Efficient and energy-saving garbage fuel stirring water heater

A garbage fuel, high-efficiency and energy-saving technology, applied in the direction of incinerators, combustion methods, water heaters, etc., can solve the problems of affecting the atmospheric environment, waste of resources and energy, and low combustion efficiency, so as to avoid accumulation of garbage, save energy, and save energy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

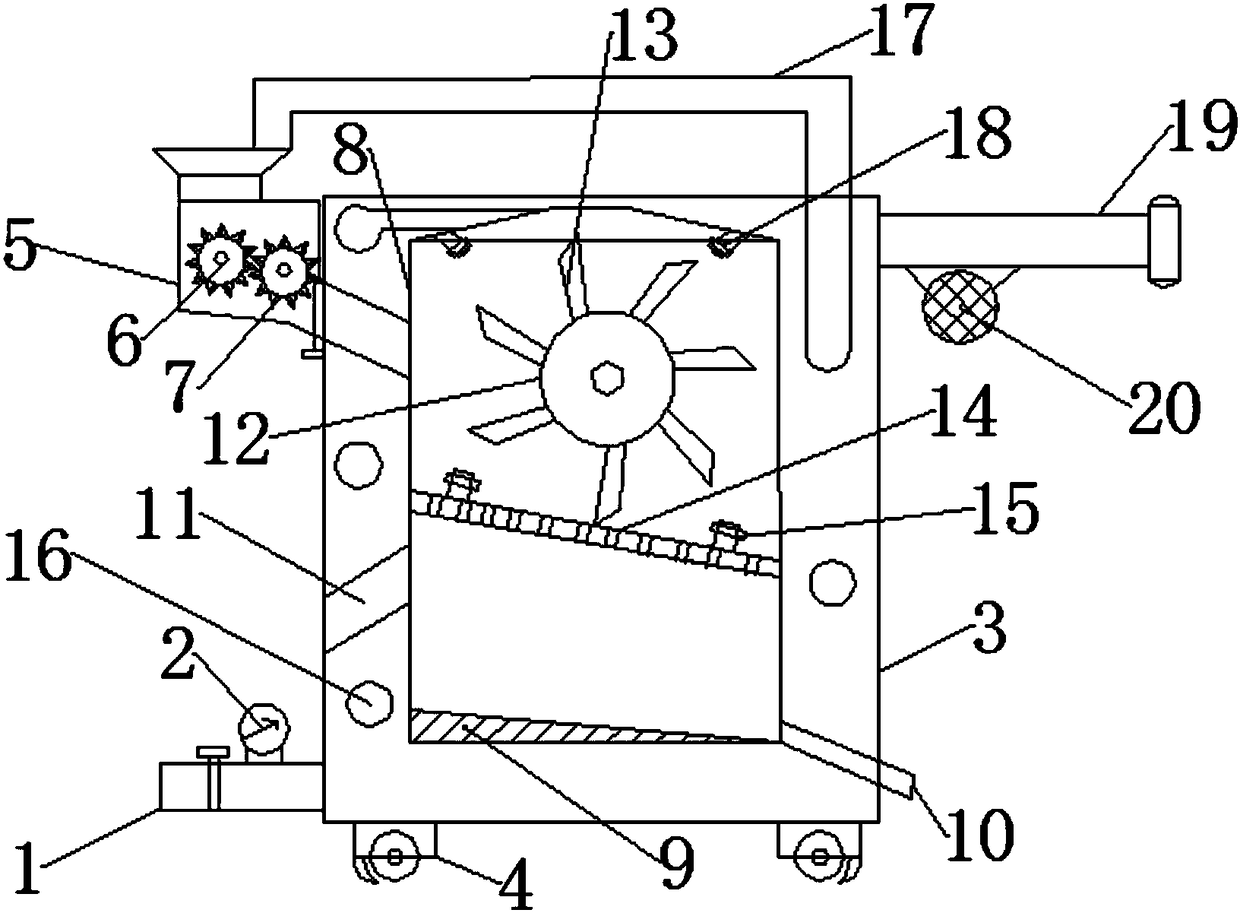

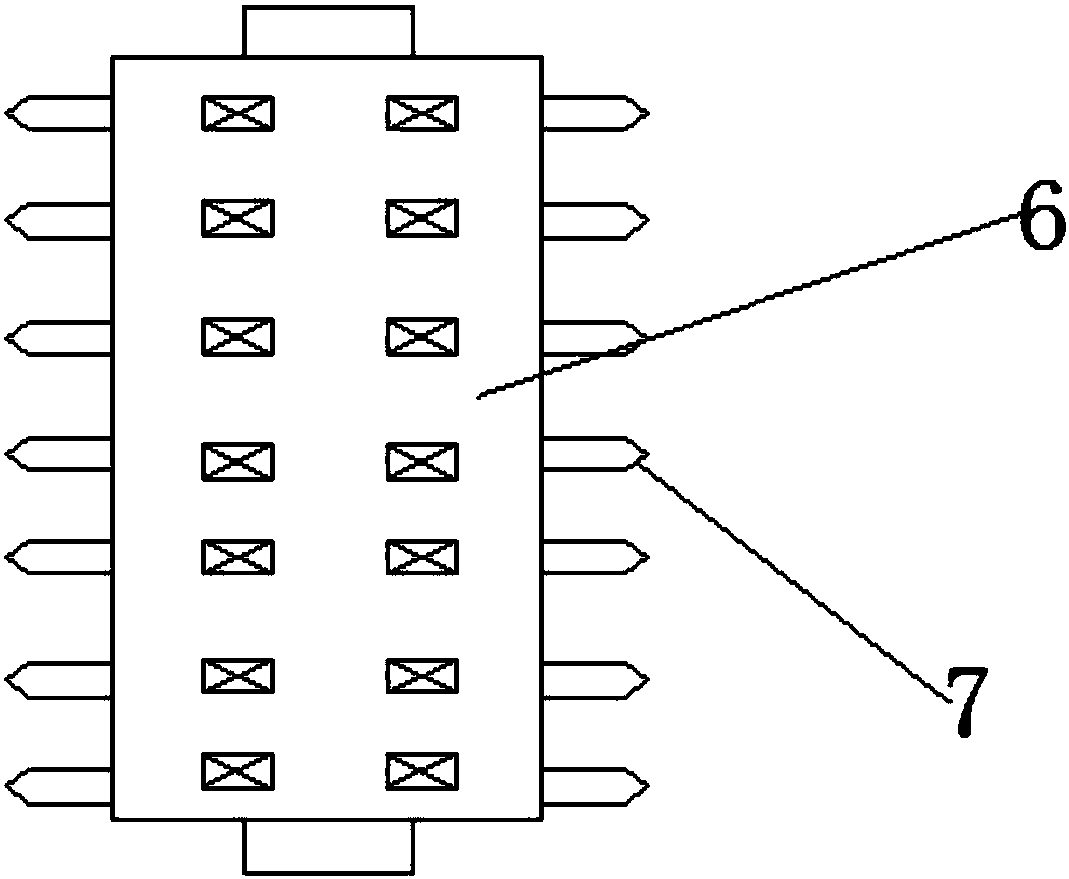

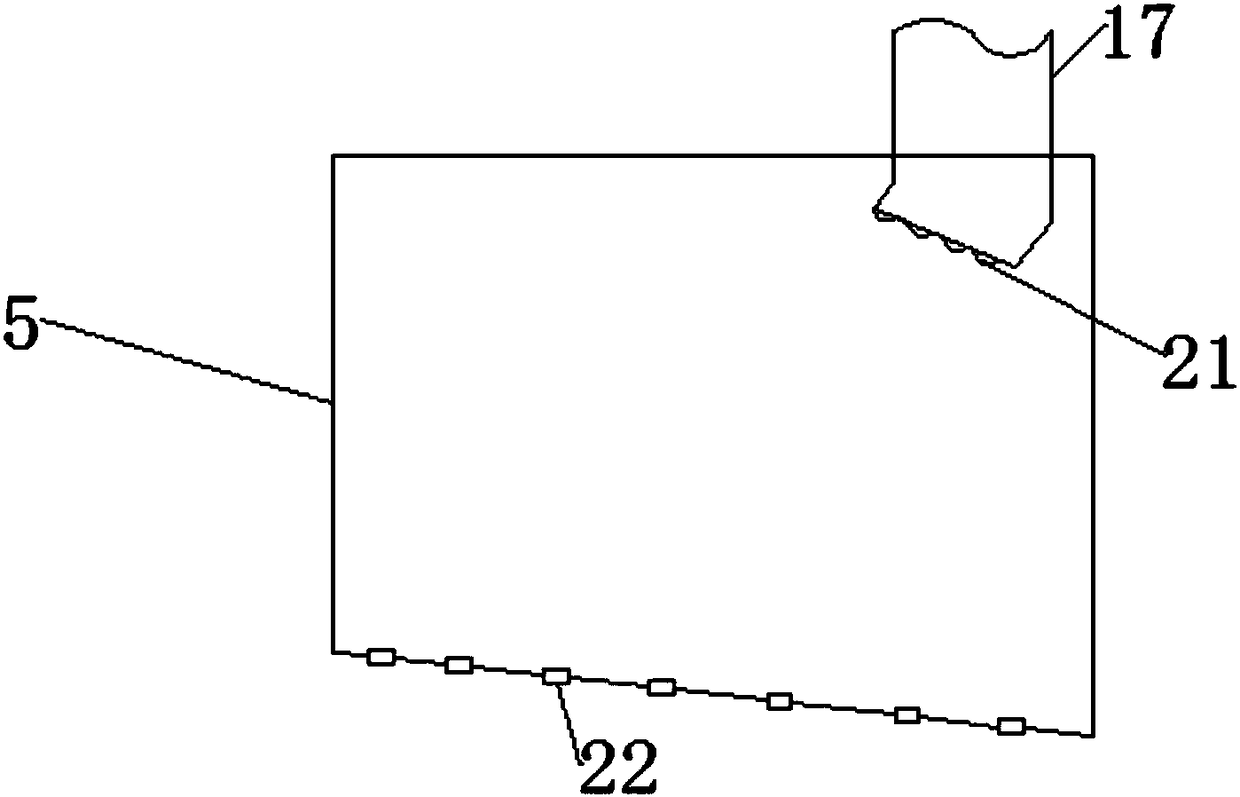

[0019] see Figure 1-3 , a high-efficiency energy-saving mixing garbage fuel water heater, comprising a water inlet pipe 1, a shell 3, a pulverizer 5, a rotating drum 6, a pulverizer knife 7, a combustion furnace 8, an ash guiding slant plate 9, an ash outlet pipe 10, and an air inlet pipe 11. Stirring roller 12, stirring blade 13, combustion plate 14, heat exchange pipe 16, air outlet pipe 17 and water outlet pipe 19, the bottom end of the shell 3 is provided with a universal wheel 4, and the universal wheel 4 is provided with a handbrake, The universal wheel 4 facilitates the movement of the device, saving time and effort. The side wall of the housing 3 is connected to the water inlet pipe 1. A flow meter 2 is installed on the water inlet pipe 1. The water inlet pipe 1 is convenient for external water to enter, and the water volume entering is me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com