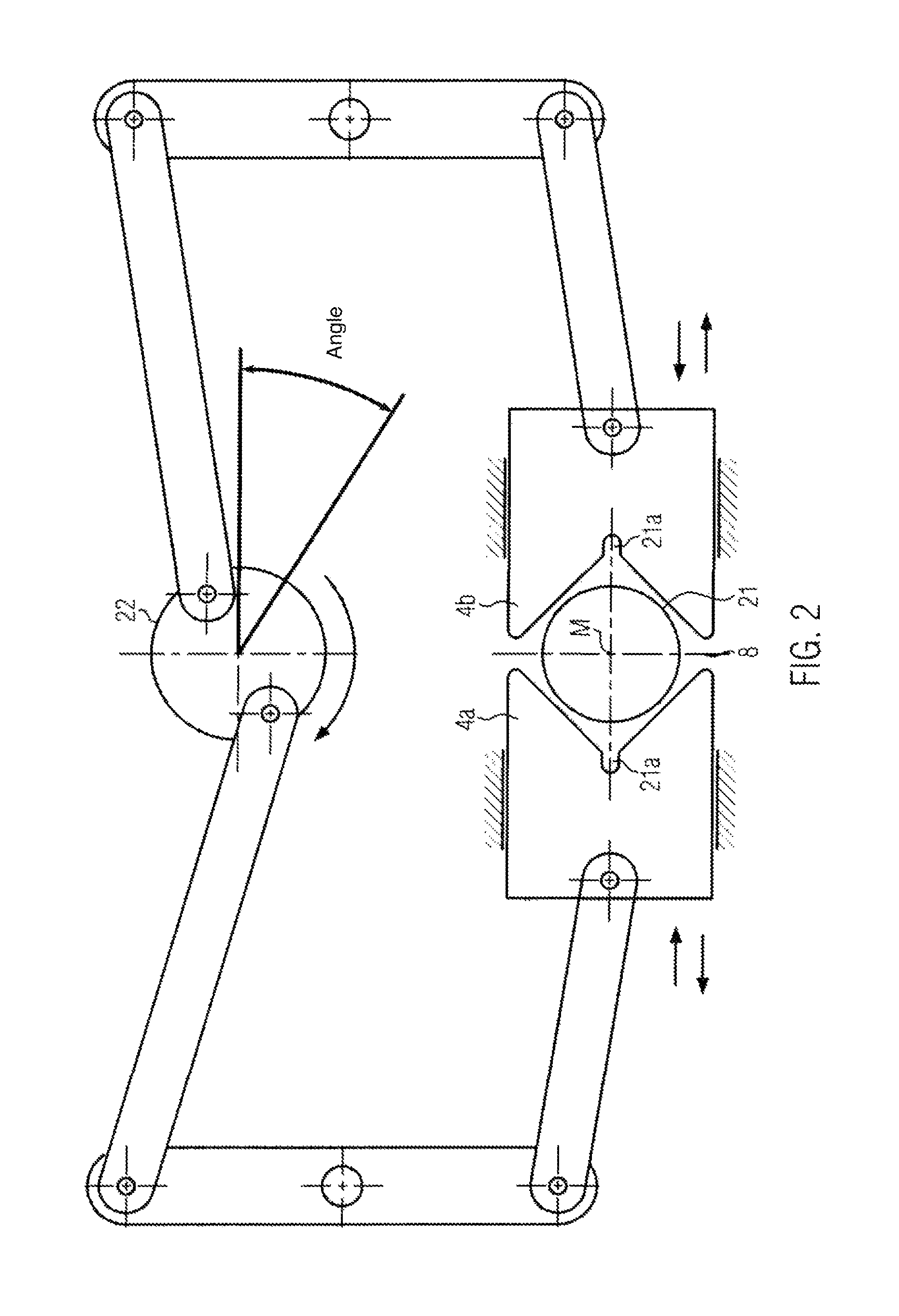

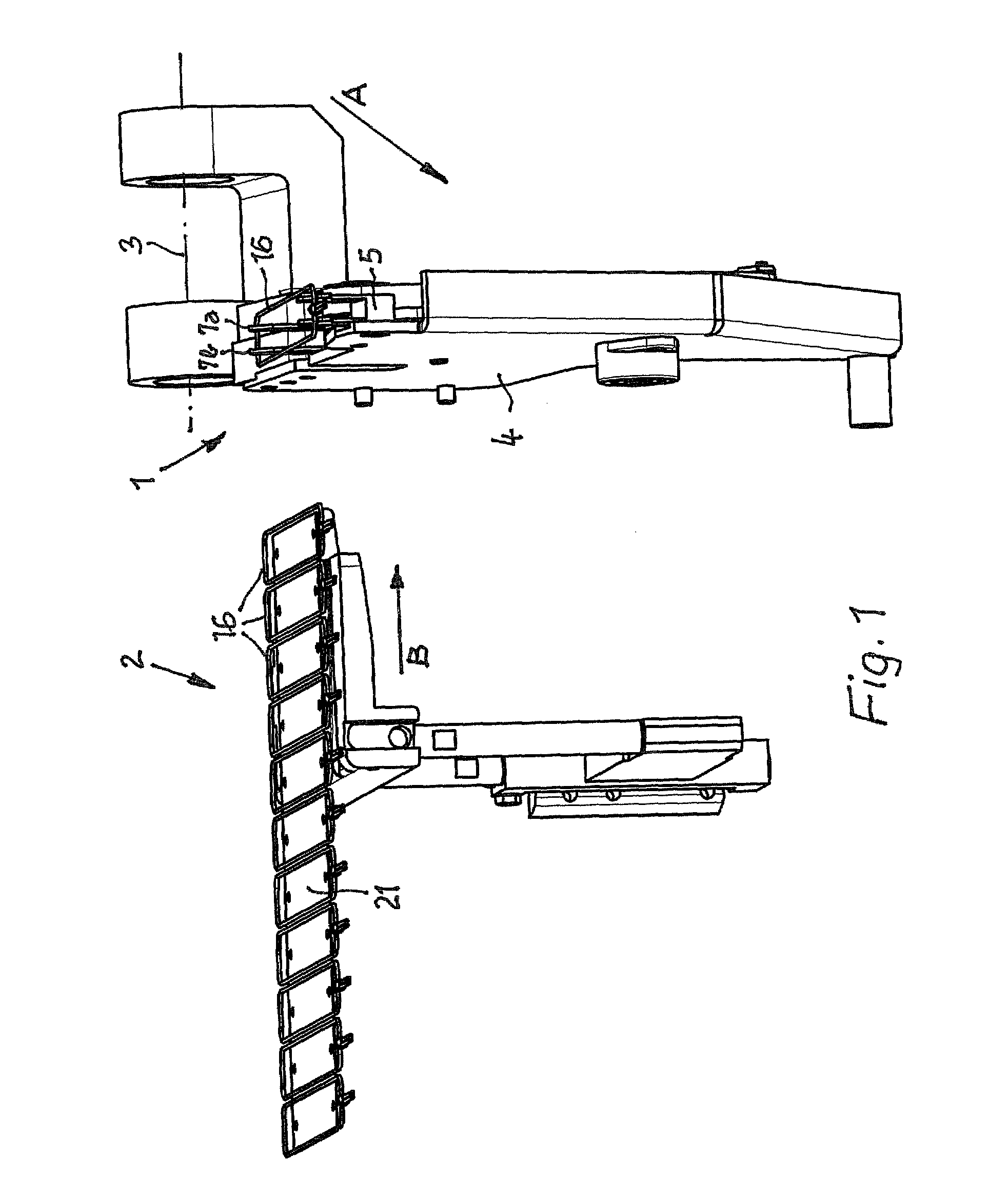

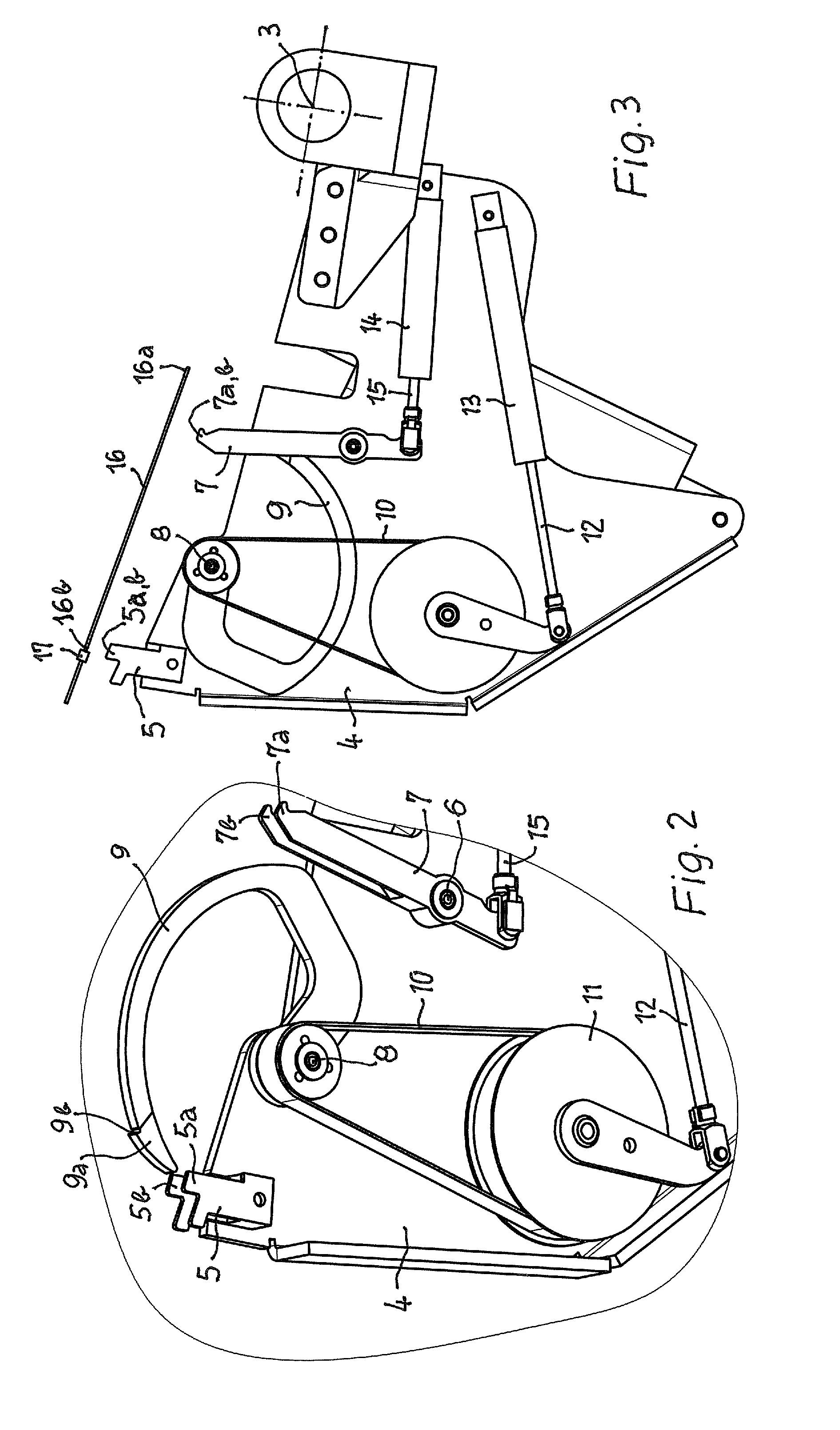

An apparatus for dividing a sausage strand includes at least two opposite spaced-apart guide elements having a distance which can be adapted to a sausage caliber such that the filled sausage strand can be moved between and through the guide elements in the transportation direction along a first axis and rotated by the guide elements about the first axis, and a means for jointly rotating the guide elements about the first axis. The sausage strand is first filled with a filling tube of a filling unit, and then guided in the transportation direction through the at least two opposite spaced-apart guide elements whose distance can be adapted to the sausage caliber, and the guide elements are rotated about a first axis extending along the transportation direction, wherein the filled sausage strand is also rotated about the first axis, the filled sausage strand being simultaneously supported at a place in the transportation direction behind the guide elements.

