Electric heating distiller

A water distiller and distilled water technology, applied in the direction of heating water/sewage treatment, etc., can solve the problems of high production cost, waste of energy, large output, etc., and achieve the effect of simple production, low production cost and full utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

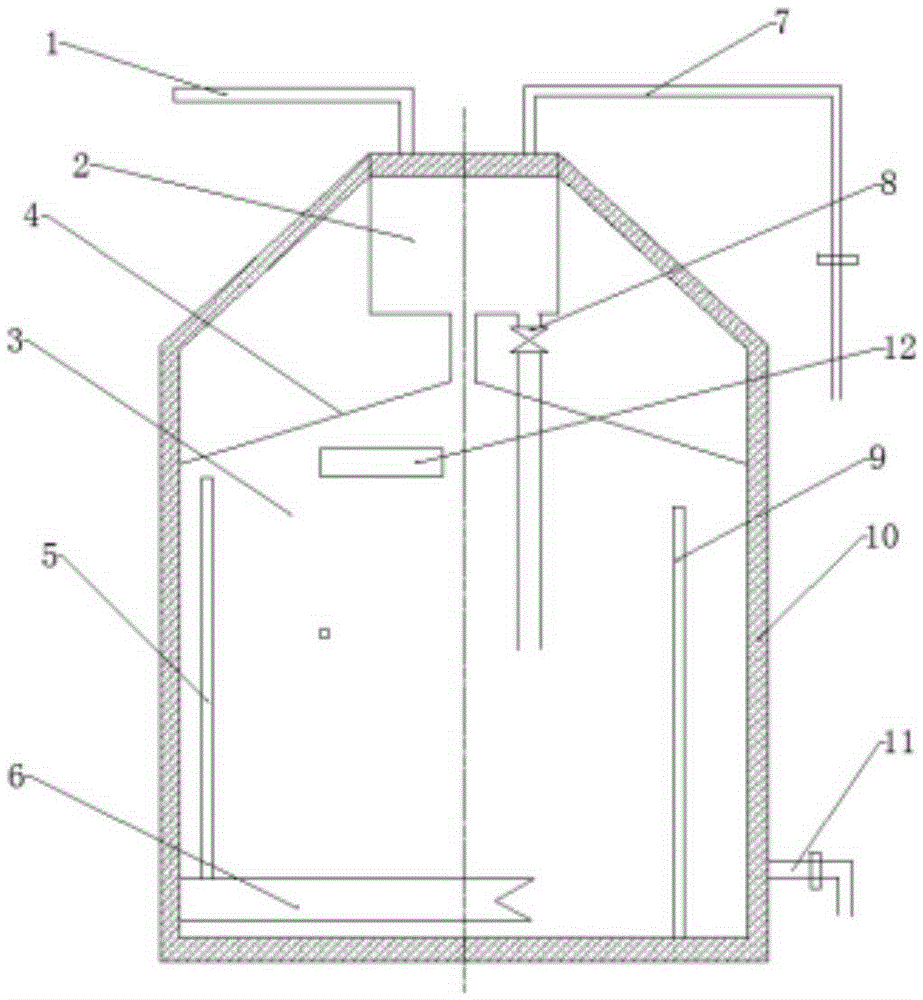

[0015] Below in conjunction with accompanying drawing, the present invention will be further described, as figure 1 As shown, the electric heating water distiller must check whether there is water in the heating chamber 3 before turning on the power, and the water cannot be higher than the upper limit of the water level sensor 9 or lower than the lower limit of the water level sensor, then turn on the switch of the water inlet 1, and turn on Power supply, the boiling water in the heating chamber 3 generates steam, when the temperature sensor 12 is kept at 100 degrees, the electric heating tube 6 is automatically disconnected, and when it is lower than the evaporation temperature, the electric heating tube is automatically turned on, and the generated steam passes through the gas collecting hood 4 Collected into the condensation tube of the condensation chamber 3, the steam in the condensation tube is condensed into distilled water, which is released and collected from the water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com