Continuous thermal decomposition method and apparatus for sludge

A technology of thermal decomposition and sludge, applied in pyrolysis sludge treatment, dehydration/drying/concentrated sludge treatment, special form of dry distillation, etc. High temperature and other problems, to achieve the effect of small heat loss and avoid air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

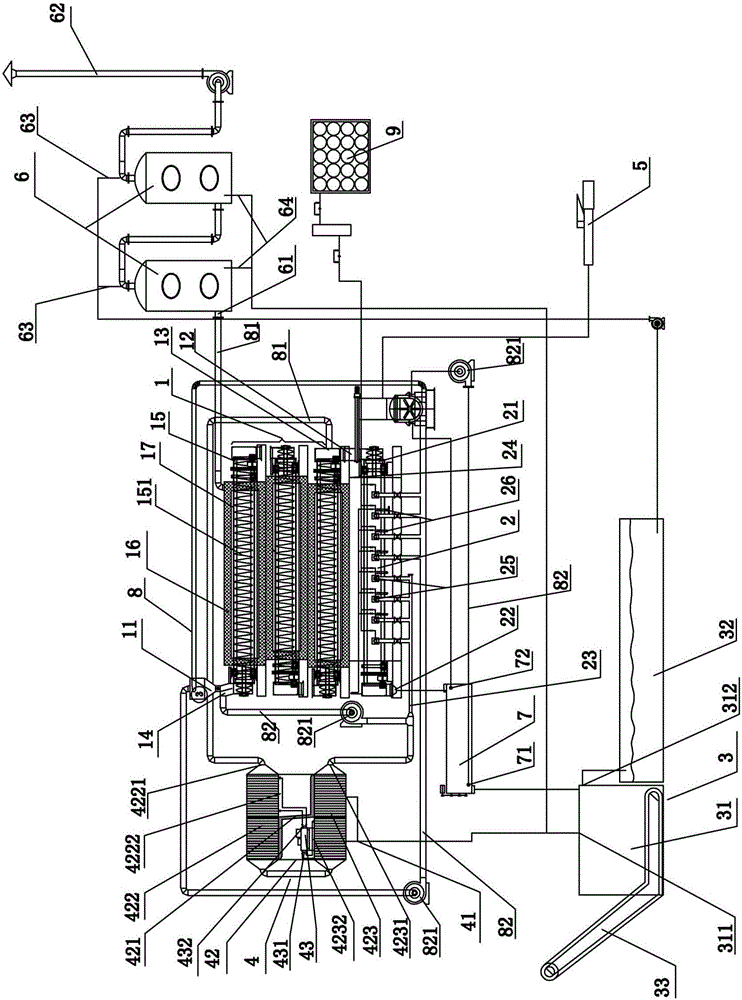

[0037] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

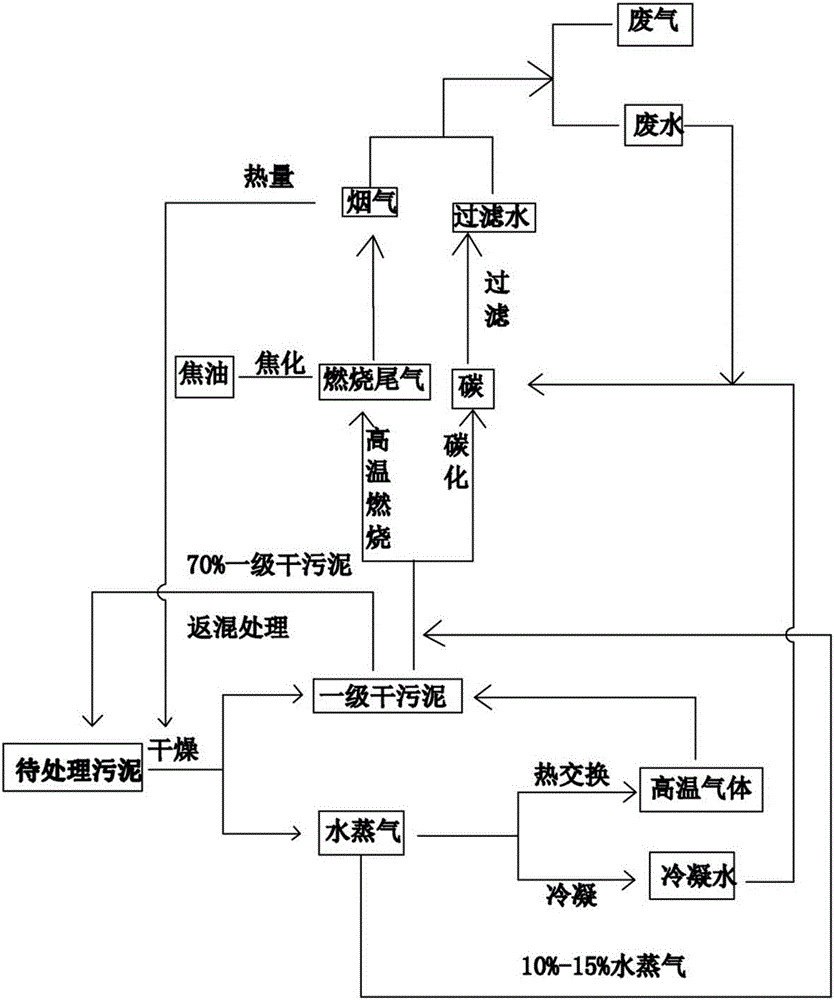

[0038] like figure 1 Shown, a kind of continuous sludge pyrolysis method is characterized in that, comprises the following steps:

[0039] Step 1) Drying process: Stir the sludge to be treated with a moisture content of 80%-90% in the conveying device evenly and then transfer it to the drying kiln. Internally dried to a water content of 10%-30%, forming a first-level dry sludge and generating high-temperature water vapor, the first-level dry sludge is divided into two parts, which are the sludge to be carbonized and accounting for 20%-40% of the total weight Circulating sludge with a total weight of 60%-80%; return the circulating sludge to the conveying device and mix it with the sludge to be treated to form secon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com