Owner:ALBERT HANDTMANN MASCHFABRICK

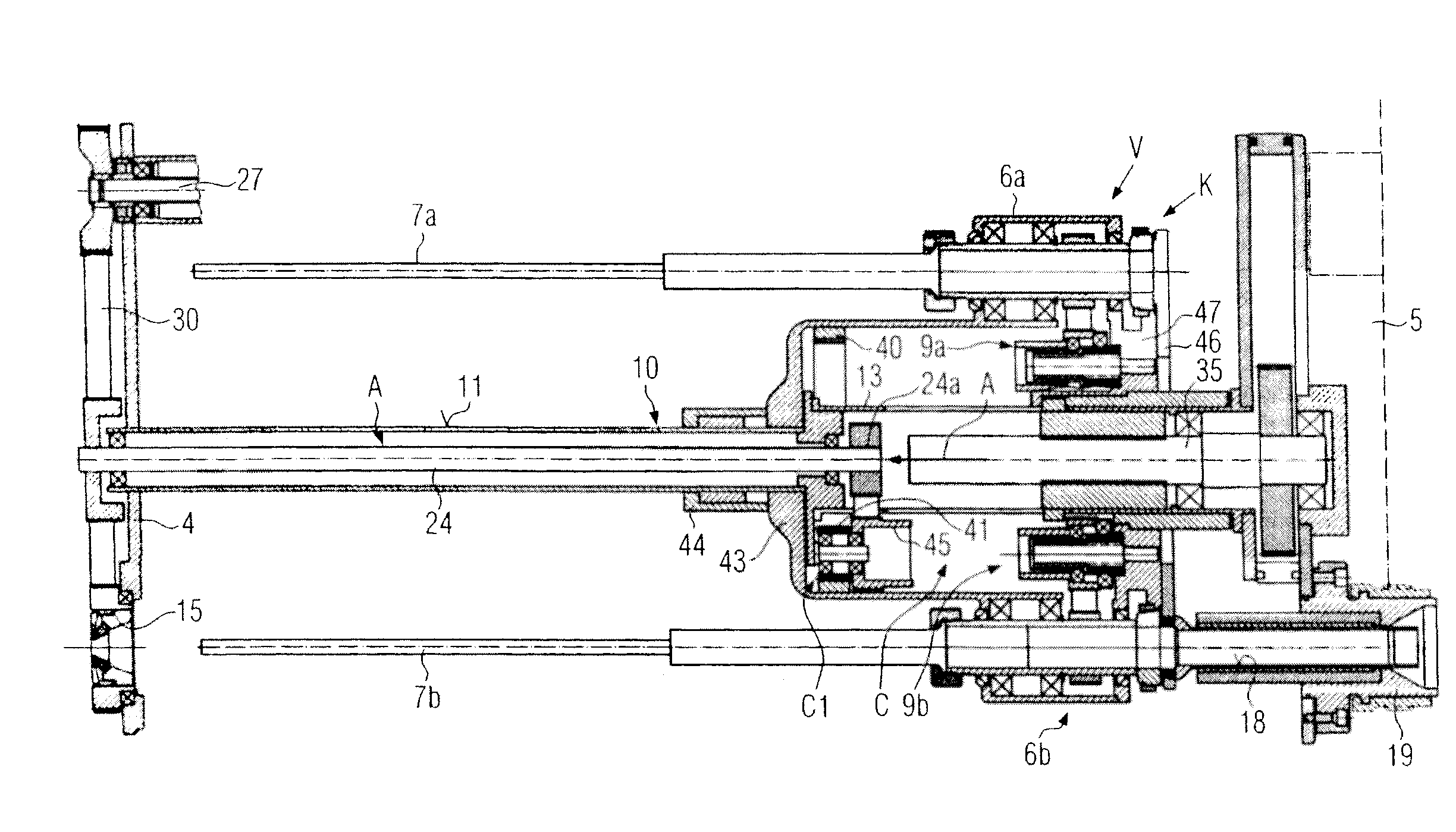

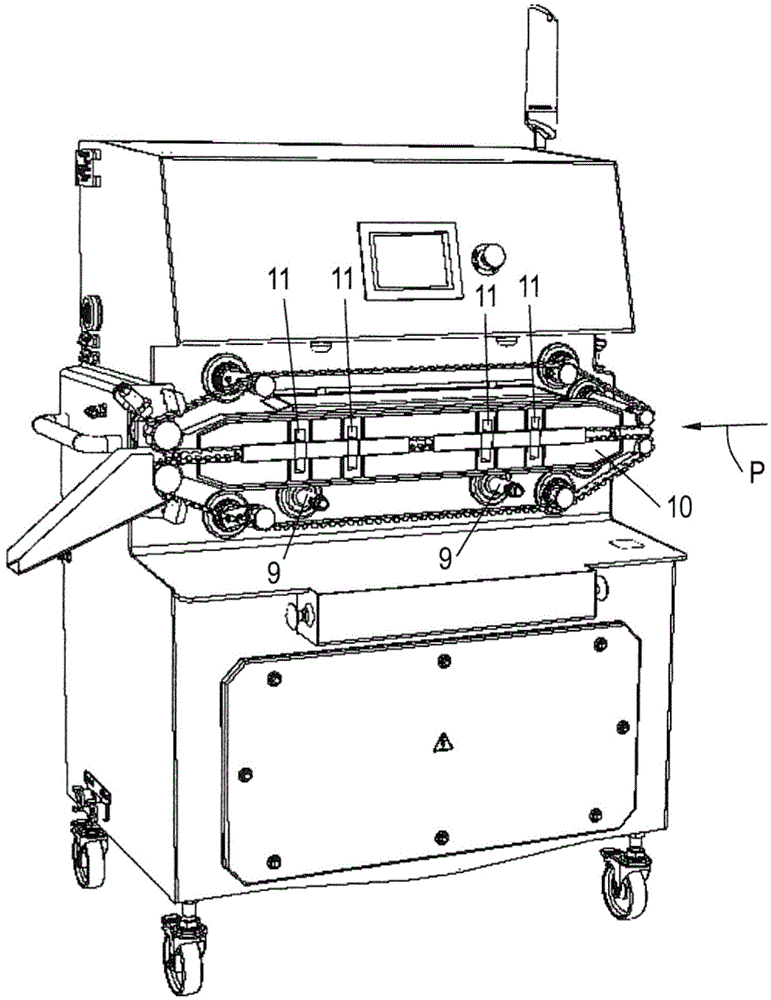

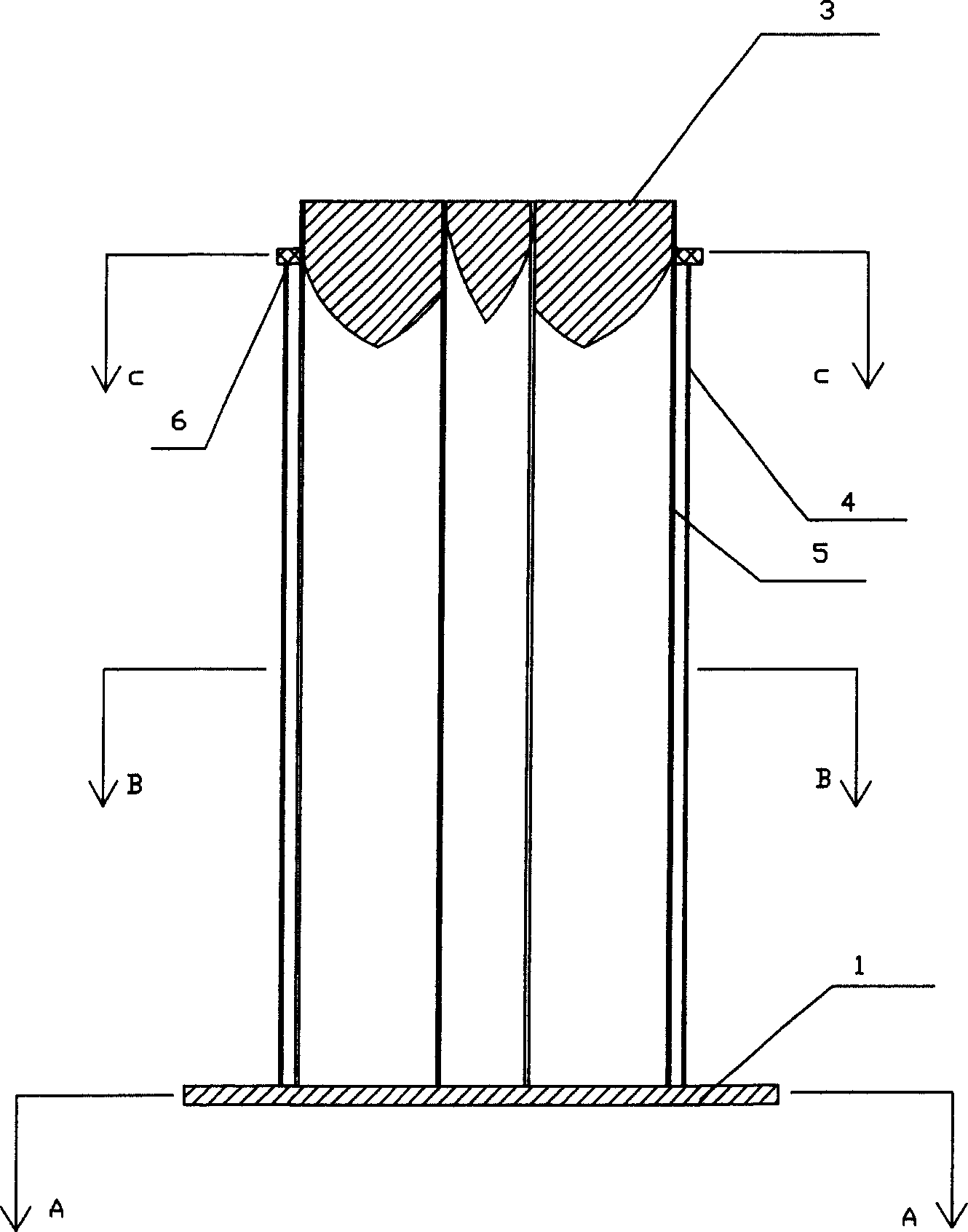

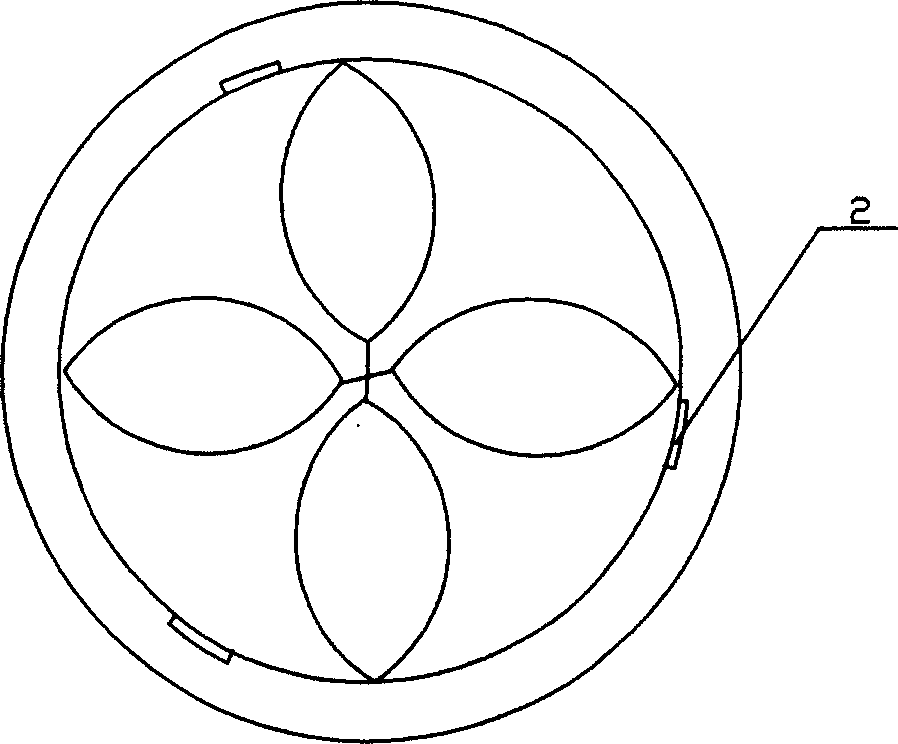

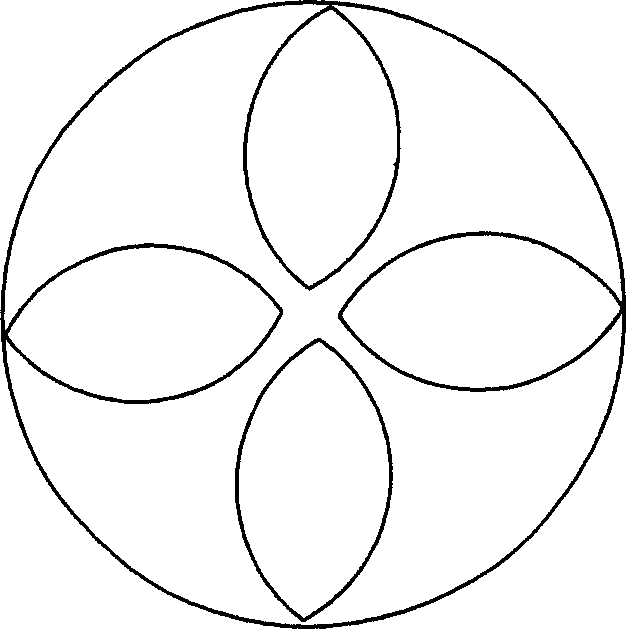

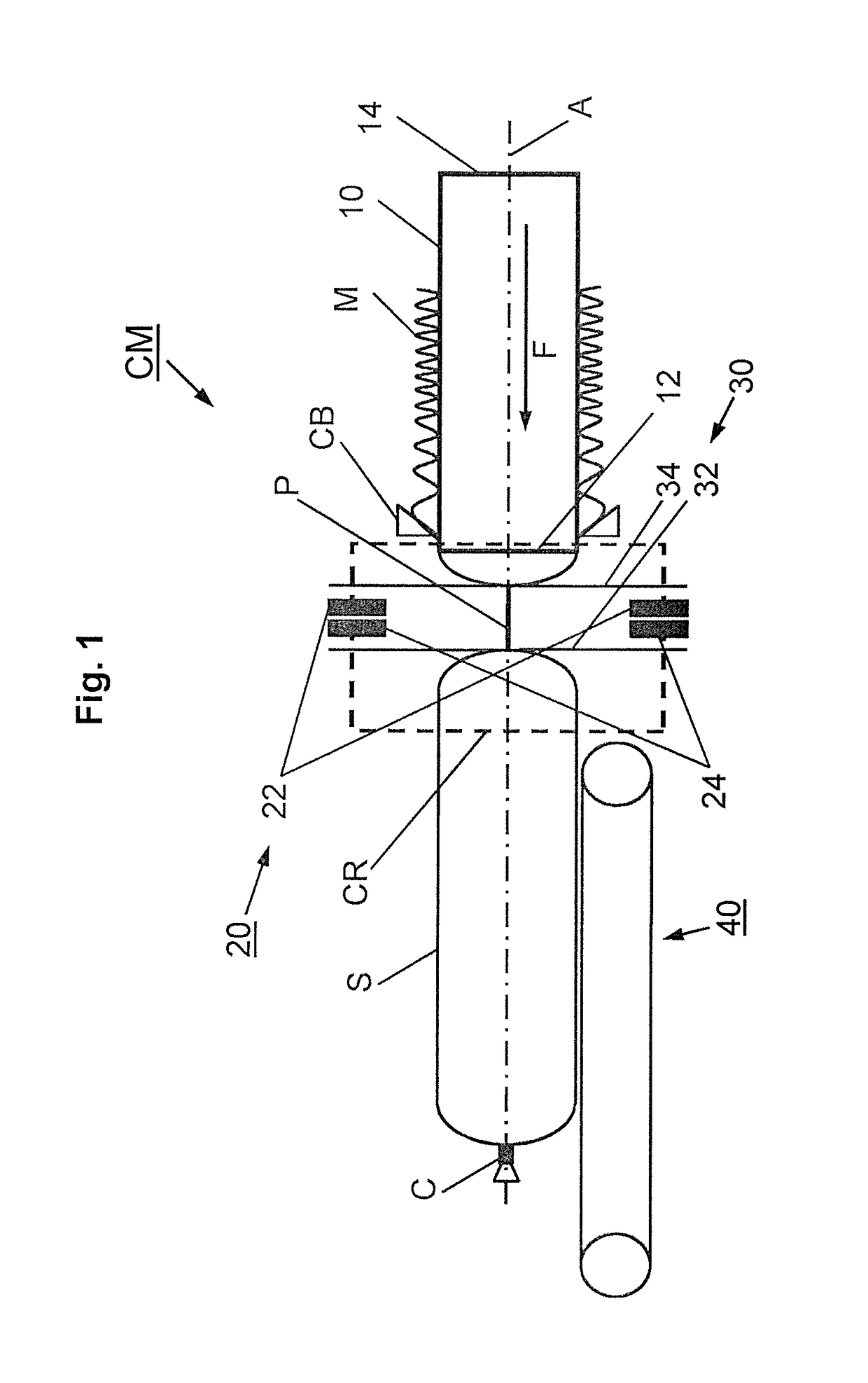

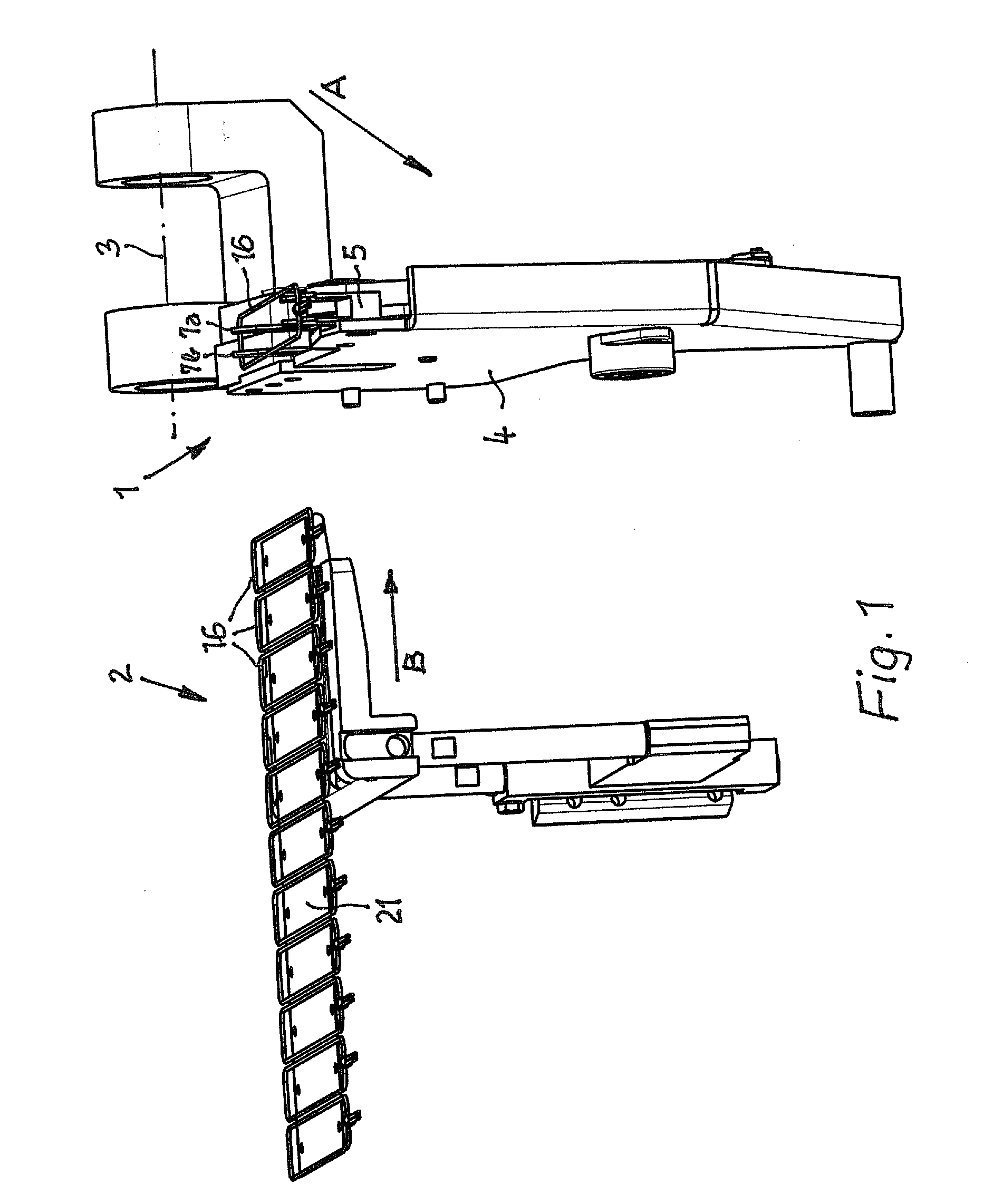

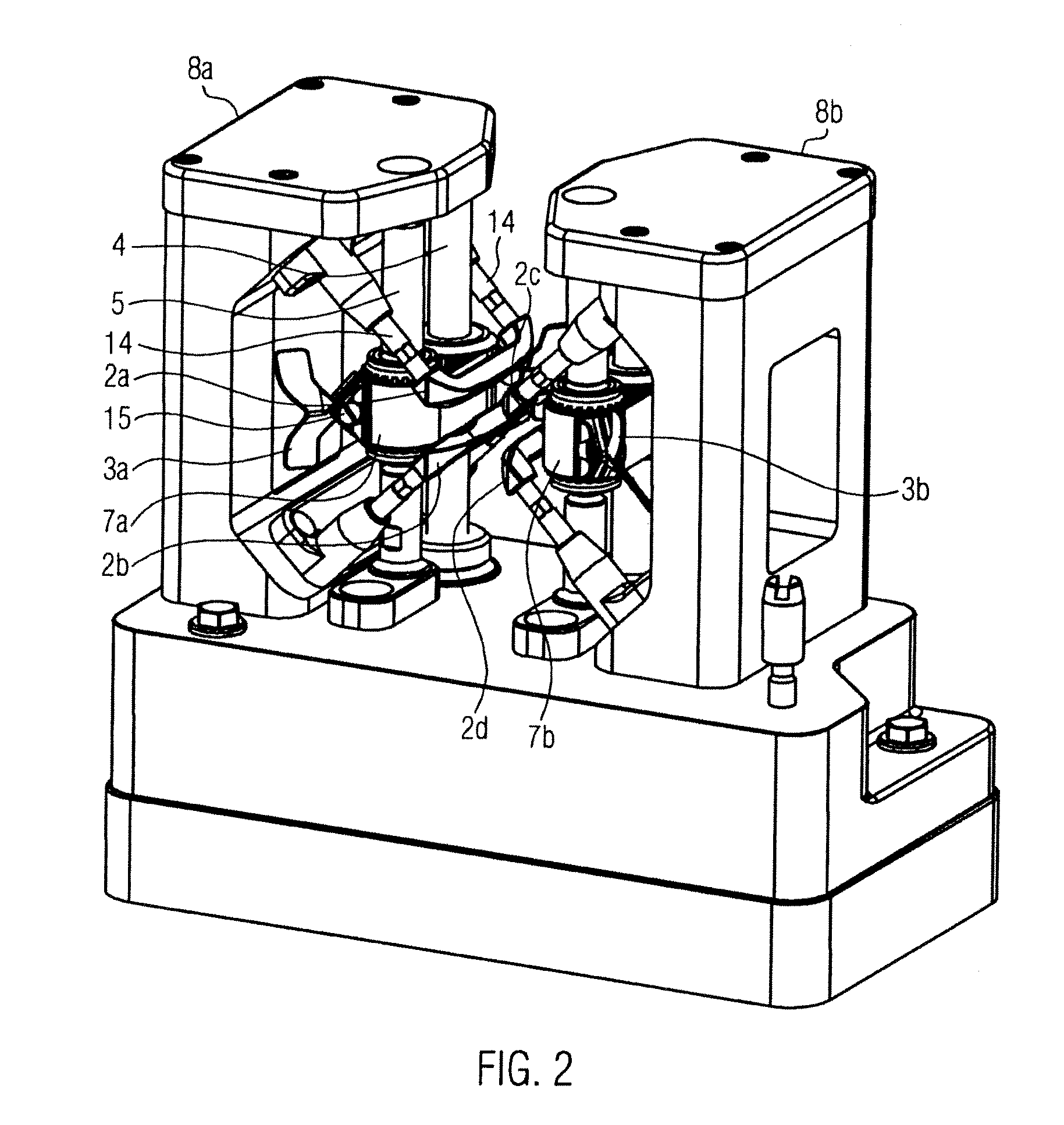

Device for Filling Casings

ActiveUS20100330891A1Simple designSausage filling/stuffing machinesSausage twisting/linking machinesEngineeringMechanical engineering

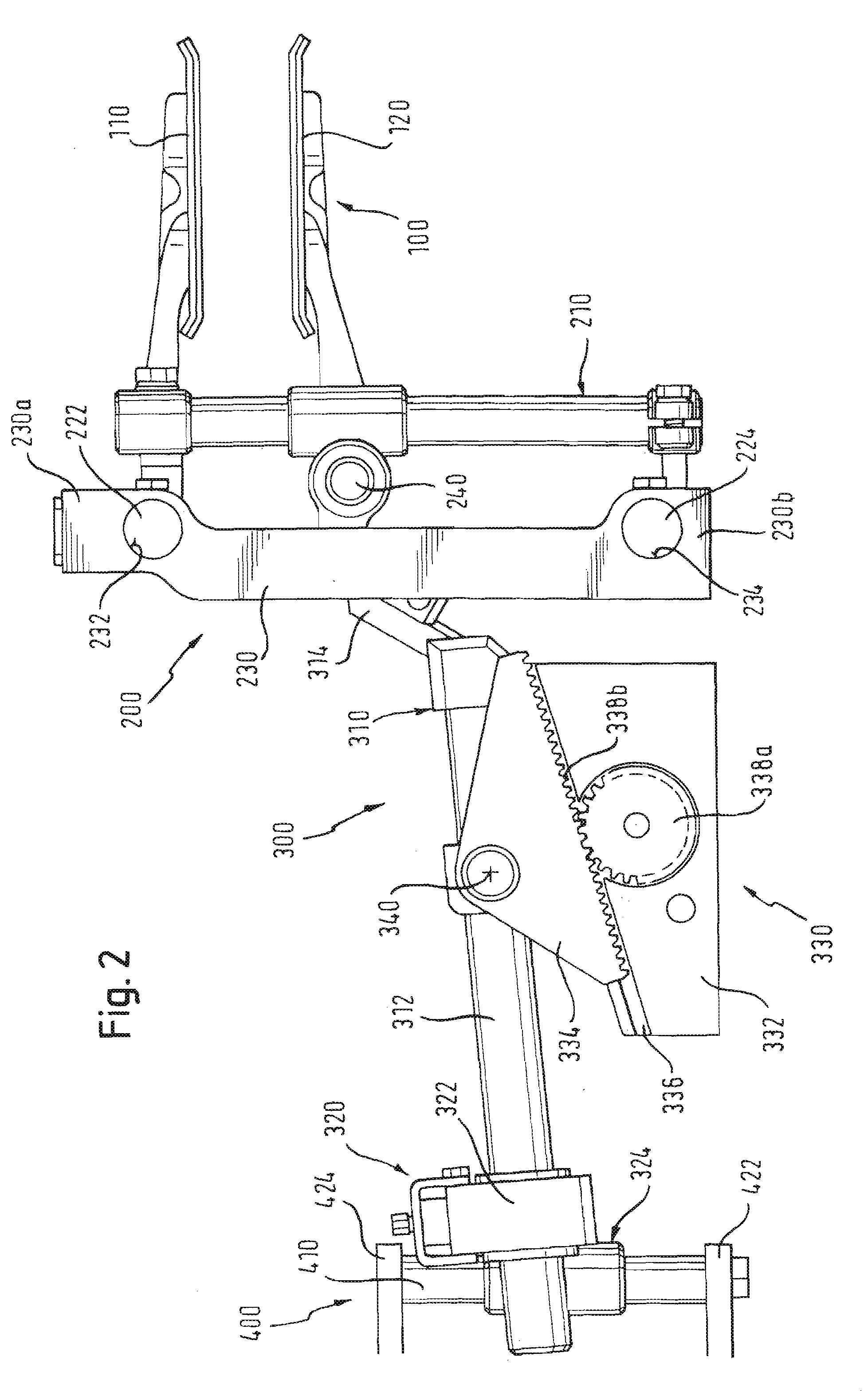

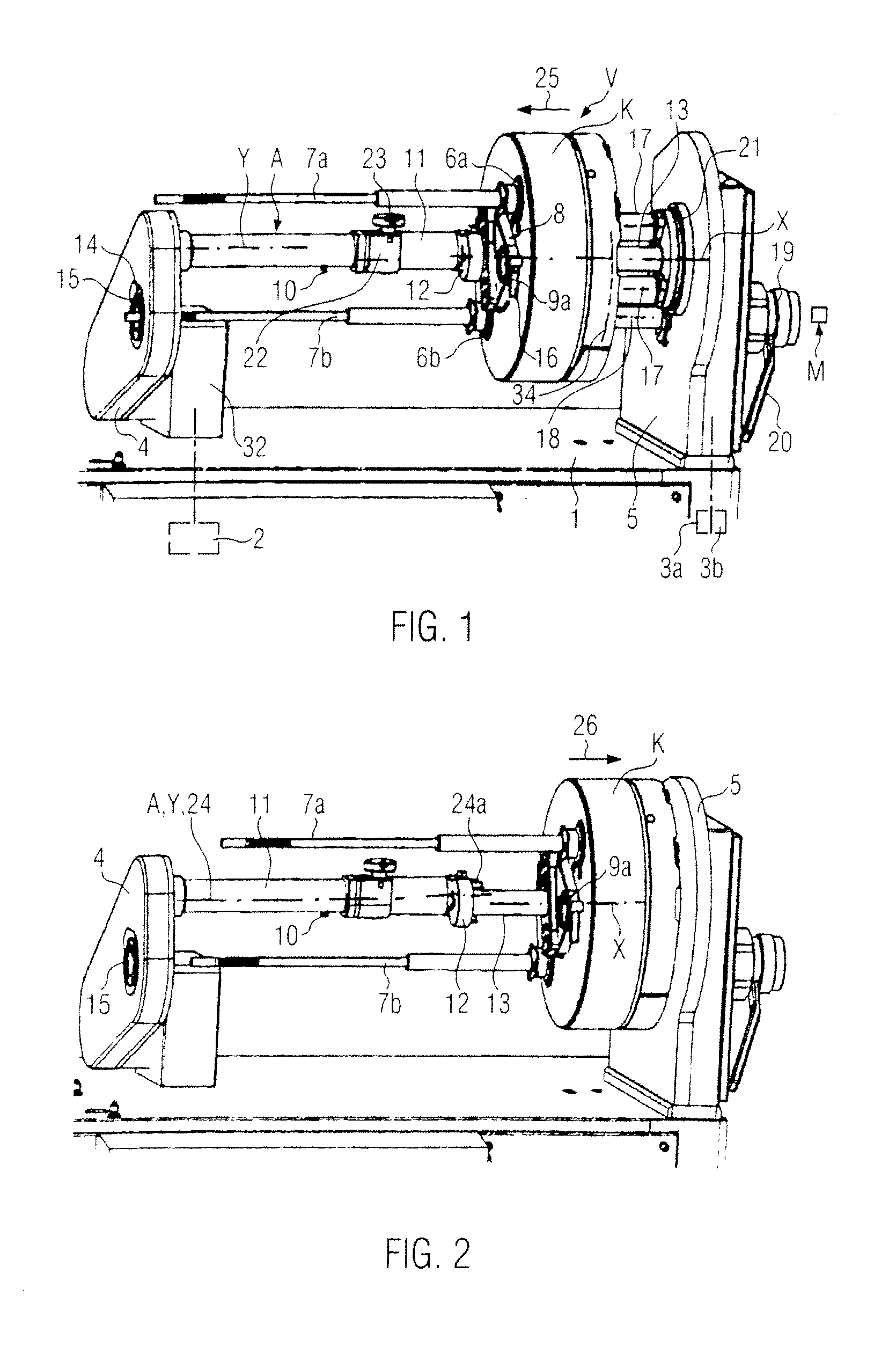

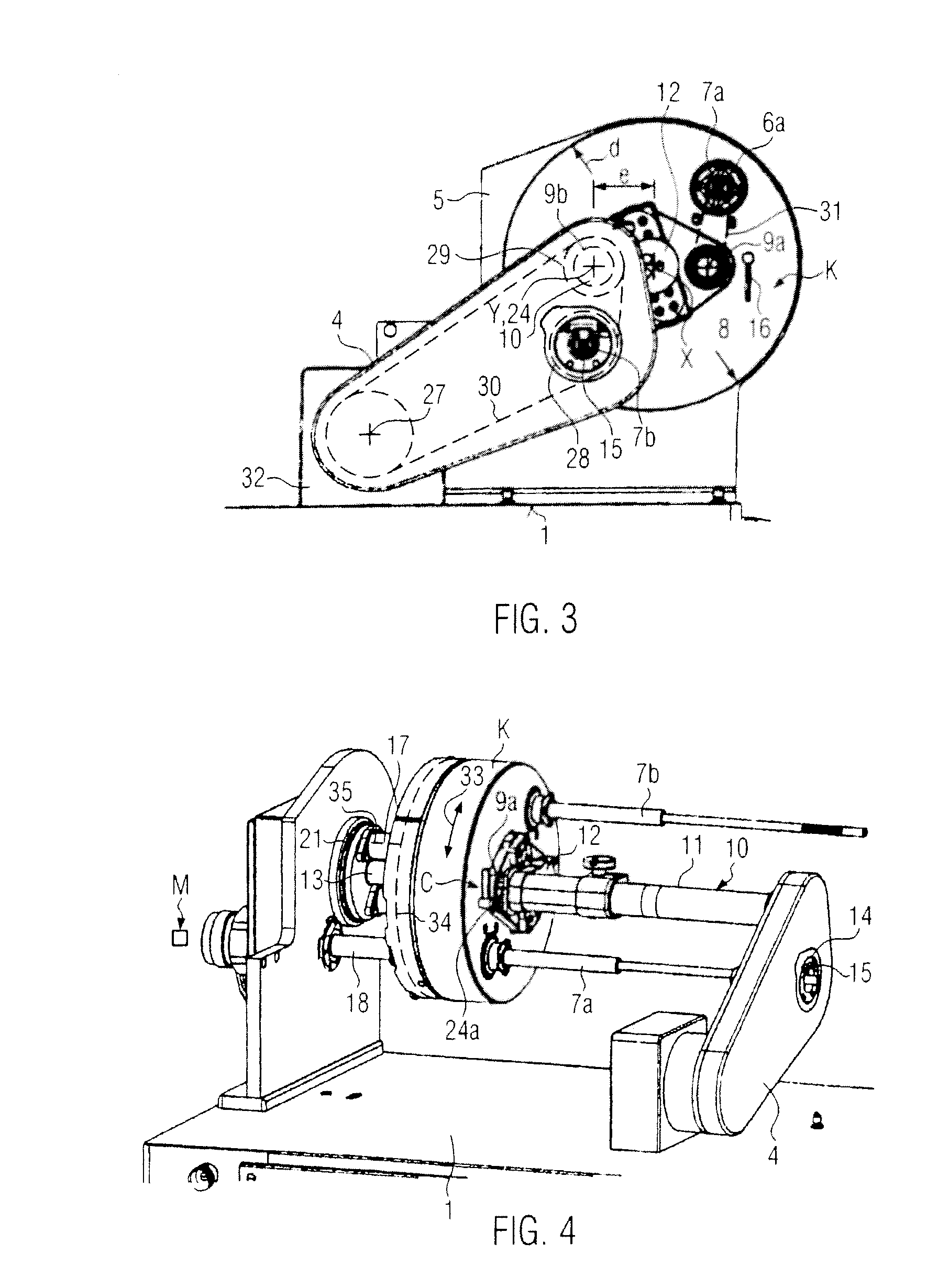

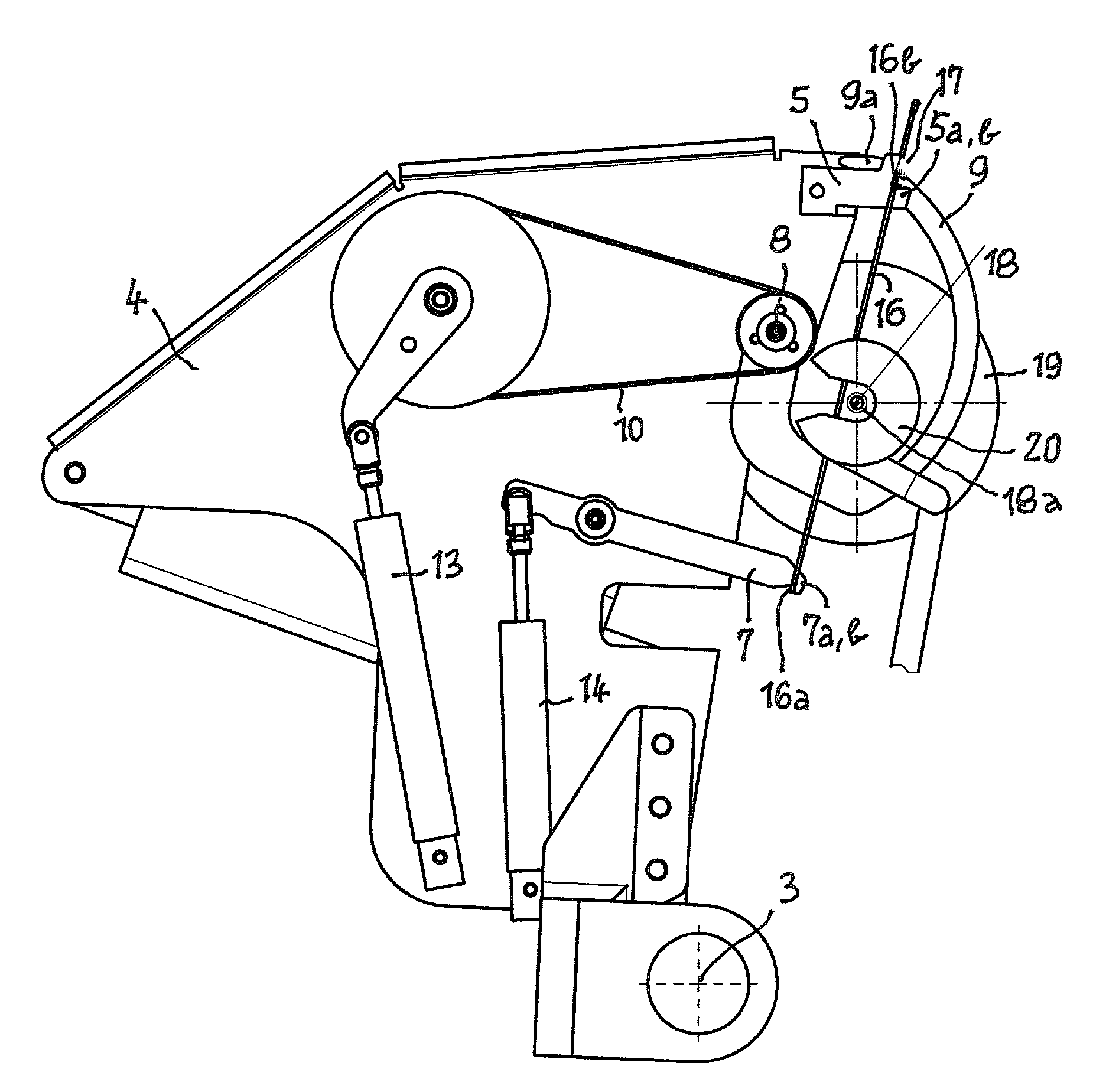

A device for filling casings, having a twist-off head which comprises circumferentially offset filling tubes and which is arranged on a support panel to be displaceable in axially parallel fashion and to be rotatable, and a rotatingly drivable casing brake which is axially aligned with a filling tube located in the filling position, the casing brake and the support panel being connected via a rigid shaft which comprises a support section extending towards the casing brake and a guide section extending centrally through the twist-off head, with a drive train being arranged in said shaft.

