Slope roof concrete construction device and method

A construction device and concrete technology, applied in the direction of roofing, tools for roof engineering, construction, etc., can solve the problems of inability to meet the requirements of pumping, low concrete slump, difficulty in tamping and vibration, etc., to ensure compactness, speed up The effect of construction progress and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

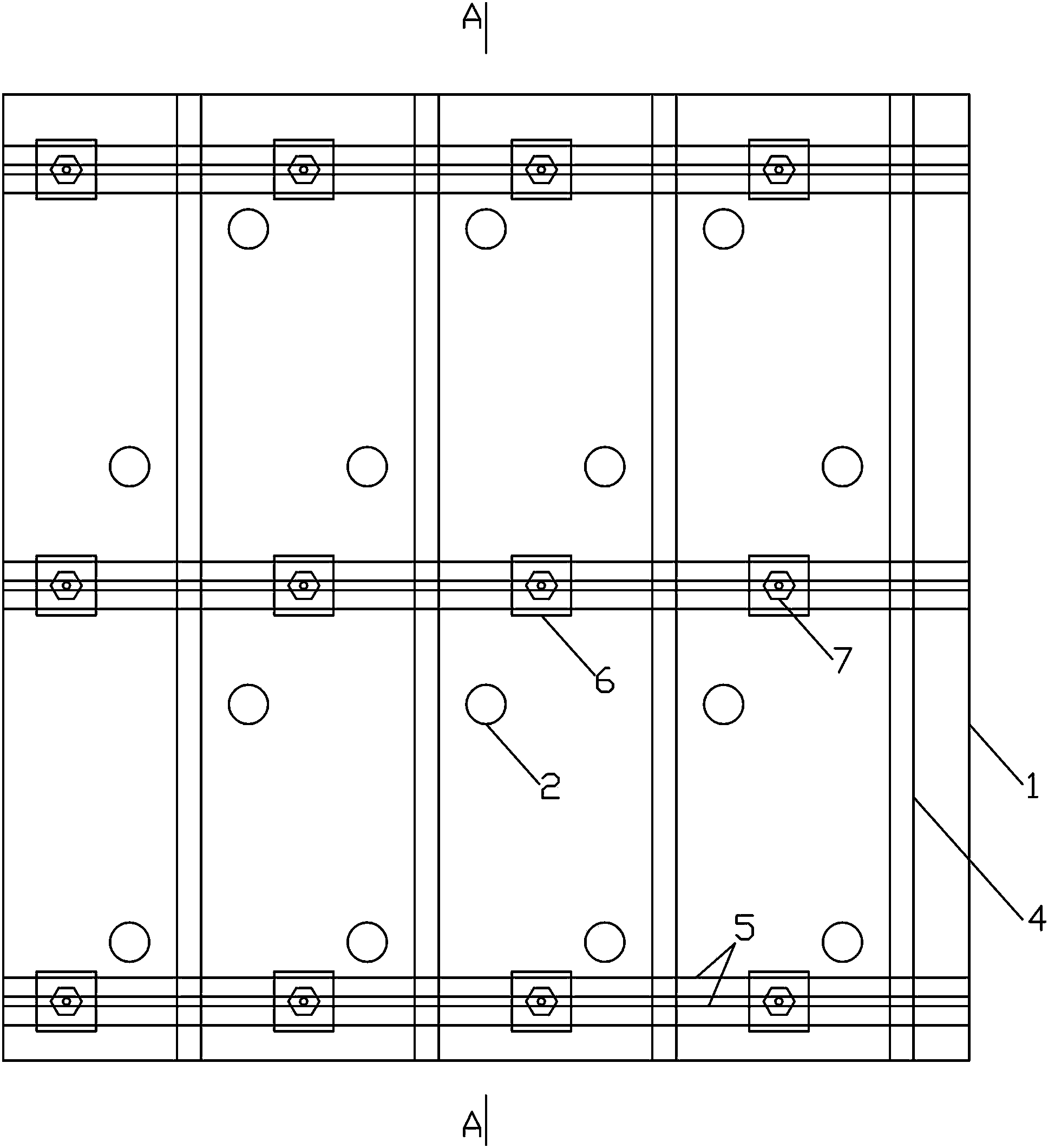

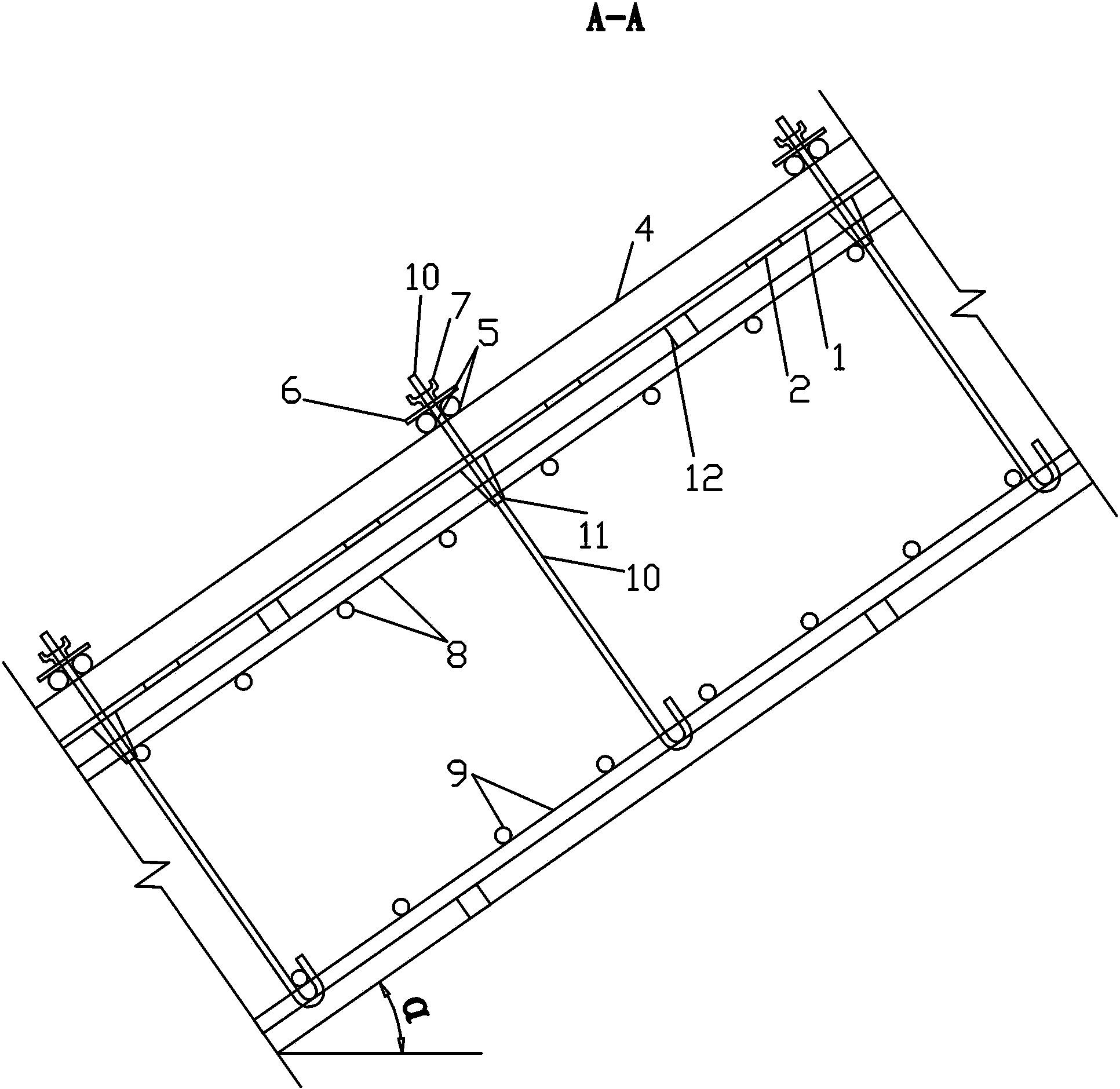

[0033] Such as Figure 1~5 Among them, a slope roof concrete construction device comprises a lower layer of steel mesh 9 and an upper layer of steel mesh 8 arranged along the slope roof, and a plurality of concrete pads 12 are arranged on the upper layer of steel mesh 8, and the concrete pad 12 is provided with There is a formwork 1, and the tie rods 10 are connected to the upper reinforcement mesh sheet 8 and the lower reinforcement mesh sheet 9. The ends of the tie rods 10 pass through the formwork 1 and are connected to the nuts 7. A plurality of concrete vibrating holes 2 are arranged on the formwork 1, and there are also The vibrating hole filling 3 installed in the concrete vibrating hole 2;

