Material bag air-washing system

A material bag, air washing technology, applied in the directions of dissolving, mixer, chemical instruments and methods, etc., can solve the problems of high equipment maintenance and maintenance costs, small dosage, high investment costs and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

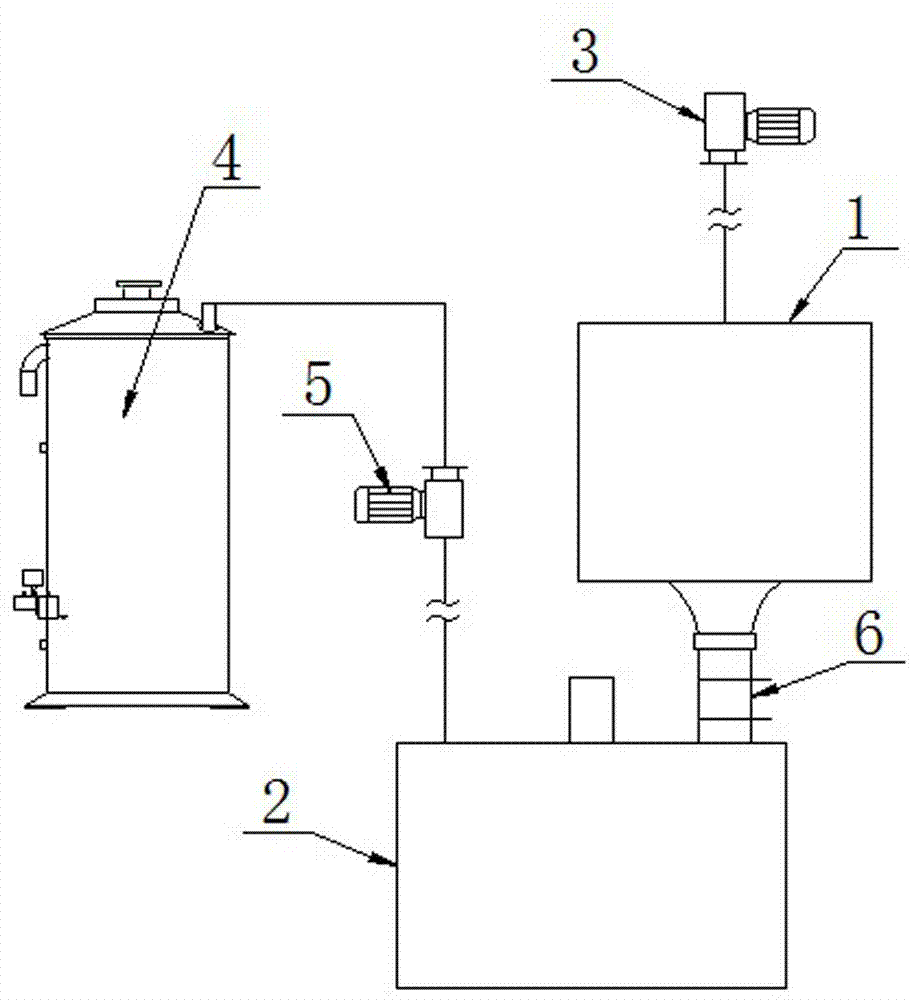

[0017] Embodiment: a kind of air-washing system for material package, comprising material package 1, mixing cylinder 2, air supply device 3 and dust collection device 4, described dust collection device is connected with air induction device 5, and described mixing cylinder has a device for adding The material inlet, the water inlet for adding water, and the liquid outlet for discharging the mixed liquid composed of water and materials, the upper opening of the material bag is connected with the air supply device, and the material bag The outlet at the lower end communicates with the mixing cylinder, and the mixing cylinder communicates with the dust collection device. When the material bag is discharged by the feeding device, in order to make the remaining material in the material bag out of the material bag, the outlet at the lower end of the material bag is connected with the mixing cylinder, and the air induction device and the air supply device are opened. The airflow gen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com