Asphalt concrete stirring apparatus

A technology of asphalt concrete and mixing device, which is applied in the directions of mixer accessories, mixer, transportation and packaging, and can solve problems such as uneven mixing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

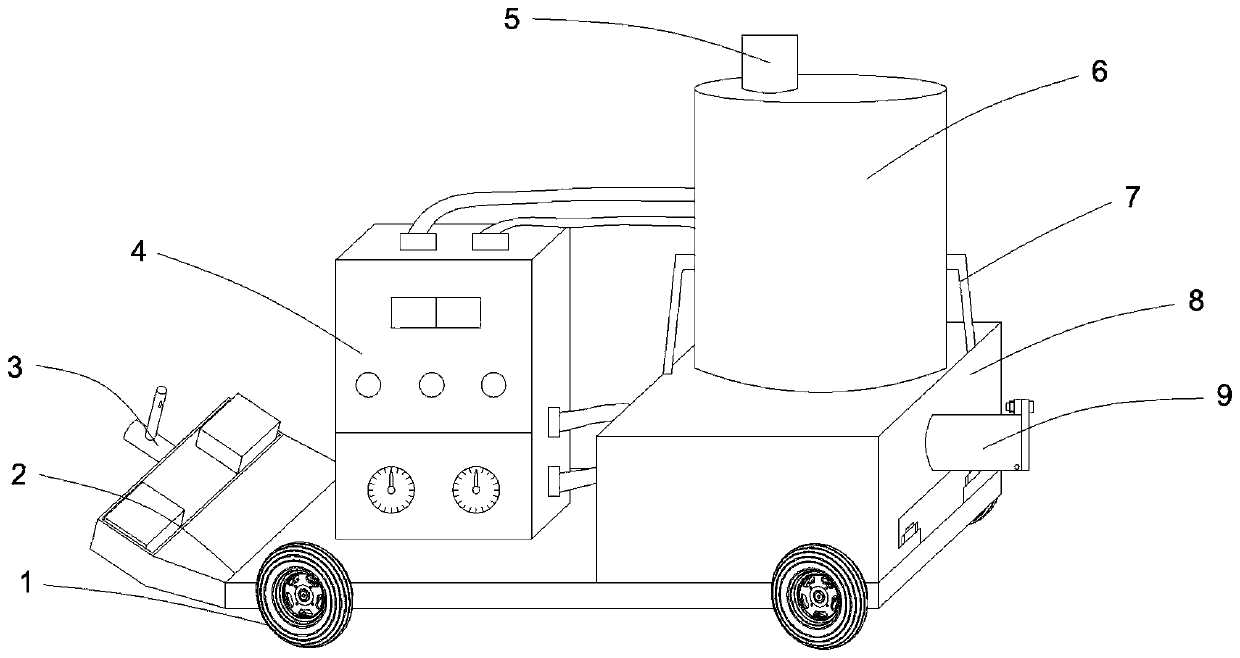

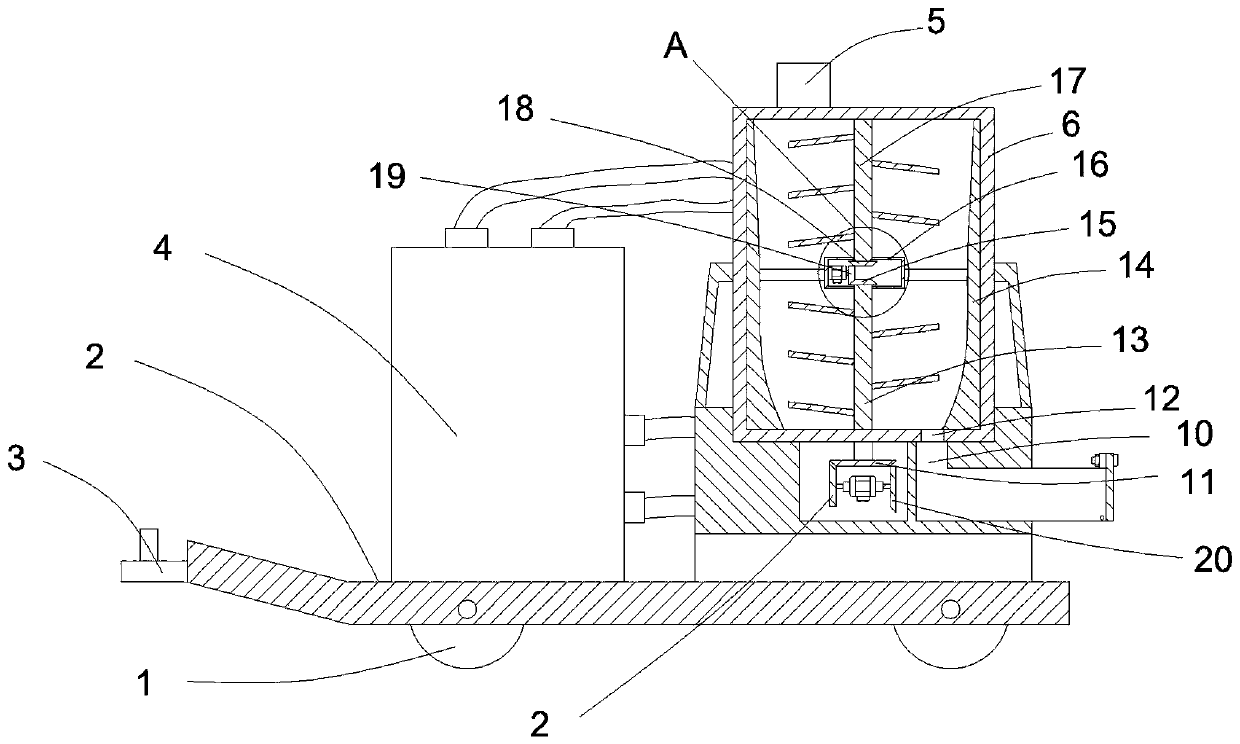

[0030] see Figure 1~3, a mixing device for asphalt concrete, comprising a base 2, an adjustment box 8 is arranged on the base 2, a mixing drum 6 is arranged on the upper side of the adjustment box 8 to reciprocate relative to the rotation, and a first device for driving the rotation of the mixing drum 6 is arranged in the adjustment box 8 An adjustment mechanism, the middle part of the inner cavity of the stirring drum 6 is provided with a base 16, the upper side and the lower side of the base 16 are respectively rotated to be provided with a first stirring shaft 17 and a second stirring shaft 13, and the base 16 is provided with a drive first Stirring shaft 17, the second adjusting mechanism that the second stirring shaft 13 rotates in turn, the upper side of the base 16 is provided with the electric box 4 that cooperates with the first adjusting mechanism, the second adjusting mechanism, the upper side and the lower side of the stirring drum 6 The feed pipe 5 and the discha...

Embodiment 2

[0033] This embodiment is further optimized on the basis of implementation 1, specifically:

[0034] The underside of the base 2 is provided with a positive four-wheel running mechanism 1, and the annular surface of the base 2 is provided with a hook 3 along the side where the positive four-wheel running mechanism 1 moves. The design of positive four-wheel walking mechanism 1 makes the present invention easy to move, has the advantage of convenient transfer, and the design of hook 3 is convenient to the present invention that trailer is connected, so that transfer.

[0035] As a preferred manner, the end of the adjustment box 8 opposite to the mixing drum 6 is connected through an embedded connection, and the upper side of the adjustment box 8 is provided with an annular bracket 7 sleeved on the mixing drum 6 to cooperate with rotation. The adjustment box 8 and the mixing drum 6 are connected embeddedly, that is, the lower end of the mixing drum 6 is located in the adjustment ...

