Chuck for meat encasing machines

a technology of meat encasing machine and chuck, which is applied in the directions of sausage twisting/linking machine, application, butchering, etc., can solve problems such as casing ruptur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

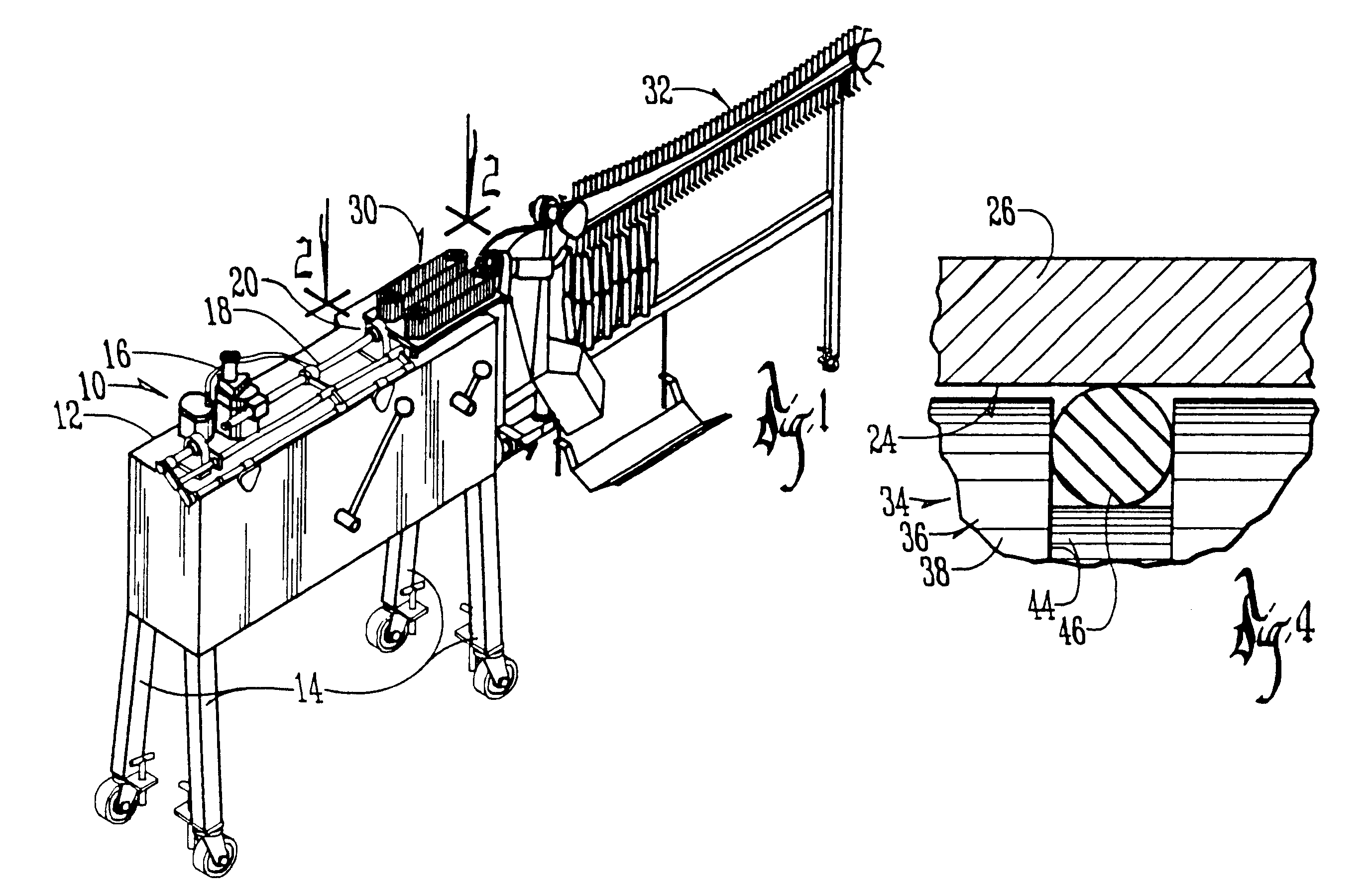

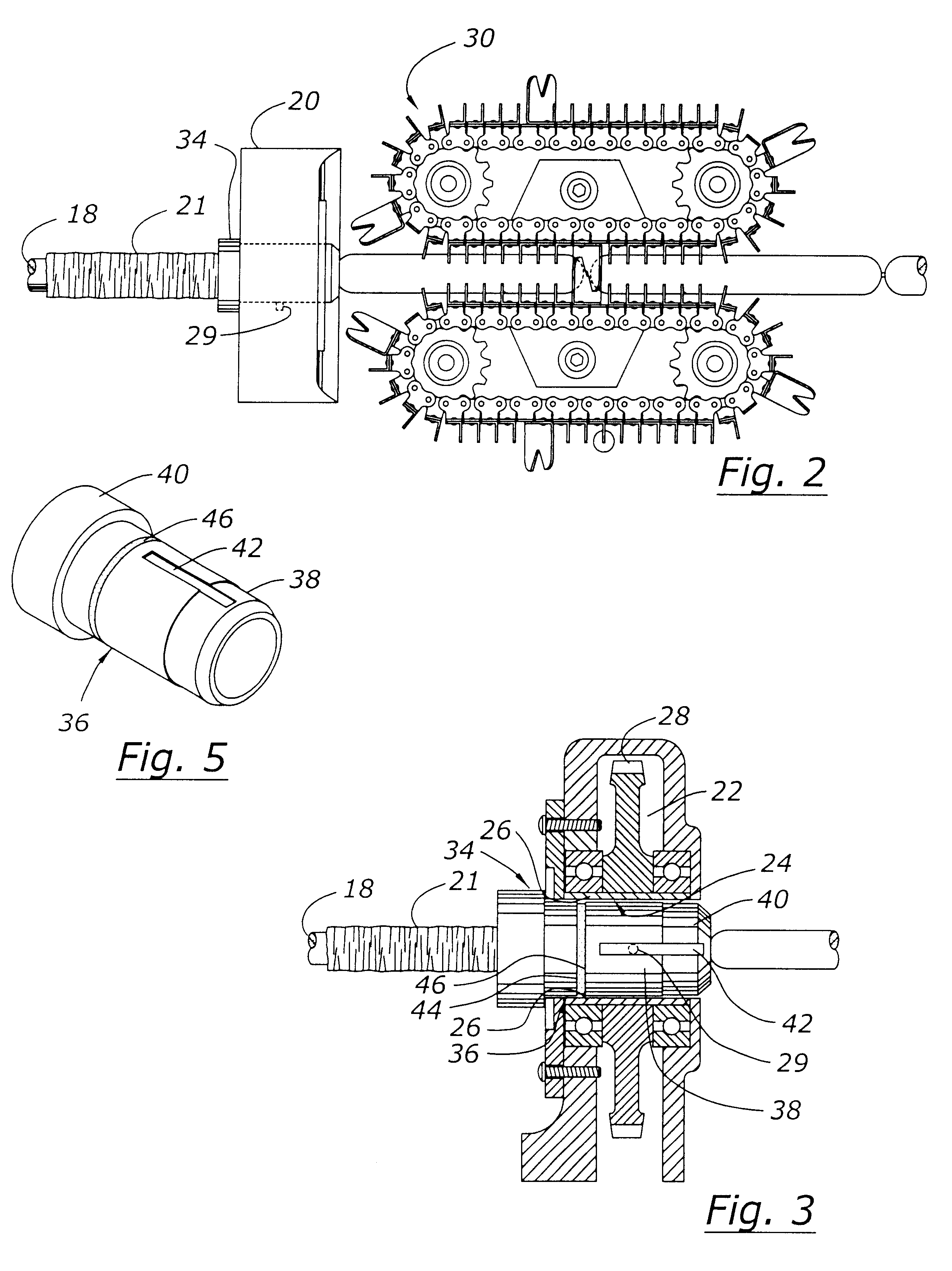

The conventional machine 10 in FIG. 1 has a frame 12 and supporting legs 14. A meat emulsion pump 16 is mounted on the top of frame 12 and is connected to a conventional elongated stuffing horn 18.

A drive housing 20 is mounted on the top of frame 12 and receives the discharge end of stuffing horn 18. A conventional shirred (telescopically compressed) casing 21 is mounted on stuffing horn 18.

