Low temperature reaction kettle provided with feeding device

A low-temperature reaction and feeding device technology, which is applied in feeding devices, chemical/physical/physical chemical fixed reactors, organic chemistry, etc., can solve problems such as hindering precipitation reactions, increasing stirring time, and polluting the working environment to reduce Heat generation, reduced motor power, and high reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

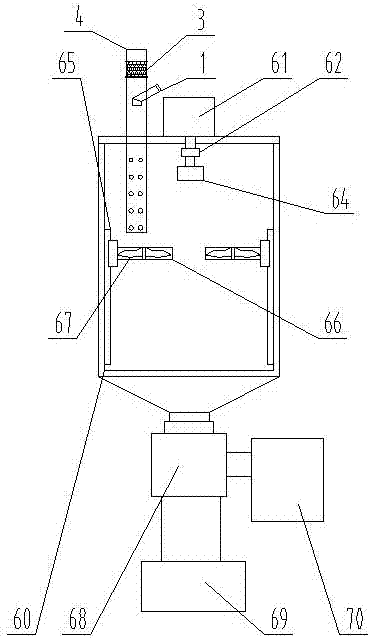

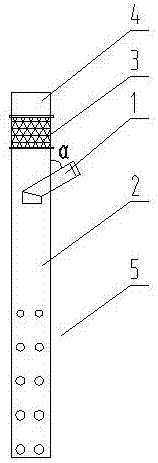

[0012] As shown in the drawings, the present invention includes a low-temperature reactor body 60, a feeding device, a low-temperature control device, a stirring device and a centrifugal solid-liquid separation device. The top of the low-temperature reactor body 60 is provided with a feed port, and the bottom is provided with an outlet. The feed port and the feeding device include a blanking elbow 1, a feed pipe 2, a stuffing box 3 and a fan 4. There are many groups of holes on the wall of the homogenizing pipe 2 at one end of the low-temperature reactor body 60, and there are mounting holes for the feeding elbow on the wall of the homogenizing pipe 2 at the outer end of the low-temperature reactor body 60. Elbow 1 is installed on the hole, and one end of said blanking elbow 1 is located in the uniform material pipe 2, and the opening is downward; The opening of the material pipe 2 communicates, and the low temperature control device includes an alcohol box 61, an electric con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com