Owner:ALBERT HANDTMANN MASCHFABRICK

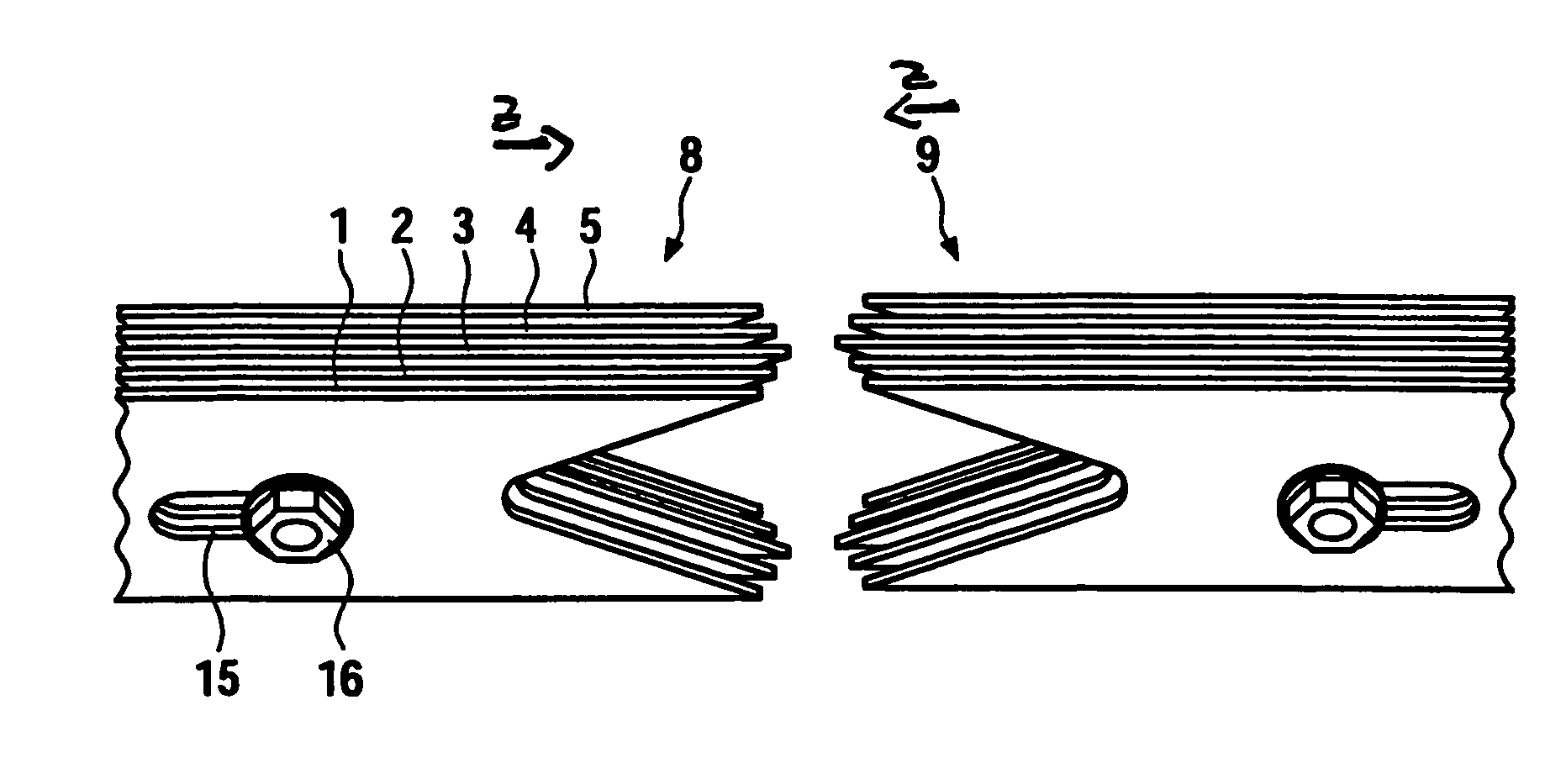

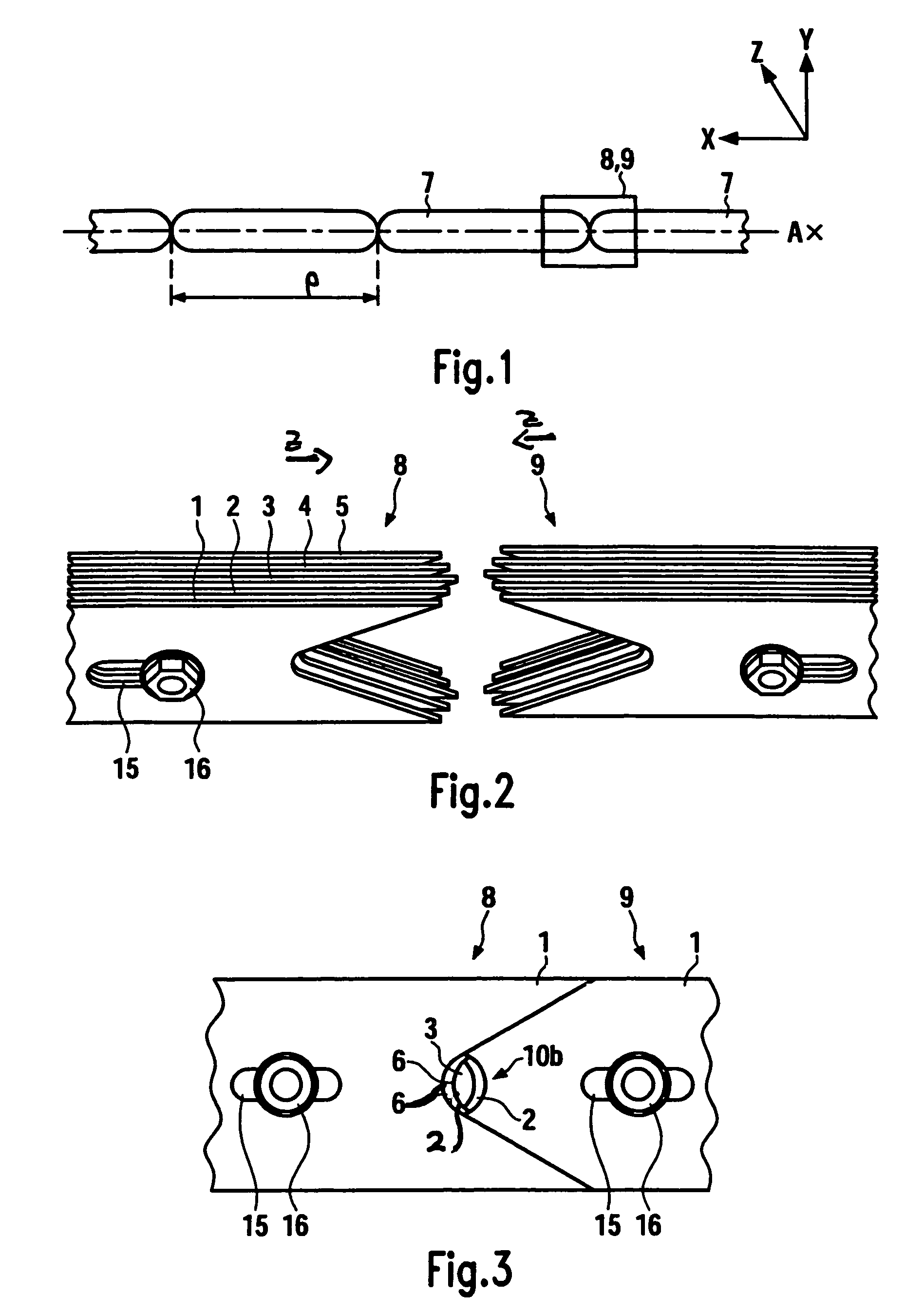

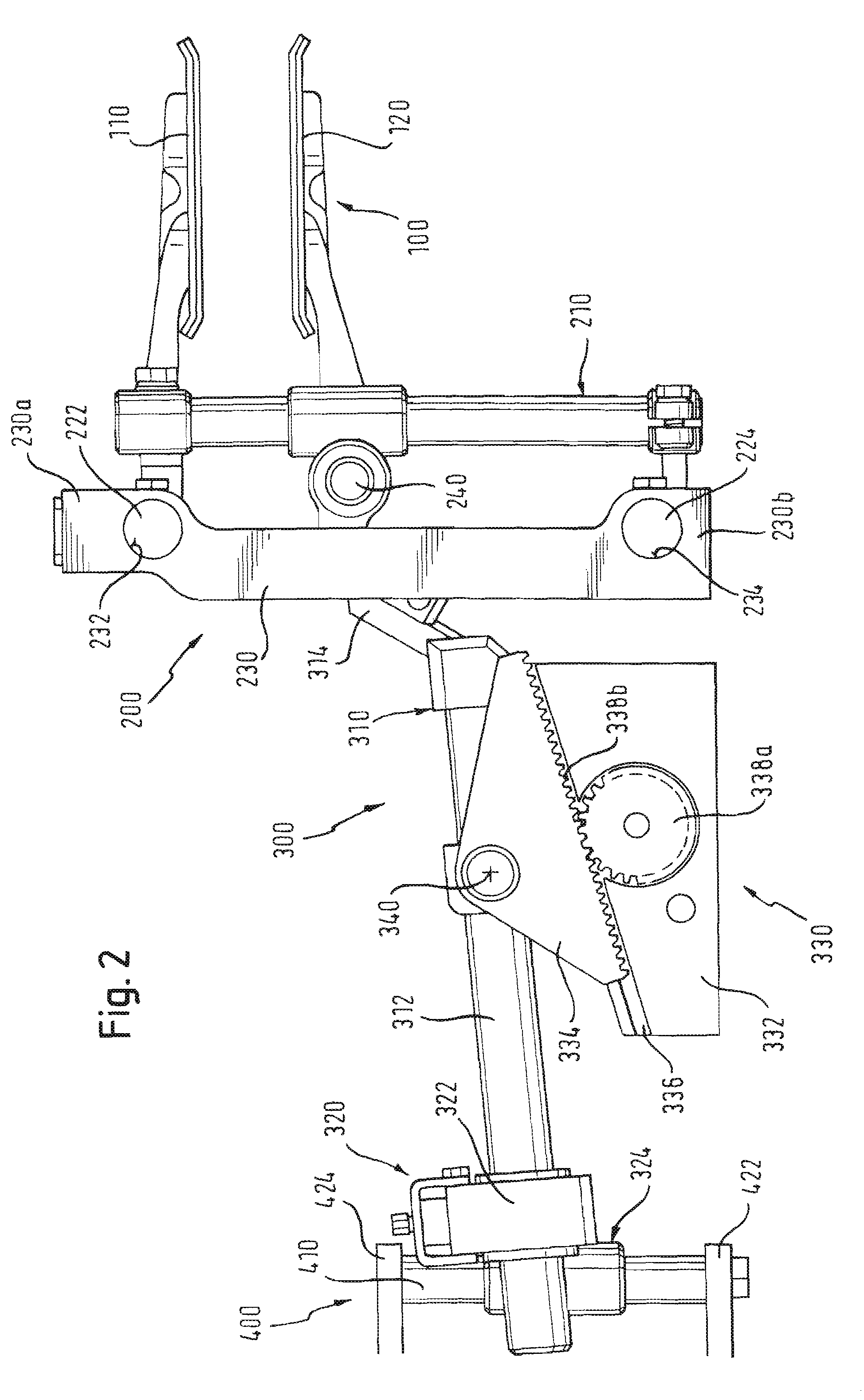

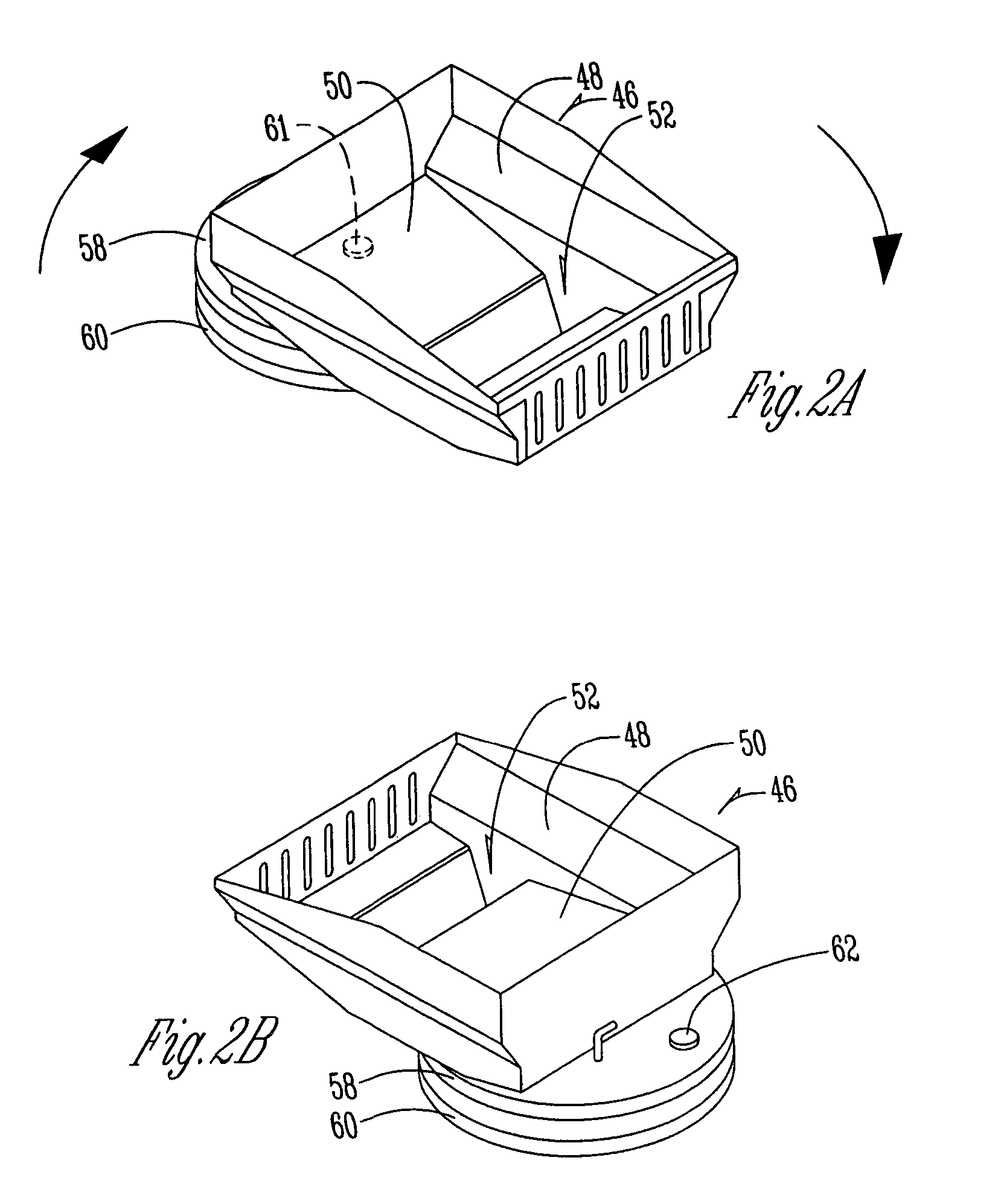

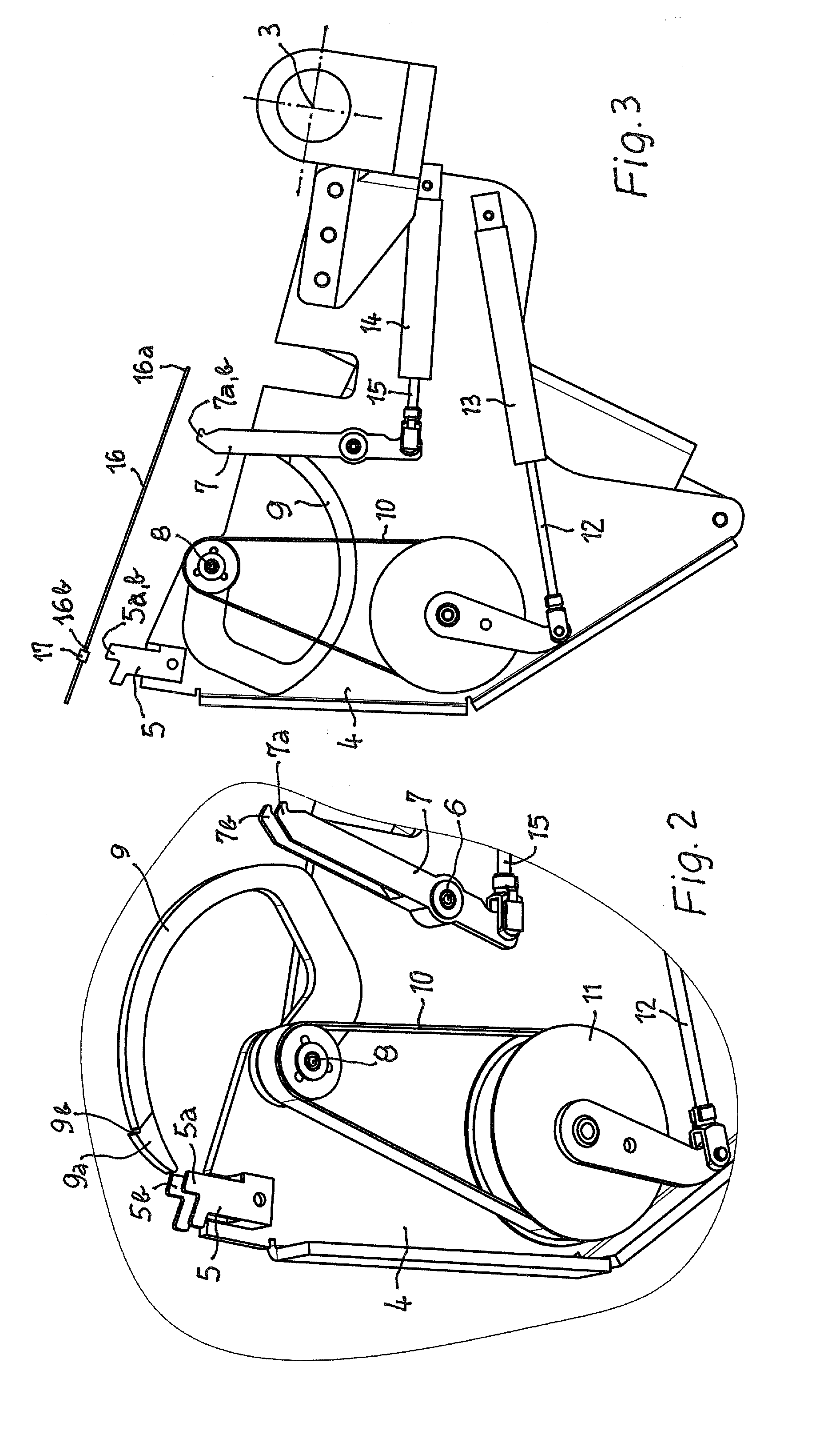

Displacement elements for a clip machine

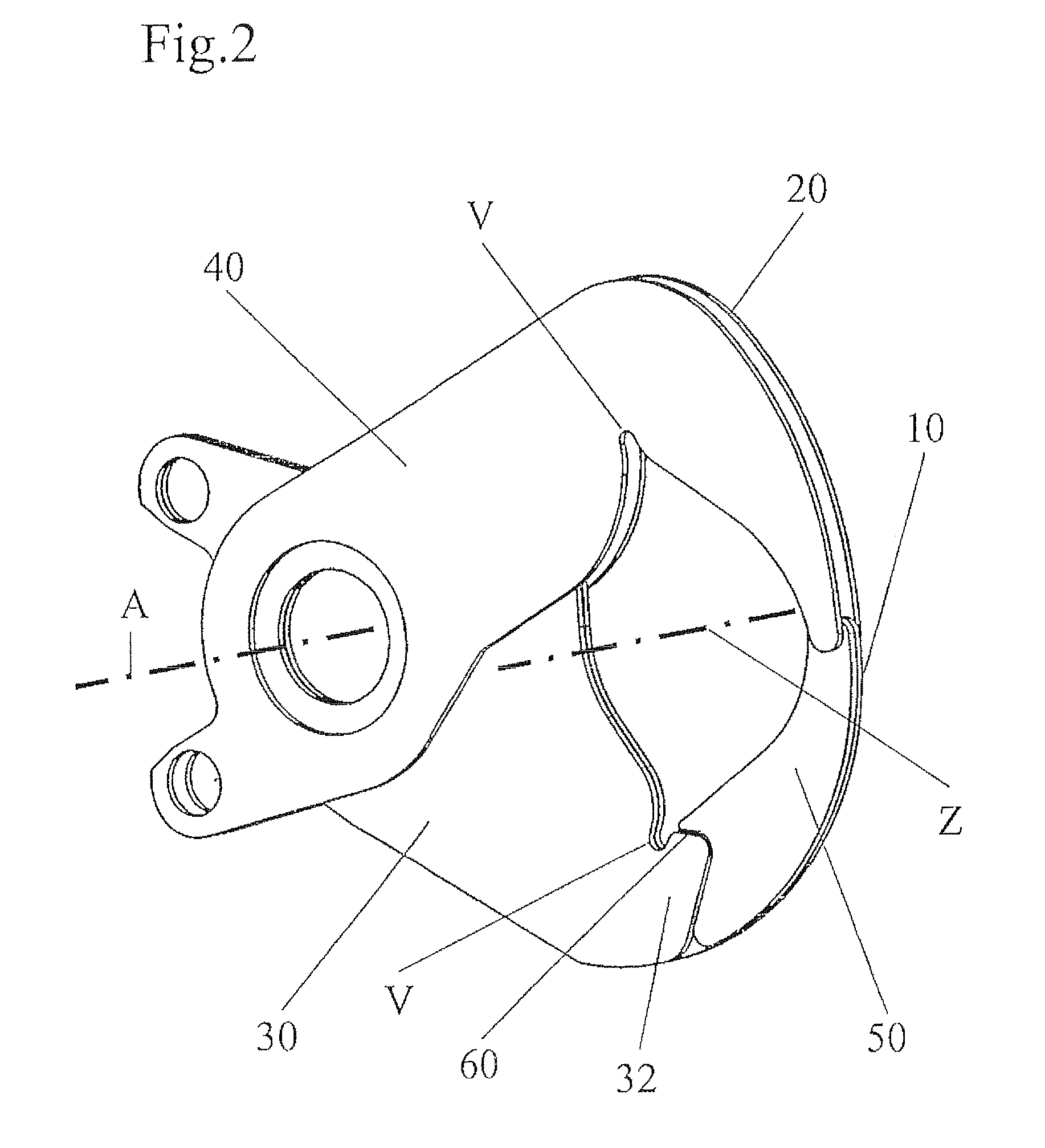

ActiveUS8113925B2Avoid damageShorten the lengthSausage skin tying apparatusSausage filling/stuffing machinesFilling materialsEngineering

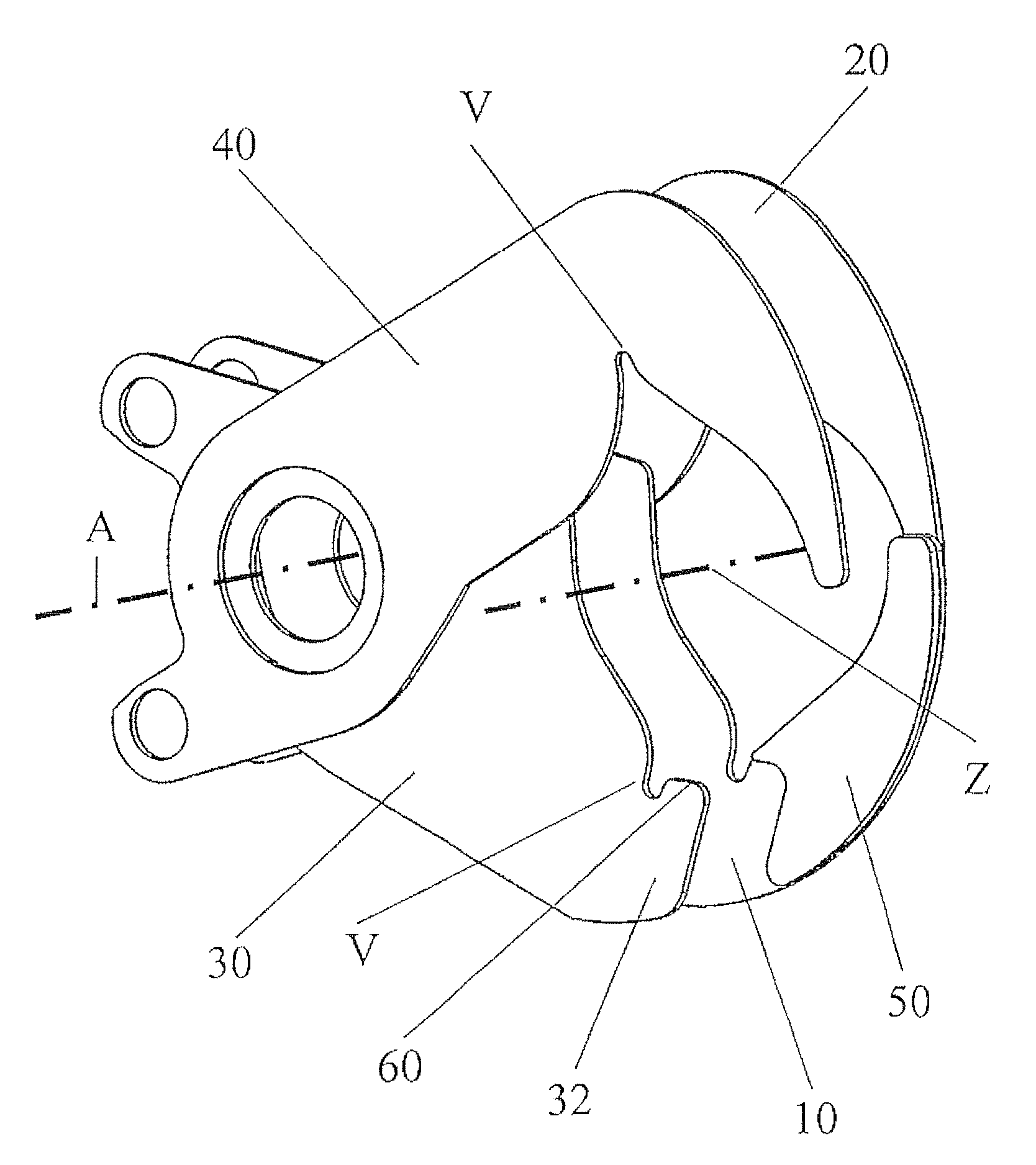

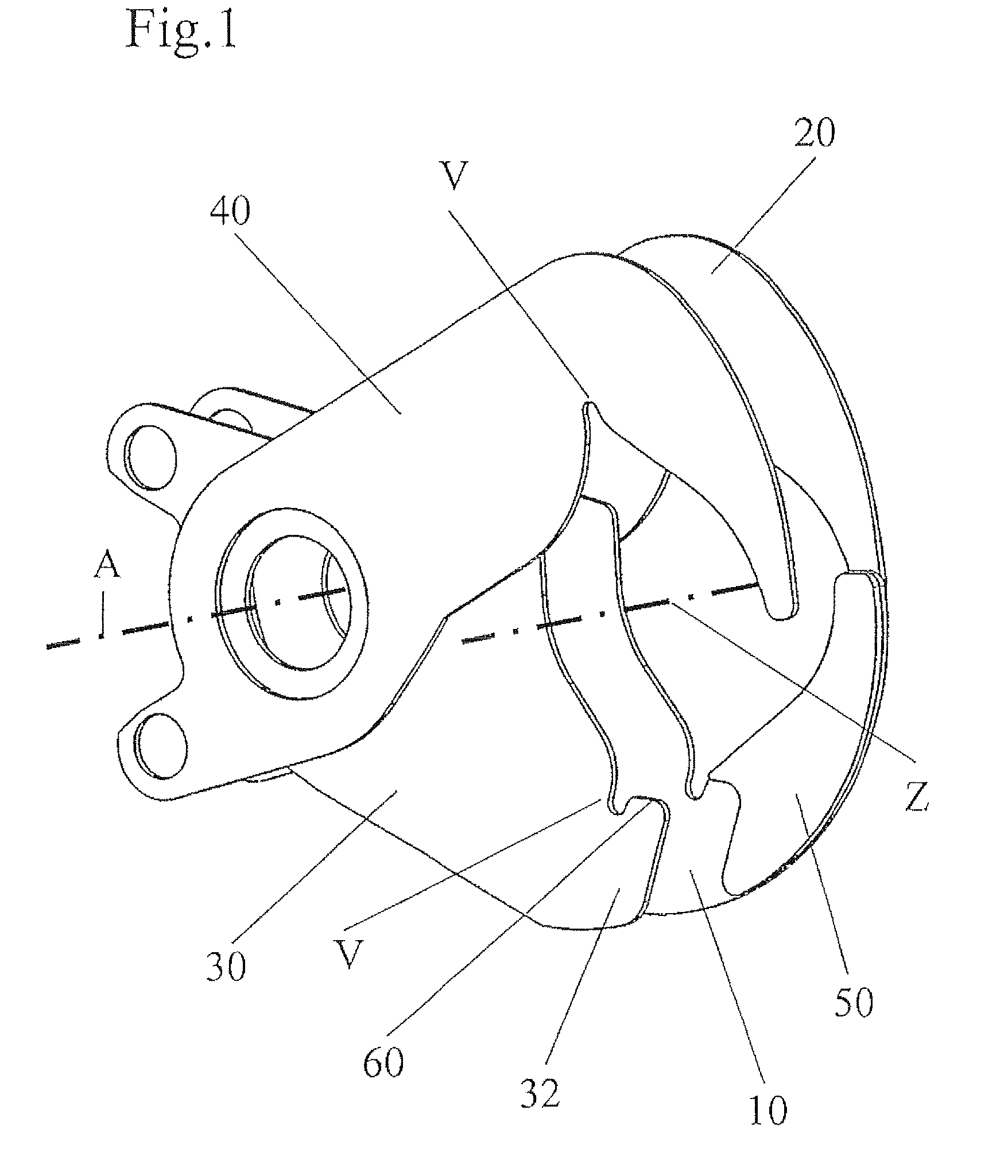

A displacer assembly for a clip machine, in particular a sausage clip machine, including at least a first pair of displacer shears and a second pair of displacer shears arranged parallel thereto. The displacer shears are arranged pivotably about a common axis and are reversibly movable towards each other for constriction of the filled packaging casing for forming a filling material-free plaited portion. In that respect the first pair of displacer shears comprises two displacer shears which are at least approximately identical in minor image relationship and the second pair of displacer shears has a second displacer shear which is at least approximately identical to the displacer shears of the first pair of displacer shears, as well as a first, shorter displacer shear. The first displacer shear of the first pair of displacer shears has a reinforcement which at least approximately reproduces the contour of the part, which is cut off for shortening purposes, of the first displacer shear of the second pair of displacer shears.

Owner:POLY CLIP SYST

Coated food product, composition, method and apparatus for making same

InactiveUS20050220946A1Improve cohesionConstrict flowOther dairy technologySausage casingsEngineeringCalcium alginate

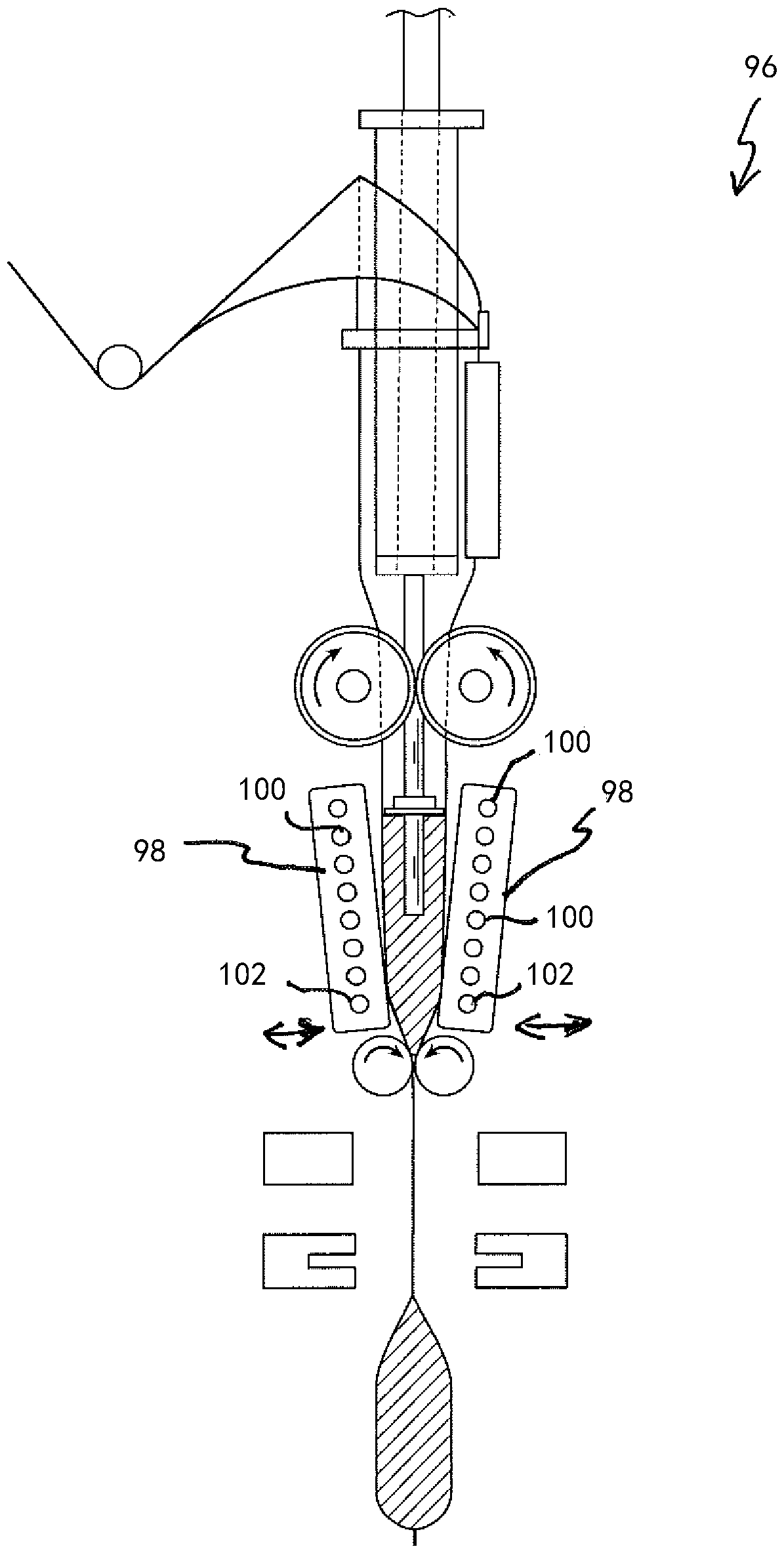

The technical field of the invention is that of manufacturing apparatuses for automatically making sausages. The present invention relates to a coated food product, in particular a sausage, to a composition for coating the food product, to a method of coating food products, and to apparatus enabling the method to be implemented. The method comprises in succession the following steps: a sausage of raw sausage meat, purée , or paste is molded by being passed through a tubular mold; the mold is cut up into segments having ends that are preferably rounded; the segments are moved while being covered in a first composition containing sodium alginate so as to coat the segments in a film of this first composition; and the coated segments are put into contact with a second composition containing a calcium salt in order to cause a gel of calcium alginate to be formed, coating the segments.

