Polyethylene terephthalate (PET) esterification reaction kettle

A technology for an esterification reaction kettle and a kettle body, which is applied in the field of polyethylene terephthalate esterification reaction kettles, can solve the problems of hidden dangers of production accidents, high manufacturing costs, high operating costs and the like, and achieves reduction of production and operating costs. , The effect of reducing equipment maintenance work and capital investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

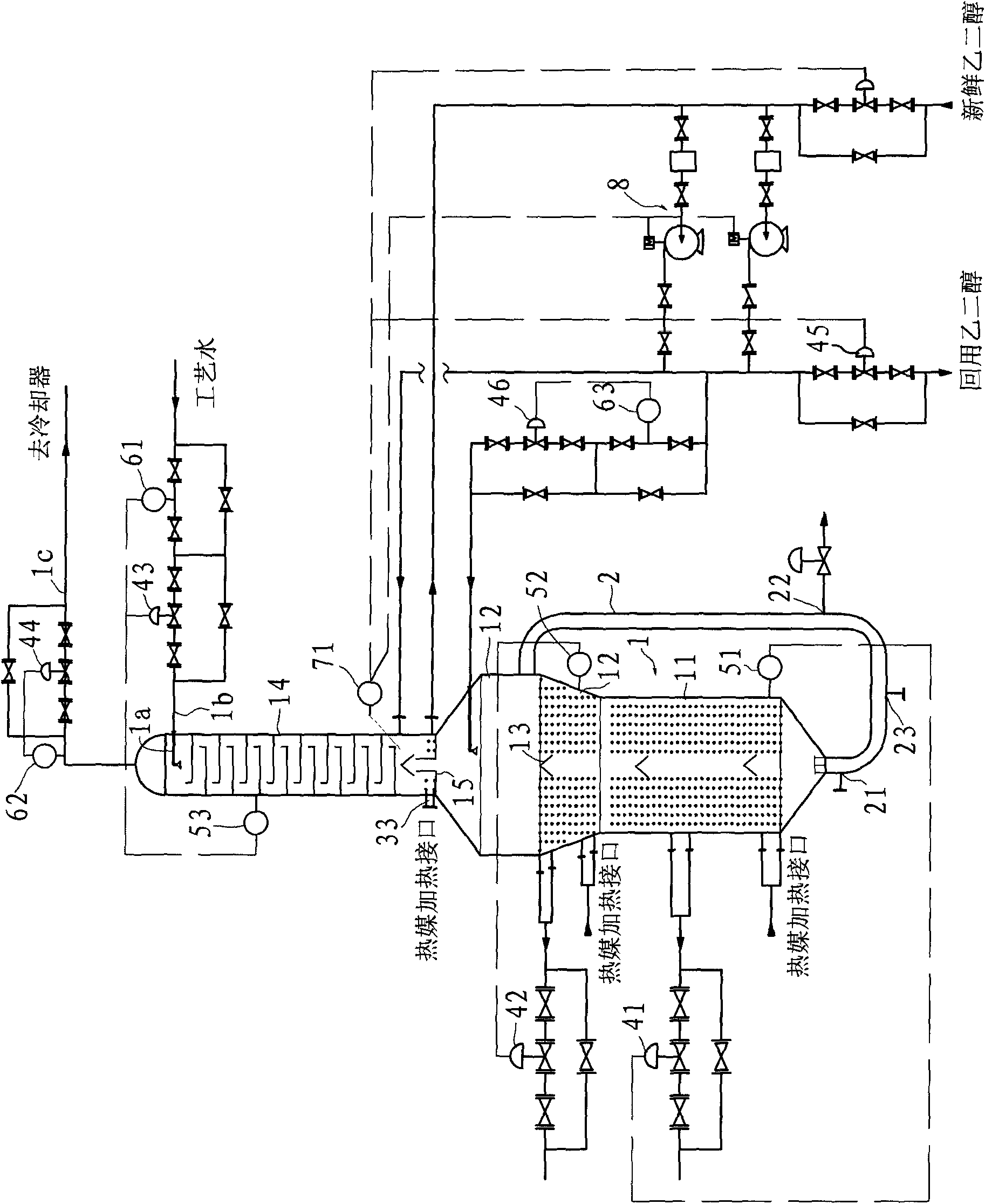

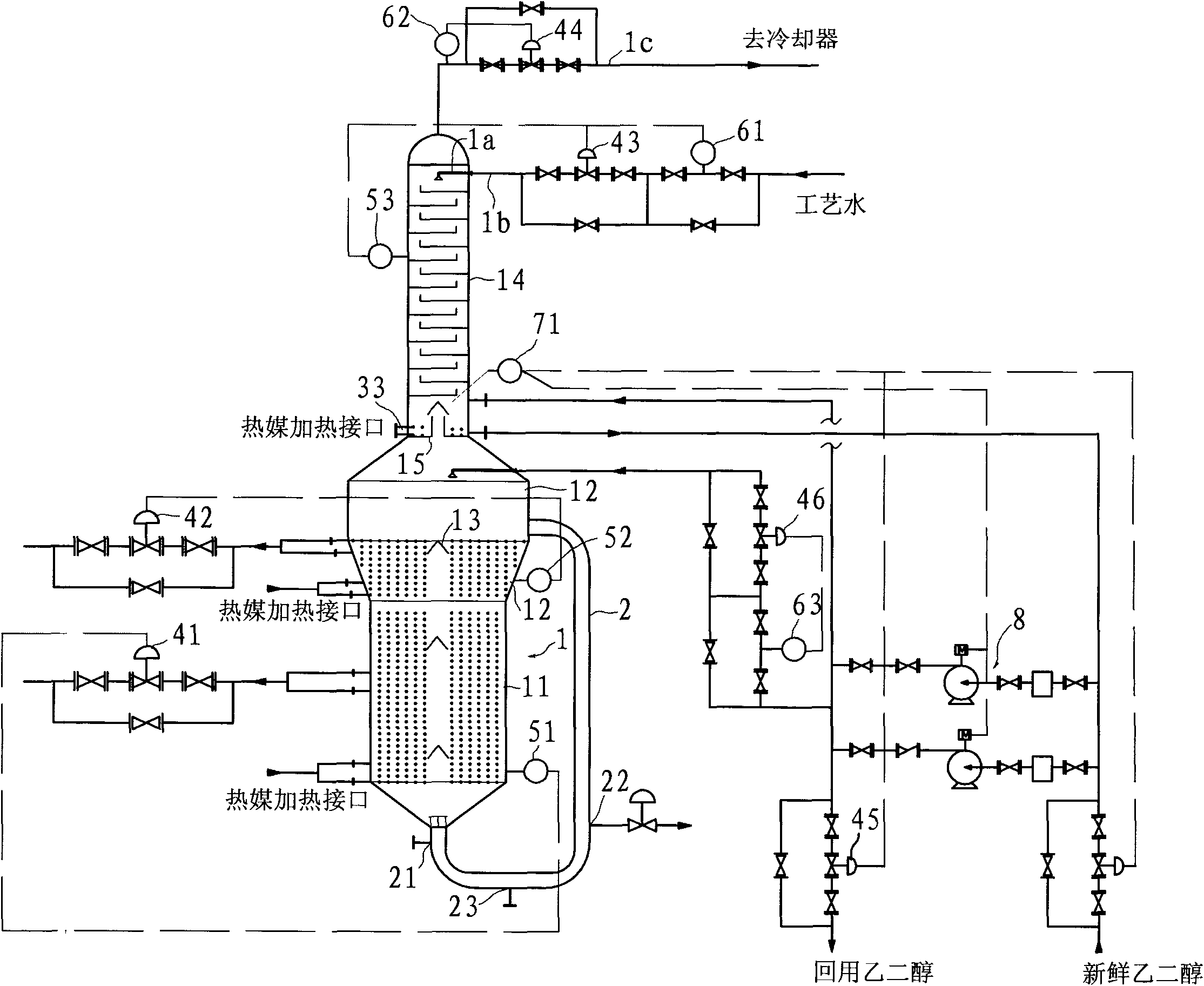

[0020] Such as figure 1 As shown, the PET esterification reaction kettle in this embodiment includes a kettle body 1, a process tower 14 and a circulation pipeline 2, and the kettle body 1 includes a small cavity 11 at the lower end and a large cavity 12 at the upper end, and the small cavity The inner diameter of 11 is smaller than the inner diameter of large cavity 12, and the axial length of small cavity 11 is greater than the axial length of large cavity 12. Both small cavity 11 and large cavity 12 are provided with turbulence that increases the flow resistance of the slurry. The flow plate 13 and the spoiler 13 are conical and arranged longitudinally. Corresponding to the lower ends of the small cavity 11 and the large cavity 12 are respectively provided a lower heating coil 31 and an upper heating coil 32 .

[0021] The circulation pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com