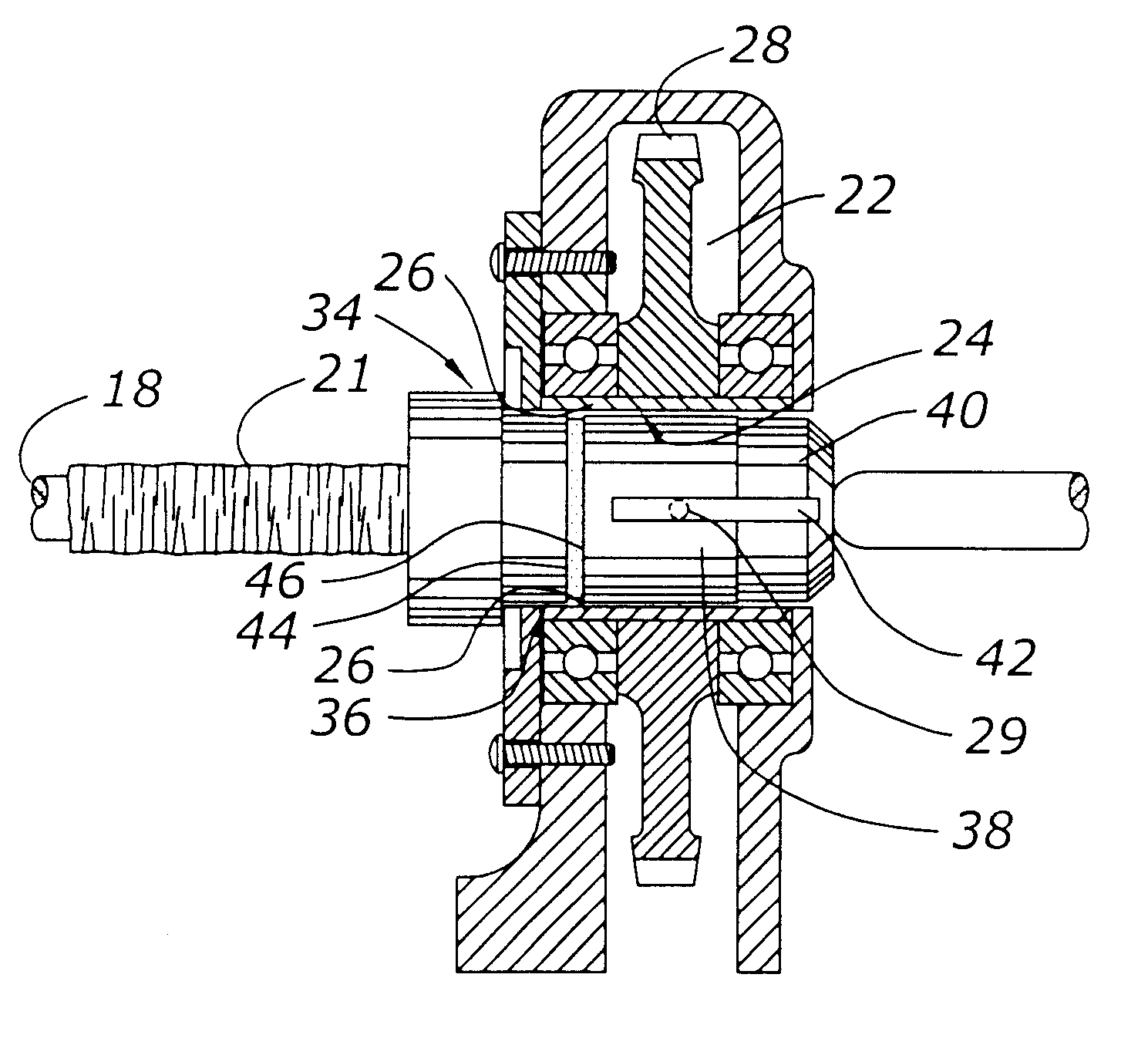

Drive housing 20 has a hollow interior compartment 22 and a hollow bore 24 extending therethrough. A bearing sleeve or socket 26 is mounted within housing 20 and is adapted to be rotatably driven by drive gear 28 which is connected to a source of rotational power (not shown). A drive pin 29 shown in dotted lines in FIGS. 2 and 3 extends inwardly from bearing sleeve 26 to engage and drive the chuck of this invention as will be described hereafter.

A conventional linking mechanism 30 is mounted on the top of frame 12 downstream from the discharge end of stuffing horn 18. Similarly, a conventional co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com