Owner:PALGA INT

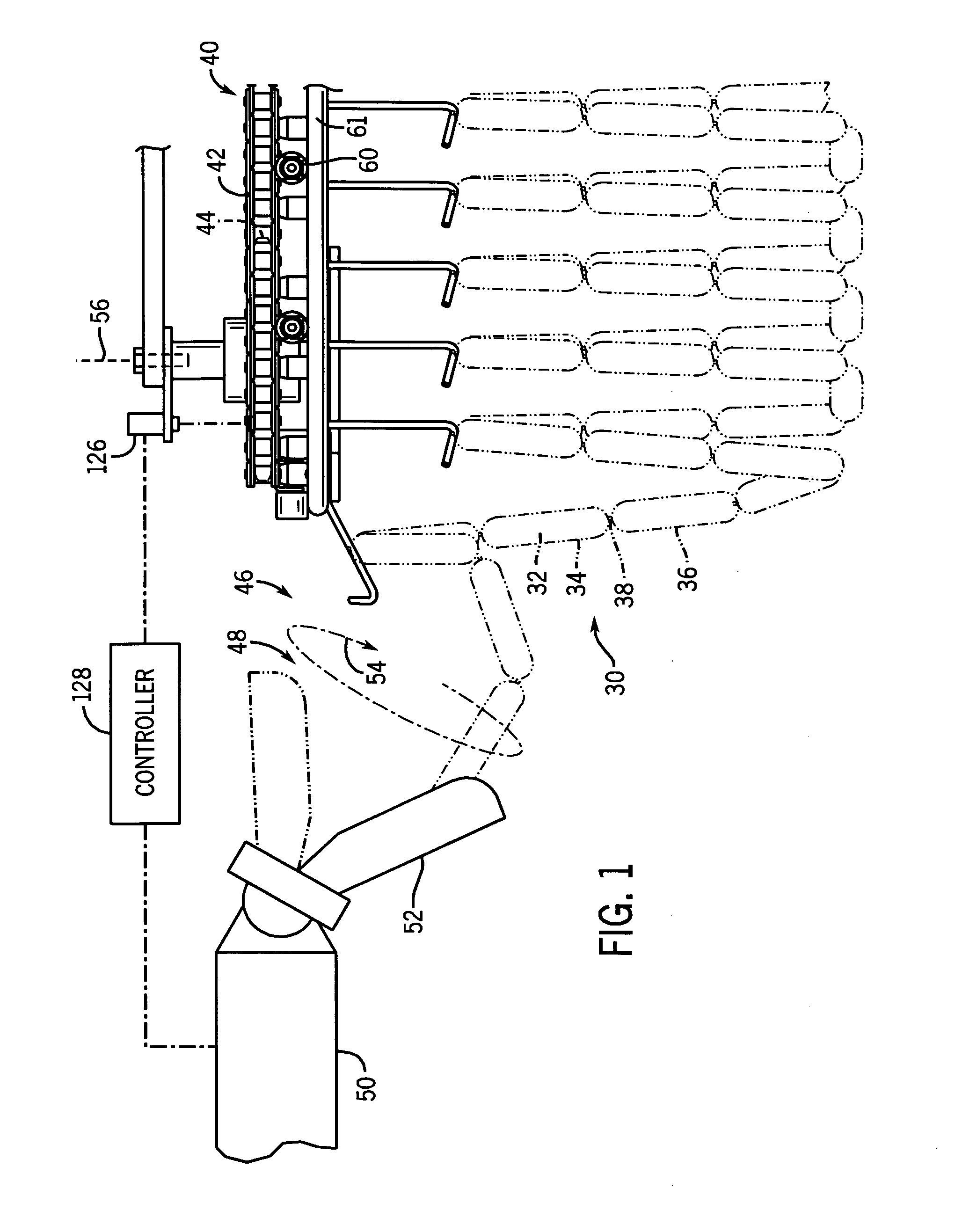

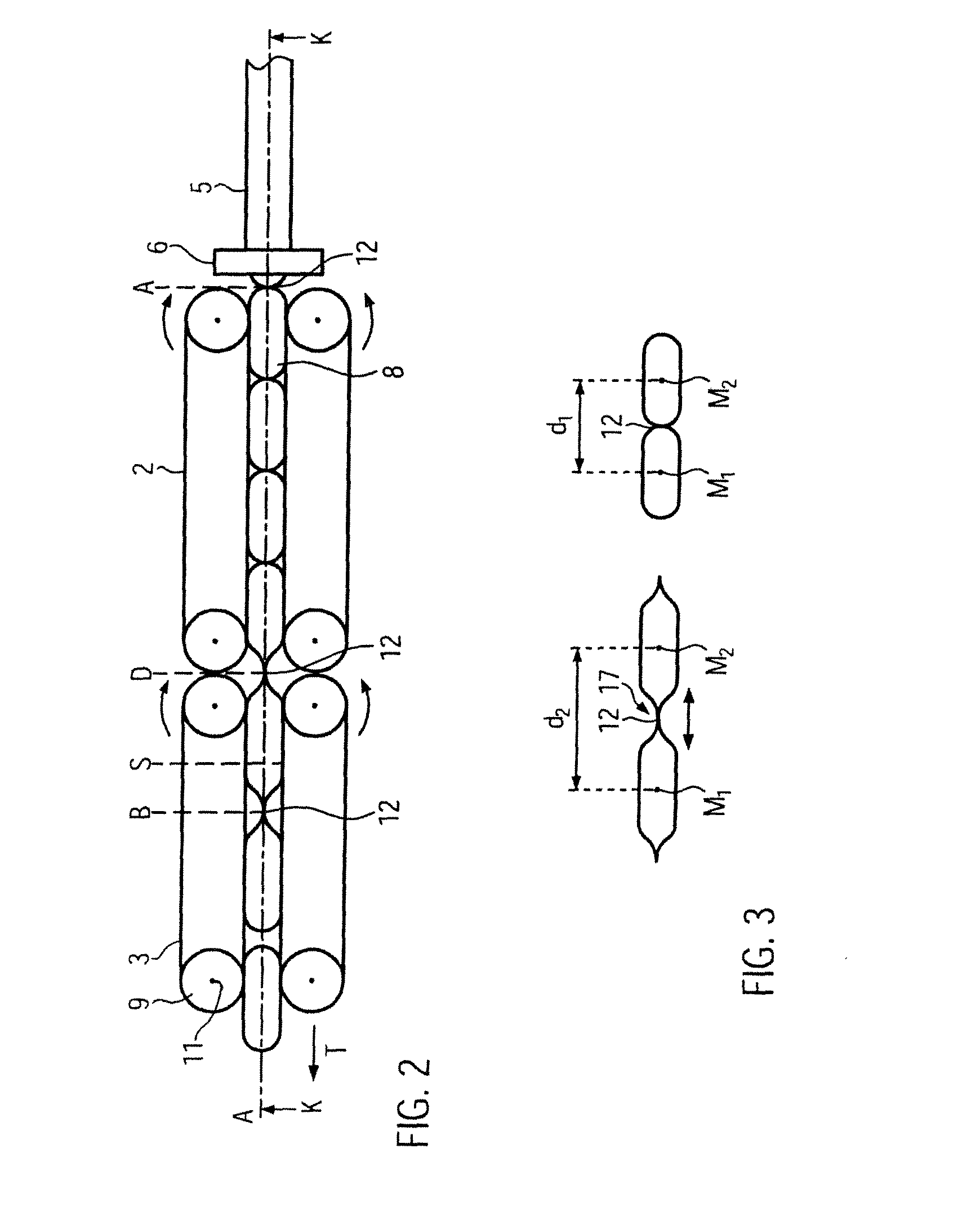

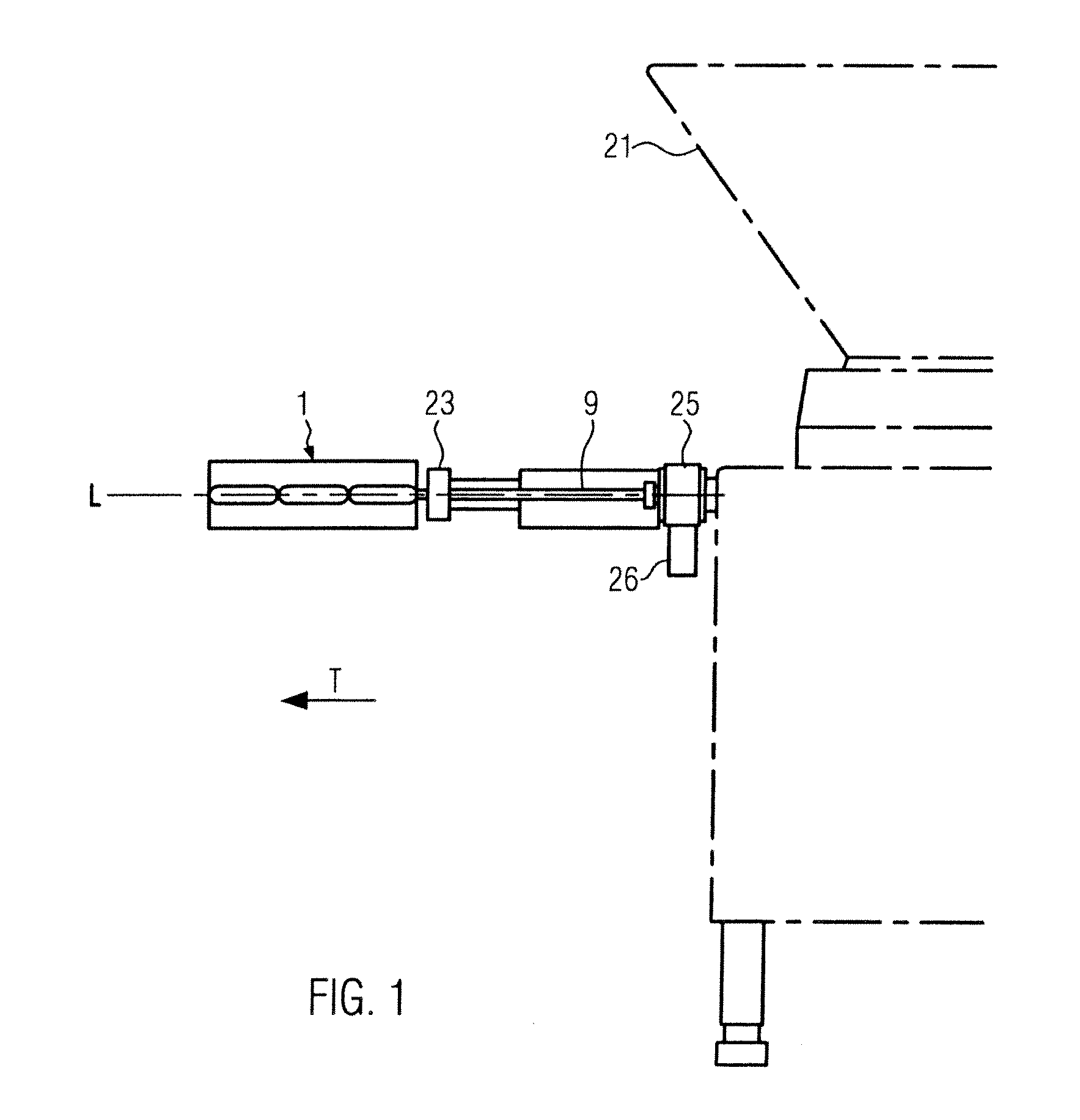

Apparatus and method for dividing a stuffed sausage skein

ActiveUS20080070489A1Product softEases engagementSausage filling/stuffing machinesSausage twisting/linking machinesEngineering

An apparatus and a method for dividing a stuffed sausage skein, wherein a transport element pair is provided, including rotating opposite transport elements between which the stuffed sausage skein is conveyed in a transport direction and each of which include at least one dividing element. To be able to configure the length of the portions flexibly without mechanical adaptation, the apparatus comprises several adjacently arranged transport element pairs drivable independently of each other with corresponding dividing element pairs. The speed of the transport element pairs is adjusted such that the spacing between the points of separation corresponds to a predetermined length of the divided sausage skein.

Owner:ALBERT HANDTMANN MASCHFABRICK

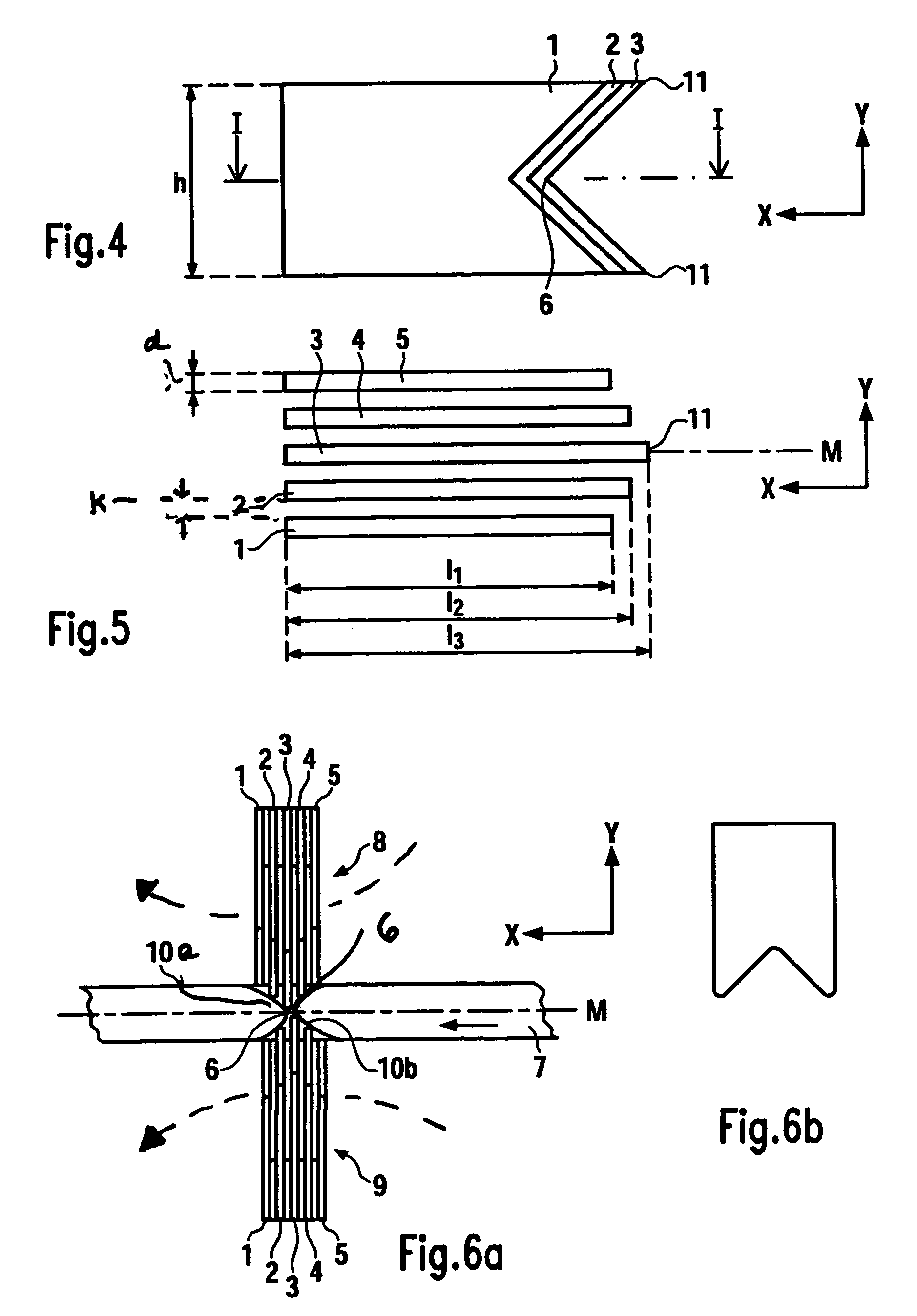

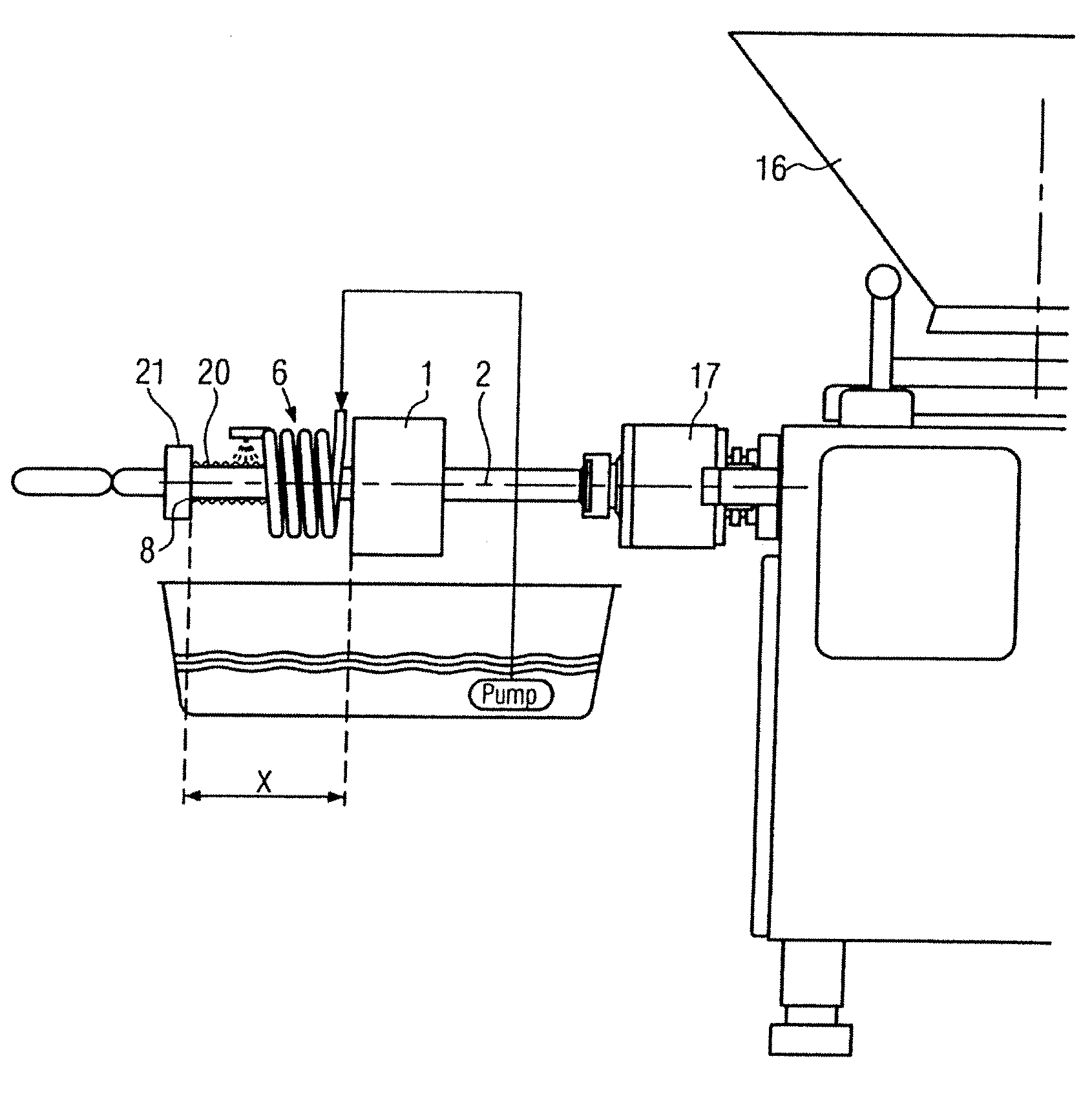

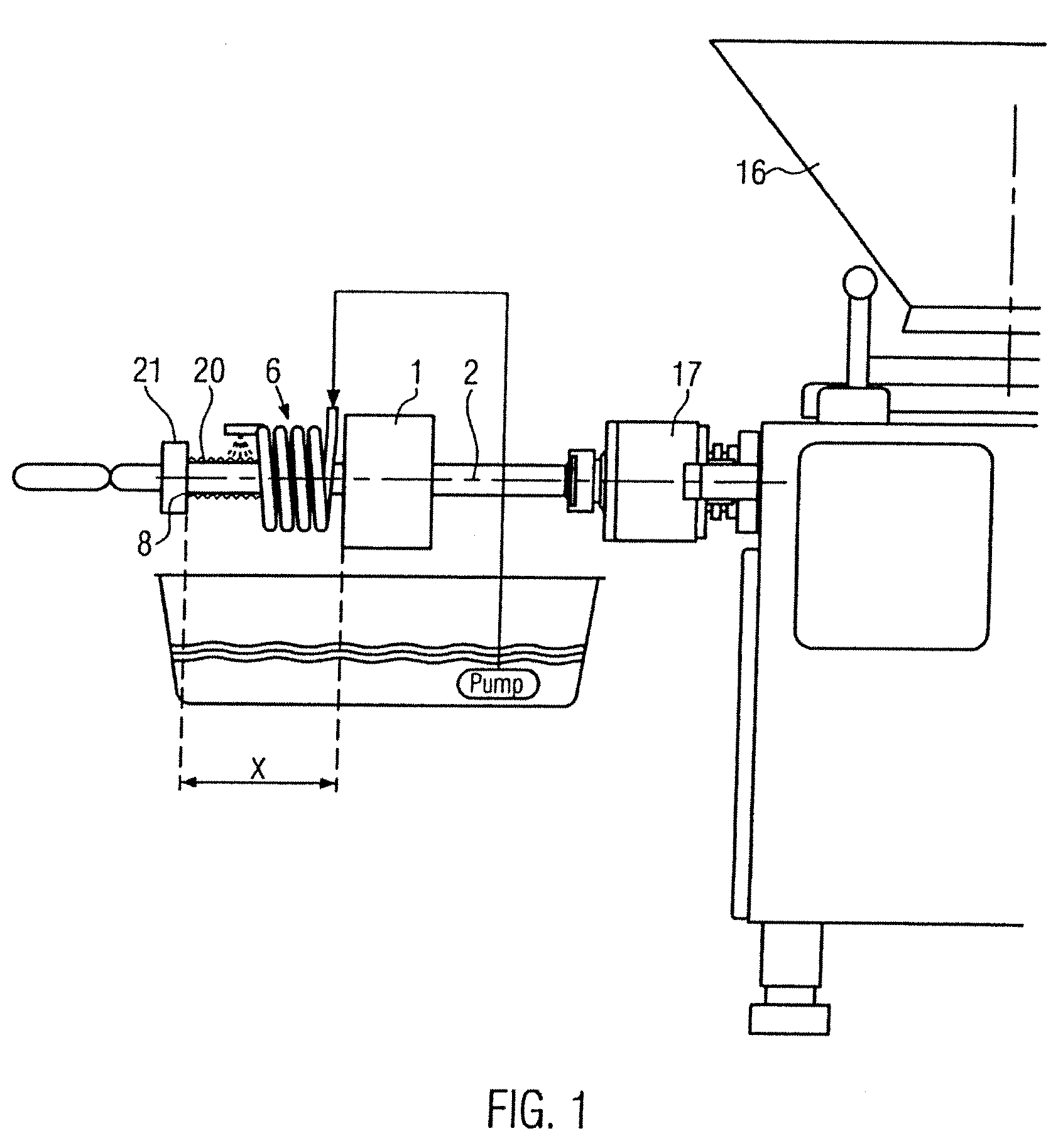

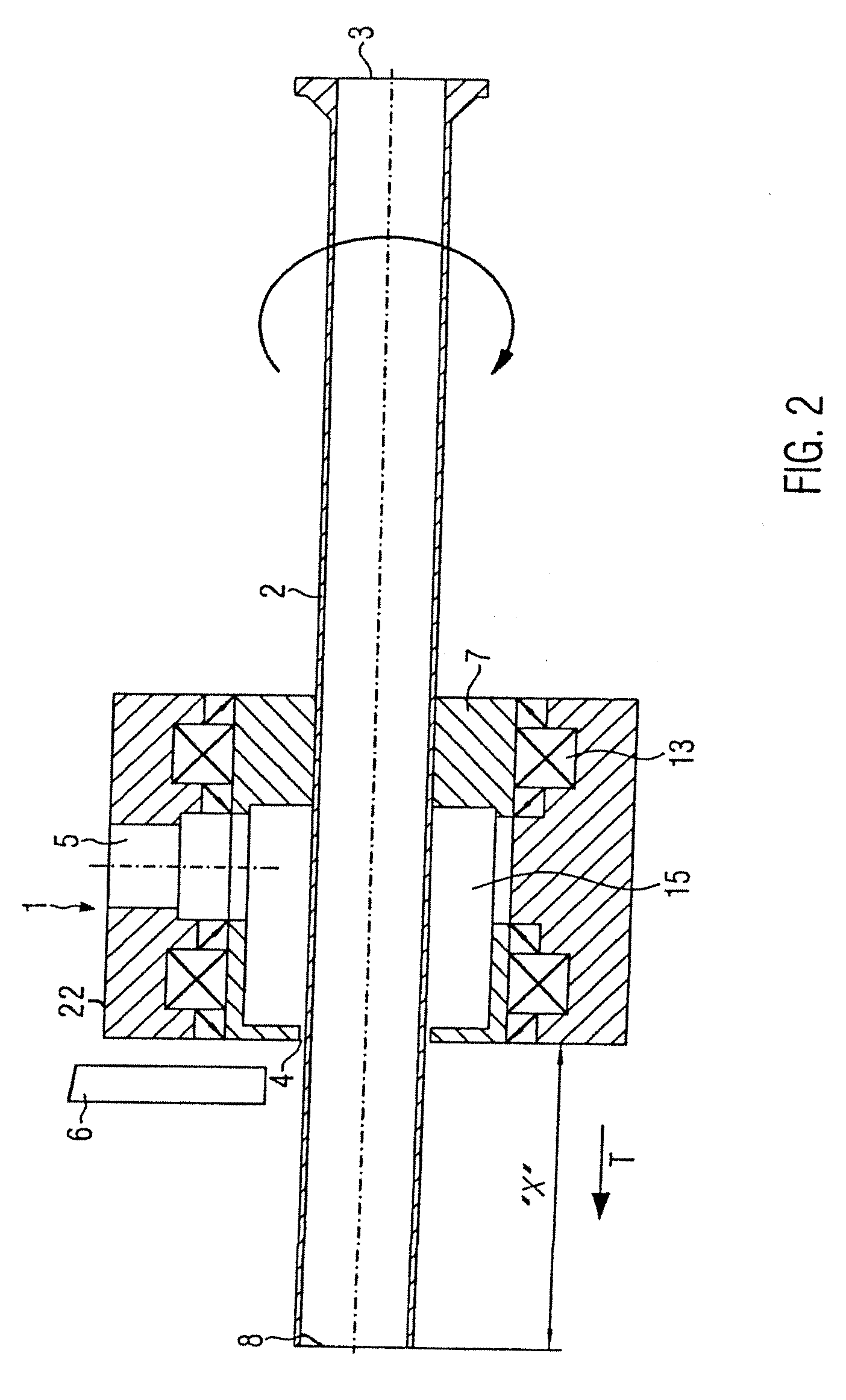

Device and method for manufacturing sausages

ActiveUS20090023373A1Easy to manufactureIncrease pressureSausage casing manufactureSausage filling/stuffing machinesEngineeringMechanical engineering

A device and a method for the manufacture of sausages from paste mass, in particular sausage meat, with a coextrusion head for coextruding the paste mass and a sausage casing, wherein the coextrusion head comprises a filling tube for the ejection of the paste mass as well as an extrusion die assigned to the filling tube with an extrusion gap for ejecting the casing material. In order to produce strong sausage casings, the filling tube protrudes by a distance X beyond the annular gap so that the casing material is extruded through the annular gap onto the filling tube and solidifies along the filling tube.