Embodiment 3

[0040] This embodiment is further optimized on the basis of implementation 1, specifically:

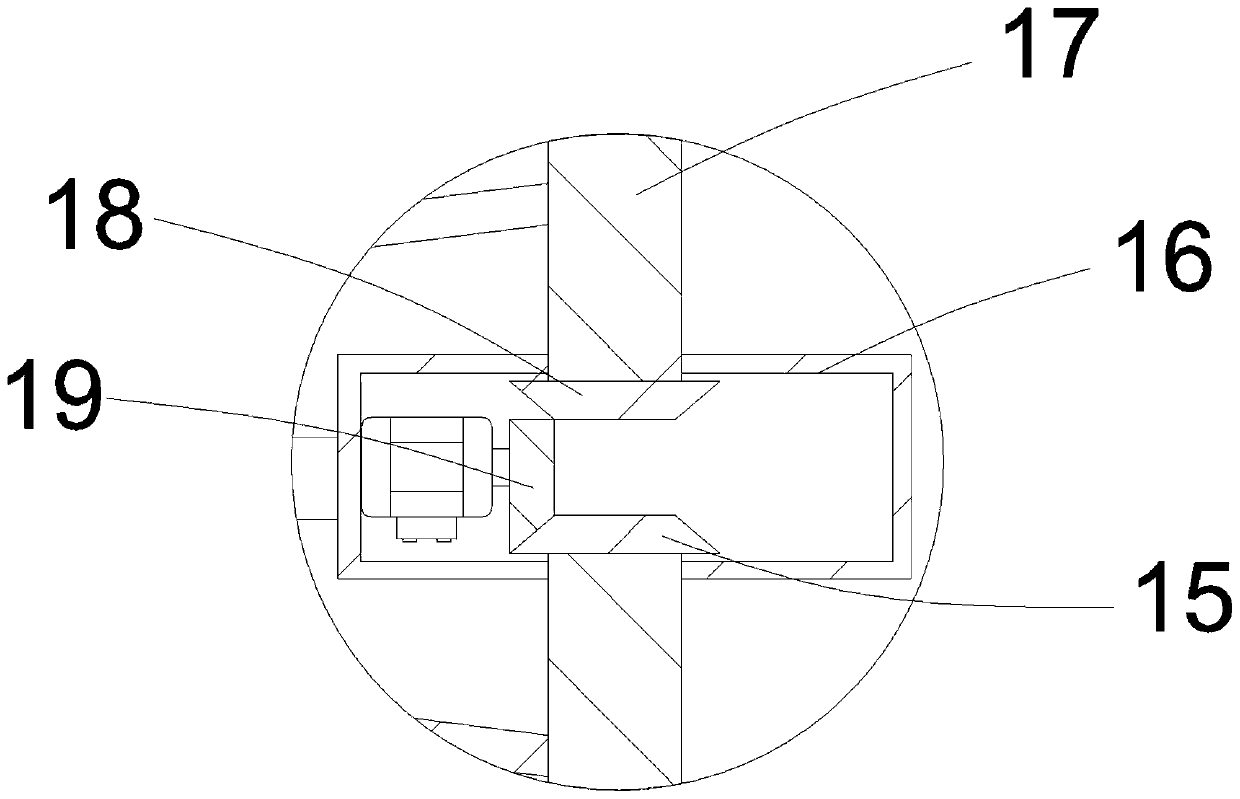

[0041] The base 16 is connected with the inner wall of the stirring drum 6 through a support arm, and the second adjusting mechanism includes a second bevel gear 18 and a third bevel gear which are arranged in the base 16 and are respectively connected with the first stirring shaft 17 and the second stirring shaft 13. 15. The base 16 is provided with a second half-bevel gear 19 that can mesh with the second bevel gear 18 and the third bevel gear 15 in sequence, and the arc of the gear portion of the second half-bevel gear 19 is less than π, and the second half-bevel gear One side of the gear 19 is connected with a driving motor, and the driving motor is connected with the electric box 4 . The electric box 4 supplies power to the driving motor, and the driving motor drives the second half bevel gear 19 to rotate, and the second half bevel gear 19 drives the second bevel gear 18 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com