Air-locking feeding device and biomass gasification system using same

A feeding device and gasification reaction technology, applied in the direction of granular/powdered fuel gasification, packaging, educts, etc., can solve the problems of energy waste, low calorific value of gas, and low gasification efficiency of gasifier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

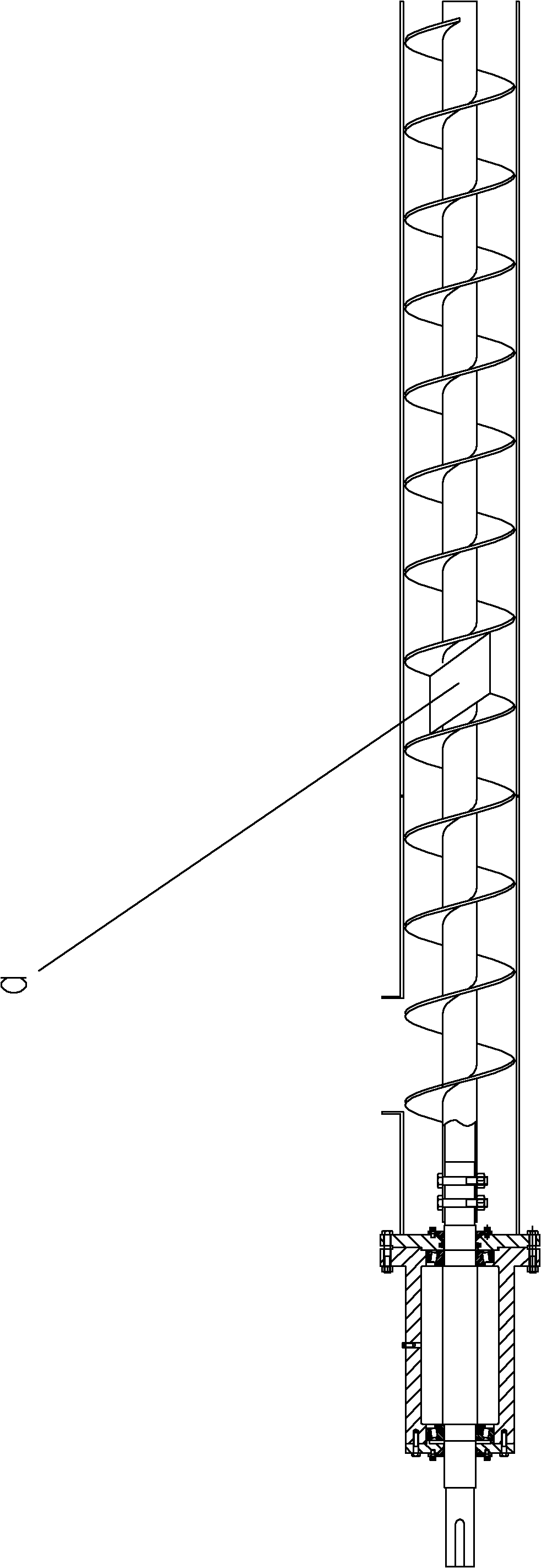

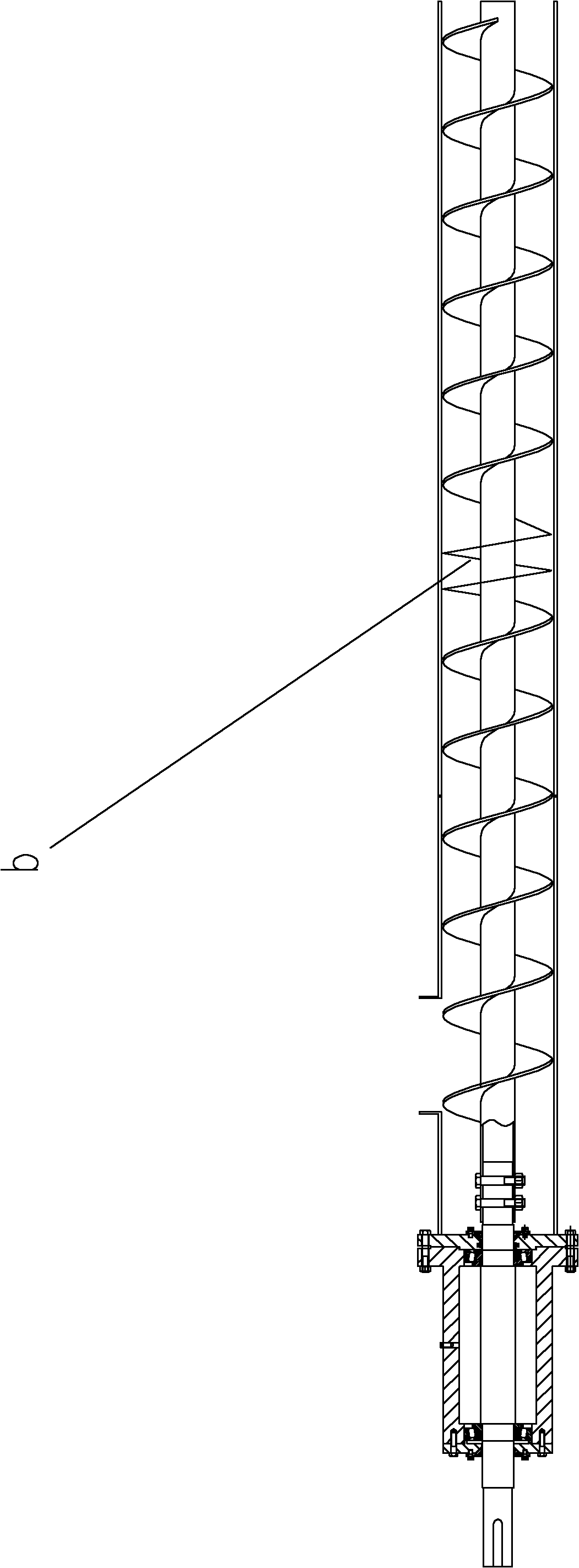

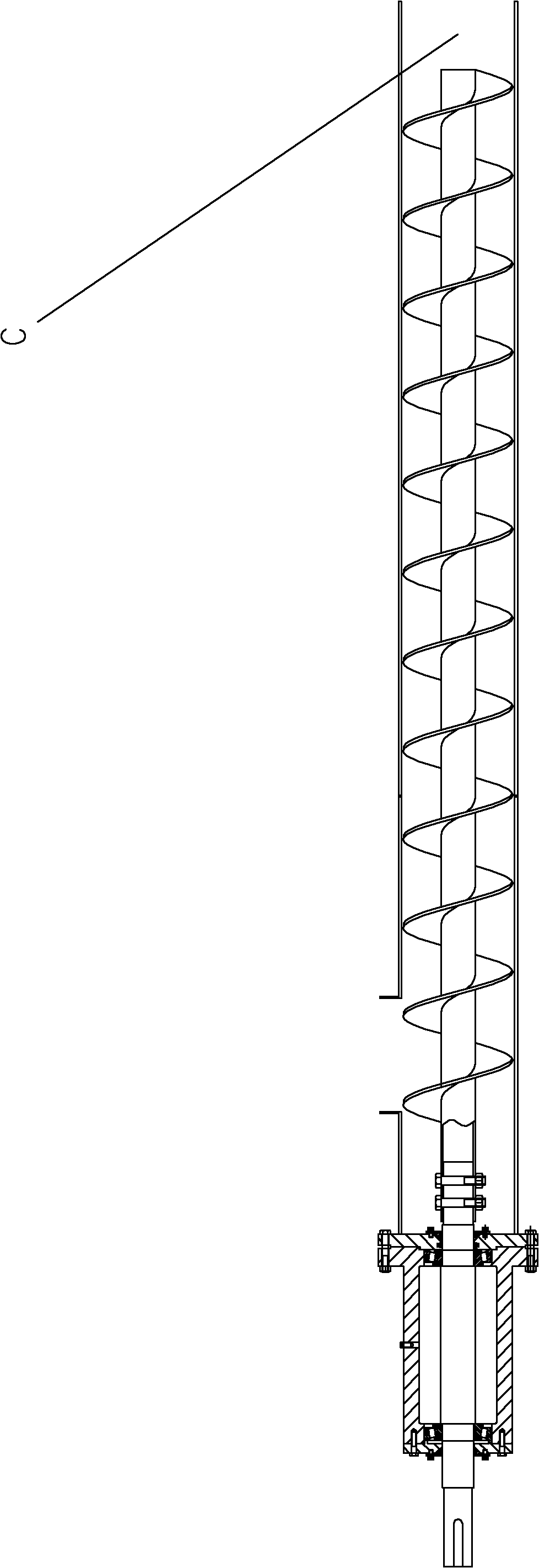

[0060] Such as figure 1 As shown, the first embodiment of the air-locking feeding device of the present invention includes: a motor, a deceleration device, a rotating shaft, a spiral blade, and a feeding tube.

[0061] Among them, the motor is connected to the decelerating device, and the two drive the rotating shaft to rotate. The rotating shaft is fixedly sleeved with spiral blades. The spiral blade is covered with a feed tube. The feed tube is provided with a feed port and a discharge port. The terminal and the discharge port of the feed pipe are flush. The inlet of the feeding pipe is located below the outlet of the storage device in front of the furnace. The outlet of the feeding pipe is connected to the inlet of the fluidized bed gasification reactor; the inlet and outlet of the feeding pipe are There is a section of the rotating shaft that is thicker than the other parts, and the length of the rotating shaft is a pitch of the spiral blade (such as figure 1 Shown in a).

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com