Owner:ALBERT HANDTMANN MASCHFABRICK

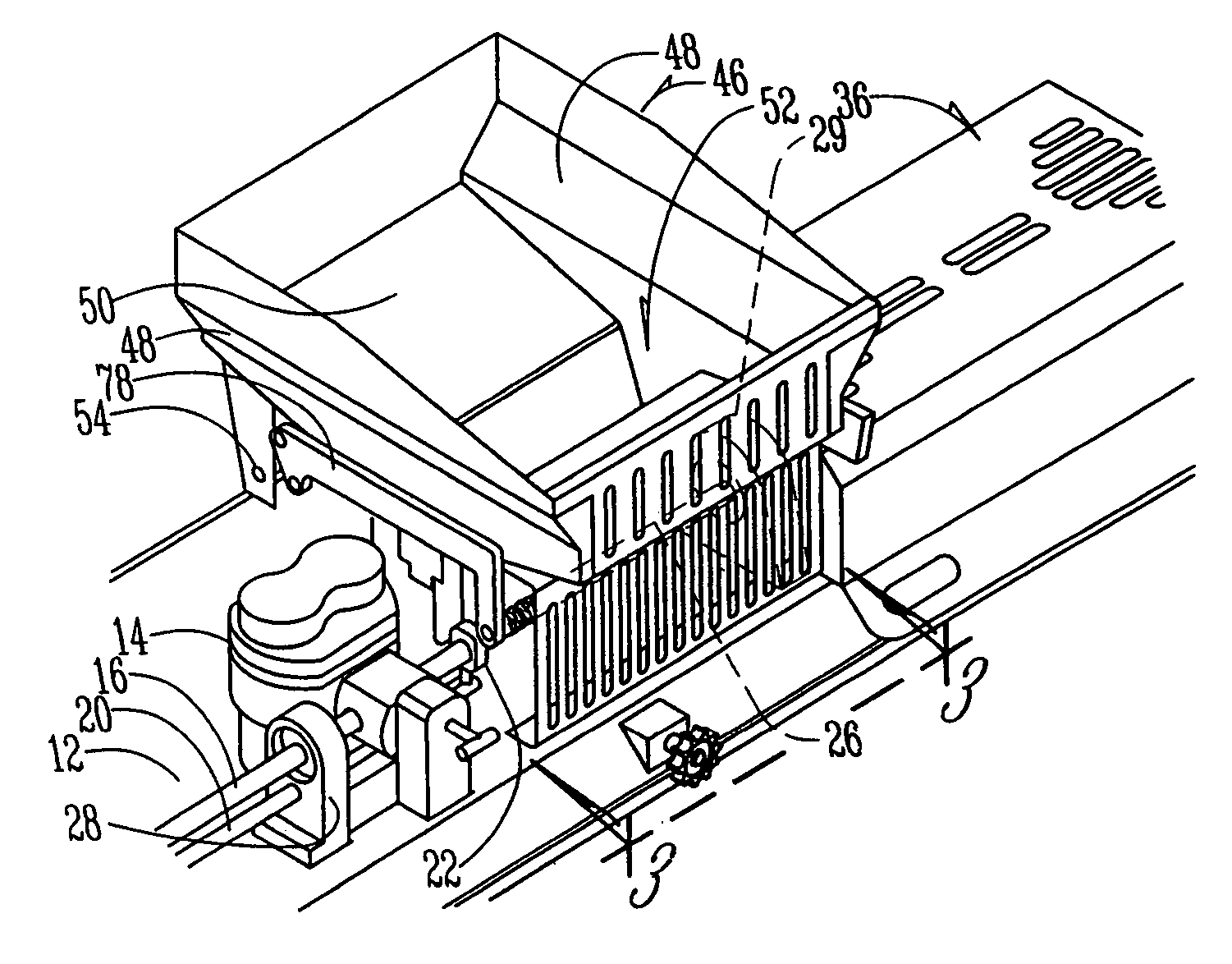

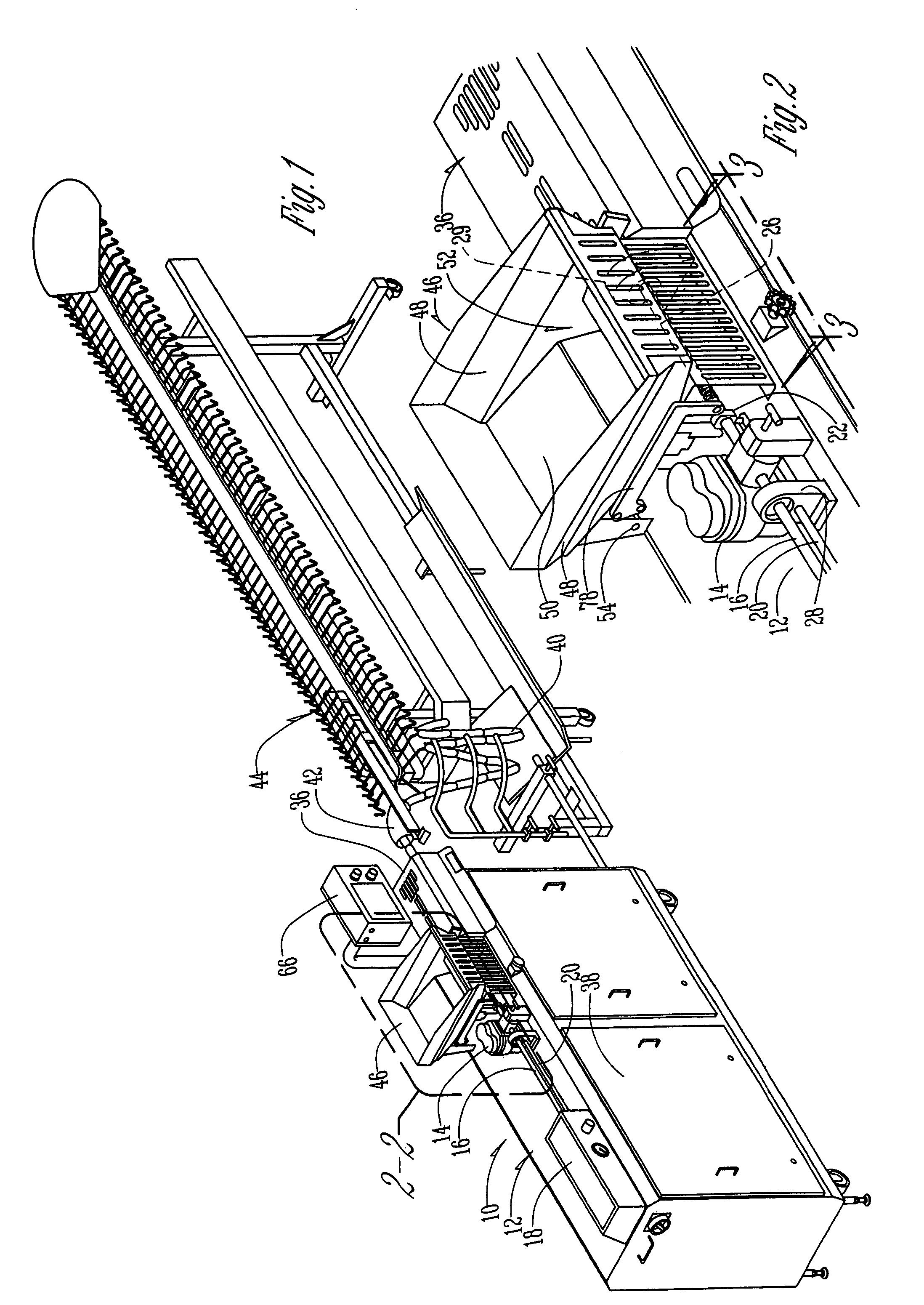

Method and means for filling natural casing sausages

InactiveUS6981912B2Sausage filling/stuffing machinesSausage twisting/linking machinesEngineeringPrimary energy

A method for filling a natural hollow elongated casing with meat emulsion that involves placing a natural casing on an elongated meat emulsion stuffing tube and longitudinally pumping meat emulsion through the stuffing tube for expansive discharge into the natural casing at a sufficient volume and velocity to provide the primary energy within the natural casing. The method also involves providing a casing hopper that can be pivoted from a forward operating position to a rearward inoperative position.

