Method for producing dihydroxyacetone by using gluconobacter sp.

A technology of dihydroxyacetone and Gluconobacter, which is applied in the field of dihydroxyacetone produced by Gluconobacter CGMCC No.5146, which can solve the problems of prolonged production cycle, high separation cost, complicated process, etc., to reduce solvent consumption and environmental pollution, The effect of simplifying the process and shortening the process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

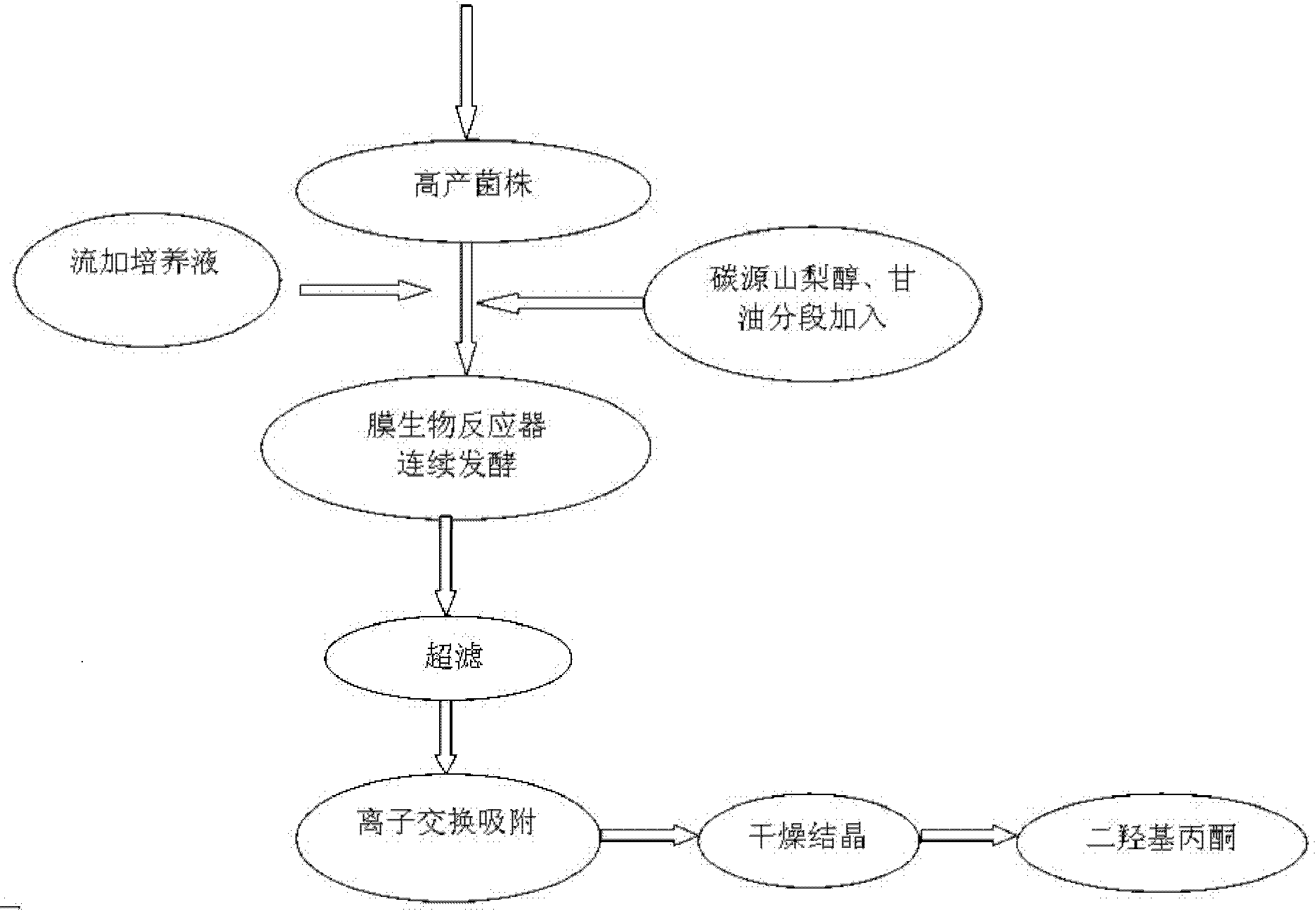

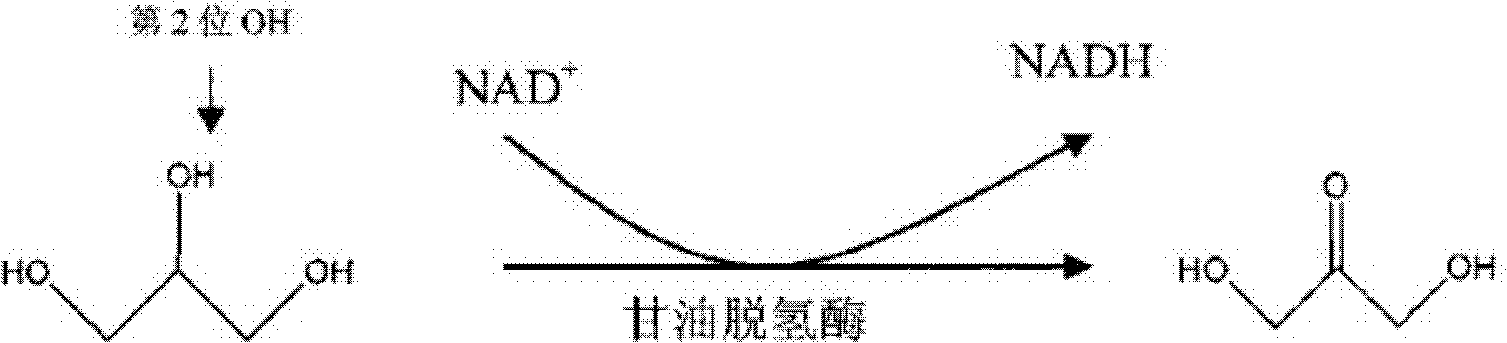

[0040] Gluconobacter sp. CGMCC No.5146 was cultured for initial fermentation using sorbitol as a substrate medium, the initial concentration of sorbitol was 30g / L, the fermentation temperature was 28°C, and pH 6.0. The bacteria begin to grow slowly. After the continuous fermentation reaches a stable period, continuous fermentation is carried out in the membrane bioreactor with the inner pressure membrane of the hollow fiber ultrafiltration membrane using glycerol as the substrate. During the continuous fermentation, the membrane bioreactor continuously draws out The product DHA without bacterial cells is supplemented with fresh medium at the same time, which reduces the inhibition of the fermentation process by the accumulation of high-concentration substrates in the fermenter, and makes the accumulation of DHA take place in a longer period of time. At the same time, the bacteria were not drawn out during the whole fermentation process, but the DHA product was still accumulated...

Embodiment 2

[0045] Gluconobacter sp. CGMCC No.5146 was cultured for initial fermentation using sorbitol as a substrate medium, the initial concentration of sorbitol was 30g / L, the fermentation temperature was 28°C, and pH 6.0. The bacteria begin to grow slowly. After the continuous fermentation reaches a stable period, continuous fermentation is carried out in the membrane bioreactor with the inner pressure membrane of the hollow fiber ultrafiltration membrane using glycerol as the substrate. During the continuous fermentation, the membrane bioreactor continuously draws out The product DHA without bacterial cells is supplemented with fresh medium at the same time, which reduces the inhibition of the fermentation process by the accumulation of high-concentration substrates in the fermenter, and makes the accumulation of DHA take place in a longer period of time. At the same time, the bacteria were not drawn out during the whole fermentation process, but the DHA product was still accumulated...

Embodiment 3

[0050] The other steps and conditions are the same, and 3 times of absolute ethanol is added during the purification of DHA to remove impurities. The conversion rate of glycerol reaches more than 90%, and the yield reaches more than 80%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com