Unordered stirring reaction kettle

A technology for stirring reactors and reactors, applied in chemical/physical/physical-chemical stationary reactors, dissolving, mixers, etc., can solve problems such as affecting sealing performance, spending a lot of manpower and material costs, small gaps, etc., to achieve the effect. Good, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

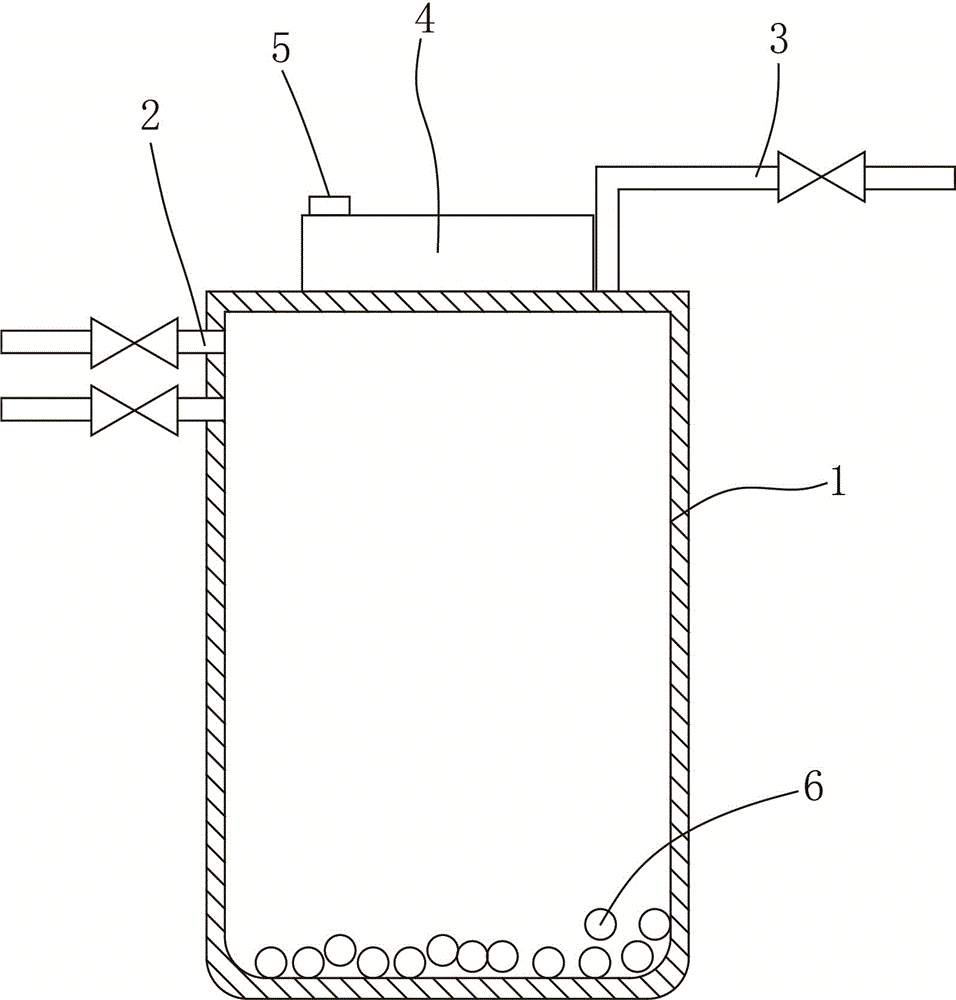

[0010] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see figure 1 , a disorderly stirred reactor, comprising a reactor shell 1, a number of liquid inlet pipes 2 and air extraction pipes 3 are connected to the shell 1, an electromagnet 4 is arranged above the shell 1, and the electromagnetic The iron 4 is connected with a control switch 5, and a plurality of steel balls 6 are arranged in the housing 1, and the outside of the plurality of steel balls 6 is coated with an inert material layer, and the inert material layer is a polytetrafluoroethylene layer. With this structure, when stirring is required in the reactor, the steel ball in the housing 1 is continuously raised and lowered by controlling the opening and closing of the switch 5 to achieve the purpose of stirring. The electromagnet 4 is detachably connected to the housing 1, so that one electromagnet 4 can be used in multiple reaction ket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com