Owner:STORK TOWNSEND BV

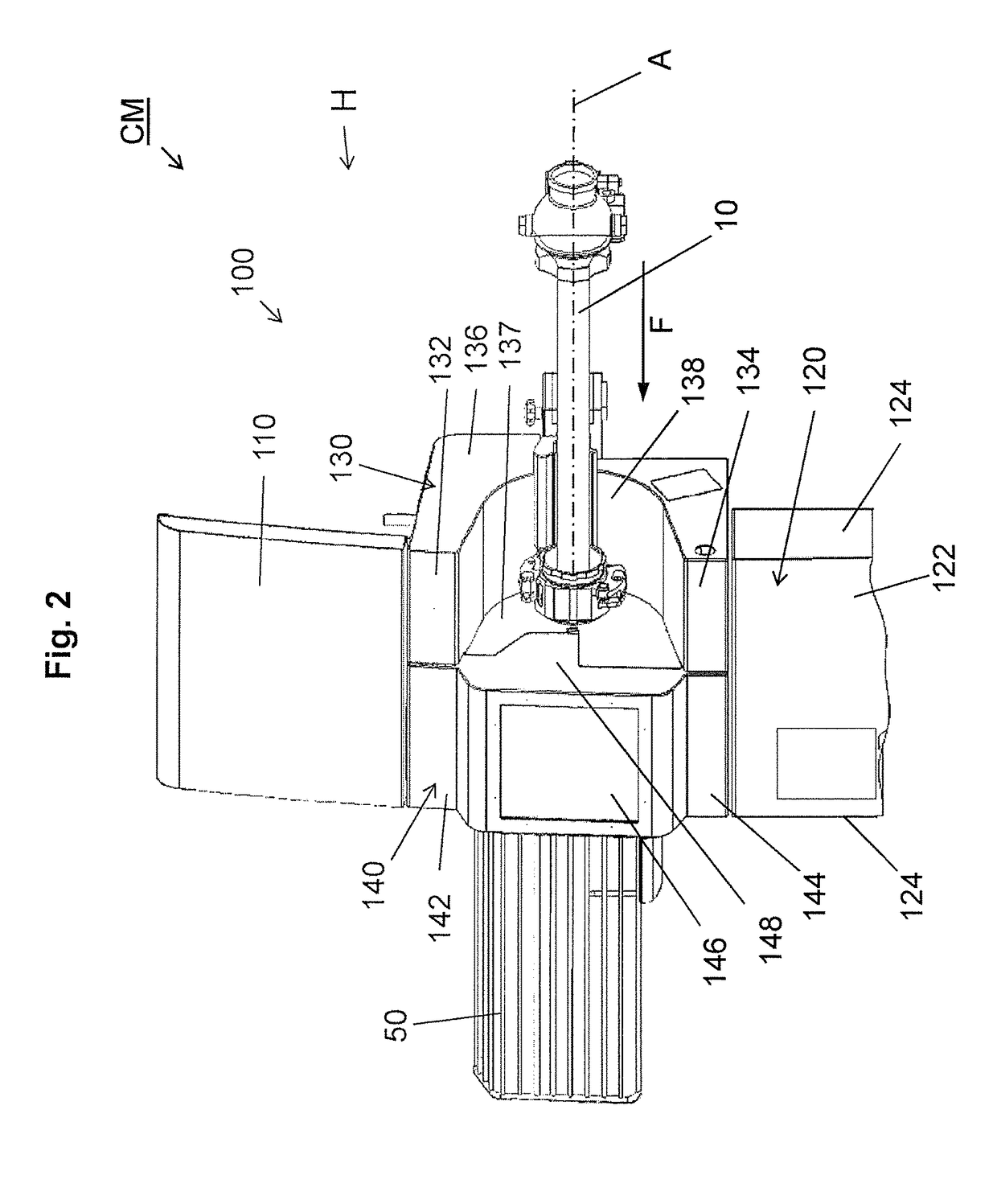

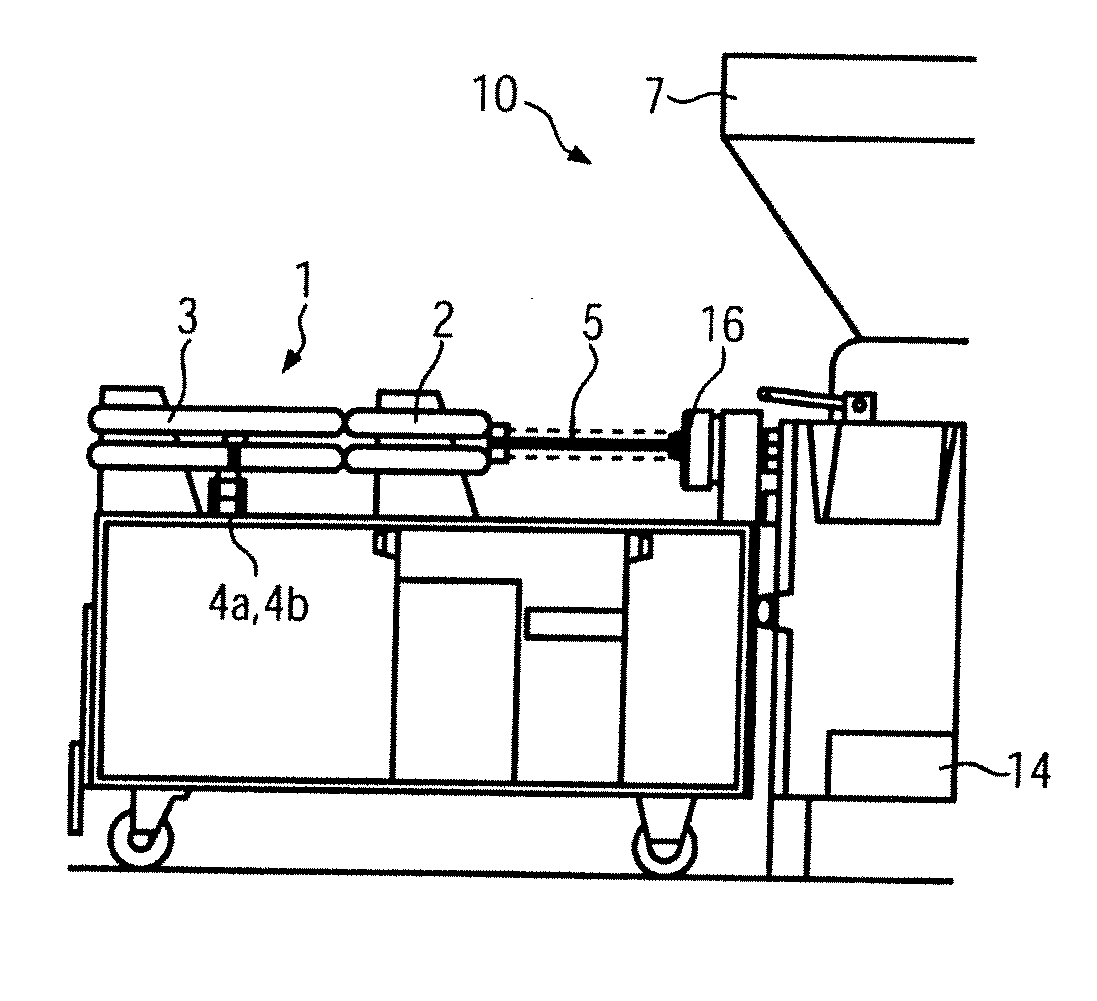

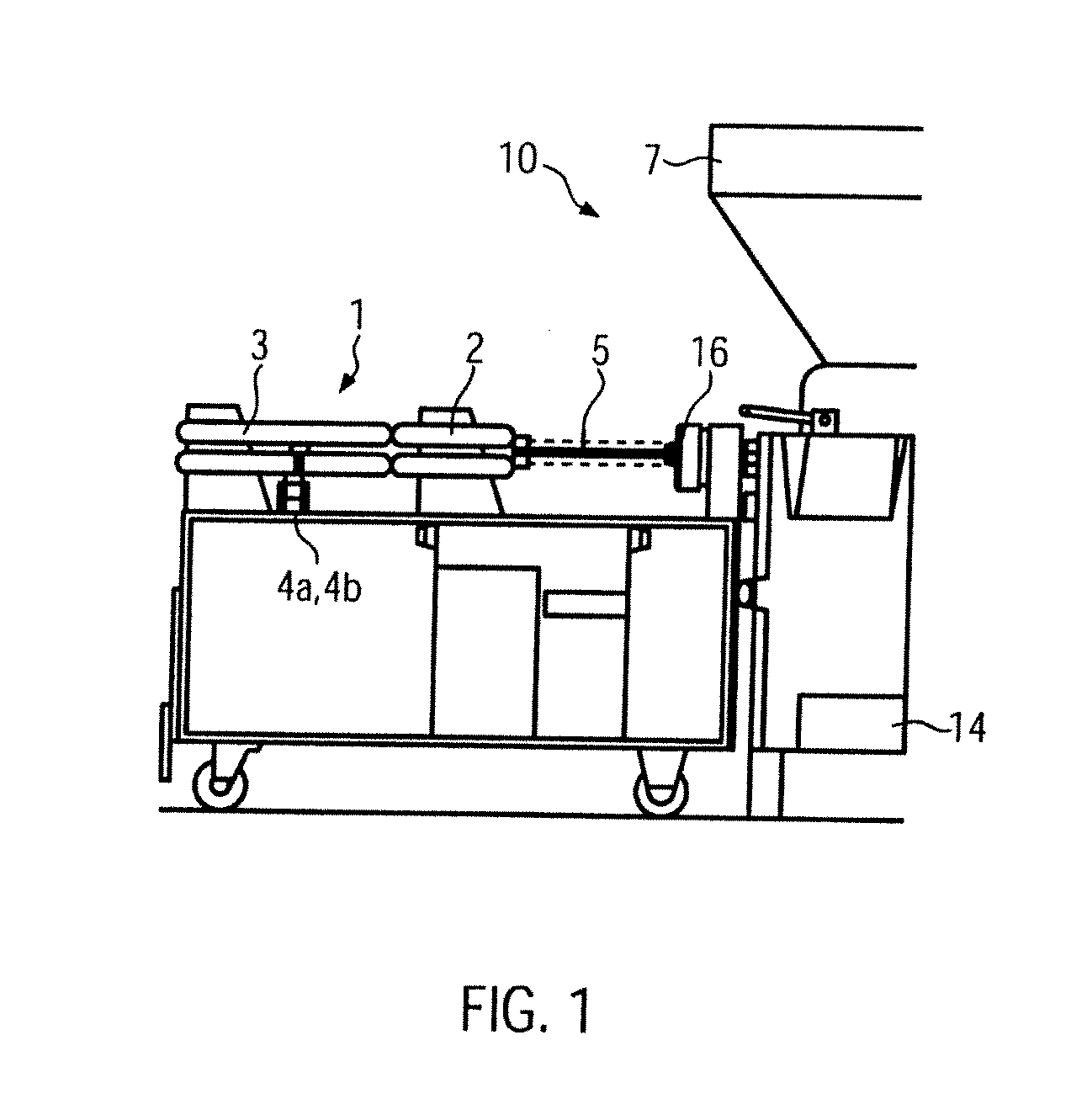

Clipping machine with easy access

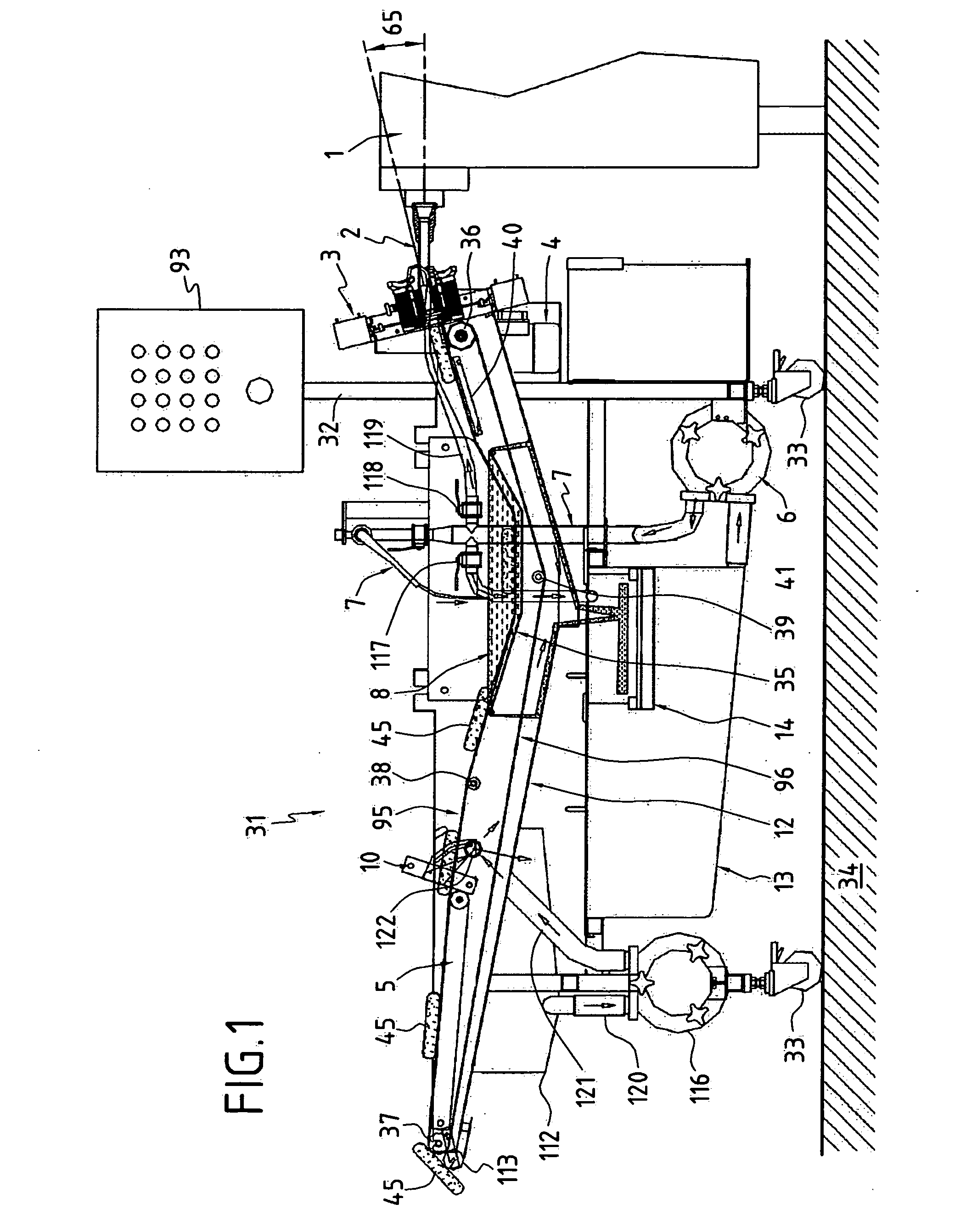

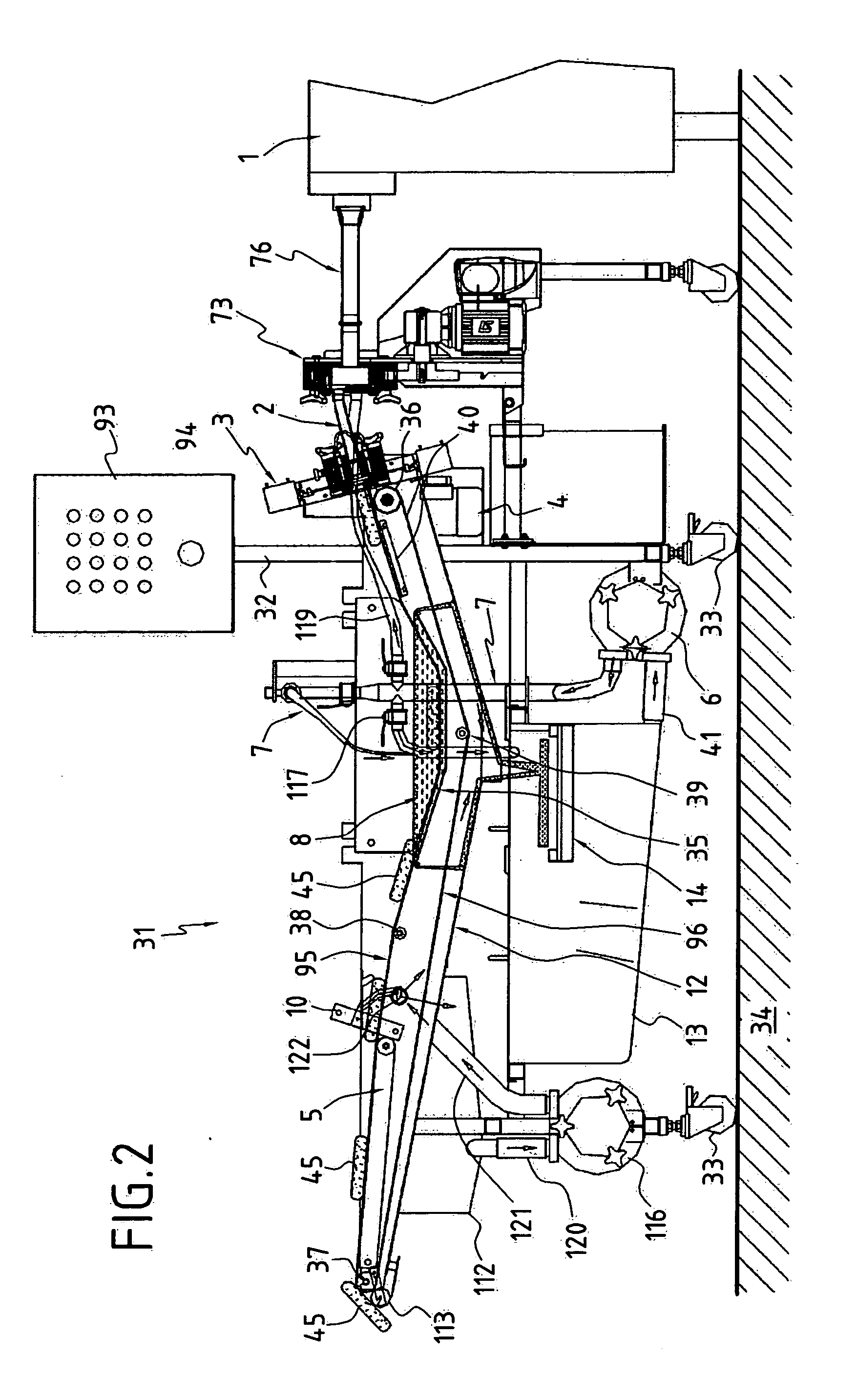

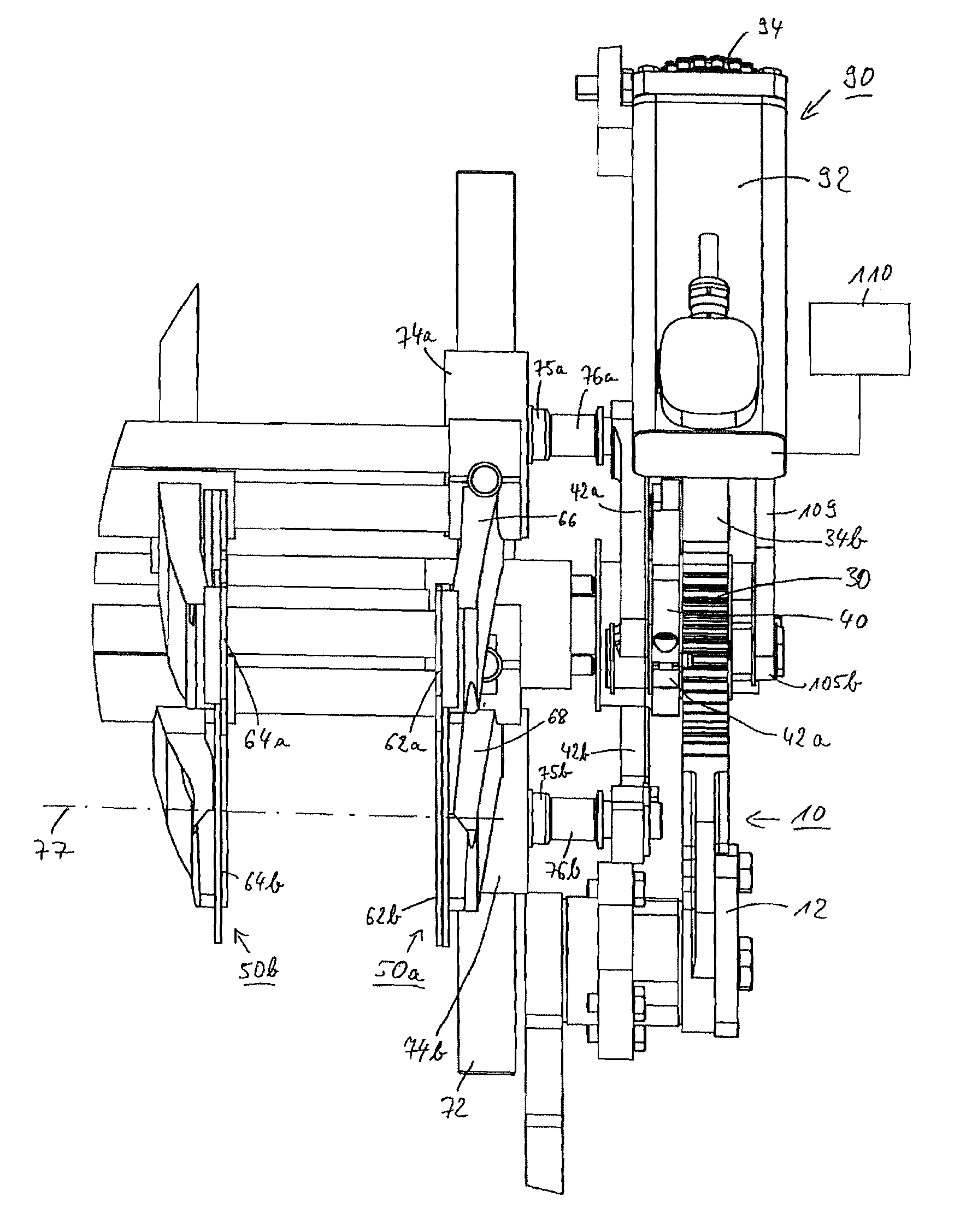

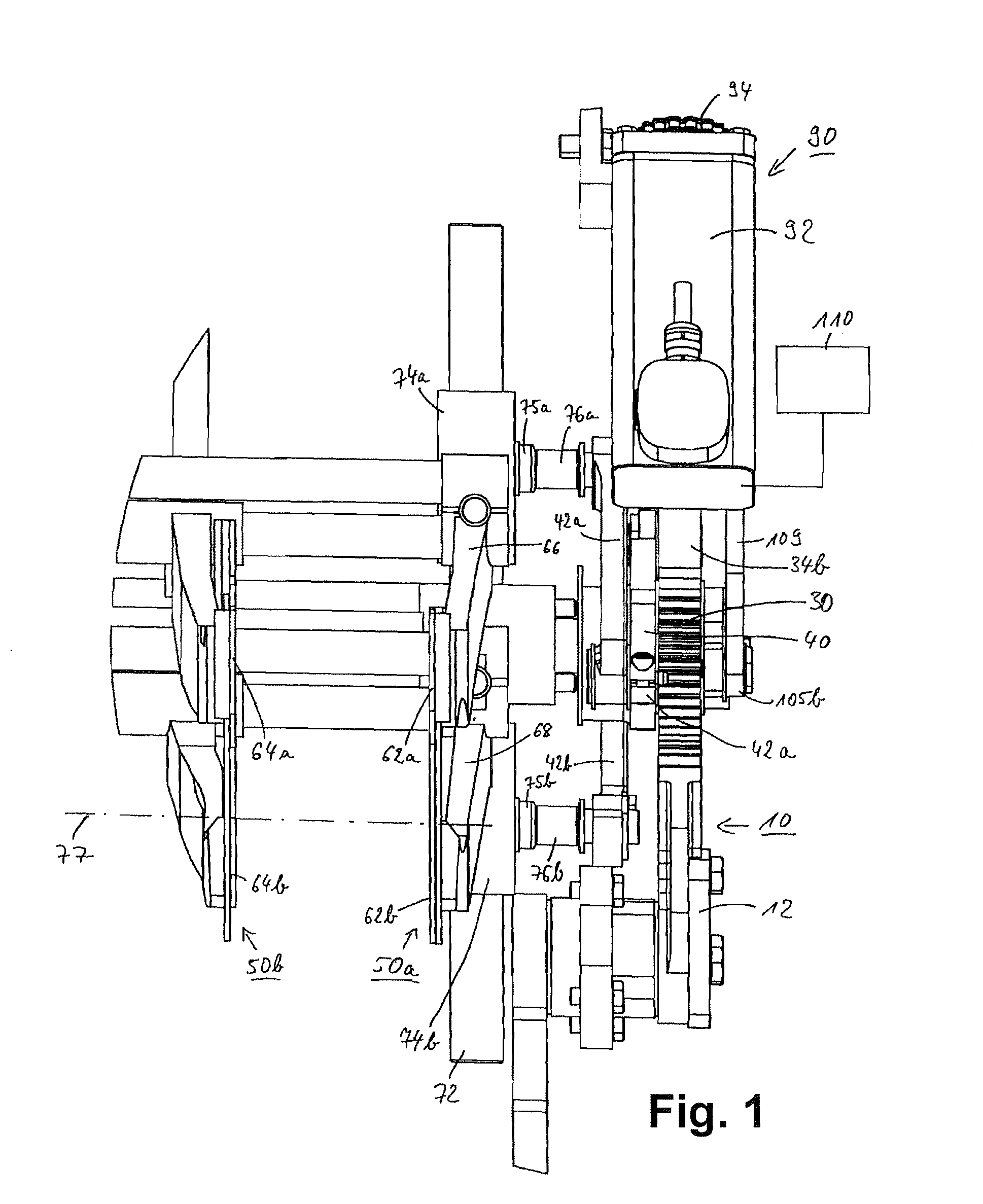

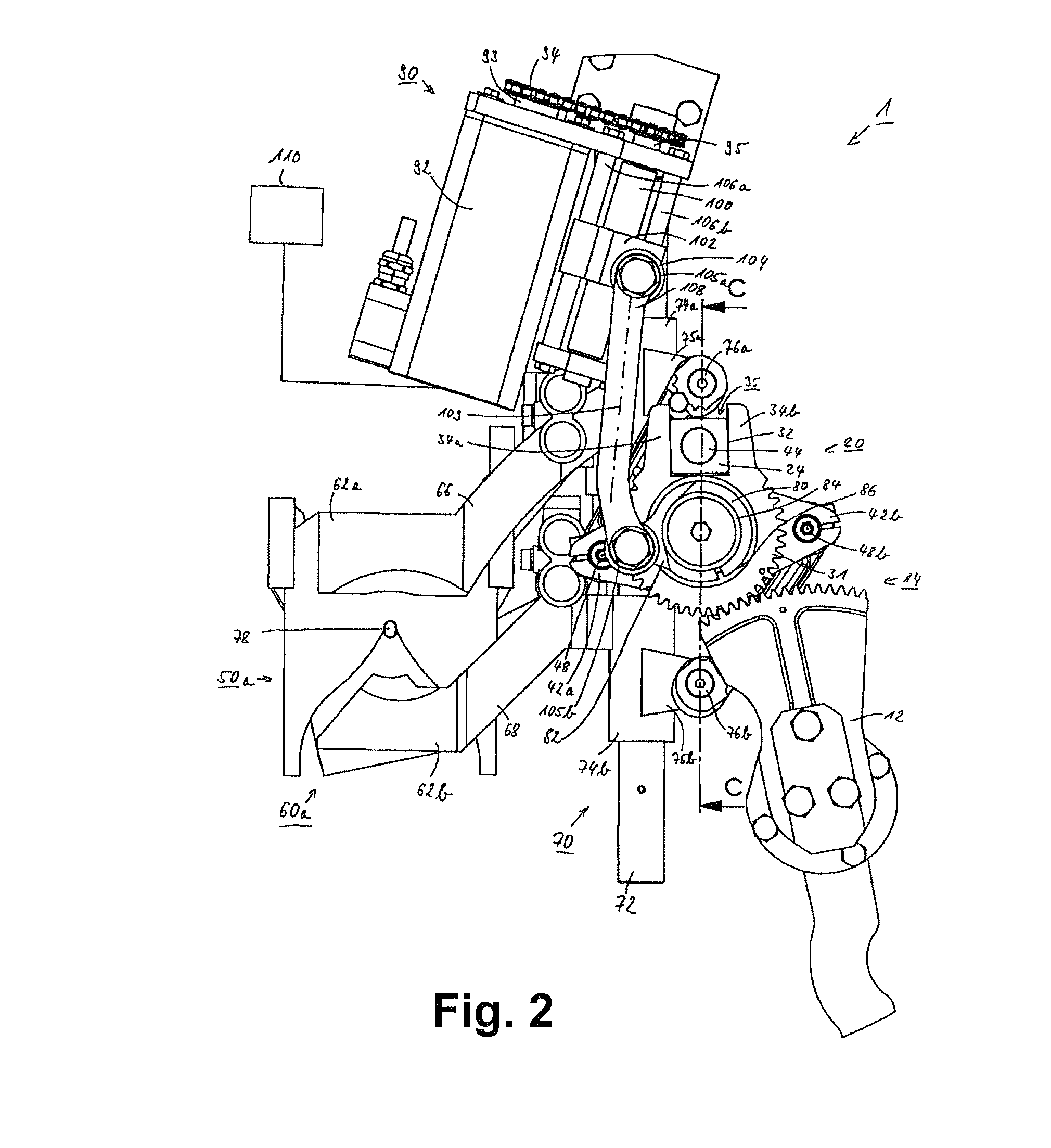

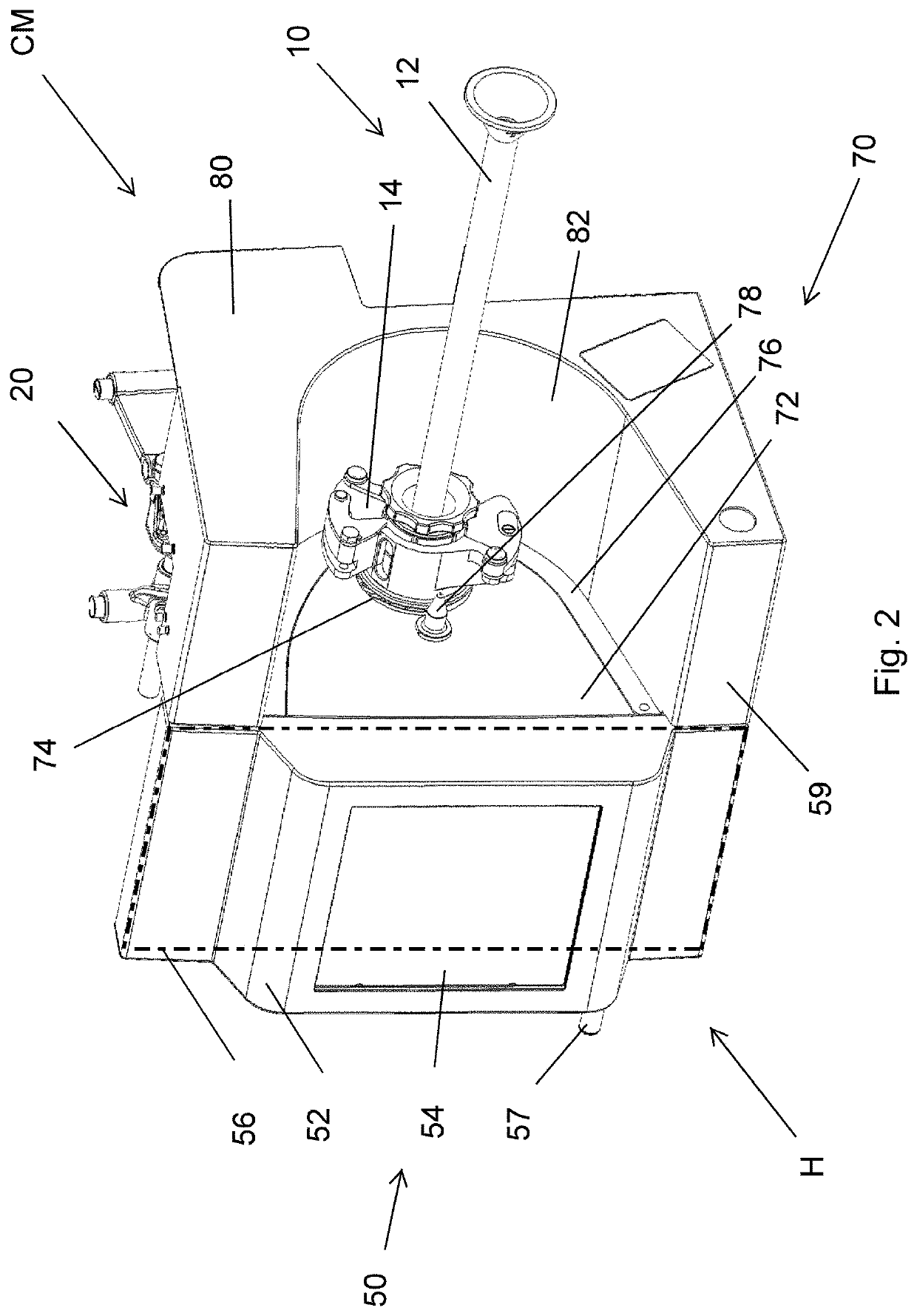

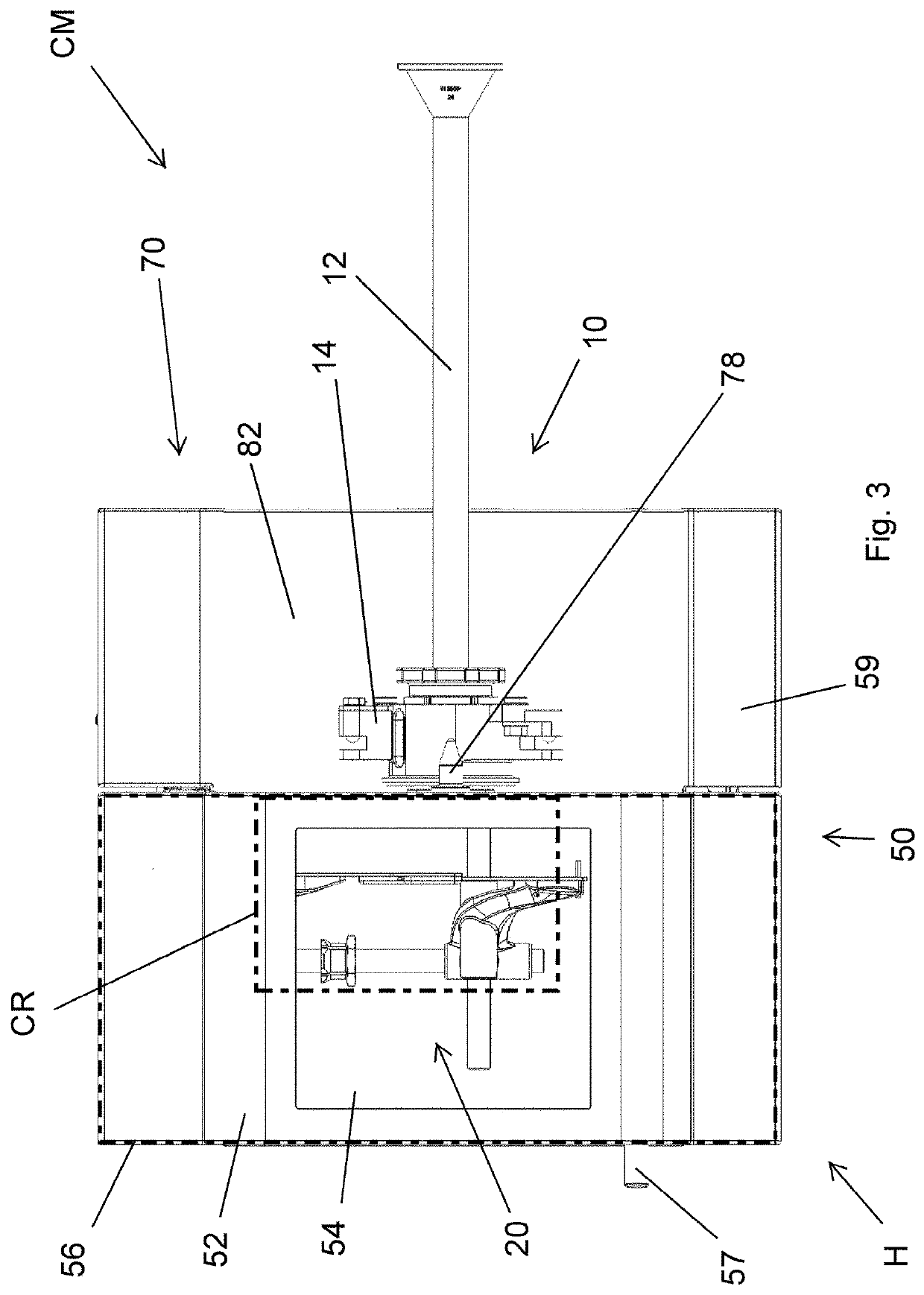

ActiveUS9986744B2Reduce stepsPrecise positioningHorizontally conveying sausagesWrapper twisting/gatheringFilling materialsEngineering

The present invention relates to a clipping machine for producing sausage-shaped products, like sausages, by filling a tubular or bag-shaped packaging casing with filling material and closing said filled tubular or bag-shaped packaging casing. The clipping machine includes a filling tube through which the filling material is fed into said tubular or bag-shaped packaging casing which is stored on said filling tube, a casing brake assembly arranged on the filling tube for limiting the movement of the tubular packaging casing at least while being filled, gathering means for gathering said filled tubular packaging casing and for forming a plait-like portion thereto, and a clipping device for applying at least one closure means, like a closure clip, to the plait-like portion formed on the filled tubular or bag-shaped packaging casing in a closing region. The clipping machine further comprises a housing defining at least a front wall, a rear wall, and two side walls of the clipping machine, for enclosing at least the clipping device and the gathering means. The housing includes at least one housing element arranged in the front wall of the housing for covering at least the closing region, wherein the at least one housing element is coupled to the clipping machine by a linking device including a shifting mechanism for reversibly shifting the housing element relative to the clipping machine, in a shifting direction, for granting access to the closing region of the clipping machine.

Owner:POLY CLIP SYST

Device and method for controlling a filling machine

ActiveUS9480264B2Easy and reliable adjustmentThe method is simple and reliableSausage skin tying apparatusSausage filling/stuffing machinesCommunication interfaceControl system

Owner:ALBERT HANDTMANN MASCHFABRICK

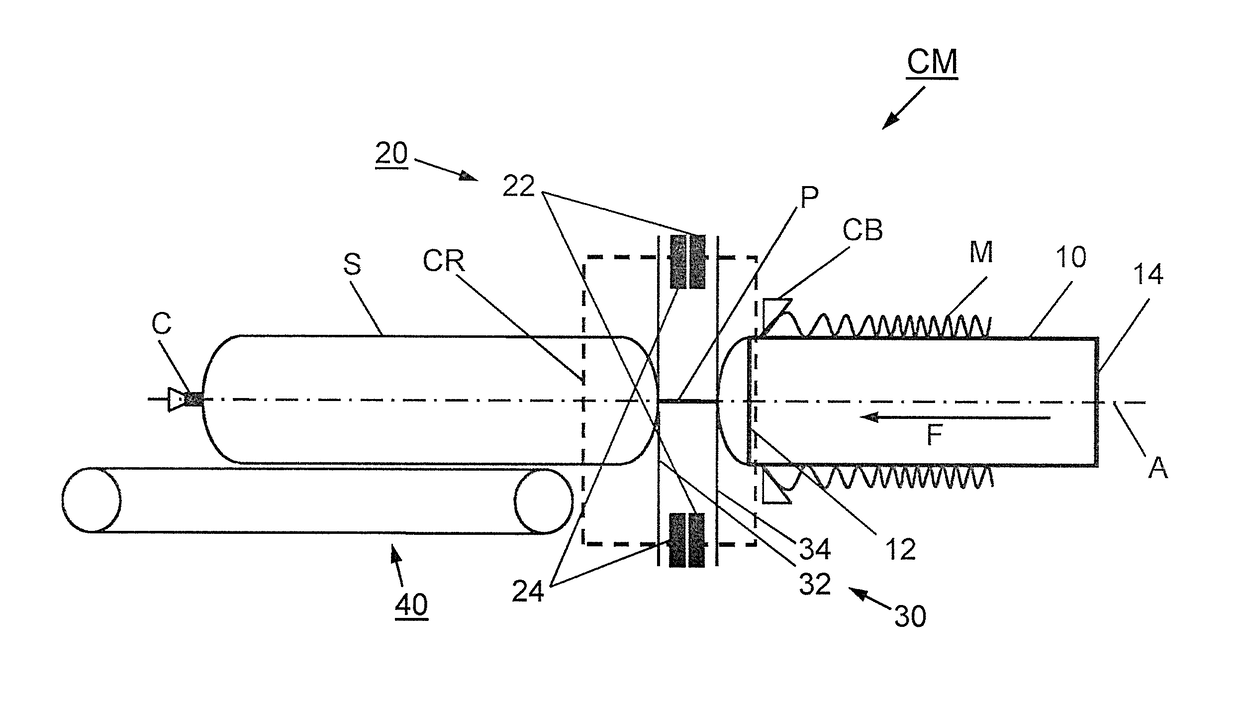

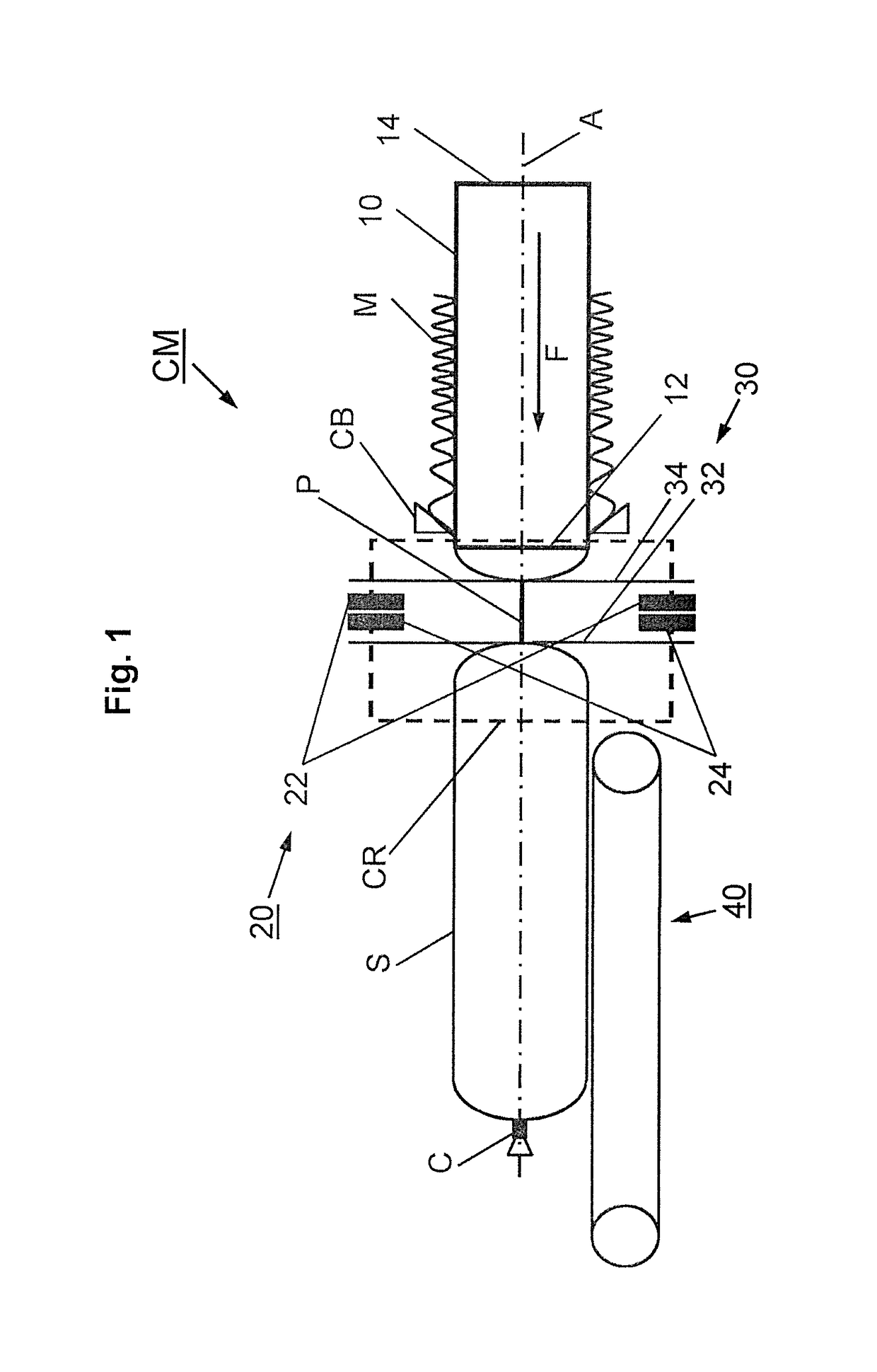

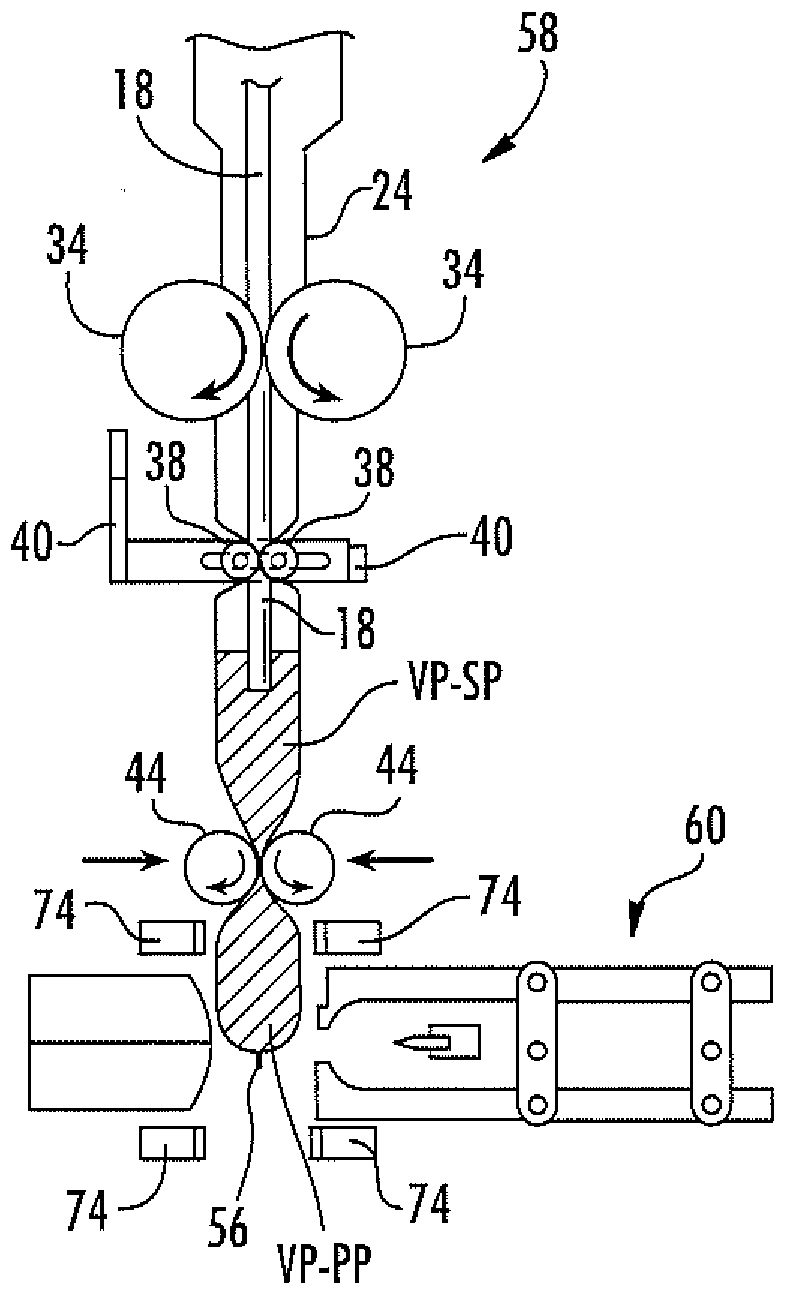

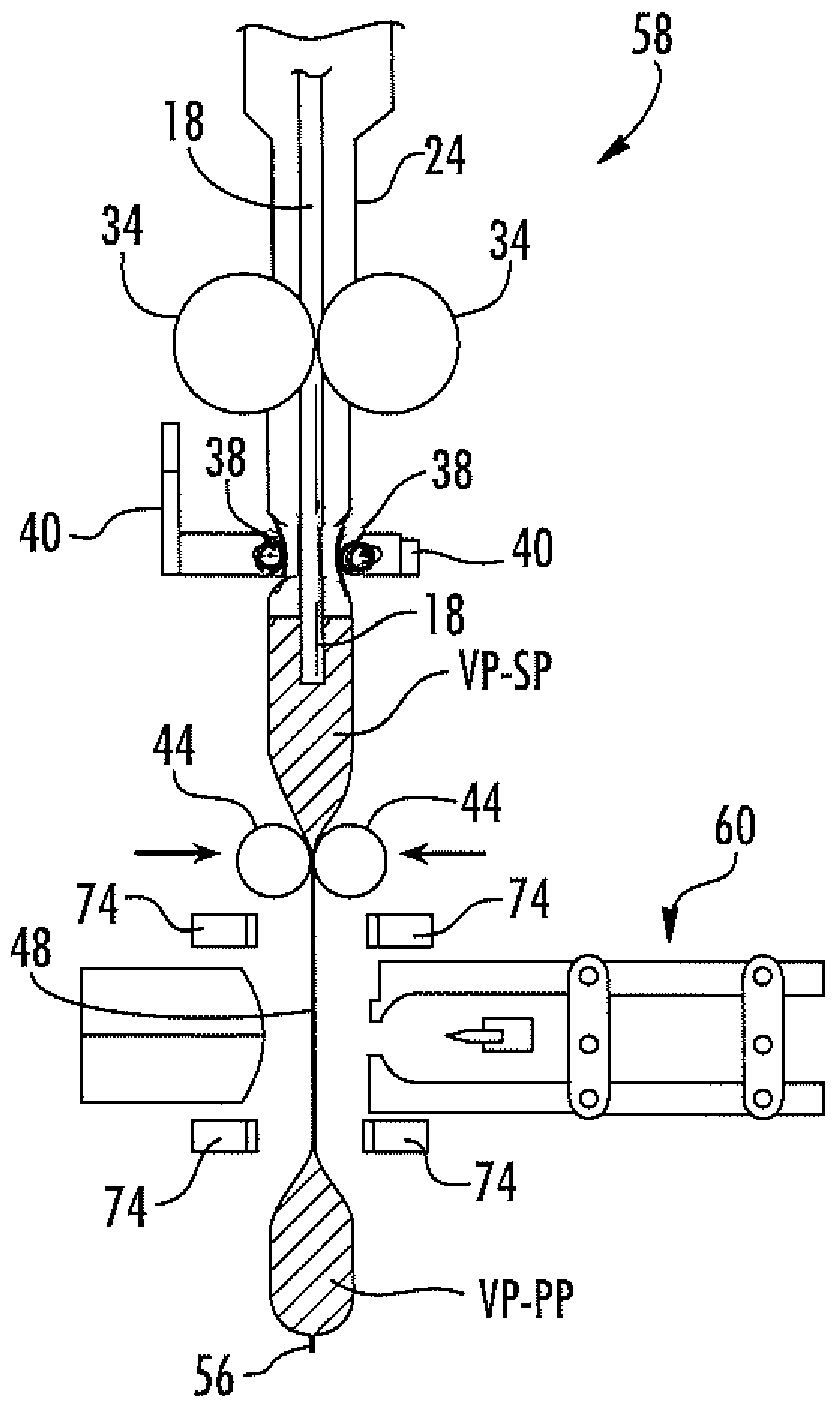

Process and machine for making clipless chub package contaning viscous product

ActiveCN108349599AWrapping material feeding apparatusWrapper twisting/gatheringEngineeringMechanical engineering