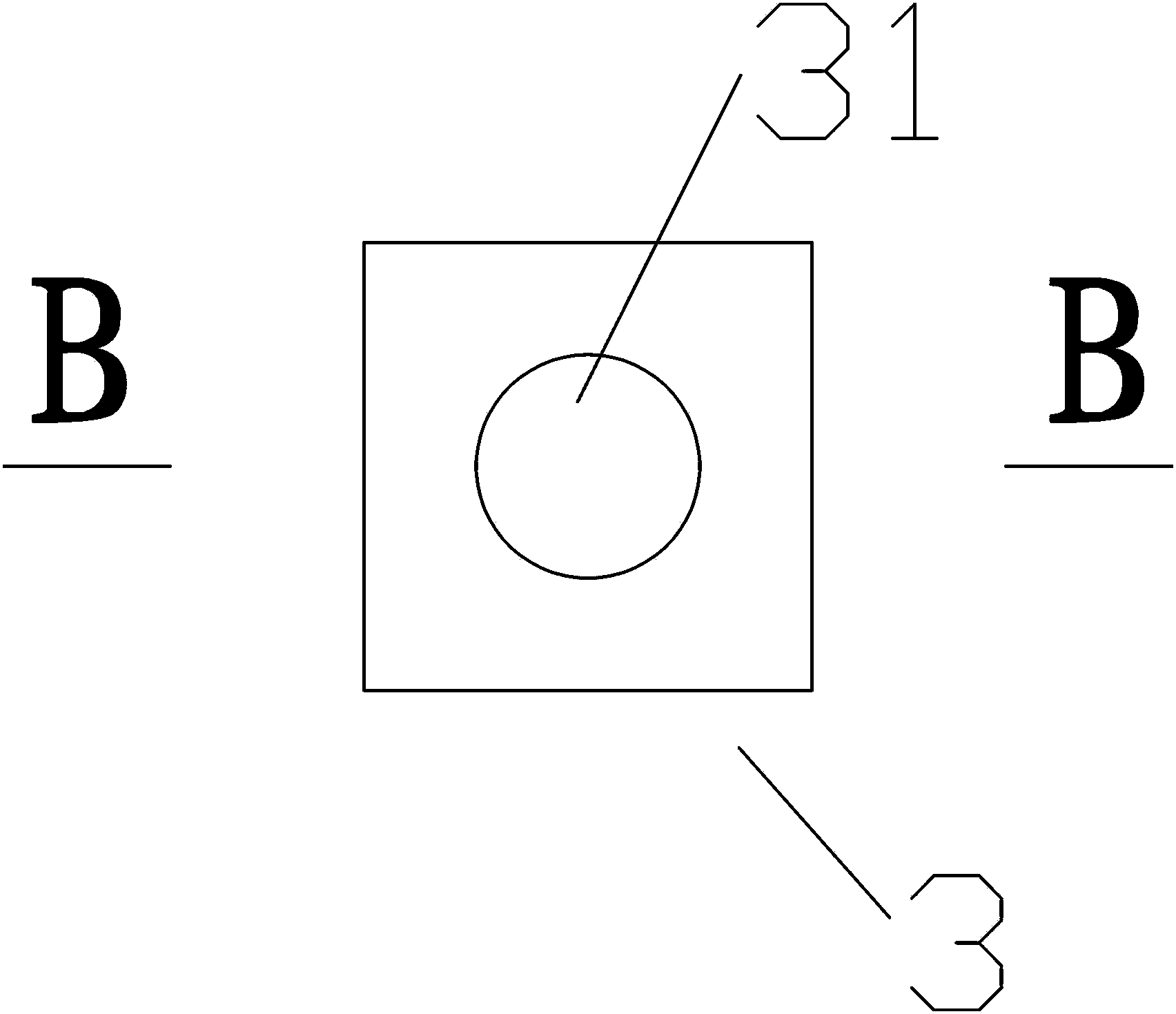

[0034] In the vibrating hole filling 3, the bottom plate 32 is provided with a filling plate 31, and the diameter of the filling plate 31 is the same as that of the concrete vibrating hole 2. The same at this time means that the filling plate 31 can just be placed in the concrete v...

Embodiment 2

[0040] A method for concrete construction of a slope roof using the above structure, comprising the following steps:

[0041] 1. According to the angle а of the slope roof, set the lower steel mesh 9, the upper steel mesh 8 and the tie rods 10;

[0042] Two, a plurality of concrete pads 12 are set on the upper steel mesh sheet 8, and the slope formed by the concrete pads 12 is the same as the slope roof angle а;

[0043] 3. According to the radius of action of the concrete vibrating rod, a plurality of concrete vibrating holes 2 are opened on the formwork 1. The diameter of the concrete vibrating hole 2 is greater than the diameter of the concrete vibrating rod; the distance between the concrete vibrating holes 2 and the hole size The size needs to meet the vibration needs of concrete.

[0044] 4. Lay the prepared template 1 on the concrete pad 12, set the wooden frame 4 on the back of the template 1 as the vertical keel at the bottom, and the steel pipe 5 as the horizontal k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com