Apparaus and method for producing paste material and extrusion head separately used for the apparatus and method

A paste-like material, extrusion head technology, applied in application, food science, sausage rolling machine, etc., can solve problems such as large space and achieve the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

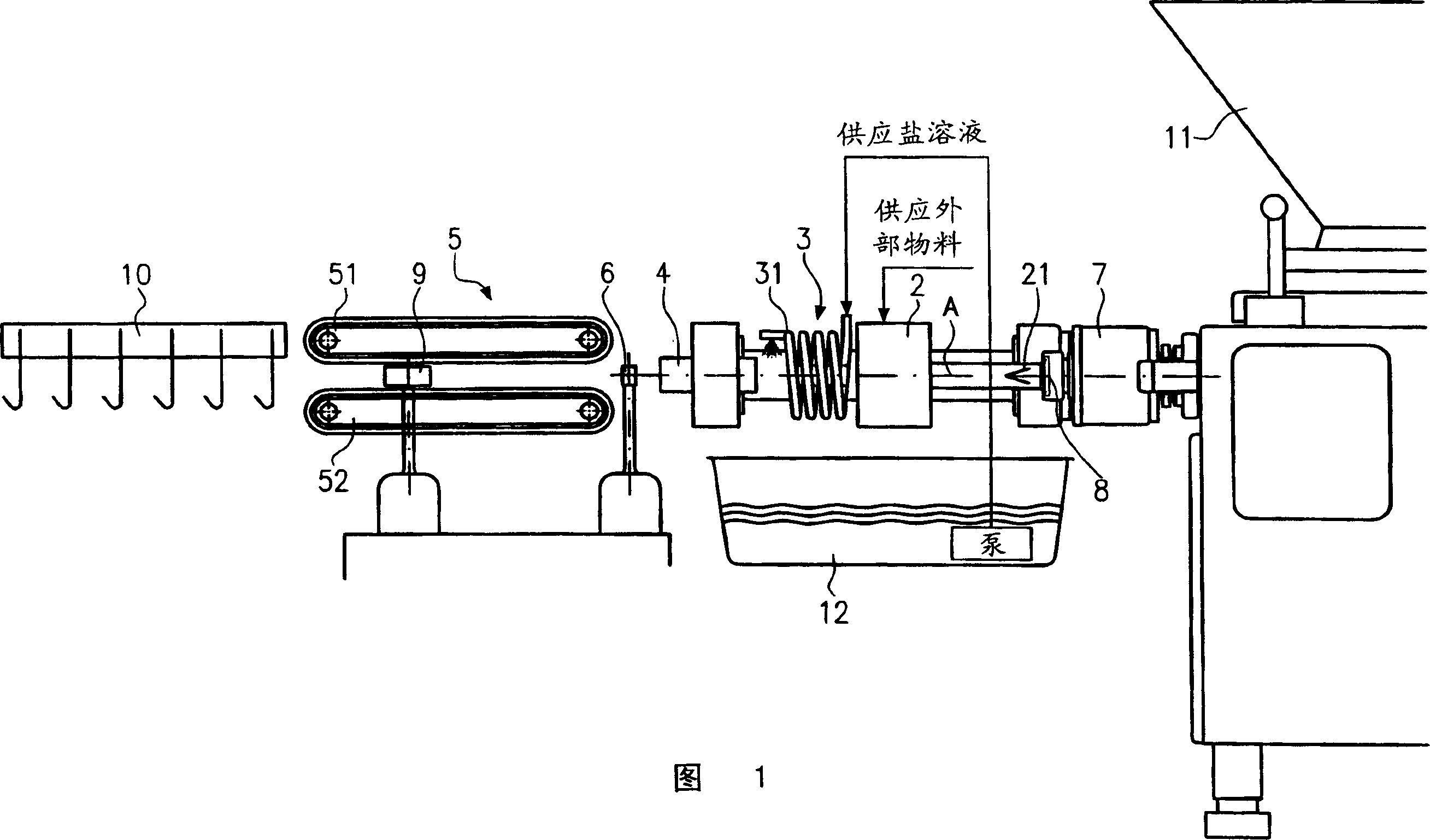

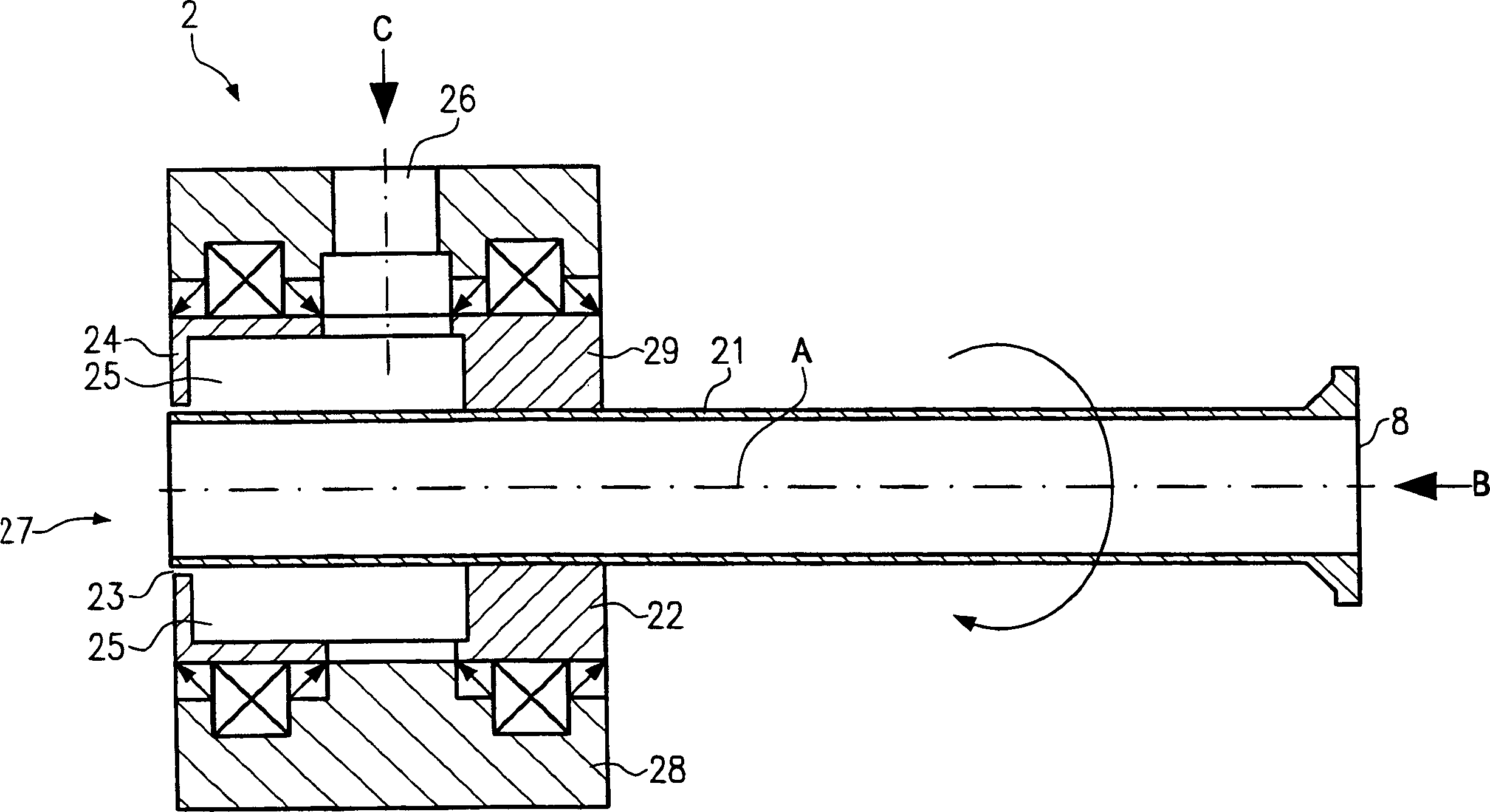

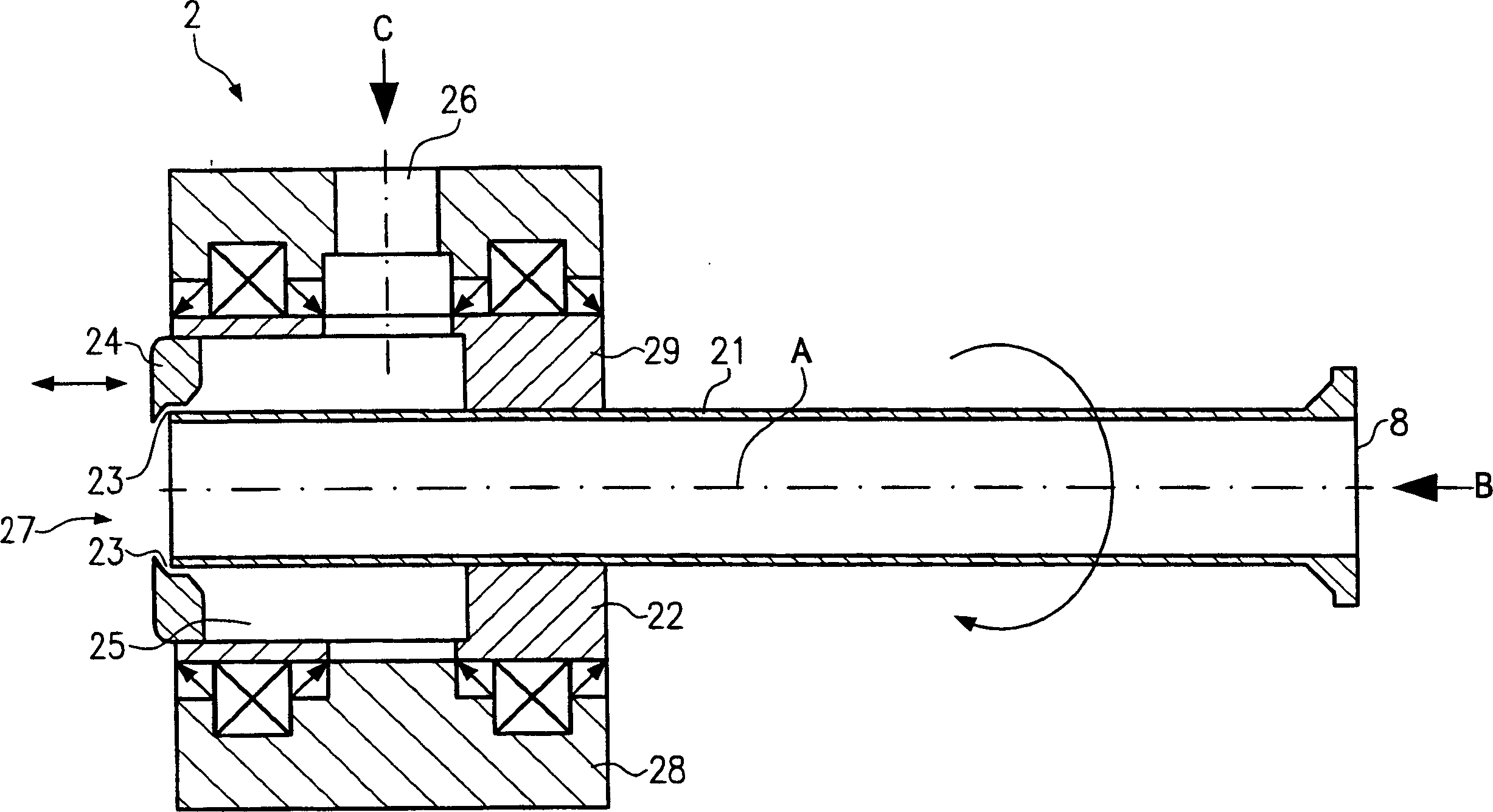

[0050] As shown in FIG. 1 , the device comprises a reservoir 11 through which a pasty substance, such as sausage meat, is conveyed to a filling tube 21 . The sausage meat is introduced under pressure into the filling tube 21 through the opening 8 and conveyed to the extrusion head 2, which can also be Figure 2a shown in the cross-sectional diagram. The extrusion head 2 is connected to a supply 26 for a foreign substance such as casing material.

[0051] For co-extrusion, the sausage meat is fed as an internal mass via the filling tube 21 to the extrusion head 2 in the direction of arrow B, while the casing material is fed to the extrusion head 2 in the direction of arrow C via the supply 26 . This is shown in particular in FIG. 2 .

[0052] As can further be seen in FIG. 1 , the coextruded sausage strand emerging from the extrusion head 2 passes through an annular spray head 31 which is part of the curing device 3 and which is arranged downstream of the extrusion head 2 . T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com