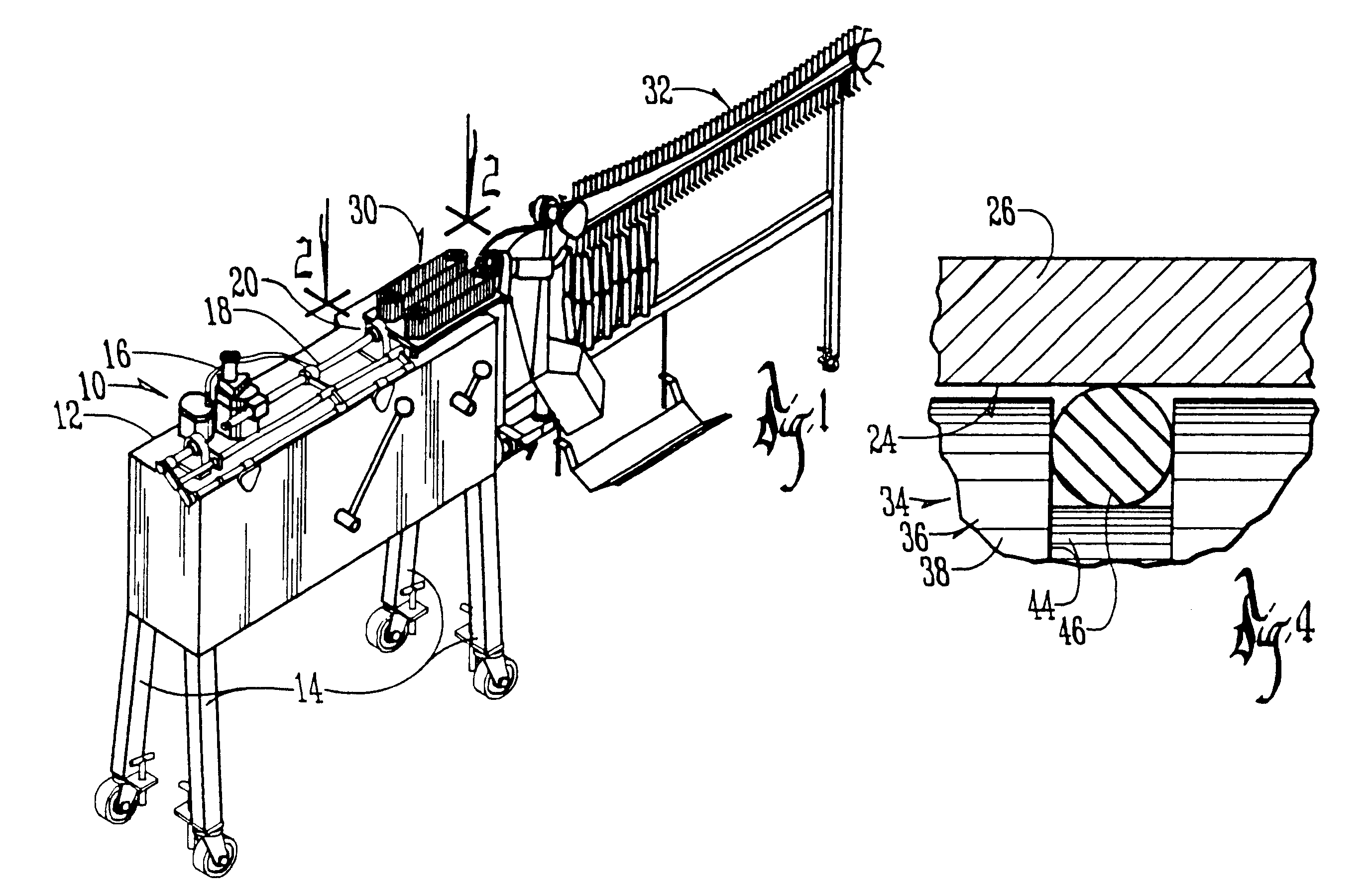

A cyclic packaging process, such as VFFS or HFFS, packages a product with a viscosity of >=100,000 centipoise without leaving substantial air pockets in the package, by utilizing a means (38) for restricting upstream flow of viscous product in the strand of tubing (24). The result is that packages of uniform weight of the viscous product can be made without substantial air pockets therein, and without having to use metal clips. An apparatus (10) for carrying out the process is disclosed.

Owner:CRYOVAC ILLC

Device for treating a string of sausages

InactiveCN104604998AMonitor fireEasy to cleanMeat/fish preservationLinked sausage separationEngineeringRadiation

Device for treating a string of sausages composed of a plurality of sausages which are disposed so as to be behind one another, having a sausage casing from an organic material which in the region between two sausages displays in each case a twist, wherein at least one microwave applicator which has at least one application chamber and is assigned at least one microwave generation unit for generating the microwave radiation to be supplied to the application chamber, and which has at least one conveying unit for conveying the string of sausages through the at least one application chamber is provided, wherein at least one measuring unit (28, 29) for identifying at least one measured value which represents a measure of the temperature prevailing in the application chamber (11) is provided.

Owner:赫魏香肠公司

Device and method for parting sausage chains

ActiveUS8231442B2Reliable and simple mannerLess burstingLinked sausage separationSausage twisting/linking machinesTransport engineering

Owner:ALBERT HANDTMANN MASCHFABRICK

Technology for producing ham sausage and die for production of same

The present invention is amied at providing a production process capable of implementing production of ham sausage with various patterns and its production mould. Its production mould mainly includes base seat, jacket cylinder, intermediate pattern cylinder, upper end cover and fixing pin for fixing pattern cylinder, and its production process mainly includes the following steps: preparing raw material, preparing stuffing, first injection, removing a part of mould, secondary injection, demoulding, steaming and packaging to obtain the invented ham sausage with beautiful appearance and several tastes.

Owner:成广民

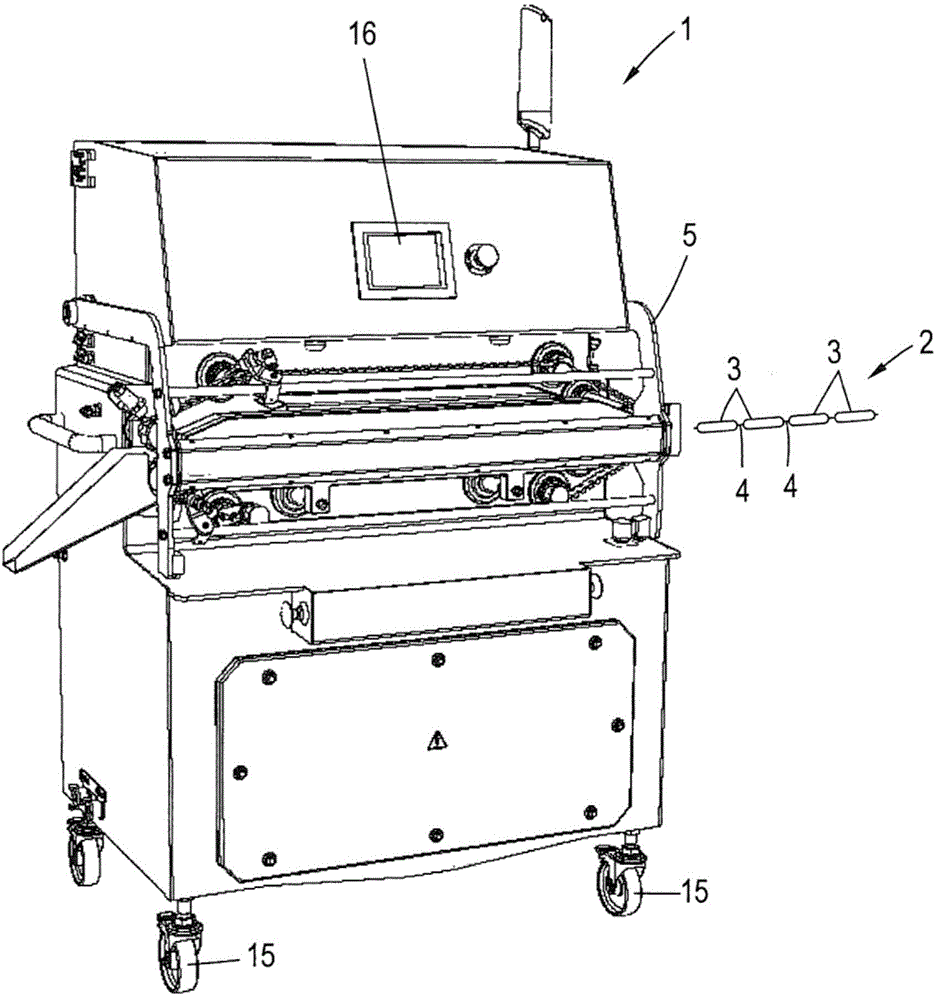

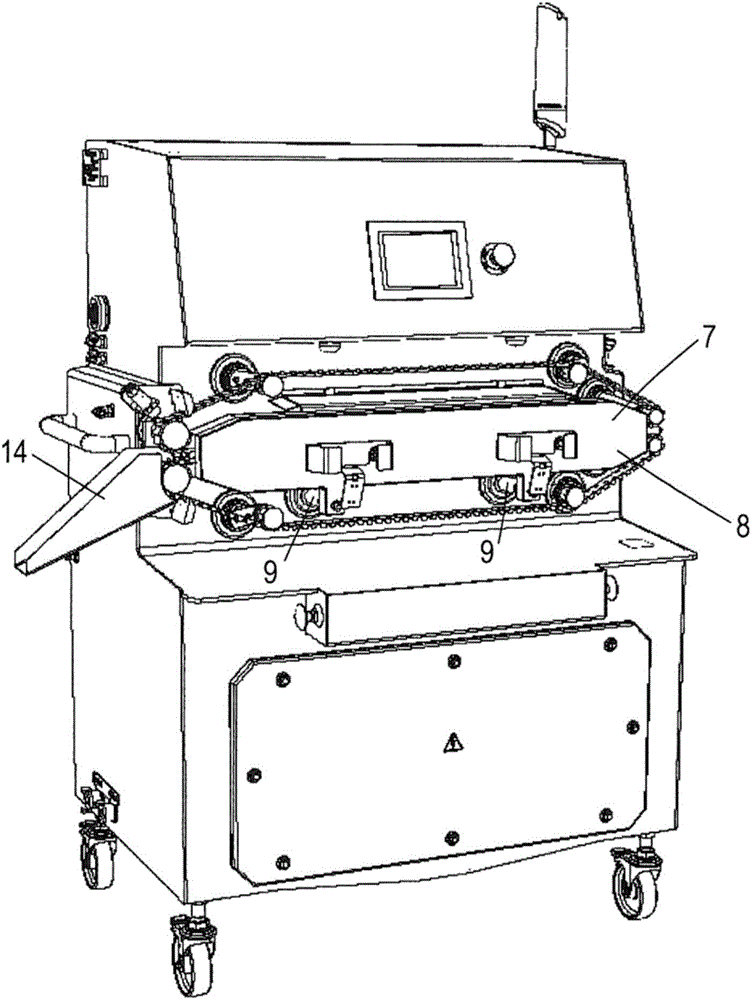

Clipping machine with easy access

ActiveUS20170172164A1Improve functionalityImprove reliabilityHorizontally conveying sausagesWrapper twisting/gatheringFilling materialsEngineering

The present invention relates to a clipping machine for producing sausage-shaped products, like sausages, by filling a tubular or bag-shaped packaging casing with filling material and closing said filled tubular or bag-shaped packaging casing. The clipping machine includes a filling tube through which the filling material is fed into said tubular or bag-shaped packaging casing which is stored on said filling tube, a casing brake assembly arranged on the filling tube for limiting the movement of the tubular packaging casing at least while being filled, gathering means for gathering said filled tubular packaging casing and for forming a plait-like portion thereto, and a clipping device for applying at least one closure means, like a closure clip, to the plait-like portion formed on the filled tubular or bag-shaped packaging casing in a closing region. The clipping machine further comprises a housing defining at least a front wall, a rear wall, and two side walls of the clipping machine, for enclosing at least the clipping device and the gathering means. The housing includes at least one housing element arranged in the front wall of the housing for covering at least the closing region, wherein the at least one housing element is coupled to the clipping machine by a linking device including a shifting mechanism for reversibly shifting the housing element relative to the clipping machine, in a shifting direction, for granting access to the closing region of the clipping machine.

Owner:POLY CLIP SYST

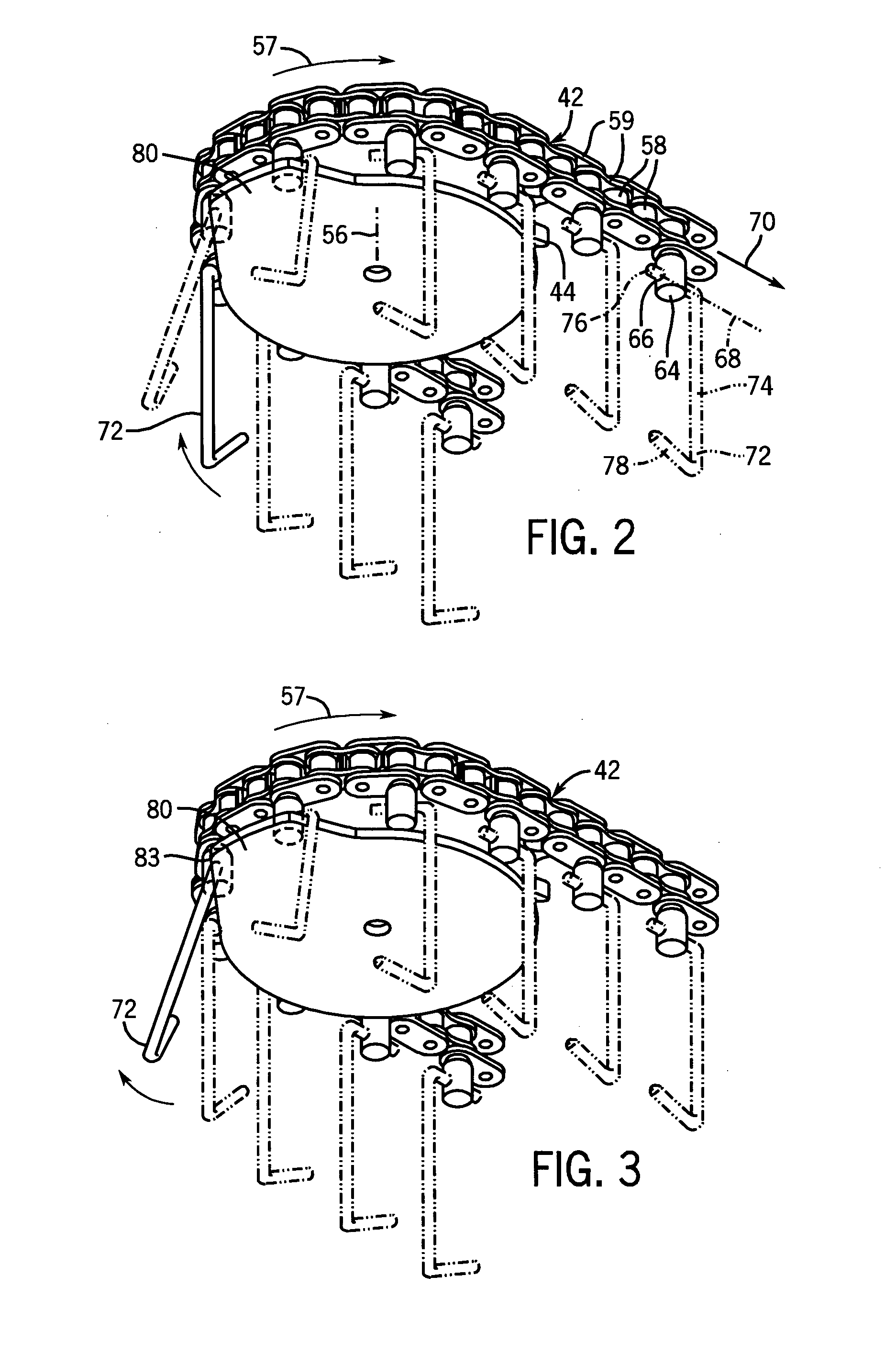

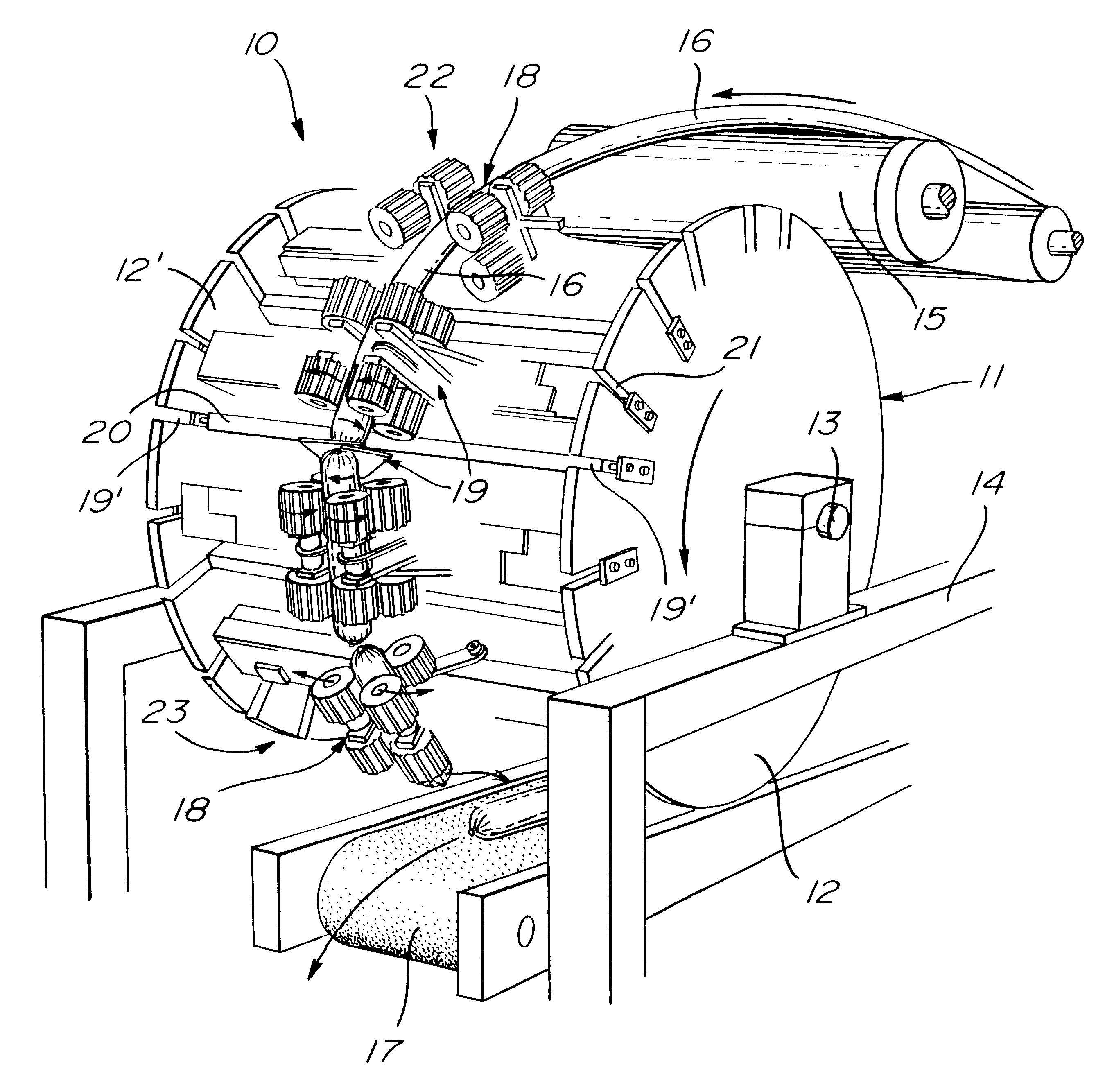

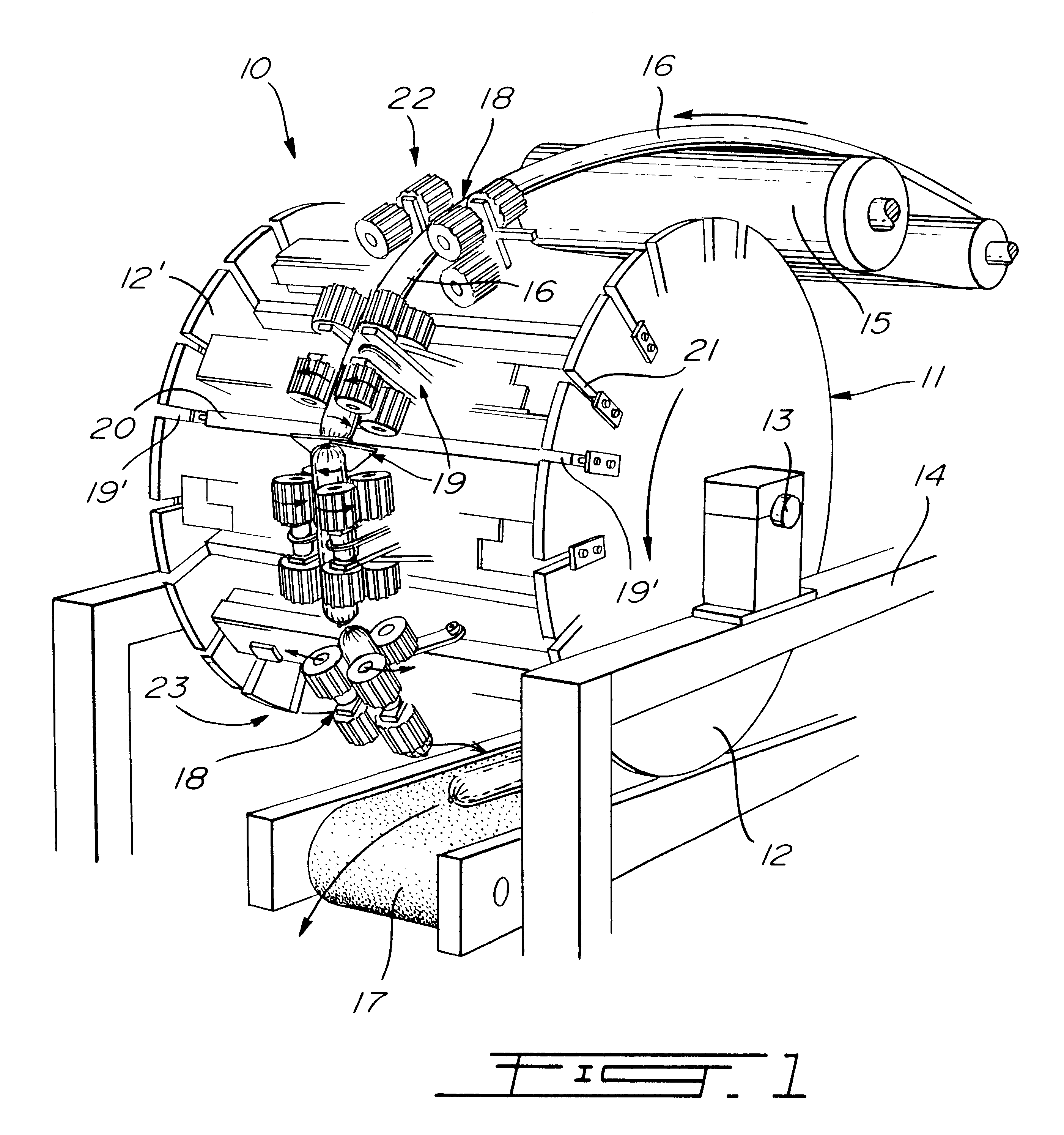

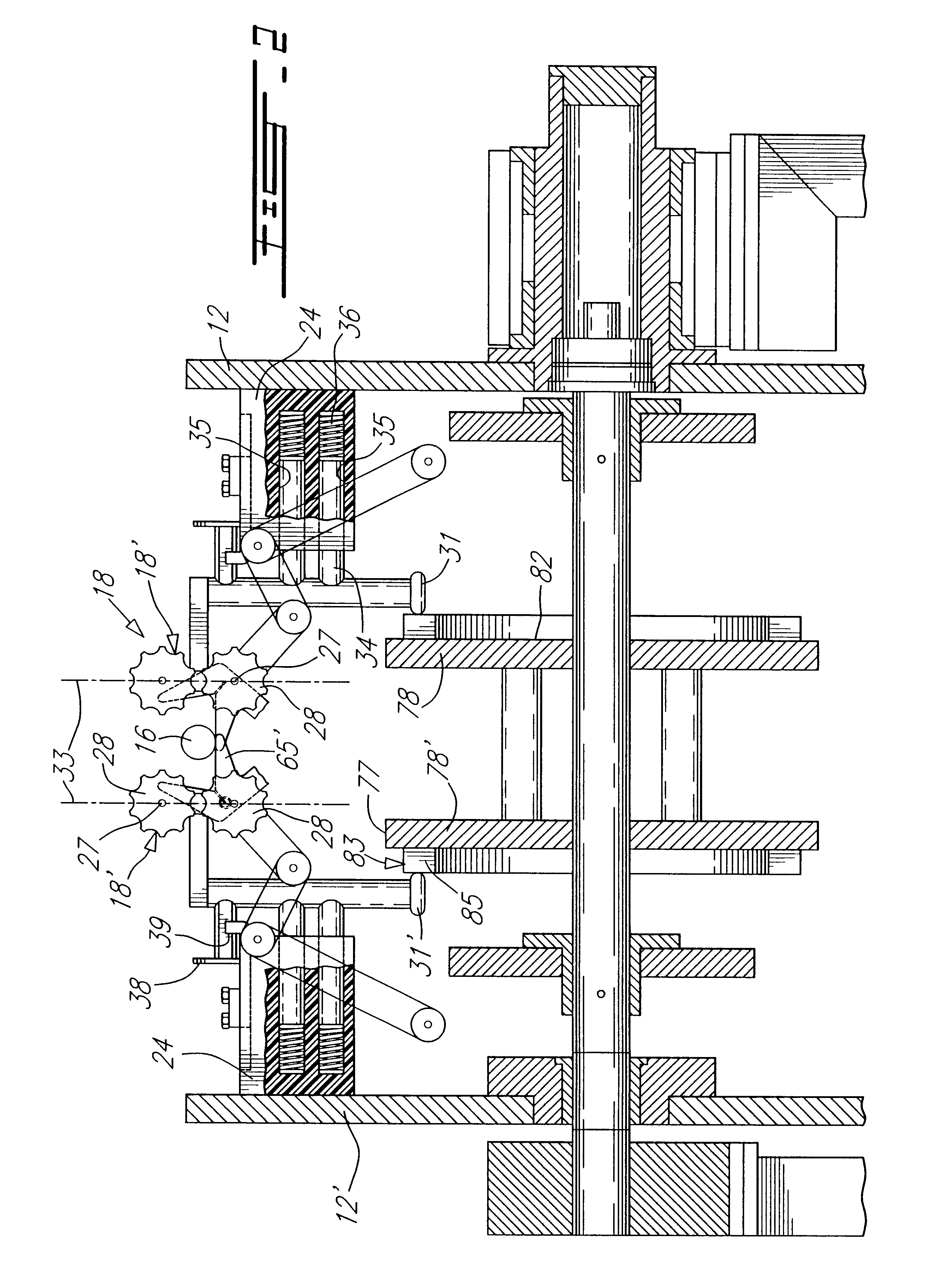

Sausage link forming machine

InactiveUS6468144B1Overcome disadvantagesNeed can be providedSausage filling/stuffing machinesSausage twisting/linking machinesEngineeringCam

A sausage link forming machine having a rotating frame secured on a drivable axle and wherein the frame has opposed parallel discs. Control cams are secured to the axle intermediate the discs. A plurality of sausage grasping head assemblies are secured between the discs and equidistantly spaced apart along a circular path. A link forming pincer mechanism is secured between each of the grasping head assemblies. These head assemblies have rotatable support rollers which are displaceable towards one another from a sausage casing receiving position to a sausage casing engaging position. A first cam follower is associated with each of the grasping head assemblies and engages a first cam portion of the control cam to displace the support rollers. A second cam follower is associated with each of the link forming pincer mechanisms and engages a second cam portion to cause the fork members to pivot to and away from one another. The support rollers are axially rotated and the forks grasp and compress a portion of the elongated sausage casing to form a sausage link twisted connection between adjacent ones of the grasping head assemblies in a portion of the rotating frame.

