Resources comprehensive treatment technology for organic waste material

A technology for organic waste and comprehensive treatment, applied in biological organic part treatment, biological sludge treatment, organic fertilizers, etc. The effect of increasing biogas yield and increasing added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

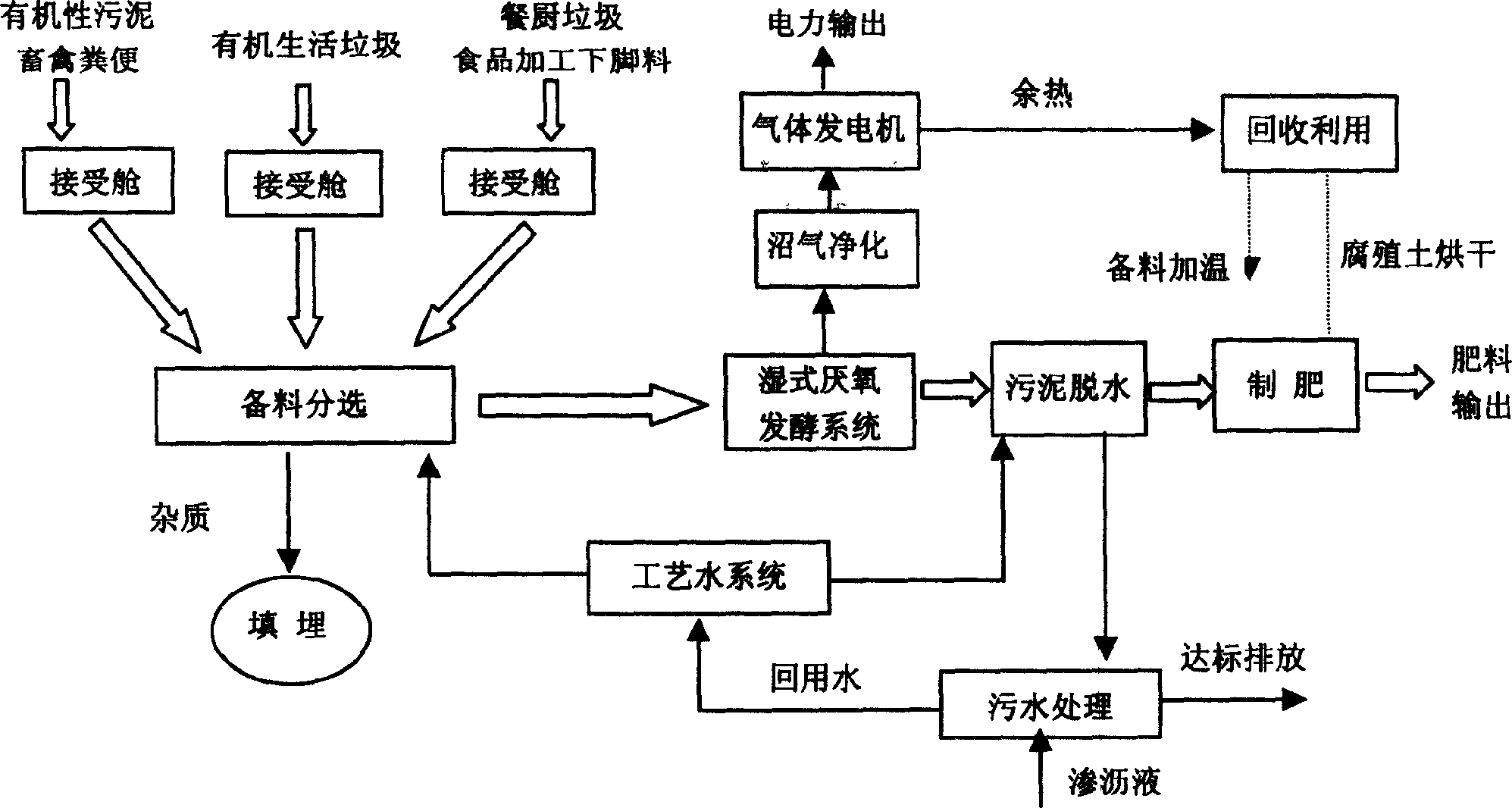

Image

Examples

Embodiment Construction

[0024] Organic domestic waste, kitchen waste, leftovers from food processing industry, organic sludge and livestock and poultry manure are transported to the material preparation tank through the screw conveyor connected to the receiving cabin, and mixed with process hot water to produce solid matter content 15 ~16%, suspended material at a temperature of 36~37°C. The function of the material preparation tank is mainly to fully mix and crush the organic waste, remove impurities, and adjust the temperature, particle size and concentration to meet the requirements of mesophilic fermentation. Crushing and mixing are done by an agitator fixed on the top of the tank, whose rotation speed is controlled by an AC frequency converter, which can not only ensure sufficient agitation but also save energy.

[0025] Light impurities (such as: wood, plastic film, cork, etc.) float on the surface, are removed by the slag scraper, and after dehydration, they are sent to the waste bin. Heavy i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com