Spiral lifting stirrer, cup lid and cup

A technology of spiral lifting and agitator, applied in the field of mixing equipment, can solve the problems of heavy overall mass, uneven mixing, complex structure, etc., and achieve the effect of easy cleaning, convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

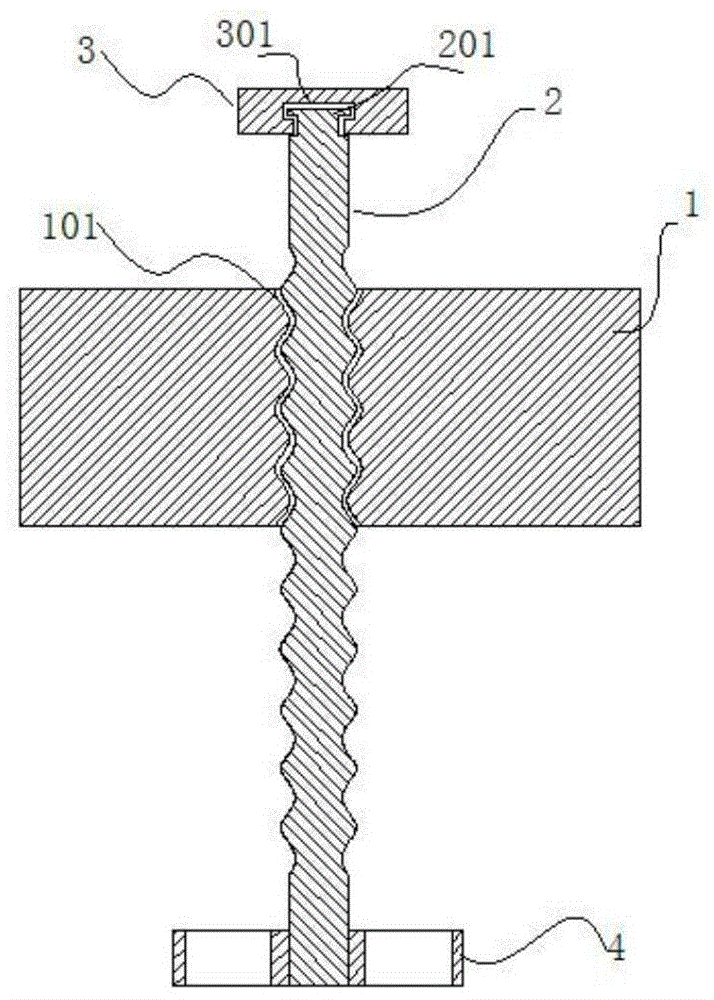

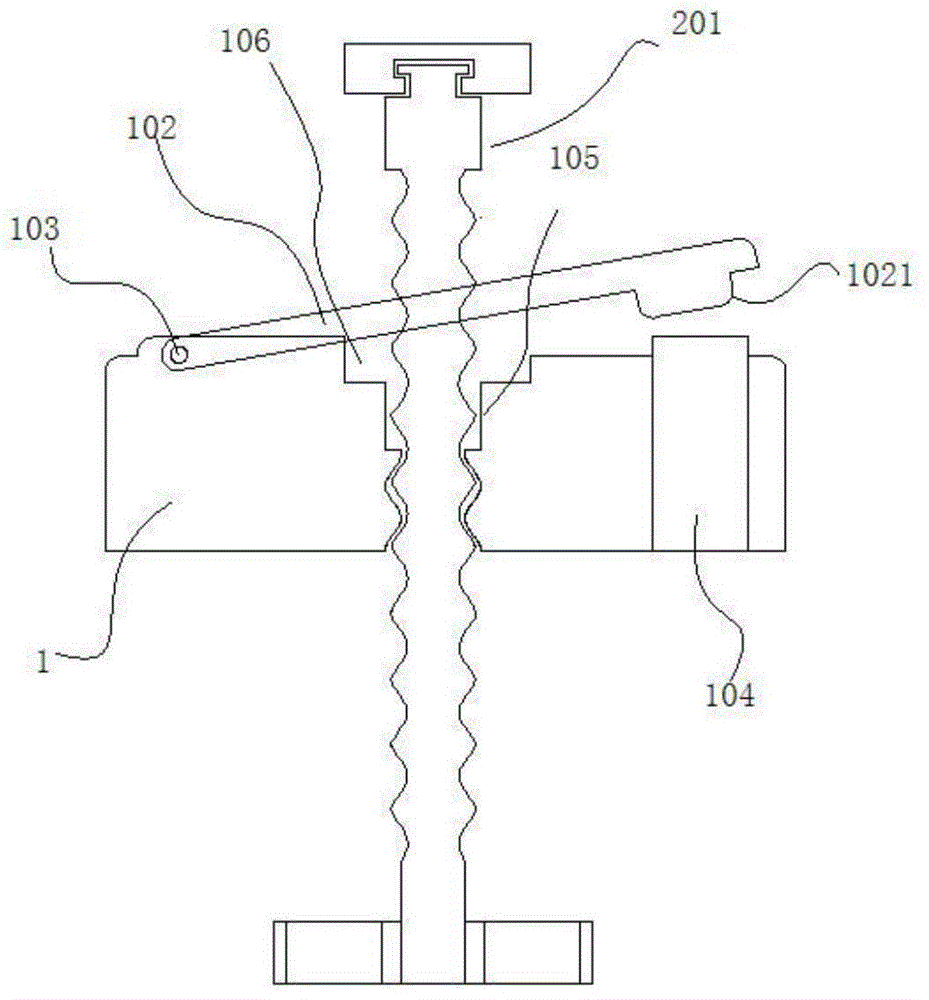

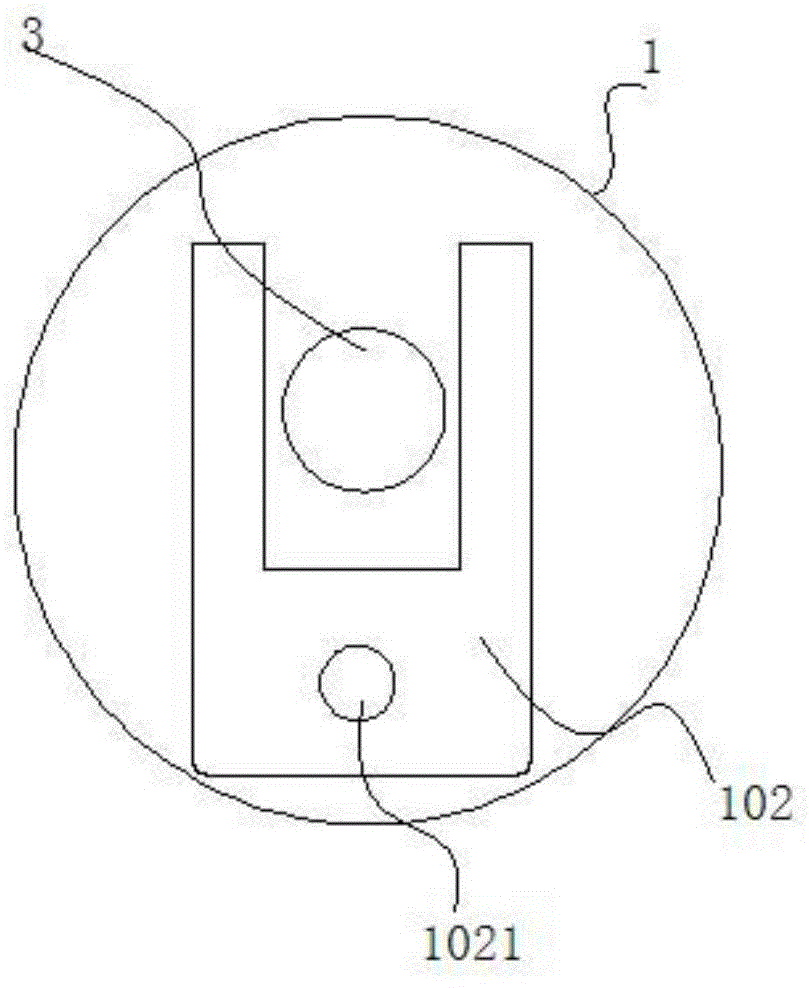

[0023] Example 1: figure 1 It shows an embodiment of a spiral lift agitator of the present invention, a spiral lift stirrer, including a main cover plate 1, a screw shaft 2, a gripping part 3 and a stirring device 4, the middle part of the main cover plate 1 is provided with a spiral Guide hole 101, the spiral guide hole 101 is pierced with a matching screw shaft 2, the upper part of the screw shaft 2 is connected with a relatively rotatable grip part 3, and the lower part of the screw shaft 2 is provided with a stirring device 4, This kind of setting fixes the main cover, hold the grip part by hand, and move it up and down, so that the screw shaft rotates in the screw guide hole, and the screw shaft and the grip part can rotate, so the up and down motion is converted into rotation movement, so as to drive the stirring device to rotate to achieve the purpose of stirring, and the vertical position of the stirring device can be changed to make the stirring more uniform. A groov...

Embodiment 2

[0024] Embodiment 2: the embodiment of a spiral lift agitator of the present invention is not shown in the figure. The difference between it and Embodiment 1 is that a bearing is provided at the connection between the spiral shaft 2 and the gripping part 3, and the spiral The shaft 2 and the inner ring of the bearing, the grip part 3 and the outer ring of the bearing are all interference fits. This connection method makes the rotation between the two parts more stable and enables them to be connected as a whole in the vertical direction. .

Embodiment 3

[0025] Embodiment 3: An embodiment of a cup cover with a spiral lift agitator is not shown in the figure, and a spiral lift stirrer according to Embodiment 1 or 2 is used, and the main cover plate 1 of the spiral lift stirrer is embedded as a whole Inside the cup cover, the screw shaft 2 passes through the cup cover and can rotate relative to the cup cover. In this way, without changing the overall structure of the cup, it is only necessary to embed the entire stirrer in the cup cover, or it can be used for active stirring Device, one stirring device corresponds to multiple containers to be stirred.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com