Degumming technology for aqueous solution of methanesulfonic acid

A technology of methanesulfonic acid and aqueous solution, which is applied in the direction of sustainable manufacturing/processing, cleaning methods using liquids, electrical components, etc., can solve the problems of high cost, irritating odor, and high cost of degumming, and achieve low cost and detachment The effect of fully and shortening the degumming time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

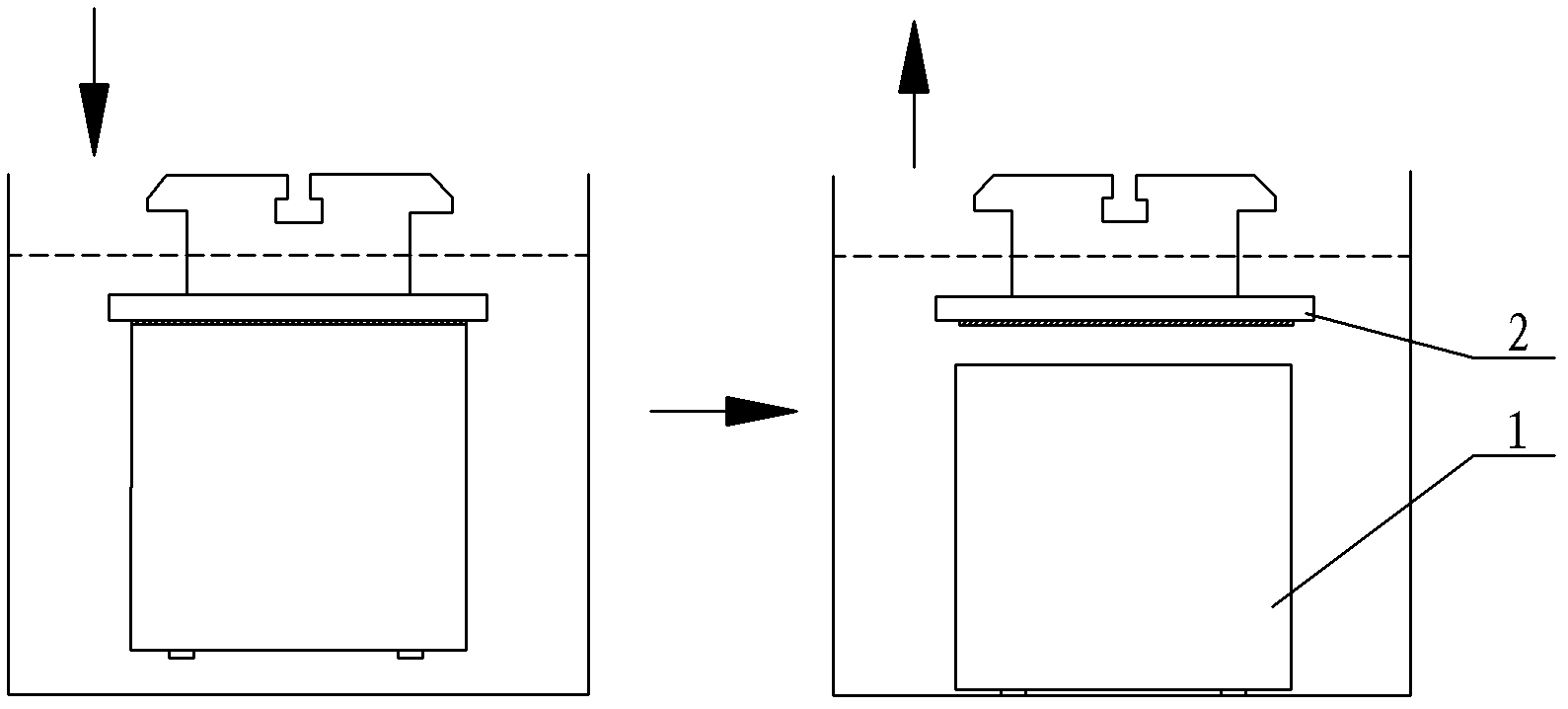

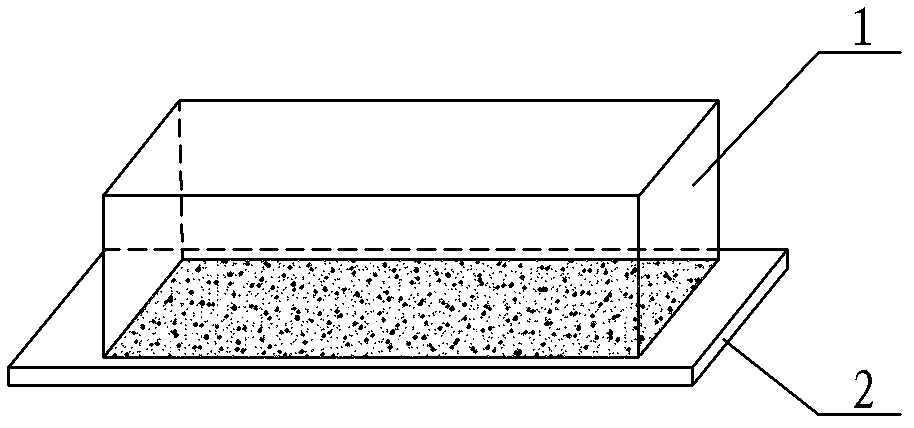

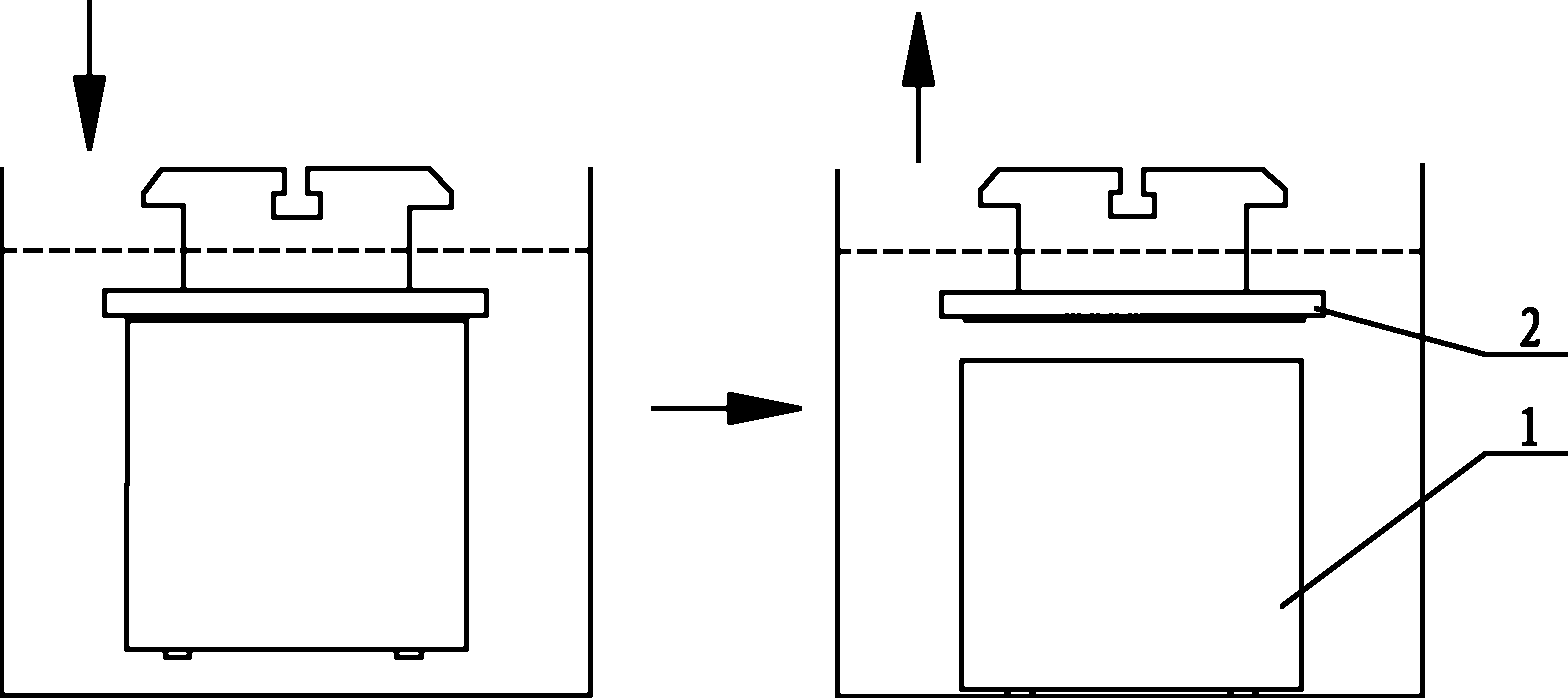

[0017] Such as Figure 1~2 As shown, in Example 1, the methanesulfonic acid aqueous solution degumming process of the present invention includes the following steps: a. Add a certain amount of water to the acid soak tank of the degumming machine, set the heating temperature to 60°C, and turn on Switch for heating; b. Add a certain amount of methanesulfonic acid with a concentration of 1% into the acid immersion tank of the degumming machine; c. Put the washed and ultrasonically washed silicon wafer 1 and the cutting substrate 2 into the acid immersion tank Soak in medium for 300 seconds; d. Lift the substrate 2 with a special tool, and remove a small amount of silicon wafers 1 that have not fallen off. The percentage of silicon wafers 1 falling off is greater than 90%.

[0018] In Example 2, the methanesulfonic acid aqueous solution degumming process of the present invention includes the following steps: a. Add a certain amount of water to the acid soak tank of the degumming mach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com