Preparation of marsh-gas in laboratory

A laboratory and conditional technology, applied in the energy field, can solve the problems of not getting rid of the traditional structure of large-scale biogas digesters, unsuitable for implementation, and unsuitable for research in large-scale biogas projects, achieving high methane content, improved experimental success rate and accuracy, Quick start of gas production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

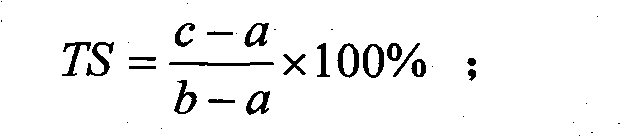

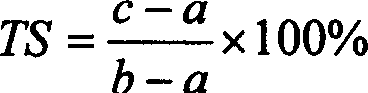

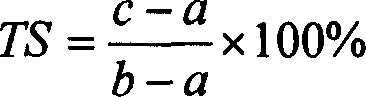

[0035] Put the fermented pig manure in a glass container, add water and stir until it becomes a thick paste. Place it for 5 days, stir twice a day, and measure the pH value once a day. After 5 days, the pretreatment of pig manure is completed. After washing the porcelain crucible, burn it in a muffle furnace at 600°C for 1 hour, and then stop burning. When the temperature of the furnace drops to 100°C, take out the porcelain crucible and cool it in a desiccator. Repeat the above steps until constant weight, weighed as a. Put the pig manure and the inoculum in a porcelain crucible respectively, weigh them, the mass is b, put them into a desiccator, and dry them at 105°C. After drying, the mass of the material and the porcelain crucible (or the inoculum and the porcelain crucible) is c, by formula TS = c - a b - a × 100 ...

example 2

[0043] Put the fermented pig manure in a glass container, add water and stir until it becomes a thick paste. Place it for 5 days, stir twice a day, and measure the pH value once a day. After 5 days, the pretreatment of pig manure is completed. After washing the porcelain crucible, burn it in a muffle furnace at 600°C for 1 hour, then stop burning. When the temperature of the furnace drops to 100°C, take out the porcelain crucible and cool it in a desiccator, repeat The above steps to constant weight, weighed as a. Put the pig manure and the inoculum in a porcelain crucible respectively, weigh them, the mass is b, put them into a desiccator, and dry them at 105°C. After drying, the mass of the material and the porcelain crucible (or the inoculum and the porcelain crucible) is c, by formula TS = c - a b - a × 100 % ...

example 3

[0051] Put the fermented pig manure in a glass container, add water and stir until it becomes a thick paste. Place it for 5 days, stir twice a day, and measure the pH value once a day. After 5 days, the pretreatment of pig manure is completed. After washing the porcelain crucible, burn it in a muffle furnace at 600°C for 1 hour, then stop burning. When the temperature of the furnace drops to 100°C, take out the porcelain crucible and cool it in a desiccator, repeat The above steps to constant weight, weighed as a. Put the pig manure and the inoculum in a porcelain crucible respectively, weigh them, the mass is b, put them into a desiccator, and dry them at 105°C. After drying, the mass of the material and the porcelain crucible (or the inoculum and the porcelain crucible) is c, by formula TS = c - a b - a × 100 % ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com