Owner:D M P IND

Automatic displacer clearance adjustment

ActiveUS8696414B2Improve productivityReduce risk of damagePaper/cardboard wound articlesSausage twisting/linking machinesFilling materialsEngineering

Owner:POLY CLIP SYST

Clipping Machine with Secured Access to the Clipping Region

ActiveUS20200329721A1Prevent openingLow bending stiffnessHorizontally conveying sausagesWrapper twisting/gatheringEngineeringStructural engineering

The present invention relates to a clipping machine for producing sausage-shaped products, like sausages, containing a flowable filling material in a tubular or bag-shaped packaging casing, the machine comprising filling means configured to feed filling material into the casing, and further comprises closing means arranged downstream the filling means, for closing the casing in a closing region. A housing is provided, enclosing at least the closing region, comprising at least a front wall and a first side wall, wherein the front wall is arranged at least substantially parallel to a longitudinally extending axis of the filling means, and further comprises an opening which can be closed by a movable door element, movable between an open position, allowing access to the closing region and a closed position, covering and blocking access to the closing region. The side wall faces the filling means and further comprises a movable housing element, movable between at least an open position and a closed position, wherein the movable housing element comprises an opening for passing through the sausage-shaped products, and wherein the movable housing element enables access from a side of the first side wall to the closing region when in the open position; and wherein the movable housing element covers and blocks access to the closing region when in the closed position.

Owner:POLY CLIP SYST

Portion pack with a suspension loop and method and device for attaching it

ActiveUS20080207104A1Reduce frictional contactIncrease volumeMeat/sausage hanging-upSausage skin tying apparatusEngineeringTwist knot

Owner:POLY CLIP SYST

Device and method for parting sausage chains

ActiveUS20110223846A1Increase speedReduced first speedLinked sausage separationSausage twisting/linking machinesTransport engineering

Owner:ALBERT HANDTMANN MASCHFABRICK

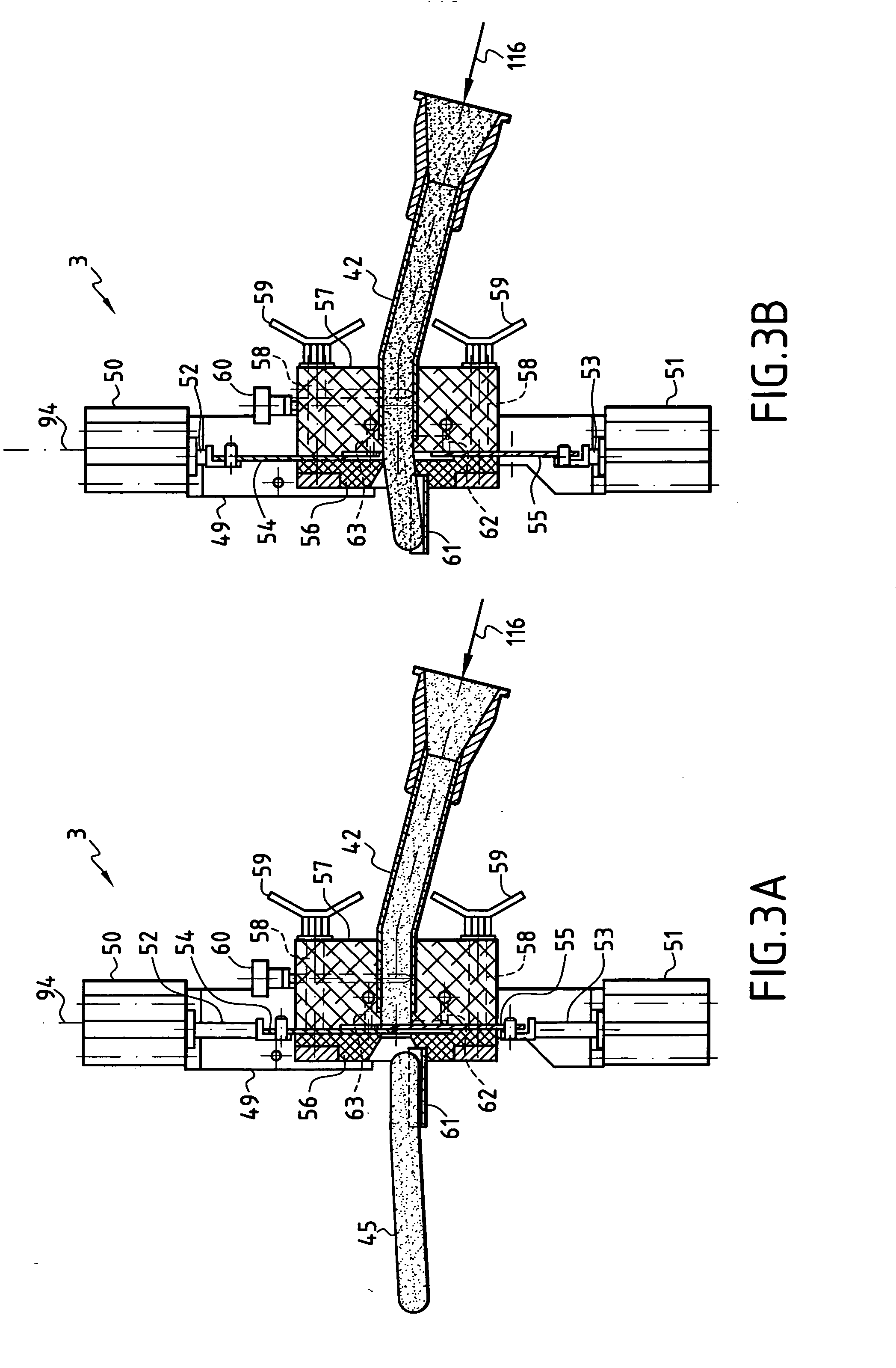

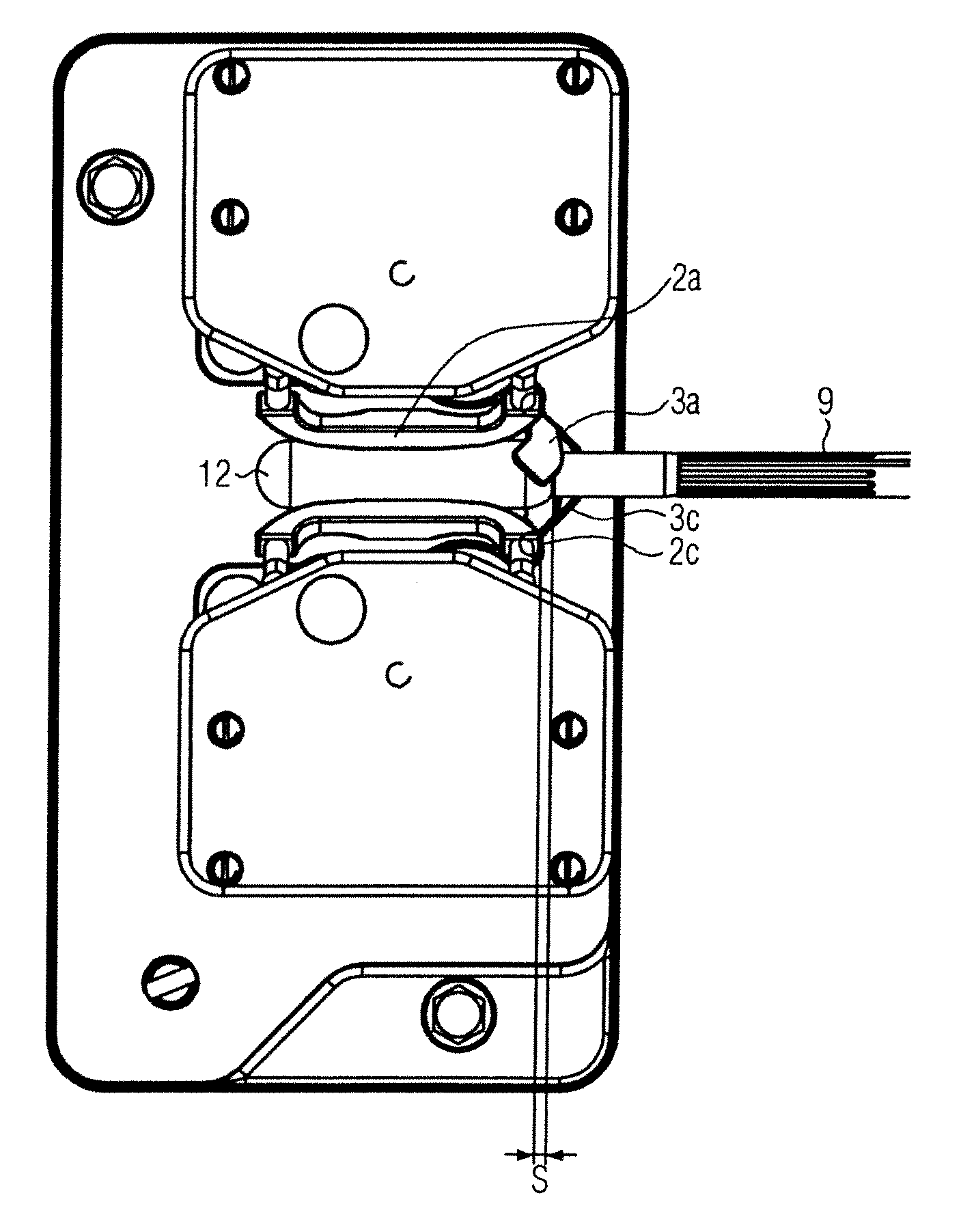

Apparatus and method for a sausage-casing-sensitive division of stuffed sausage strands

ActiveUS20100190425A1Raise the ratioImprove guidanceSausage skin tying apparatusSausage filling/stuffing machinesEngineeringCase Sensitive

An apparatus for a sausage-casing-sensitive division of stuffed sausage strands, having at least one pair of dividing elements for dividing the stuffed sausage strand and at least two guide elements between which the stuffed sausage strand is conveyed in the conveying direction. The distance between the guide elements can be adjusted in dependence upon the sausage caliber.

Owner:ALBERT HANDTMANN MASCHFABRICK

Portion pack with a suspension loop and method and device for attaching it

ActiveUS7648411B2Increase volumeReduce pressureMeat/sausage hanging-upSausage skin tying apparatusEngineeringTwist knot

Owner:POLY CLIP SYST

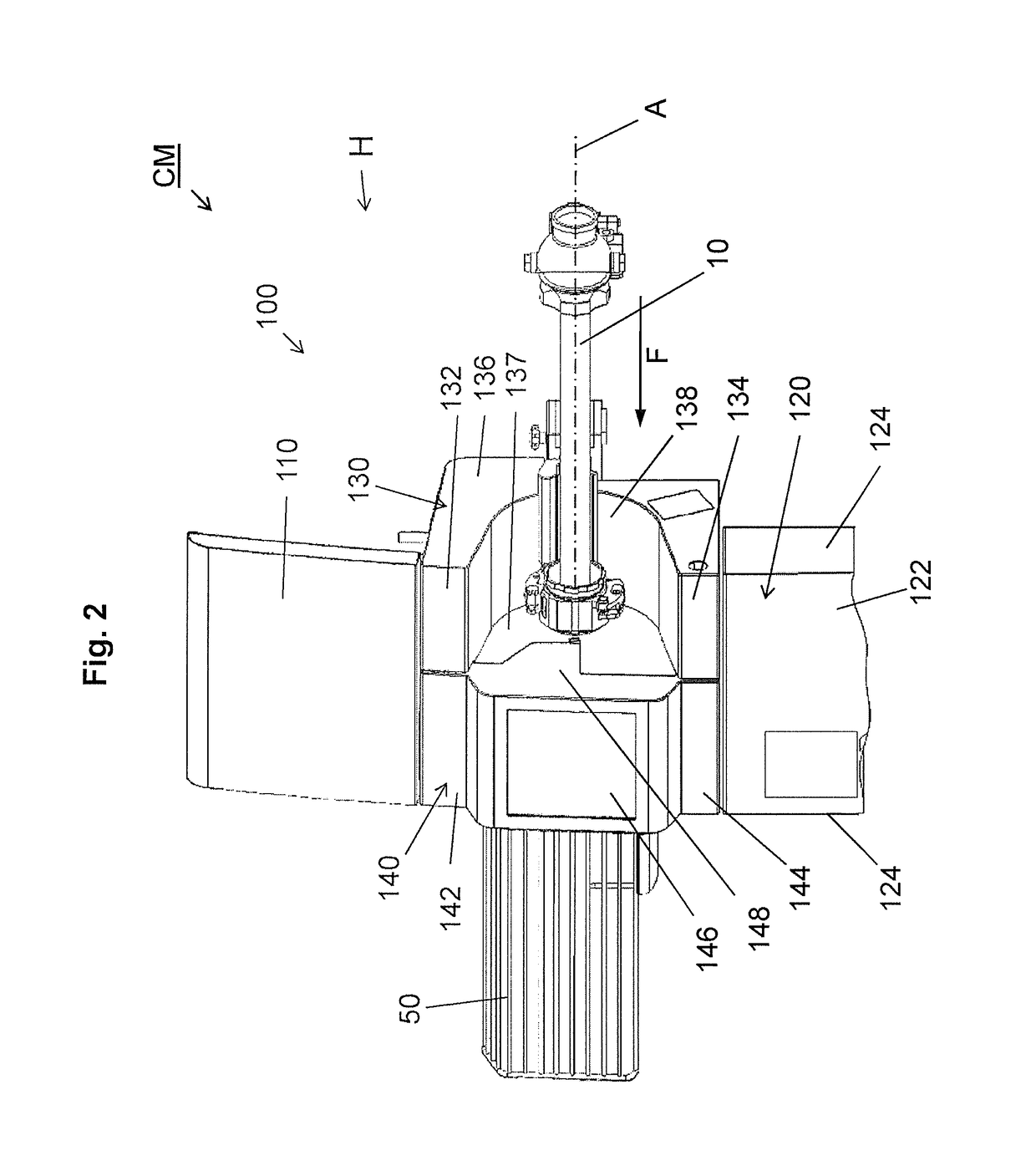

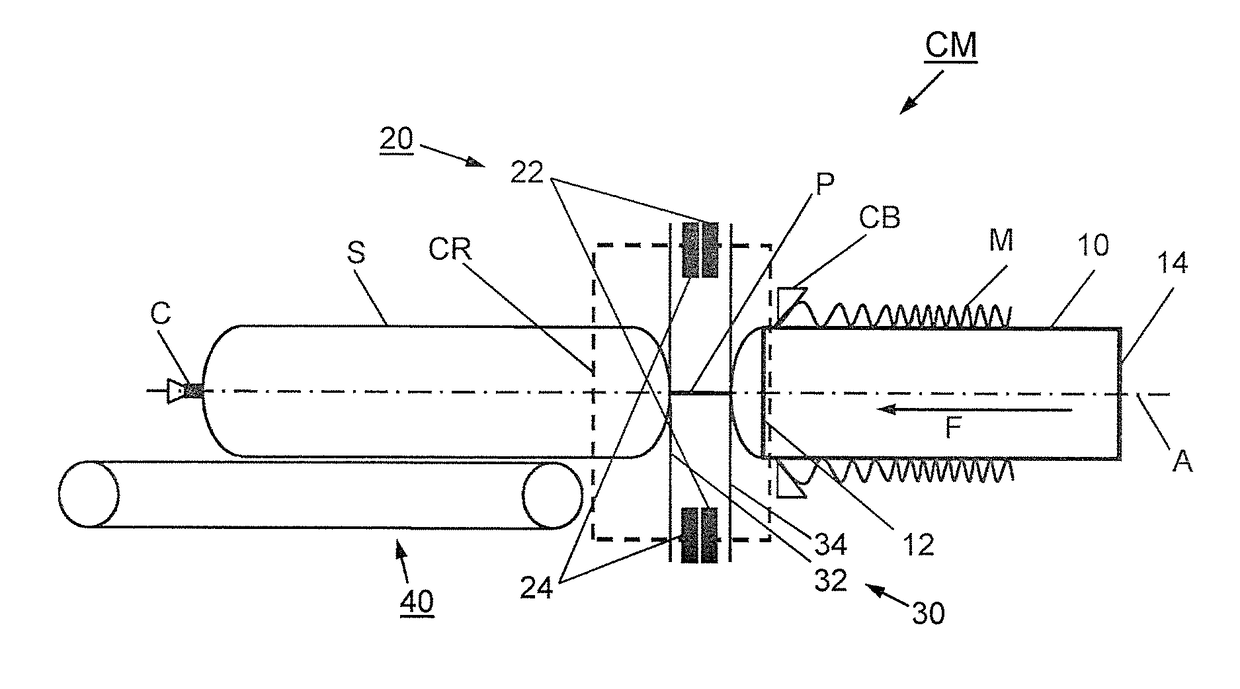

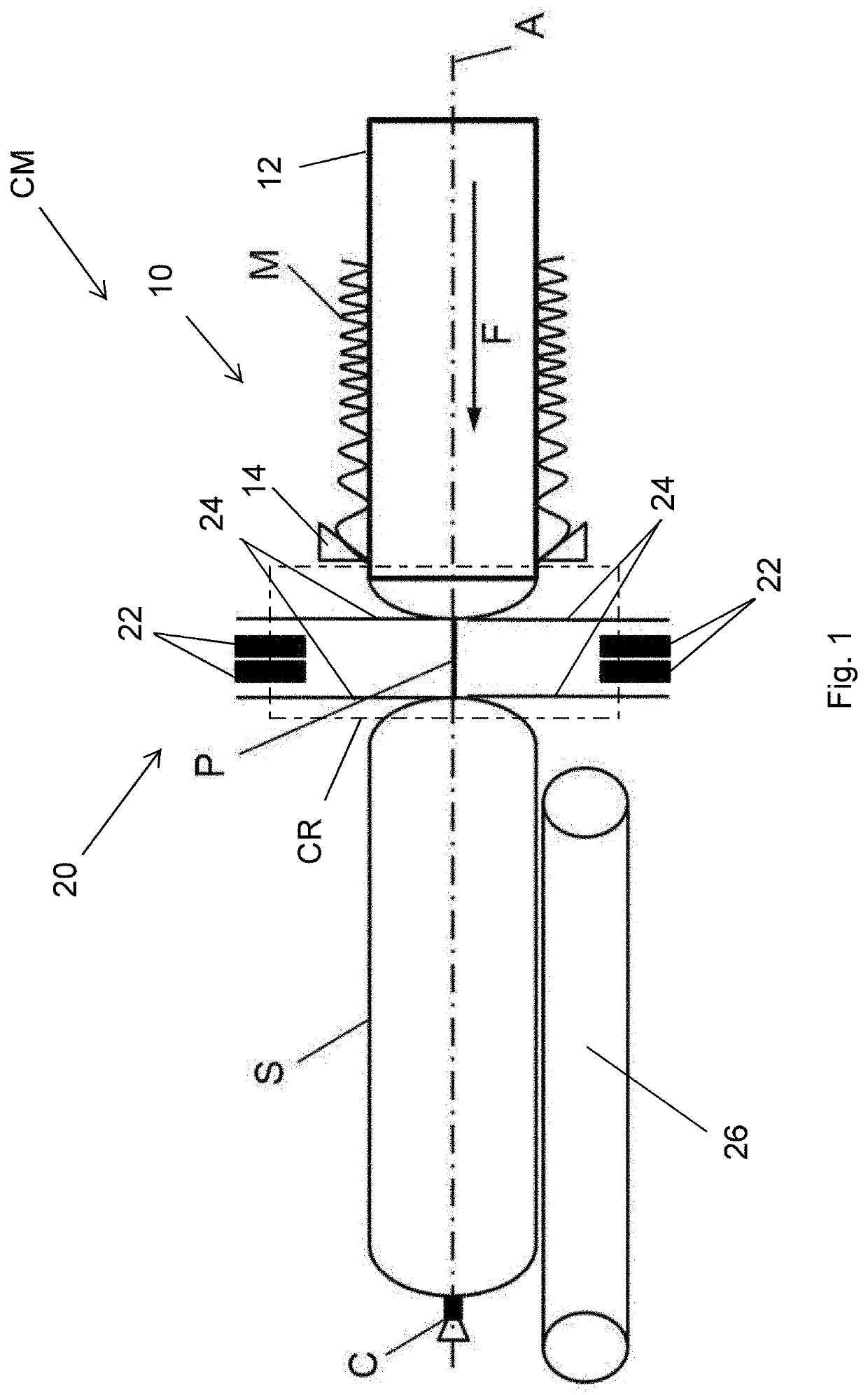

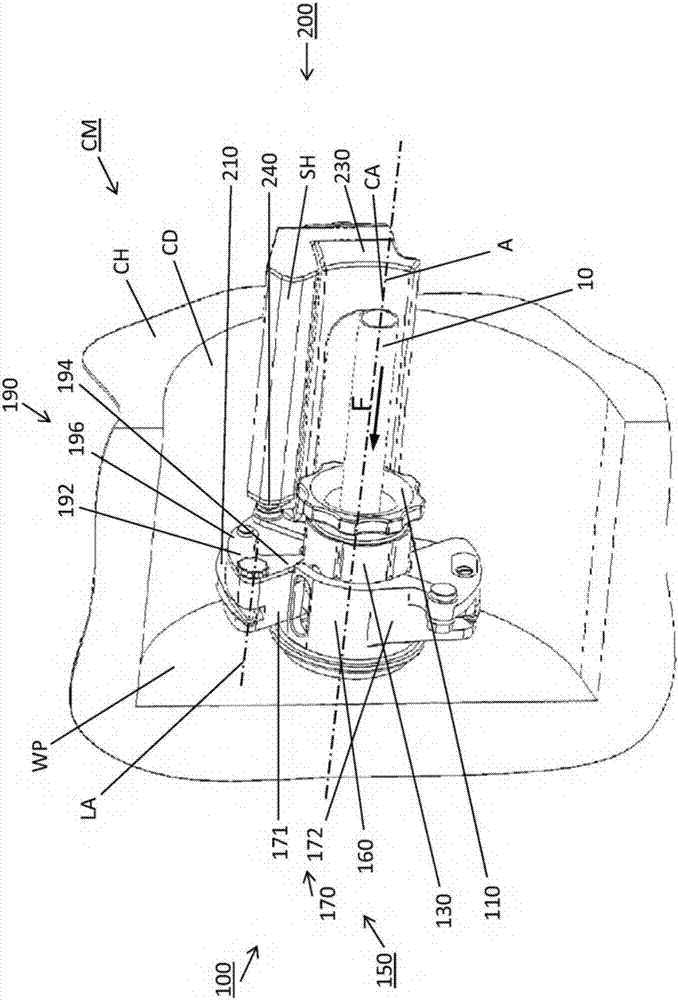

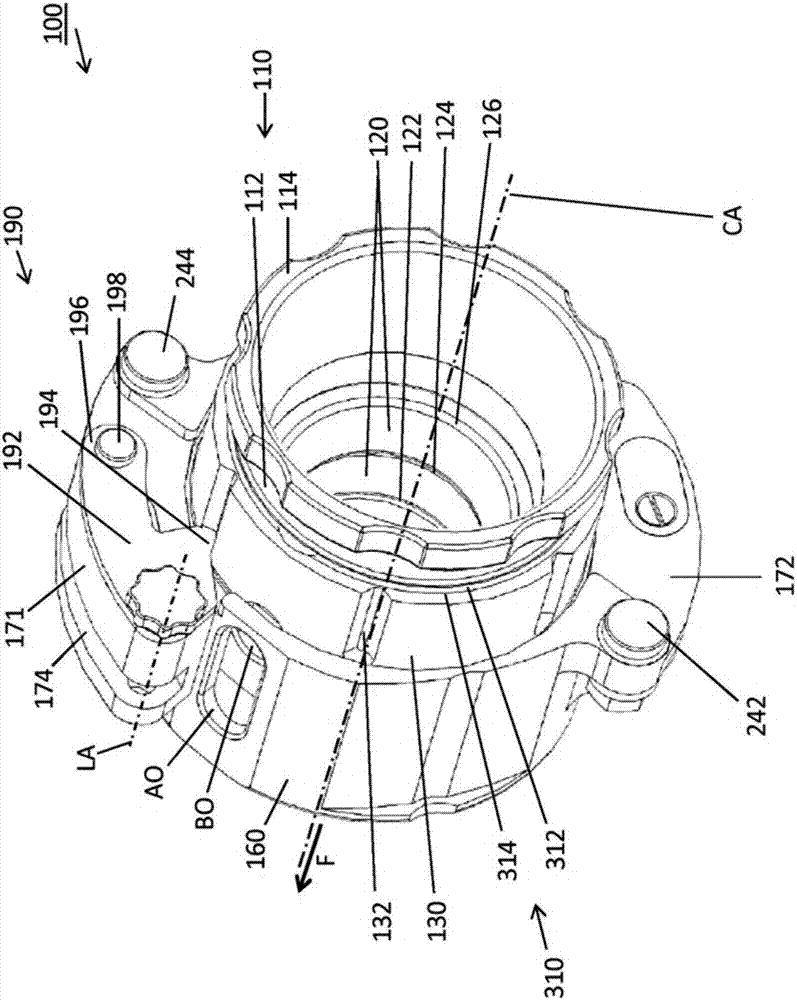

Casing brake assembly

ActiveCN106900822AHorizontally conveying sausagesSausage skin tying apparatusFriction forceBiomedical engineering

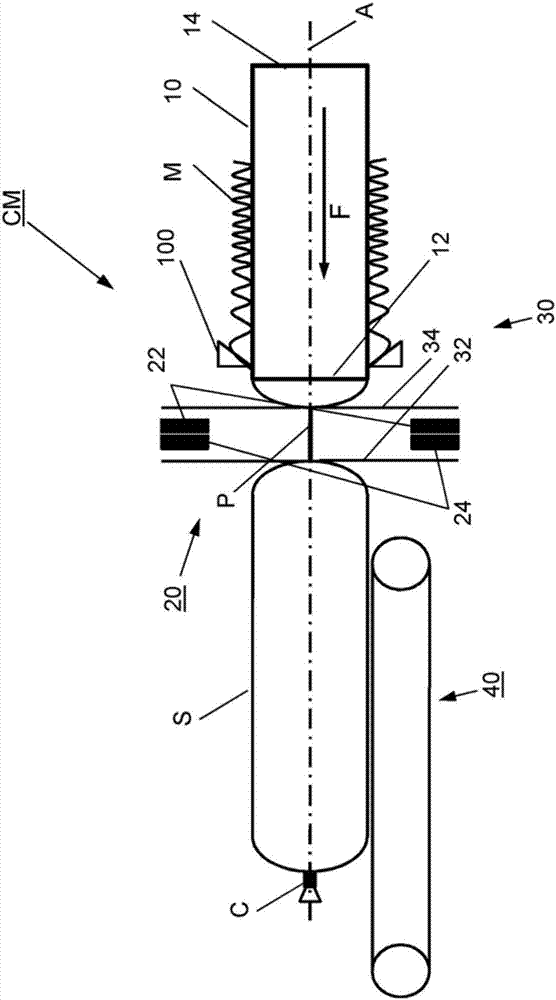

A casing brake assembly (100) is provided for applying a frictional force to a tubular casing being arranged on a filling tube (10) of a production apparatus (CM), which is used in the production of sausage-shaped products (S) and for limiting the movement of said tubular casing. The casing brake assembly (100) comprises tubular support means (110) for supporting at least one brake element having an at least approximately ring-shaped design. The casing brake assembly (100) further comprises a tubular bushing (130) for accommodating the tubular support means (110) and the brake element, and an attachment device (150) including a tubular accommodation portion (160) for accommodating the tubular bushing (130), and at least one attachment portion (170) configured for attaching the casing brake assembly (100) to the production apparatus (CM).

Owner:POLY CLIP SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com