Production line for continuously cutting off and packing meat sausages

A production line and sausage technology, applied in the field of food processing, to improve work efficiency, save manpower, and maintain consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to illustrate the technical features of the solution more clearly, the solution will be described below through specific implementation modes.

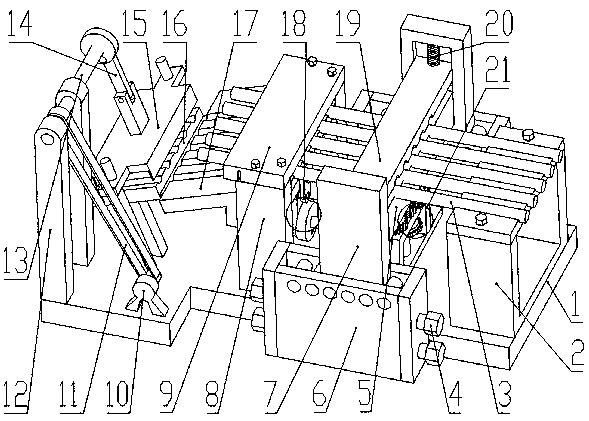

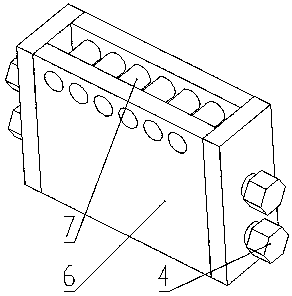

[0044] refer to figure 1 , a production line for continuous cutting and packaging of meat sausages, including a base plate 1, and a first support plate 2 fixedly arranged on the upper end surface of the base plate 1 and supporting the movement of the meat sausage 3, arranged on the front side of the first support plate 2 and capable of A cutting device for cutting sausage and a packaging device for packaging the cut sausage;

[0045] The cutting device includes a clamping mechanism for clamping the sausage forward, a driving mechanism for driving the clamping mechanism, and a cutting mechanism driven by the driving mechanism and capable of cutting the sausage;

[0046] The cutting mechanism is connected to the packaging device.

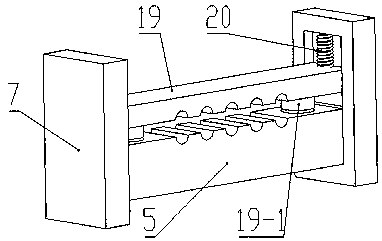

[0047] refer to figure 2 The clamping mechanism includes two sliding vertical plates 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com