Process and machine for making clipless chub package contaning viscous product

A product packaging, clip-free technology, applied in the direction of packaging, shipping packaging, shipping and packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

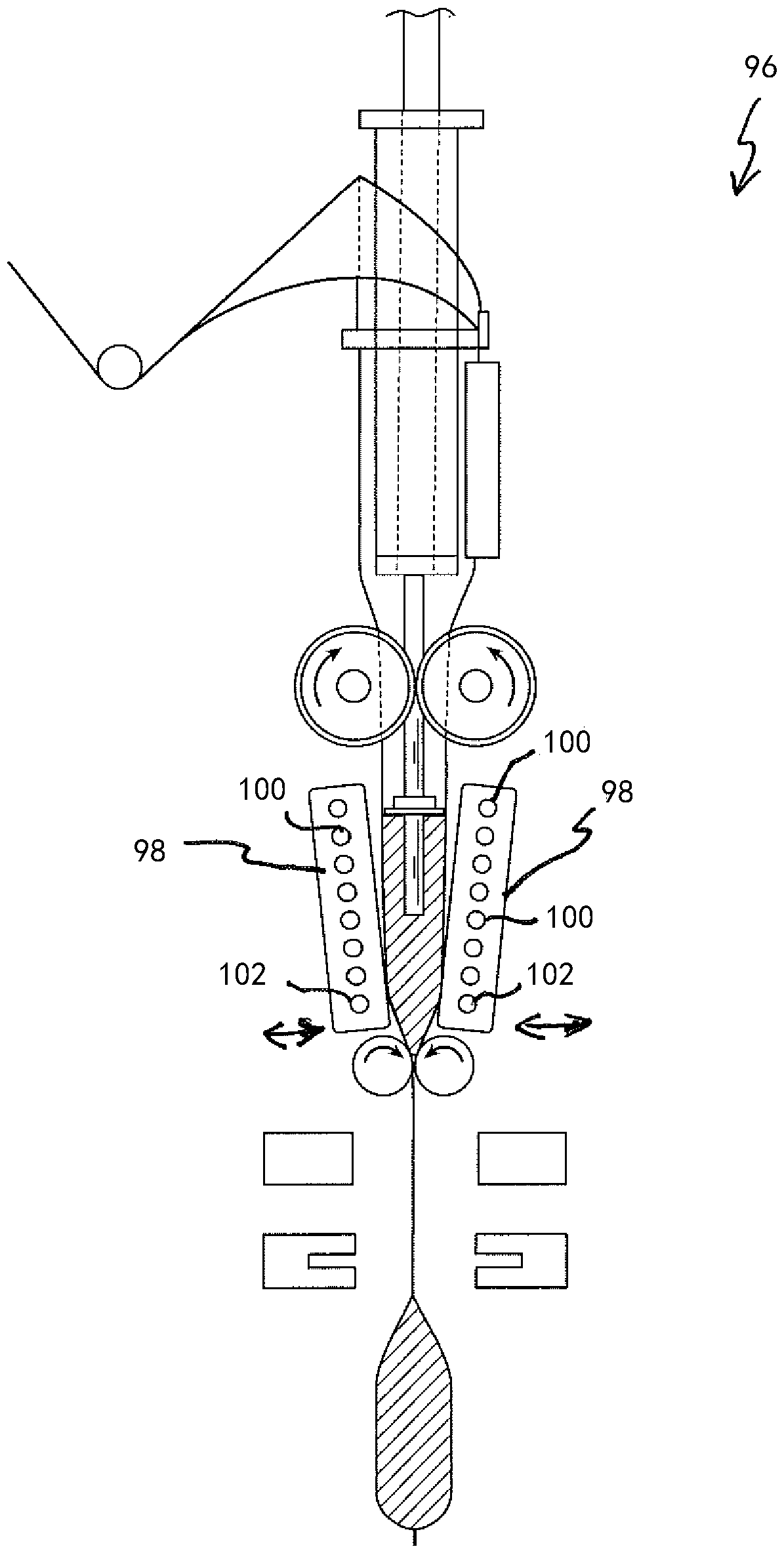

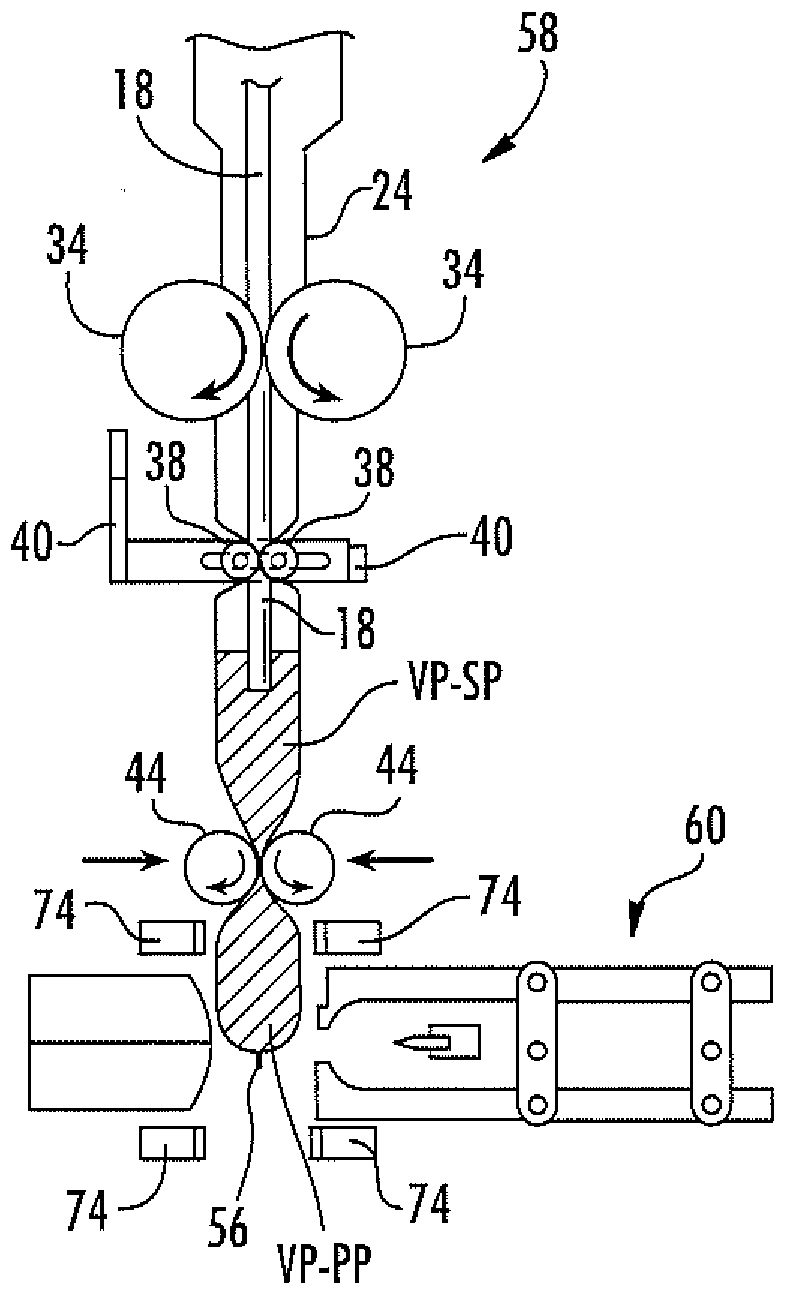

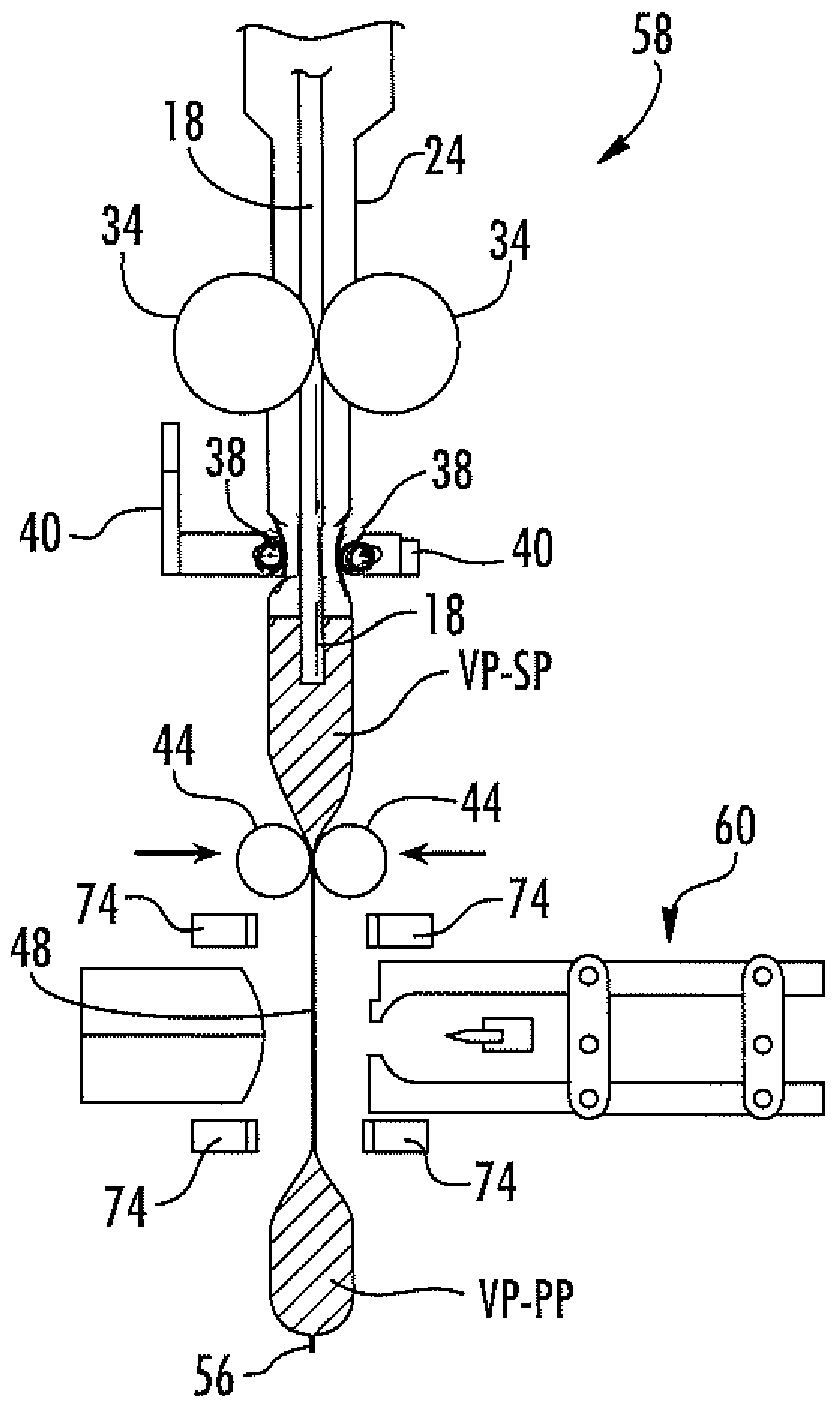

Image

Examples

Embodiment Construction

[0042] As used herein, the terms roller and wheel are used interchangeably. Both can be rotated. In an embodiment, the roller may have an axial length that is at least as long as its diameter. In an embodiment, the wheel may have an axial length of from 1% to 50% of its diameter.

[0043] As used herein, the expression "nipping relationship" refers to a wheel and roller that are in direct contact with each other at a contact location, or when the roller or wheel is in contact with the same item in between (such as a film or film tube) or Indirect contact with each other while in direct contact with a group of items between which they are in contact, such that the item(s) move as the rollers or wheels rotate together when in nip relationship. The rotation of the rollers and wheels in nip relationship is used to transfer the item(s) between the rollers or wheels. Power can be provided to one or both of the rollers or wheels in rolling relationship.

[0044] As used herein, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com